New is a relative term, and when used with reference to a concept as old as shaft kilns can be applied to a number of designs. In this case the design that is the subject of this paper, is known as the ring or annular shaft kiln as developed by Mr. Karl Beckenbach of West Germany.

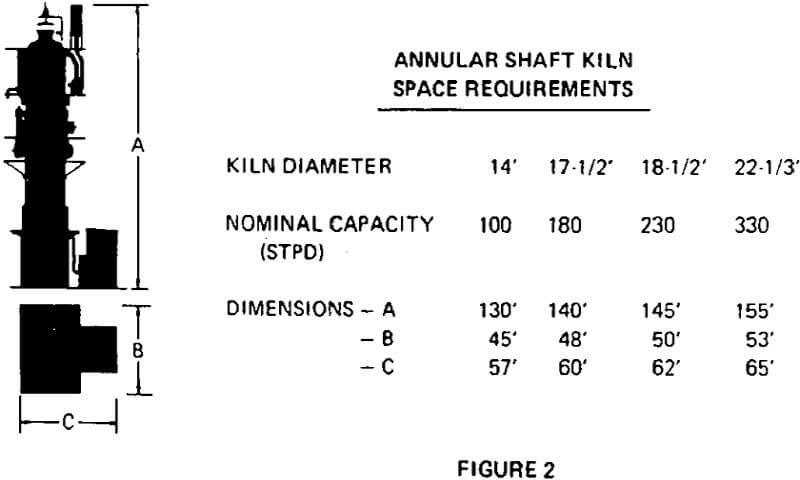

It is a single vertical cylinder to which are attached the required service platforms, combustion chambers, injectors and distribution piping. Auxiliaries such as recuperator, exhaust fan and dust collector are mounted on the appropriate service platform. The charging pan, feed conveyor, etc. are mounted at the kiln top. At the bottom of the kiln is the silo with a vibrator type discharger, and mounted separately is the required blower for injector air and fan for internal cooling.

Material flow begins with the stone being fed to the charging pan by conveyor. The charging pan is in the form of a ring mold and is rotated while being filled to insure an even distribution of stone sizing being fed to the annular space in the kiln. When the pan is loaded, the conveyor is withdrawn and the pan cover lowered into place. Next, the bottom of the charging pan and top cover of the kiln are lowered to permit the material to enter the kiln. The action between the cover of the charging pan and the top cover of the kiln is similar to the action of the double bell arrangement used on a blast furnace.

The air that is used to cool the lime is metered through the inlet pipe as it enters the silo. From the silo this cooling air passes through the lime dischargers and the bed of lime to the point where the inner cylinder changes diameter and has openings that permits the air to pass to the center of the inner cylinder. At this point the cooling air mixes with that portion of the combustion gases from the lower burners that is flowing concurrent with the material.

The injector system starts with the injector air blower. This blower delivers ambient air at approximately 7 psi to the recuperator, where it picks up heat from the exhaust gases, leaving the recuperator at approximately 850° F. From the recuperator it flows into a distribution pipe around the kiln from where it is metered to the injectors.

The preferred feed size ratio is 3:1 or less; however, units are in operation with higher ratios. The acceptable ratio in any particular instance depends upon the stone being processed and the quality of the product that is to be produced. Feed with a minimum size of ¾” is being burned in specific cases without excessive difficulty; however, an ideal feed size would be in the range of 1-¾” x 4″.