Table of Contents

The magnetic properties of rare earth-cobalt intermetallic compounds have been studied by various investigators. It was not until Strnat and Hoffer investigated single crystals of YCo5 and reported an extremely high magnetocrystalline anisotropy that systematic studies of the magnetic properties of rare earth-cobalt alloys were undertaken. These studies determined that RCo5 compounds (R = one of the light rare-earth elements such as La, Ce, Pr, and Sm) possess sufficiently high uniaxial crystal anisotropy, saturation magnetization, and Curie temperature to qualify as suitable candidates for use as permanent magnet materials. Two other metallic materials that form compounds with cobalt and also meet these requirements are: Misch metal (MM), a Ce-rich mixture of light rare earths; and Y, an element belonging to the same subgroup of the periodic table as the rare earths.

Although single-phase SmCo5 possesses maximum magnetic properties in theory, problems encountered during fabrication required the use of Sm in excess of stoichiometry. The additional Sm not only compensated for losses from oxidation and vaporization during melting but also served as a sintering aid. Because single-phase SmCo5 sintered poorly at temperatures necessary for optimum magnetic properties, excess Sm in the form of a lower melting, higher Sm-content cobalt alloy was added. This addition resulted in the formation of a second phase.

The use of various Sm-rich sintering aids has been reported. Benz and Martin first reported the use of a multiphase liquid sintering aid, consisting of 60 weight-percent Sm and 40 weight-percent Co, so called because, it is in a liquid state at sintering temperatures. Johnson and Fellows reported the use of a liquid sintering aid that consisted of 73 weight-percent Sm and 27 weight-percent Co. Carriker and Ludewig have investigated the use of a single-phase liquid sintering additive of 88 weight-percent Sm and 12 weight-percent Co (Sm3Co). In each of the above cases, the sintering aid was mechanically blended with the compound SmCo5 to a desired composition. Das reported the use of controlled excess Sm in the as-cast composition during melting. This paper presents the results of an investigation of preparing Sm-Co magnets using Sm2Co7 as a solid-state diffusion sintering aid.

If you are interested in using magnets to find lost treasures such as rings and other precious magnetic metals then be sure to check out our recently created list of the best magnet fishing kits that are available to buy as of 2021.

Experimental Procedures and Equipment

Alloy Preparation

Sm-Co compounds were prepared by nonconsumable arc-melting of 99.9 weight-percent pure metals. Charges of approximately 80 grams of these metals were melted under helium. The arc-melted buttons were inverted and remelted a total of 5 times to achieve homogeneity. An excess of Sm was added to the charge composition to compensate for Sm loss due to vaporization. For example, a charge composition of 37 weight-percent Sm and 63 weight-percent Co was used to obtain a near stoichiometric SmCo5 composition of 33.8 weight-percent Sm.

In this investigation, two methods of preparing compositions were evaluated. The first approach consisted of obtaining a particular composition by adding controlled amounts of Sm and Co to the charge before melting. This product is referred to as the “as-melted” composition. The second method involved the preparation of two separate compounds, near stoichiometric SmCo5 and Sm2Co7, and blending them in desired ratios.

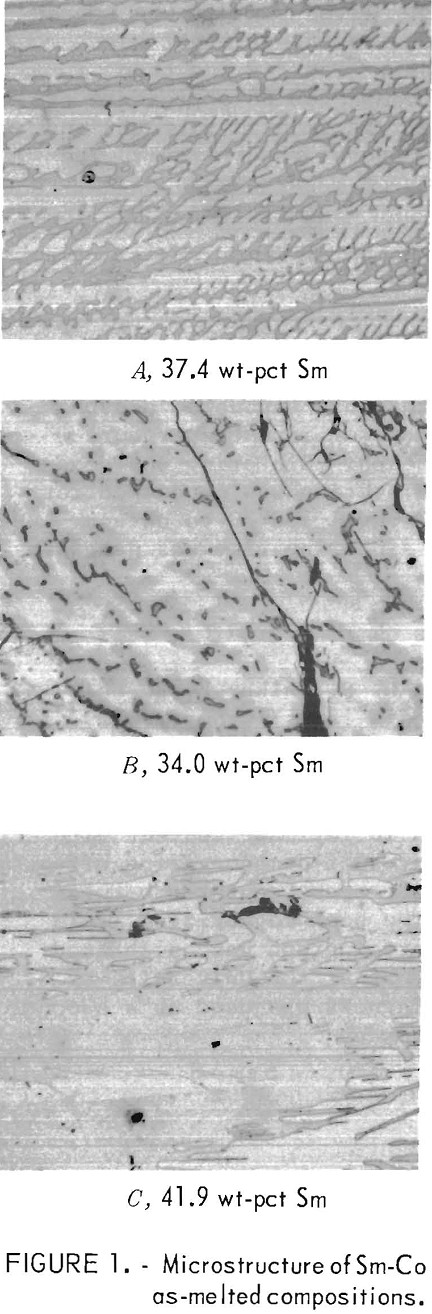

Figure 1A is a photomicrograph of a 37.4 weight-percent Sm as-melted composition. Microprobe analysis confirmed that the light phase was SmCo5 and the dark phase was Sm2Co7. Sm in excess of stoichiometric SmCo5 combined with Co to form Sm2Co7, resulting in a SmsCo7 to SmCo5 weight ratio of 3:4.

Figure 1B is a photomicrograph of near stoichiometric SmCo5 with a composition of 34.0 weight-percent Sm.

Figure 1C shows the microstructure of the sintering additive with a composition of 41.9 weight-percent Sm. The dark phase was Sm2Co7 and the light phase was SmCo5.

Quantitative analysis for Sm and Co contents was determined by wet chemical methods and by X-ray fluorescence.

Powder Preparation

The as-melted material was crushed in a tungsten carbide mortar and pestle until it passed through a 35-mesh sieve. Samples of this crushed material were analyzed for Sm, Co, and O. Fifty-gram lots of minus 35-mesh as-melted or blended compositions were ground with a Spex shatter box which consisted of a tungsten carbide container, lid, ring, and puck that was rotated with an eccentric motion. The grinding characteristics were similar to those of a mortar and pestle as opposed to impact grinding of a ball mill. The material was ground in toluene. Hexane was found unsuitable because of an unidentified residue found after vacuum drying. The temperature of grinding was held either at approximately 0° C by surrounding the shatter box container with a mixture of dry ice and water or at -60° C by covering the container with dry ice only. The temperatures reported were those of the toluene immediately after grinding. Grinding periods varied from 7 to 180 minutes with average particle sizes ranging from 10.1 to 3.0 micrometers as measured with a Fisher Sub-Sieve Sizer. The powders were vacuum dried and stored under helium until used.

