Launder Design Procedure

The design of slurry launders has usually been based on strictly empirical concepts. An examination of the most common procedures reveals that they do not

The design of slurry launders has usually been based on strictly empirical concepts. An examination of the most common procedures reveals that they do not

Stringent environmental regulations, which have limited the use of sludge ponds, coupled with the economic incentive to clean more coal or to add fine coal

Table of ContentsThe In-Situ Simulation SystemThe Simulation Test MethodSimulation Test ResultsDiscussion of the Simulation Test Findings A laboratory method for the simulation of in-situ leaching

Table of ContentsIn Situ Leaching CopperShallow DepositsBlast Design—Fragmentation Research at Duval’s Sierrita MineLeaching Experiments at El Paso’s Emerald Isle MineContainment of Leach Solutions at Cyprus

Table of ContentsAdsorption of Amyl Xanthate on Activated CarbonAction of Activated Carbon on Chalcopyrite and Galena In many multiple-sulphide ore flotation processes, it is desirable

Table of ContentsHydrology of Dump LeachingDump Flow Factors Affecting RecoveryDump Failures Resulting from Flow ProblemsHydrology of In-Situ Solution MiningRecovery Flow Patterns Dump leaching and in-situ

Table of ContentsBasic Principles of Magnetic CaptureMethodology of Evaluating Separation PerformanceModel Applications High-intensity wet magnetic separators have been successfully introduced into, the mineral processing field

Conventional practice is to add flocculant as a dilute solution to the feed slurry in a launder or feed pipe, possibly using staged addition so

Table of ContentsPilot Test ProgramFull-Scale Pilot Heap OperationMaybell Heap Leach Experience Union Carbide began looking seriously at heap leaching in 1971- At that time some

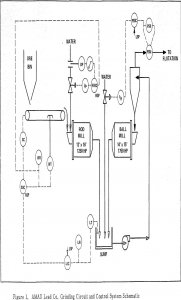

Table of ContentsOld Mill FlowsheetNew Mill FlowsheetDuval Grinding Circuit ControlA Review of Automated Grinding Control Systems Grinding Circuit Description Cyprus Pima has two concentrators, one with