In the discussion of my paper on “ Close Sizing Before Jigging,” Mr. Louis remarks: “ What we really need to know as the basis of any consistent theory (of jigging) is what occurs during each hundredth of a second.”

It is clear that for the further study of the laws involved, a jig-tester is needed which will give curves representing the amount, rate and kind of motion taken on by the plunger, the water and the sands. In pursuance of this idea the author has designed a jig-indicator for drawing curves illustrating the action of plunger jigs. The indicator (see Fig. 1) consists of a cylinder, a, of brass, 8 inches long, 6 inches diameter, with its axis vertical, suspended from and continuous with a bicycle ball-bearing, b, to eliminate friction. The cylinder is rotated by clockwork, c, with a wind-wheel escapement, d, and can be made to revolve from 3 to 25 times per minute, according to the size of the wind-wheel. Upon the surface of the cylinder is wrapped a piece of paper, 8 inches wide and 20 inches long, upon which the curves are drawn. Two vertical recording-rods, e1, e2, running in anti-friction roller-guides, f f f f, with pencils, g g, attached, and provided with devices for throwing them into gear and out of gear, serve to record vertical motion upon the paper. The abscissa of the curve represents time, the ordinate represents movement up and down. The curve of the plunger is obtained by a vertical rod, h, held down on the top of the plunger and transmitting the oscillations of the latter by a horizontal beam, i, oscillating upon its center point, j, as a pivot to one of the recording-rods, e2. When the plunger moves down, its pencil records an upward motion, and vice versa. To get the curve of the surface of the water a slab of cork, l, 10 inches square and 1 inch thick, is floated upon it and attached to the other recording-rod, e1 direct. Here the motion of the pencil is the same as that of the water. The curve of the top-layer of quartz-sand is obtained by placing on the sand a piece of sieve-cloth a little finer in mesh than the grains of quartz. This pulsates up and down with the sand, and when connected to one of the recording-rods, e1, gives the curve of the quartz. The curve of the ore-bed which underlies the quartz may be obtained by sinking the piece of sieve-cloth to the desired depth and attaching it to the recording-arm, e1.

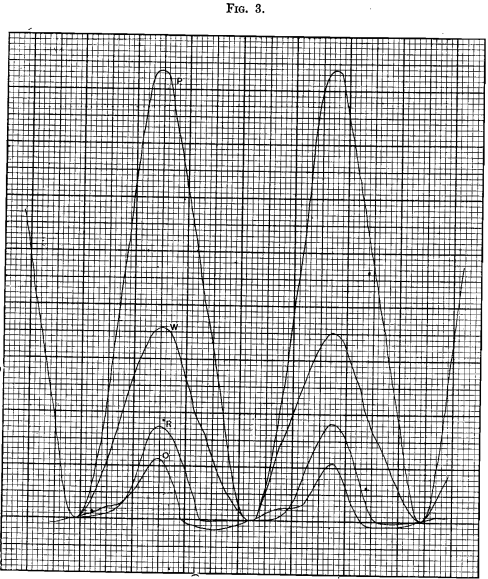

Four curves are thus obtained: that of the plunger, marked P on the diagrams; that of the water, marked W; that of the quartz or rock, marked R; and that of the ore-bed, marked O. (The diagrams are shown in Figs. 2 to 41 inclusive, all of which are of natural size.)

In the actual performance of the tests two curves only are taken at a time—namely, those of the plunger and the water; those of the plunger and the quartz or rock; and, finally, those of the plunger and the ore-bed. The diagrams have been constructed by combining these drawings. In this operation it was necessary to have some standard by which, for example, the rock-curve and the ore-curve could be superposed upon the water-curve. Such a standard was found in the parallel plunger-curves that went with each. Again, the superposed curves would often come longer or shorter than the water-curve. In that case a new curve was sketched, making the deviation on the abscissa proportional to the distance from the starting-point.

Curves have been obtained at the following mills; the Anaconda, Montana (argentiferous sulphide copper-ore); the Calumet and Hecla, Michigan (native copper); the Revenue Tunnel, Colorado (argentiferous galena); the Smuggler, Colorado (argentiferous galena); the Old Jordan and Galena, Utah (auriferous pyrites); the Colorado Mining and Smelting Co., Montana (argentiferous sulphide copper-ore); the Bunker Hill and Sullivan, Idaho (argentiferous galena); the Boston and Montana Silver and Copper Mining and Smelting Co., Montana (argentiferous sulphide copper-ore); and the Butte and Boston Mining Co., Montana (argentiferous sulphide copper-ore).