Alignment and Compaction

The powder was alined and compacted in air in a magnetic field of 8,000 G. The magnetizing apparatus consisted of a 1,200- turn coil wound with No. 10 AWG magnet wire and an iron core 1 inch in diameter and 6 inches long. Pressing was done in a single-action cylindrical die with a magnetic base, and a nonmagnetic body and plunger. The die base and body rested on the iron core within the coil as the powder

was introduced in the presence of a magnetic field. After the die was tapped and vibrated to increase the alinement of the particles, the plunger was inserted under a pressure of approximately 1,000 psi. The die was then removed from the coil, and the powder was further compacted at a pressure of 45,000 psi. The green compacts thus obtained were 7/16 inch in diameter and 3/16 inch long with a density of approximately 60 percent theoretical. The density of the green compacts was determined by direct measurements of the mass and volume, and the density of a sintered magnet was determined by immersion in toluene.

Sintering Procedure

The compacts were enclosed in stainless steel sheaths welded shut at one end and fitted with a removable plug at the open end. Extra compacts were placed at each end to serve as getters. The sheaths were evacuated and back-filled with helium. This arrangement provided a more uniform temperature distribution and protected the compacts from oxidation. Sintering was done in a tube furnace under a positive helium flow. Sintering was conducted for 2-½ hours at temperatures varying between 1,105° and 1,130° C to obtain optimum magnetic properties. The relatively long sintering time was necessary because of the low green density of the compacts.

Magnetic Measurements

The magnetic properties were measured with an O. S. Walker hysteresis-graph that was designed to plot B versus H hysteresis loops automatically. The magnetic induction B was obtained by integrating the voltage change in a search coil closely fitted around two sample magnets. A number of search coils of varying diameters and 0.25 inch long were made to accommodate the sintered magnets. Each pair of magnets tested was in intimate contact with the pole faces of the electromagnet to minimize any self-demagnetizing effects. The exciting field H was measured with a Hall-effect probe centered between the pole faces and adjacent to the search coil. The peak magnetizing field was 30 kOe at a pole gap of 0.375 inch. The hysteresisgraph was calibrated against standard samples obtained from Karl J. Strnat at the University of Dayton, Dayton, Ohio. A pair of Pt-Co permanent magnets was used as a secondary standard each time magnetic measurements were made.

Results and Discussion

Optimum Composition

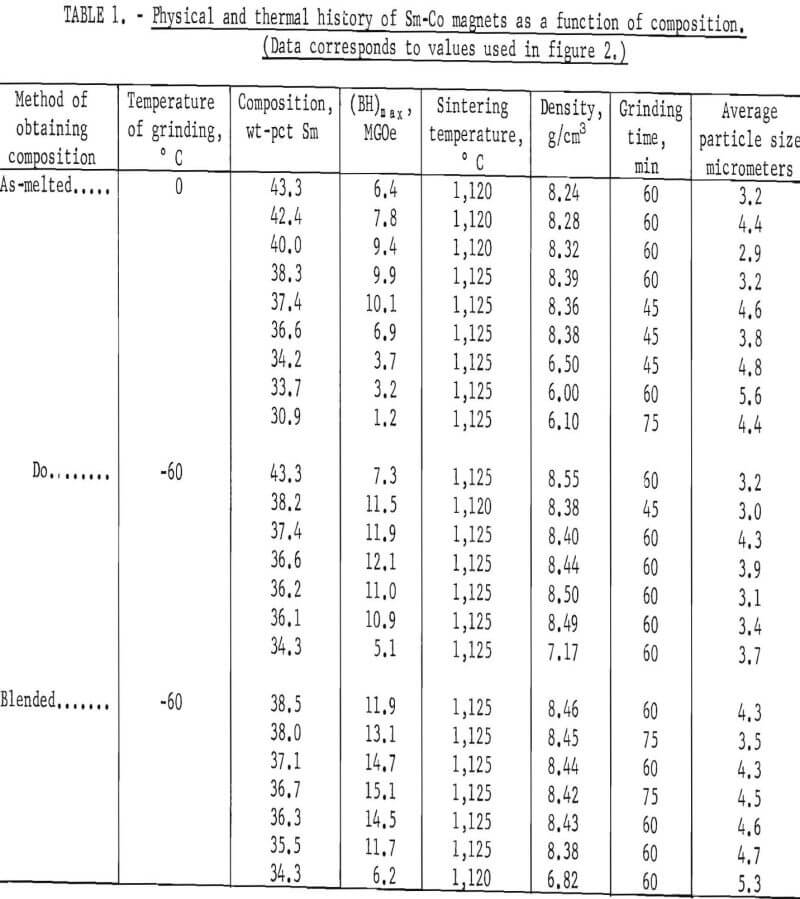

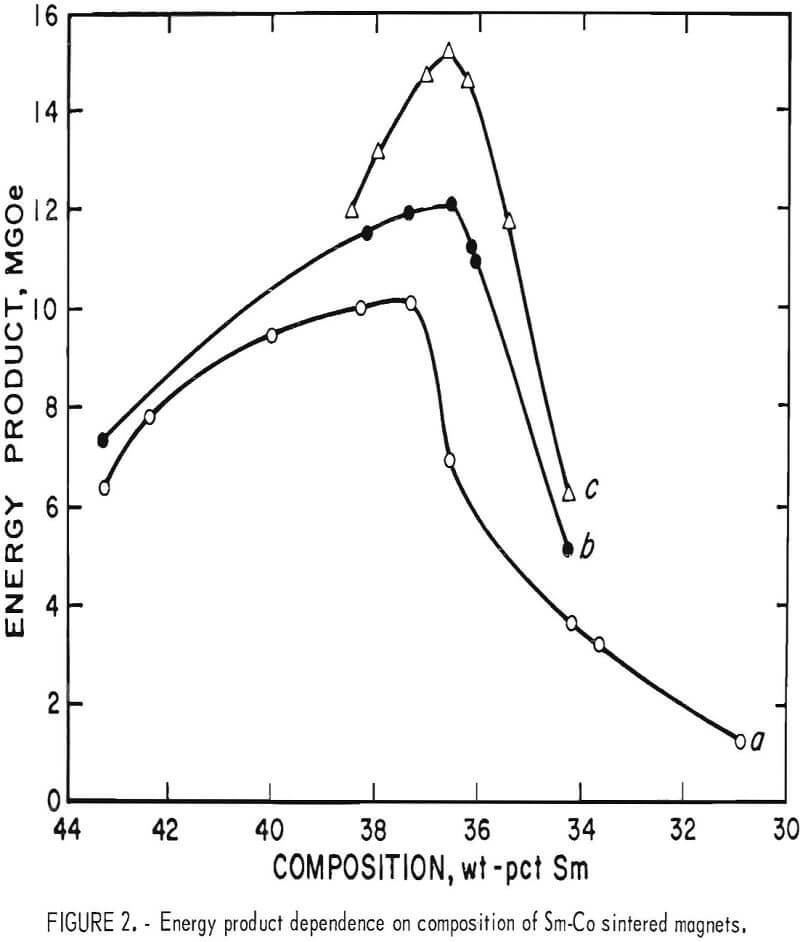

After preliminary studies were made to establish a standard procedure for fabricating Sm-Co magnets, the effect of composition on the energy product of sintered magnets was investigated. Figure 2 shows the results of three separate tests in which the peak values of energy product were plotted as a function of composition. The sintering time was 2-½ hours. The sintering temperature was either 1,120° or 1,125° C and the grinding times varied between 45 and 75 minutes. A complete listing of data obtained in these experiments is given in table 1.

The values for curve a in figure 2 were measured on magnets made from as-melted compositions ground at a temperature of 0° C. The maximum energy product of 10.1 MGOe occurred at 37.4 weight-percent Sm and 62.6 weight-percent Co. The values for curve b were also measured on magnets made from as-melted compositions but ground at -60° C. The peak value shifted slightly to 36.6 weight-percent Sm and 63.4 weight-percent Co with an increased energy product of 12.1 MGOe, probably the result of grinding at a reduced temperature. Curve c represents the data obtained using compositions prepared by blending near stoichiometric SmCo5 and Sm3Co7 and ground at -60° C. A maximum energy product of 15.1 MGOe occurred at a 36.7 weight-percent Sm composition.

The results of these tests showed that the maximum value of energy product was increased by reducing the grinding temperature, and the optimum composition for maximum energy product was 36.7±0.3 weight-percent Sm. Magnets prepared by blending Sm2Co7 and SmCo5 were superior to those prepared from as-melted compositions. It was also noted that at compositions of approximately 35 weight-percent Sm and lower, there was a marked decrease in energy product. This decrease was attributed to the correspondingly low values of sintered density, as shown in table 1.