Thanks are due to the officers of these companies for their kindness in aiding me to make these tests and to gain the other facts here presented.

Accelerated Jig

The jigs divide themselves into two main classes, the plain eccentric Harz jigs and the accelerated jigs, including the crank-arm, the sliding-block and the Collom jigs.

Before drawing conclusions as to the meaning of the curves here shown, it will be well to recall briefly certain facts demonstrated in my paper on “ Close Sizing Before Jigging.”

It was there shown that three laws of jigging had been advanced by various authorities, and a fourth law was advanced by the author.

- The law of free-settling particles (the equal-settling particles of Rittinger).

- The law of hindered-settling particles (the interstitial currents of Munroe).

- The law of acceleration (Rittinger).

- The law of suction (advanced by the author).

The results obtained on free-settling particles are embodied in the following table, corresponding with Table VII. of the paper above cited:

Example.—If a compact particle of galena, falling freely in water, settles 7 inches per second, the particle of quartz of the same shape that will settle at the same rate will be approximately 3.65 times the diameter of the galena.

The law of hindered-settling deals with particles settling in an upward current, when they are in a mass and are bumping against and hindering one another; in fact, in the condition of quicksand. Table II., abstracted from “ Close Sizing Before Jigging,” gives the author’s factors for particles that would

settle with, and be adjacent to, each other under these conditions.

Example.—If mixed grains of quartz and galena are allowed to arrange themselves in a mass, hindering and elbowing one another all the time, in an upward- moving current of water, the quartz particles, when equilibrium is reached, will be found to have approximately 5.8 times the diameter of the particles of galena poised alongside of them.

I use here the terms “ free-settling factors ” and “ hindered- settling factors ” instead of the phrases “ equal-settling factors ” and “ interstitial-current factors,” respectively used in my former paper, because I believe the new phrases are more expressive of the conditions most prominent in each case.

The third law, Rittinger’s law of acceleration, deals with the behavior of particles suddenly changing their condition from rest to motion. Rittinger demonstrated that if a small particle of galena were adjacent to a larger particle of quartz, the galena would reach its maximum speed of settling sooner than the quartz, and that this fact would aid in separating the galena particles from the quartz.

The fourth law of suction, advanced by the author, is well shown by the figures of Table III., abstracted from Table XLIII. of the paper on “ Close Sizing Before Jigging,” where a series of tests in the jigging of blende and quartz together was reported. In the first, the blend is of the same size as the quartz; in the others, the diameter of the blend is diminished in each successive test. The measure of easy or difficult jigging is the number of pulses needed to make a separation. The amount of the separation, as judged by the eye, is inserted in the table.

For the method of making the three series of tests, the first with strong suction, the second with mild suction, and the last with no suction, the reader is referred to the paper cited.

The law of suction seems to be that jigging is greatly hindered by strong suction where the two minerals are nearly of the same size, the quickest and best work being then done with no suction; but that when the two minerals differ much in size of particles, the quartz being the larger, strong suction is not only a great advantage, but may be necessary to get any separation at all. My experiments have indicated an approximate boundary between grains that are helped and those that are hindered by suction. Namely, if the diameter of the quartz- particles is equal to or greater than 3.52 times the diameter of the other mineral-particles, then separation is helped by suction; if less, separation is hindered. This value, 3.52 (obtained by dividing 0.0683 by 0.0195), is approximate only, and it will differ with the fracture of the quartz under consideration; if the quartz grains are much flattened it will have a large value. The grains are of such irregular shapes that geometrical analogy fails to help in obtaining a value; for example, in Fig. 44 the diameters of the spheres of quartz, a a a, will be 6.50 times that of the ore, b, when the ore can slip through between the quartz, while the diameters of the quartz spheres, c c c, will be only 2.44 times that of the ore, d.

Table IV. contains the measurements and computations made upon the jigs, and upon the cards obtained from them. The four elements that are new are:

- The upward velocity of the water on the pulsion-side of the curve.

- The percentage of time devoted to pulsion.

- The percentage of time devoted to return.

- The percentage of time devoted to suction.