Effects of Composition

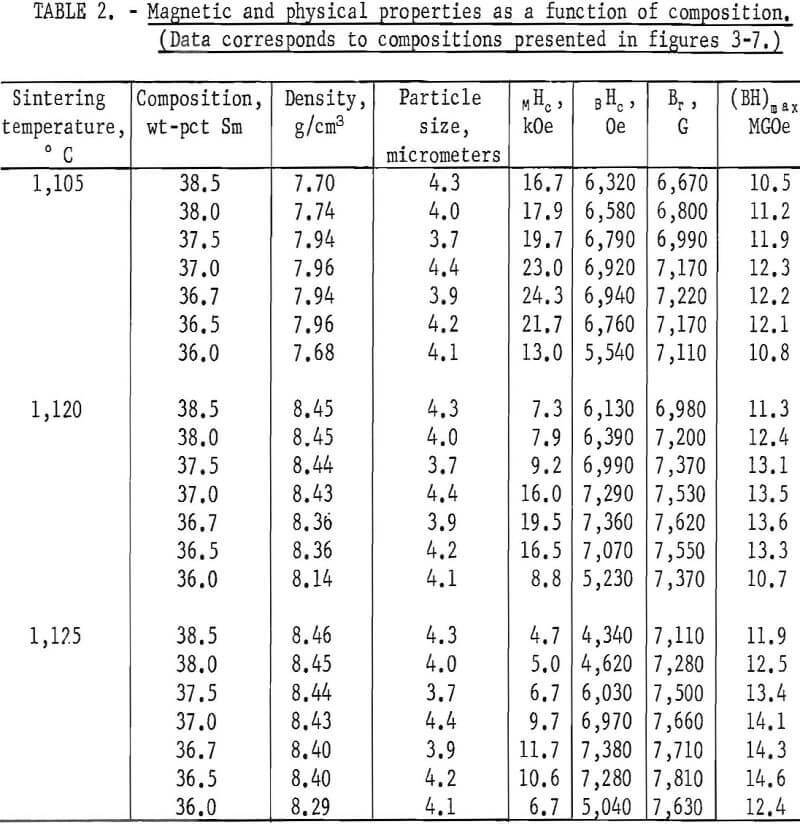

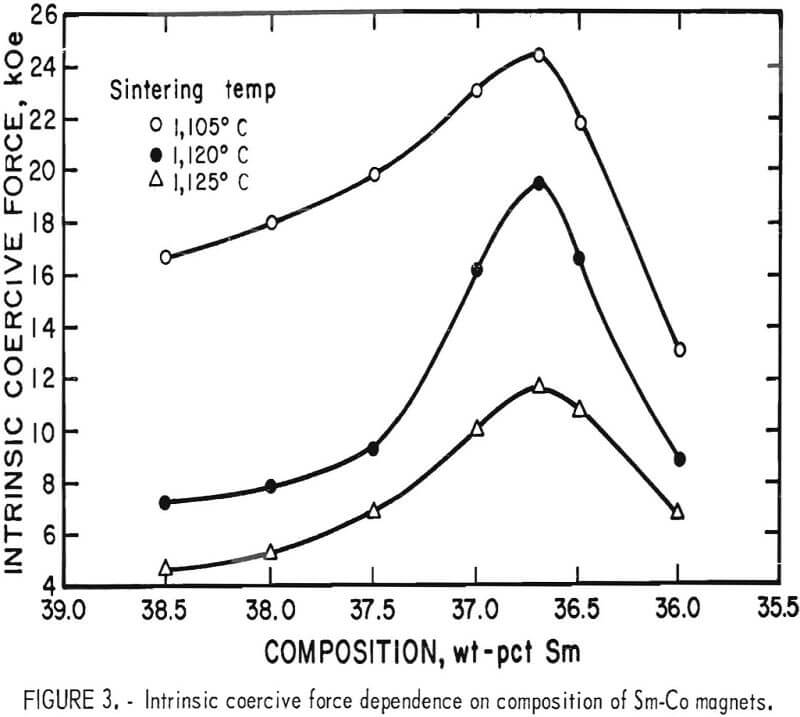

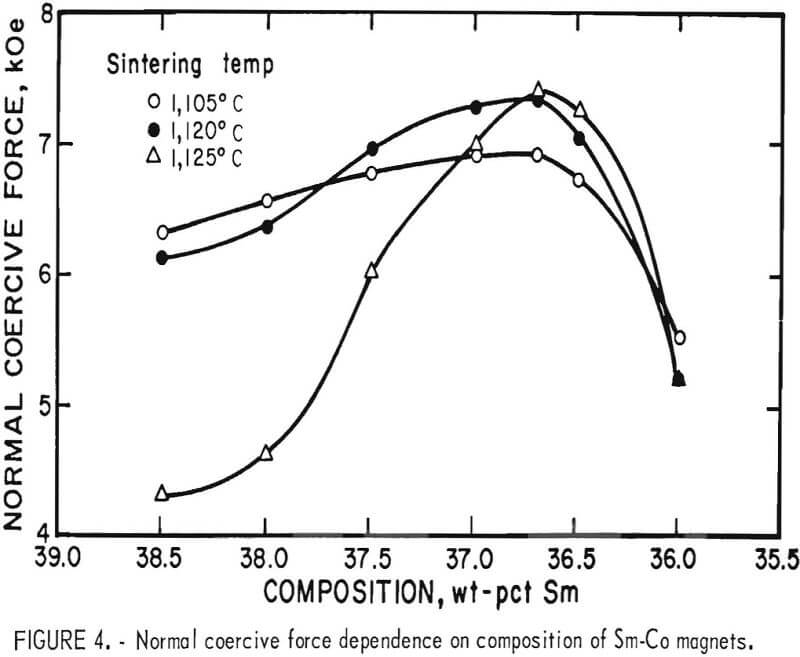

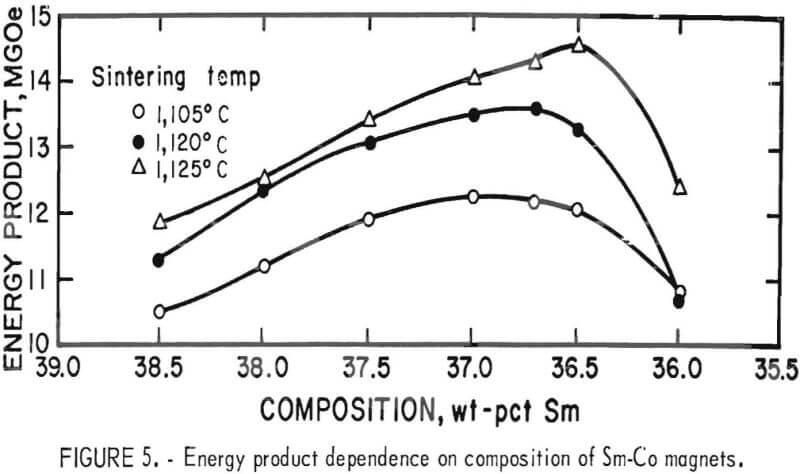

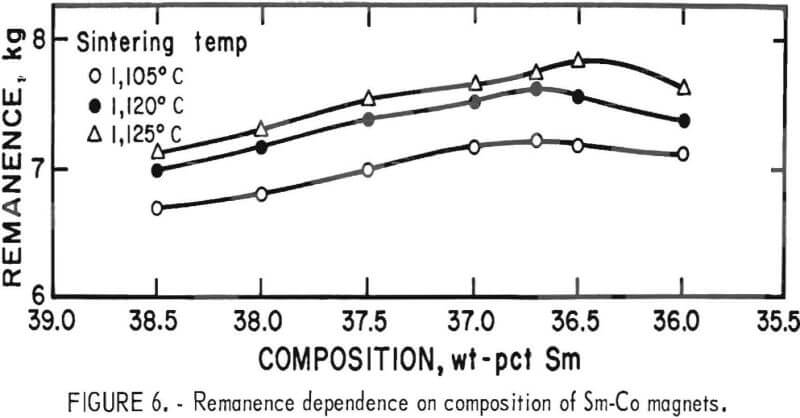

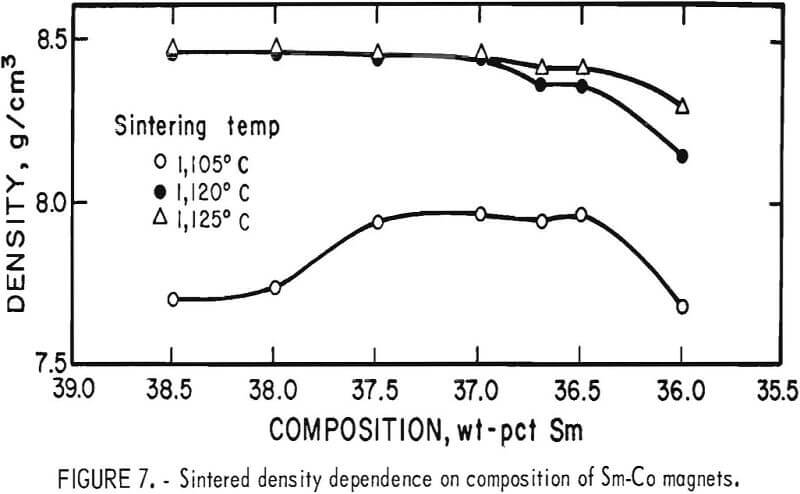

On the basis of the previous data, a precisely controlled experiment was performed to determine the effects of composition on density and on each of the following magnetic properties: Intrinsic coercive force, mHc; normal coercive force, BHc; remanence, Br ; and energy product, (BH)max. The Sm content was varied between 38.5 and 36.0 weight-percent by using increments of 0.5 weight-percent which specifically included the optimum value of 36.7 weight-percent reported in figure 2. Each composition was prepared by blending a sintering additive of 41.4 weight-percent Sm with the base component of 34.9 weight-percent Sm. These were blended as minus 35-mesh material and ground together in toluene for 60 minutes at -60° C. Sintering time was fixed at 2½ hours. The results of this study are depicted in figures 3 through 7 and summarized in table 2.

The maxima of intrinsic coercive force (fig. 3) and normal coercive force (fig. 4) occurred at 36.7 weight-percent Sm content for each sintering temperature. The remanence (fig. 6) peaked at compositions of 36.7, 36.7, and 36.5 weight-percent Sm at temperatures of 1,105°, 1,120°, and 1,125° C, respectively. The slight shift of maximum values to 36.5 weight-percent Sm at 1,125° C was probably within experimental error. Because the energy product is proportional to the remanence, the same shift appears in figure 5.

The data of this investigation indicated an optimum composition and temperature for maximum energy product were 36.7±0.3 weight-percent Sm and 1,125° C. The maximum value of intrinsic coercive force occurred at 36.7±0.3 weight-percent Sm but at a sintering temperature of 1,105° C.

Effects of Sintering Temperature

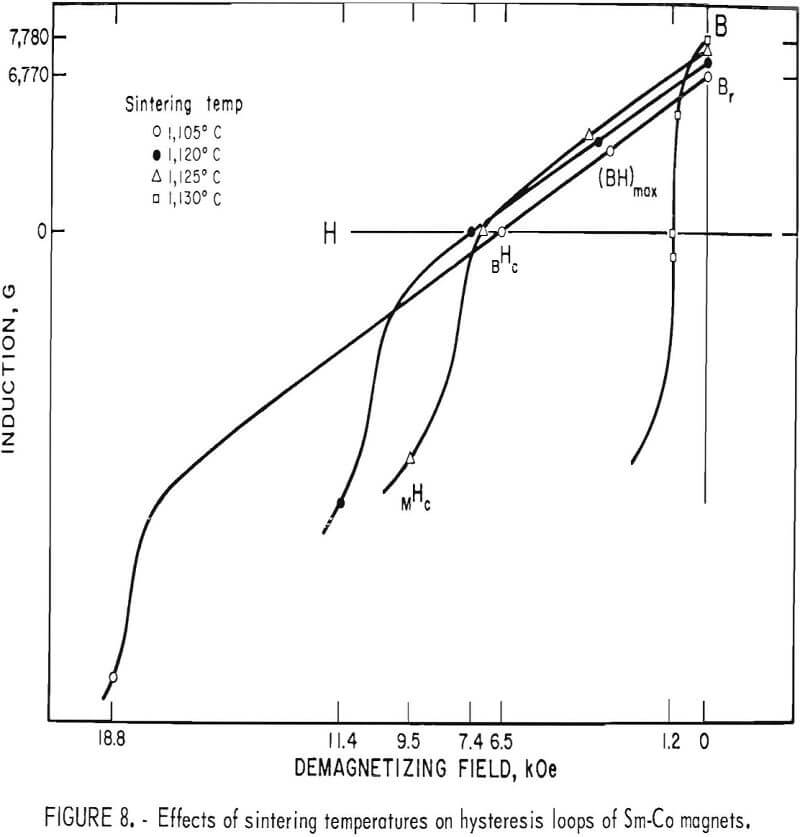

The magnetic properties were found to be very sensitive to sintering temperature although reproducible results were readily attained because temperature control presented no problem. The effects of various sintering

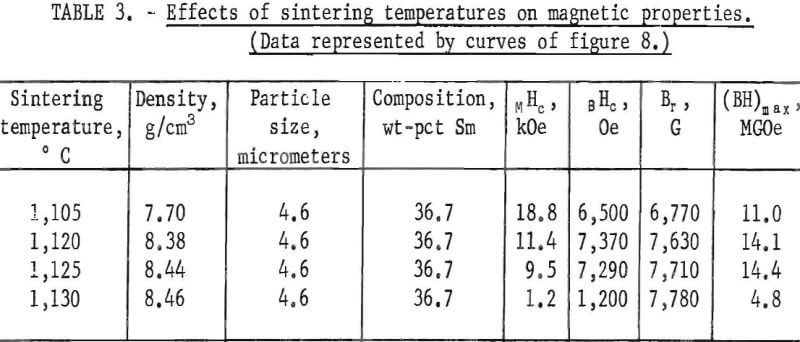

temperatures on the shape of the hysteresis loops in the second and third quadrants are shown in figure 8. The test composition was 36.7 weight-percent Sm obtained by blending two components of 42.4 weight-percent Sm and 34.3 weight-percent Sm, and then grinding it at -60° C for 60 minutes to an average particle size of 4.6 micrometers. Sintering time was fixed at 2-½ hours.

The data for each magnet are listed in table 3. The curves in figure 8 are reproductions of the original hysteresis loops of the magnets redrawn to a convenient scale. The remanence, Br, was the value of the induction where the demagnetizing field, H, was zero. The normal coercive force, BHc, was the value of the demagnetizing field where the induction, B, was zero. The energy product, (BH)max, was the maximum product of the coordinate values (B, H) on the curve in the second quadrant. The intrinsic coercive force, MHC, was the value of the induction that was numerically equal to the demagnetizing field in the third quadrant.

Figure 8 shows that the maximum value of the intrinsic coercive force occurred at the lowest sintering temperature, 1,105° C, and decreased sharply with increasing temperature. A drastic reduction of coercive force was observed at 1,130° C. The remanence increased gradually with temperature more or less proportional to the increase in density.