The first of these is a rather weak determination, as the cards, even of an eccentric jig, did not always show exactly the same slope on both sides. They are, however, accurate enough (since, where the error exists, it makes the figure a little too high) to demonstrate the fact that the law of free-settling particles has no bearing upon jigging, unless it may apply in the case of a few stray, floating grains on the surface of the finest jigs; for, on the one hand, the current was in no case strong

enough to lift the particles according to the free-settling law, and, on the other hand, the particles were not under free-settling conditions, even if the current had been strong enough.

The curves of water and quartz will be of most interest, because it is from the quartz that we wish to catch the straying mineral, and it is by the water that we wish to catch it.

It will be seen upon inspection of the diagrams that the water-curve, W, and the quartz-curve, R, rise to their highest points and then descend, but that the quartz always gets down before the water. We may say that there are three periods: 1. Pulsion; 2. Return; and 3. Repose or suction.

To aid in this discussion, two ideal diagrams (Figs. 42 and 43) have been drawn. In Fig. 43 two top-curves are given; the flat top, e, and the pointed top, d. A few of the diagrams (Figs. 26, 28, 33 and 34), indicate that the flat top is normal; but the remaining accelerated-jig curves speak for the pointed top.

The three periods named may be further discussed as follows :

Period I.—Pulsion, P, or upward movement. The water- and quartz-curves diverge, because the water is moving up faster than the quartz. Here the law of hindered settling is acting to bring the coarse galena below the quartz, and the fine galena adjacent to, and in equilibrium with, the proper size of quartz.

Period II.—Return downwards, T, which is divided into three periods:

(a) A moment when the quartz- and water-curves are converging, because the water is moving down faster than the quartz. Here the fine grains of galena acquire their maximum velocity downwards before the coarse grains of quartz; and hence Rittinger’s law of acceleration is probably at work, helping the fine galena to get below the coarse quartz.

(b) A moment when the two lines of quartz and water are parallel, that is, a moment of relative idleness as to separation.

(c) A moment when the curves of quartz and water are diverging. The sand is falling faster than the water; hence the law of hindered settling is again at work.

Period III.—Suction, S. Here the sand reposes upon the sieve. The water-curve, W, is converging rapidly towards the horizontal quartz-line, R; therefore, the water is passing down through the sand at a high rate of speed. Here suction comes in to draw downwards through the interstices the small particles of galena which the law of hindered settling has placed adjacent to, and in equilibrium with, the larger particles of quartz.

Having thus observed the periods into which jigging is divisible, may we not conclude that a jig which is spending longer time upon the pulsion is doing the work of pulsion more thoroughly, and that a jig which devotes more time to suction is performing that special work more thoroughly ? It should be noted here that the period of return counts to a greater or less extent as suction, particularly upon the jigs treating the finer sizes (as shown, for example, in Figs. 8, 9, 14, 21, 86 and 37). In all jigs the downward passage of the water is carrying into the hutch fine particles of ore that have already found their way into the ore-bed.

Looking at the jigs by classes, we see that the eccentric jigs invariably spend more time upon pulsion than the accelerated jigs. Is it not fair to conclude that the eccentric jigs are better adapted for treating sands which require the most pulsion ? Such sands are the sized products from the trommel and the first spigot of the hydraulic classifier.

On the other hand, may not the long-protracted mild suction of the accelerated jig be the best adapted to the treatment of such products as require primarily suction for their separation —for example, the second spigot and following spigots of the hydraulic classifier ?

This may be the reason that the Collom jig has found so great favor at Lake Superior and at Anaconda, where all the jigging is done upon true hydraulic-separator products, except the first sieve of the first jig.

We should, however, bear in mind that the somewhat harsh suction of the excentric jig can be made milder by increasing the hydraulic water. This will diminish the hardening of the bed, but it cannot lengthen the time of suction, so as to secure the condition as presented in this particular by the accelerated jigs.

The two extreme suggestions arising from a contemplation of these curves are :

- That on closely-sized products an accelerated jig should be used, run backwards, to lengthen out the pulsion-period, which is the only period that does any work; and

- That the accelerated jig should be run forward on the spigot-products of the hydraulic separator, to increase the period of suction.

There are in the way of the first suggestion two difficulties, either of which may cancel the advantage: First, the violent downward motion of the quick return will tend to “ blind up ” the sieve ; and, secondly, the same action will tend to pulverize a soft mineral like galena.

I am aware that in southwest Missouri blende is jigged, all sizes together, from ½-inch downwards, upon a 6-sieve Harz jig, and that by using a moderately coarse sieve on the jig, and not allowing the bed to be too deep, and by employing a very strong suction, a concentration is effected which is considered commercially a success. It seems to me, however, probable that if the price of zinc-blende were not so low, the principles of close sizing would be adopted, in this, as in other cases, resulting in closer saving. In that case the principles discussed in this paper would be found essential to the greatest success.

Nor am I ignorant of the wide difference between theoretical speculation and commercial operation, in which it often happens that some small, unnoticed need of practice undoes a beautiful theory, rendering it unsuited for adoption. The suggestions offered in this paper are therefore put forward simply as ideas which appear to have merit and to be worthy of further study and test.

Butte and Boston Mining Co. (Argentiferous Sulphide Copper-ore.) Size of grains, 2½ to 1½ inches ; throw of plunger, 4¾ inches; throws per minute, 140; area of plunger, 24 by 48 inches ; area of sieve, 24 by 48 inches; mesh of sieve, round hole, 3/8 inch diameter.

Butte and Boston Mining Co. (Argentiferous Sulphide Copper ore.) Size of grains, 1½ inches to 15 mm. ; throw of plunger, 4.17 inches ; throws per minute, 140 ; area of plunger, 24 by 48 inches; area of sieve, 24 by 48 inches; mesh of sieve, round hole, 3/8 inch diameter.

Butte and Boston Mining Co. (Argentiferous Sulphide Copper ore.) Size of grains, 15 inches to 8½ mm. ; throw of plunger, 2.20 inches ; throws per minute, 140 ; area of plunger, 17 by 30 inches; area of sieve, 17 by 30 inches; mesh of sieve, No. 4.

Butte and Boston Mining Co. (Argentiferous Sulphide Copper ore.) Size of grains, 8½ to 4½ mm. ; throw of plunger, 2 inches ; throws per minute, 160 ; area of plunger, 15 by 31 inches; area of sieve, 15 by 31 inches; mesh of sieve, No. 4.

Butte and Boston Mining Co. (Argentiferous Sulphide Copper ore.) Size of grains, (first spigot of separator) 4½ mm. to 0 ; throw of plunger, 1.11 inches ; throws per minute, 180 ; area of plunger, 15 by 31 inches; area of sieve, 15 by 31 inches; mesh of sieve, No. 5.

Butte and Boston Mining Co. (Argentiferous Sulphide Copper ore.) Size of grains, (second spigot of separator) 4½ mm. to 0 ; throw of plunger, 1.19 inches ; throws per minute, 180 ; area of plunger, 15 by 31 inches; area of sieve, 15 by 31 inches; mesh of sieve, No. 6.

Butte and Boston Mining Co. (Argentiferous Sulphide Copper ore.) Size of grains, (third spigot of separator) 4½ mm. to 0 ; throw of plunger, 0.48 inches ; throws per minute, 200 ; area of plunger, 15 by 31 inches; area of sieve, 15 by 31 inches; mesh of sieve, No. 8.

Butte and Boston Mining Co. (Argentiferous Sulphide Copper-ore.) Size of grains (fourth spigot of separator), 4½ mm. to 0; throw of plunger, 0.28 inch ; throws per minute, 210; area of plunger, 15 by 31 inches; area of sieve, 15 by 31 inches ; mesh of sieve, No. 12.

Butte and Boston Mining Co. (Argentiferous Sulphide Copper-ore.) Harz Excentric Jig. Size of grains, 1½ to 7/8 inch ; throw of plunger, 2.57 inch ; throws per minute, 165; area of plunger, 22½ by 42 inches; area of sieve, 21½ by 42 inches ; mesh of sieve, 3/8 inch square hole.

Boston and Montana Co. (Argentiferous Sulphide Copper-ore.) Size of grains, 7/8 to 3/8 inch ; throw of plunger, 1.77 inches; throws per minute, 174 ; area of plunger, 24 by 36 inches : area of sieve, 24 by 36 inches; mesh of sieve, No. 3.

Boston and Montana Co. (Argentiferous Sulphide Copper-ore.) Size of grains, 5 to 2½ mm. ; throw of plunger, 1.05 inches; throws per minute, 180; area of plunger, 21 to 41 inches; area of sieve, 21 by 41 inches; mesh of sieve, No. 6.