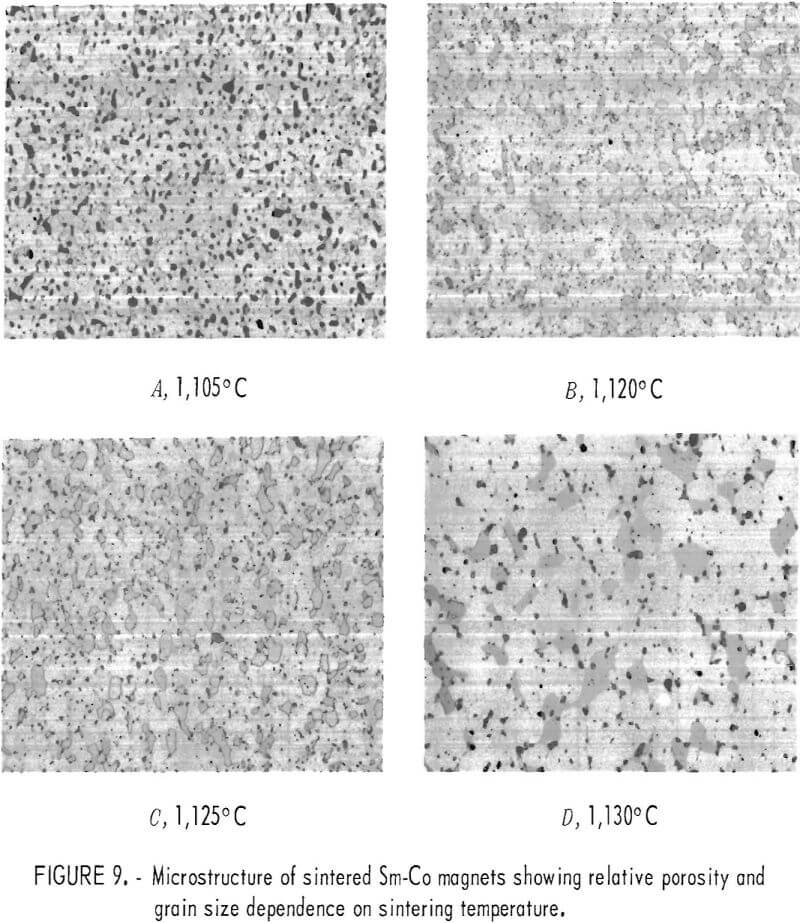

Representative microstructures of sintered Sm-Co magnets showing the effects of sintering temperatures on the porosity and grain size are illustrated in figure 9. In order to obtain magnets with a closed pore structure, a sintered density of greater than 85 percent theoretical was required. Figure 9A is a photomicrograph of the closed pore structure of a 90-percent dense (7.7 g/cm³) magnet sintered at 1,105° Ca Figures 9B and 9C show the microstructure obtained at sintering temperatures of 1,120° and 1,125° C, respectively. Very little grain growth or porosity is seen. Considerable grain growth is visible in figure 9D. The increase in grain size at 1,130° C was believed to be the primary cause for the severe loss of coercivity shown in figure 8.

Effects of Grinding

Reduction of minus 35-mesh material to a fine powder was one of the most critical steps in the fabrication of Sm-Co magnets. Oxidation and contamination were minimized by grinding in toluene at -60° C. In addition, grinding at this low temperature was believed to have reduced the detrimental effects of crystal lattice deformation and cold-working of the alloy.