Boston and Montana Co. (Argentiferous Sulphide Copper-ore.) Evans’ Excentric Jig. Size of grains (first spigot of separator), 2½ mm. to 0; throw of plunger, 0.75 inch ; throws per minute. 193; area of plunger, 11 by 39 inches ; area of sieve, 22 by 39 inches; mesh of sieve, No. 6.

Boston and Montana Co. (Argentiferous Sulphide Copper-ore.) Evans’ Jig. Size of grains (fourth spigot of separator), 2½ mm. to 0; throw of plunger, 0.39 inch; throws per minute, 193; area of plunger, 22 by 39 inches; area of sieve, 22 by 39 inches; mesh of sieve, No. 10.

Bunker Hill and Sullivan Co. (Argentiferous Galena) Size of grains, 7 to 5 mm.; throw of plunger, 1.45 inches; throws per minute, 150 ; area of plunger, 17 by 32 inches ; area of sieve, 15 by 30 inches; mesh of sieve, No. 8.

Bunker Hill and Sullivan Co. (Argentiferous Galena.) Size of grains (first spigot of separator), 3 mm. to 0 ; throw of plunger, 0.68 inch ; throws per minute, 162; area of plunger, 19 by 34 inches ; area of sieve, 18 by 32 inches; mesh of sieve, No. 10.

Colorado Mining and Smelting Co. (Argentiferous Sulphide Copper-ore.) Size of grains, 7 to 4½ mm. ; throw of plunger, 1.05 inches ; throws per minute, 160 ; area of plunger, 16 by 38 inches; area of sieve, 23 by 35 inches; mesh of sieve, No. 3.

Colorado Mining and Smelting Co. (Argentiferous Sulphide Copper-ore.) Size of grains (only spigot of separator), 3 mm. to 0 ; throw of plunger, 0.57 inch ; throw per minute, 210; area of plunger, 16 by 38 inches; area of sieve, 23 by 35 inches ; mesh of sieve, No. 10.

Old Jordan and Galena Works. (Auriferous Pyrites.) Size of grain, 4/10 to ¼ inch; throw of plunger, 0.67 inch; throws per minute, 240 ; area of plunger, 17 by 30 inches; area of sieve, 17 by 30 inches; mesh of sieve, No. 2½.

Old Jordan and Galena Works. (Auriferous Pyrites.) Size of grains (spigot of separator), 1/8 inch to 0 ; throw of plunger, 0.20 inch ; throws per minute, 400 ; area of plunger, 17 by 30 inches ; area of sieve, 17 by 30 inches; mesh of sieve, No. 8.

Revenue Tunnel. (Argentiferous Galena.) Plain Excentric Jig. Size of grains (first spigot of separator), 5/64 inch to 0; throw of plunger, 0.27 inch; throws per minute, 198 ; area of plunger, 17¾ by 24¾ inches; area of sieve, 16 by 23 inches ; mesh of sieve, No. 16.

Smuggler Mill. (Argentiferous Galena.) Crank-arm Accelerated Jig. Size of grains, 40 to 25 mm. ; throw of plunger, 2.42 inches; throws per minute, 96 ; area of plunger, 18 by 30 inches ; area of sieve, 18 by 31 inches ; mesh of sieve, 8 mm. square hole.

Smuggler Mill. (Argentiferous Galena.) Crank-arm Accelerated Jig. Size of grains, 25 to 16 mm. ; throw of plunger, 2.10 inches; throws per minute, 105 ; area of plunger, 18 by 30 inches ; area of sieve, 18 by 34 inches ; mesh of sieve, 8 mm. square hole.

Smuggler Mill. (Argentiferous Galena.) Crank-arm Accelerated Jig. Size of grains, 16 to 12 mm.; throw of plunger, 1.42 inches; throws per minute, 121 ; area of plunger, 18 by 25 inches; area of sieve, 18 by 29 inches ; mesh of sieve, 8 mm. square hole.

Smuggler Mill. (Argentiferous Galena.) Crank-arm Accelerated Jig. Size of grains, 12 to 8 mm. ; throw of plunger, 1.36 inches; throws per minute, 123 ; area of plunger, 18 by 25 inches; area of sieve, 18 by 29 inches; mesh of sieve, 5 mm. square hole.