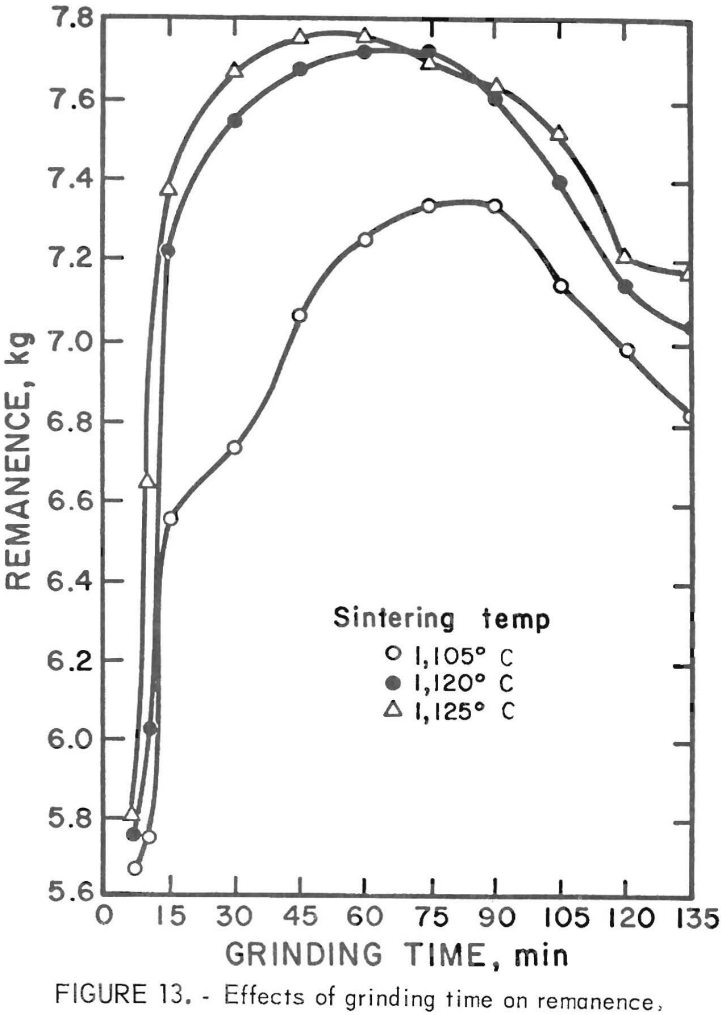

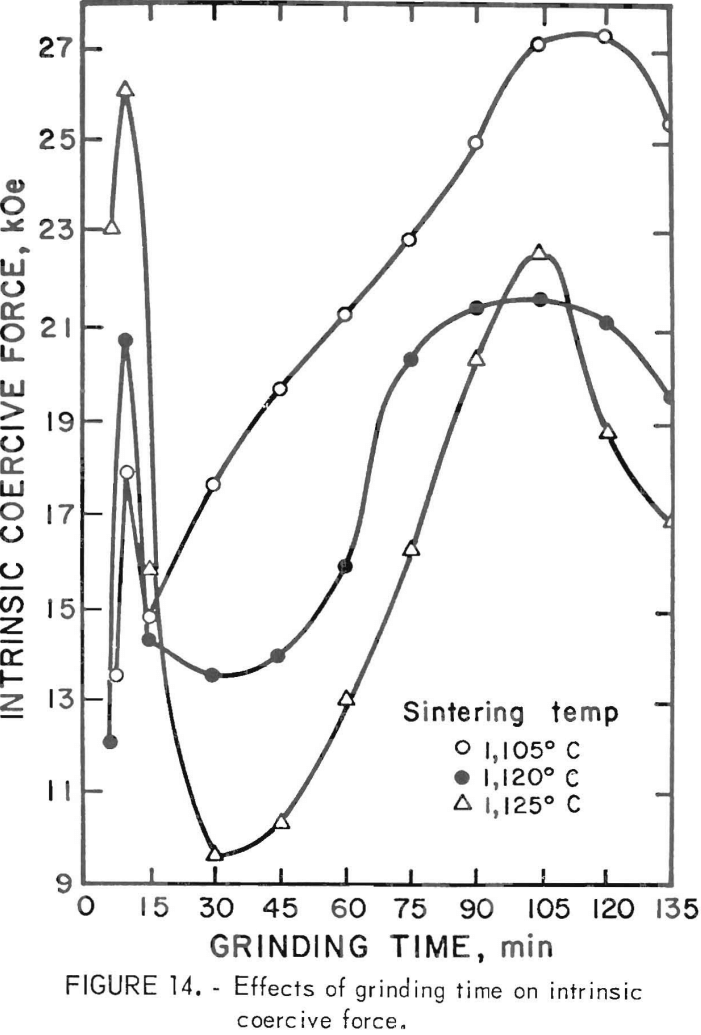

This series of grinding experiments used the optimum value of 36.7 weight-percent Sm composition, prepared by blending a 42.4 weight-percent Sm sintering aid with a 34.3 weight-percent Sm base compound. Fifty-gram charges were ground from 7 to 135 minutes in a shatter box. The sintering temperatures were 1,105°, 1,120°, and 1,125° C, with time fixed at 2-½ hours.