Smuggler Mill. (Argentiferous Galena.) Crank-arm Accelerated Jig. Size of grains, 8 to 5 mm. ; throw of plunger, 1.18 inches; throws per minute, 132; area of plunger, 18 by 25 inches ; area of sieve, 18 by 29 inches ; mesh of sieve, 5 mm. square hole.

Smuggler Mill. (Argentiferous Galena.) Crank-arm Accelerated Jig. Size of grains, 5 to 3½ mm.; throw of plunger, 1.07 inches ; throws per minute, 138 ; area of plunger, 18 by 25 inches ; area of sieve, 18 by 29 inches; mesh of sieve, 2 mm. square hole.

Smuggler Mill. (Argentiferous Galena.) Crank-arm Accelerated Jig. Size of grains, 3½ to 2 mm.; throw of plunger, 0.81 inch; throws per minute, 133; area of plunger, 18 by 25 inches ; area of sieve, 18 by 29 inches; mesh of sieve, 1½ mm. square hole.

Smuggler Mill. (Argentiferous Galena.) Crank-arm Accelerated Jig. Size of grains, 3½ to 2 mm. ; throw of plunger, 0.7 inch ; throws per minute, 133 ; area of plunger, 18 by 25 inches ; area of sieve, 18 by 29 inches ; mesh of sieve, 2 mm. square hole.

Smuggler Mill. (Argentiferous Galena.) Crank-arm Accelerated Jig. Size of grains (first spigot of separator), 2 mm. to 0; throw of plunger, 0.51 inch ; throws per minute, 135; area of plunger, 18 by 25 inches: area of sieve, 18 by 29 inches; mesh of sieve, 5 mm. square hole.

Smuggler Mill. (Argentiferous Galena.) Crank-arm Accelerated Jig. Size of grains (second spigot of separator), 2 mm. to 0; throw of plunger, 0.36 inch ; throws per minute, 141 ; area of plunger, 18 by 25 inches; area of sieve, 18 by 29 inches; mesh of sieve, 5 mm. square hole.

Smuggler Mill. (Argentiferous Galena.) Crank-arm Accelerated Jig. Size of grains (third spigot of separator), 2 mm. to 0; throw of plunger, 0.4 inch; throws per minute, 163 ; area of plunger, 18 by 25 inches ; area of sieve, 18 by 29 inches; mesh of sieve, 2 mm. square hole.

Revenue Tunnel. (Argentiferous Galena.) Crank-arm Accelerated Jig. Size of grains, 13/32 to 21/64 inch; throw, 1.38 inches ; throws per minute, 130; area of plunger, 17¾ by 24¾ inches; area of sieve, 16 by 23 inches; mesh of sieve, No. 8.

Calumet Mill of Calumet and Hecla Co. (Native Copper.) Collom Accelerated Hammer-driven Spring-return Jig. Size of sand (first spigot of separator, second sieve of jig), 3/16 inch to 0; throw of plunger, 0. 51 inch ; throws per minute, 134; area of plunger, 22 by 17 inches ; area of sieve, 22 by 32 inches ; mesh of sieve, No. 8.

Calumet Mill of Calumet and Hecla Co. (Native Copper.) Collom Accelerated Hammer-driven Spring return Jig. Size of sand (first spigot of separator, second sieve of finishing- jig), 3/16 inch to 0; throw of plunger, 0.45 inch; throws per minute, 134; area of plunger, 22 by 17 inches; area of sieve, 22 by 32 inches; mesh of sieve, No. 12.

Anaconda Mill. (Argentiferous Sulphide Copper-ore.) Collom Accelerated Hammer-driven Spring-return Jig. Sand (first spigot of separator) has been through a screen with 3/16 by 3/8-inch slots; throw of plunger, 1 inch ; throws per minute, 130; area of plunger, 22 by 17 inches; area of sieve, 22 by 34 inches; mesh of sieve, No. 8.

Anaconda Mill. (Argentiferous Sulphide Copper-ore.) Collom Accelerated Hammer-driven Spring-return Jig. Fig. 39 (the upper diagram) represents the sand from the second spigot of separator; Fig. 40 from the third spigot; the throw of plunger is 7/8-inch in Fig. 39, and 5/8-inch in Fig. 40 ; throws per minute, 140 ; area of plunger, 22 by 17 inches ; area of sieve, 22 by 34 inches; mesh of sieve, No. 10.