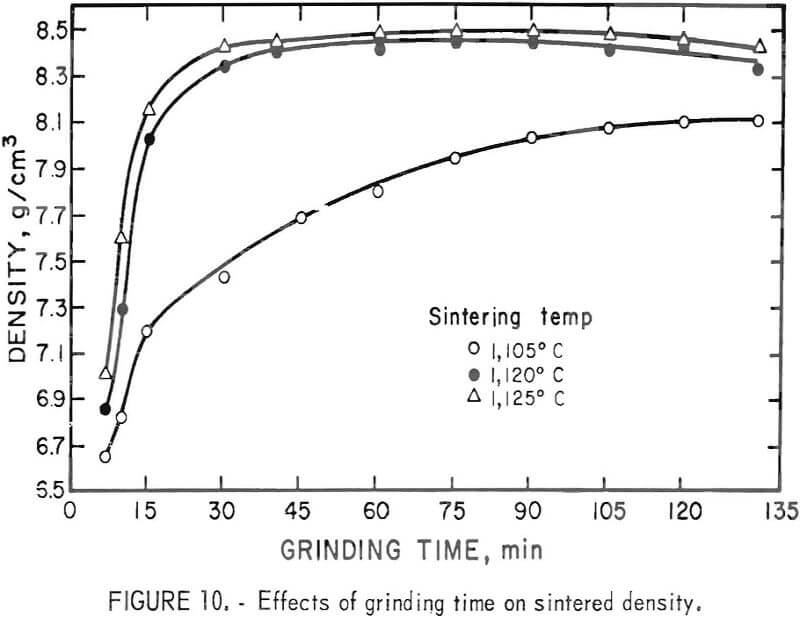

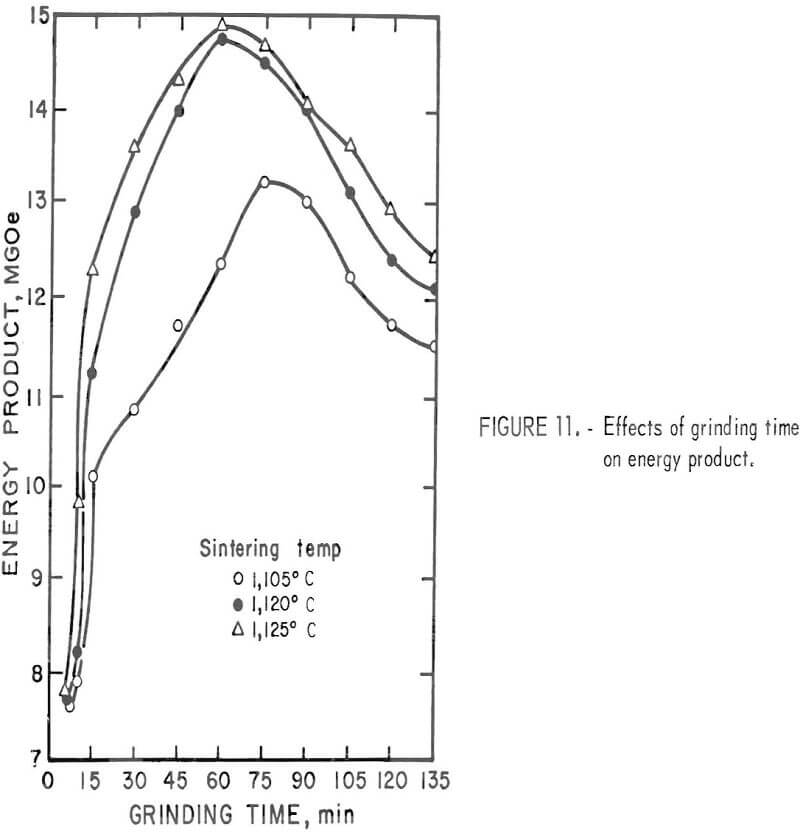

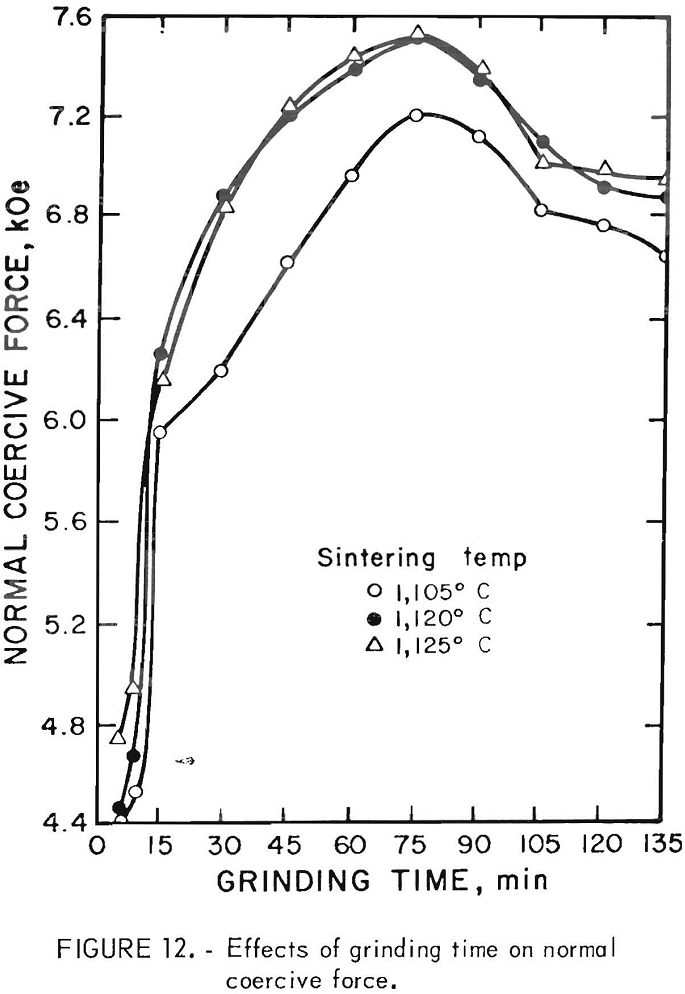

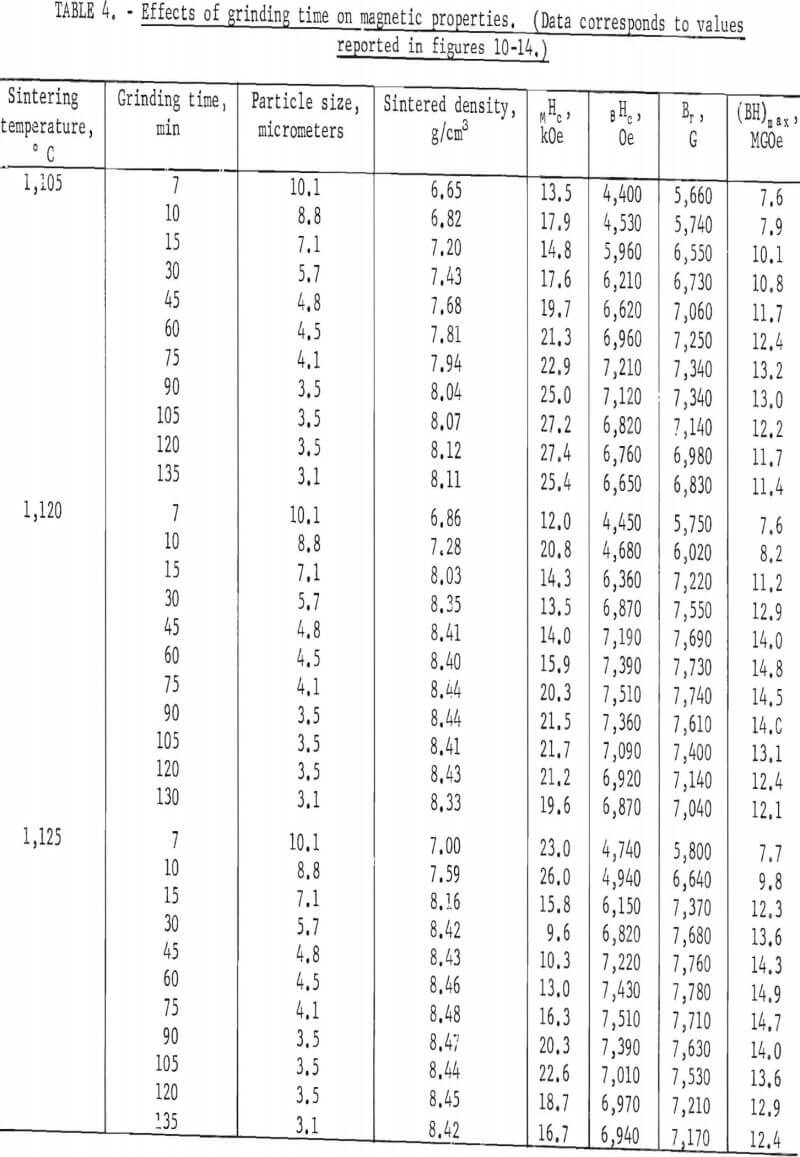

The effects of grinding time on the magnetic properties are shown in figures 10 through 14, and the dependence of the average particle size on the time of grinding is shown in table 4. The sintered density exhibited a marked dependence on the average particle size, particularly for short grinding times. At sintering temperatures of 1120° and 1,125° C, high-strength, high-density magnets were obtained with powder as large as 7 micrometers. At 1,105° C, however, the maximum tolerable particle size was approximately 5 micrometers. Optimum magnetic properties were obtained with powders ground between 60 and 75 minutes (average particle size of 4.5 to 4.1 micrometers) and sintered at 1,120° and 1,125° C.

The intrinsic coercive force curves of figure 14 show two peaks. The first occurred at a 10-minute grinding time but the sintered densities were of such low values that the magnets produced did not have stable properties. The second peak occurred at grinding times of 105 and 120 minutes, A maximum intrinsic coercive force of 27,400 Oe was obtained at a sintering temperature of 1,105° C with a closed pore density of 8.12 g/cm³. Although this result represents a relatively low density, the magnets showed no signs of degradation in air at room temperature.

Conclusions

A procedure for manufacturing Sm-Co permanent magnets was developed. The optimum composition was determined to be 36.7±0.3 weight-percent Sm obtained by blending two near stoichiometric compounds, Sm2Co7 and SmCo5. This method of preparing compositions was superior to the direct melting method in which the Sm content was directly controlled during melting. The optimum sintering temperature was 1,125°±2° C for maximum energy product and 1,105°±2° C for maximum intrinsic coercive force. In order to obtain a high degree of magnetic stability, a closed pore density of greater than 90 percent theoretical was required. Lowering the temperature of grinding from 0° to -60° C resulted in a significant increase for all magnetic properties. Maximum energy product was obtained with powders ground 60 to 75 minutes (average particle size of 4.5 to 4.1 micrometers) and maximum intrinsic coercive force, with 120 minutes (average particle size of 3.5 micrometers).