Table of Contents

The experiments described in this paper were undertaken primarily for the purpose of measuring the quality of work done in screening and sorting in American concentrating-mills for Prof. Richards’ work on Ore-Dressing. For this purpose a series of samples of screened and sorted products was obtained from four different mills, and a plan was devised for sizing these products, and for tabular and graphic representation of the results. The results, together with discussions as to their significance, so far as they serve to interpret the quality of mill-work, have already been published in the above-mentioned work, and it is not the purpose of this paper to duplicate the work, except so far as is necessary to explain and illustrate methods and appliances.

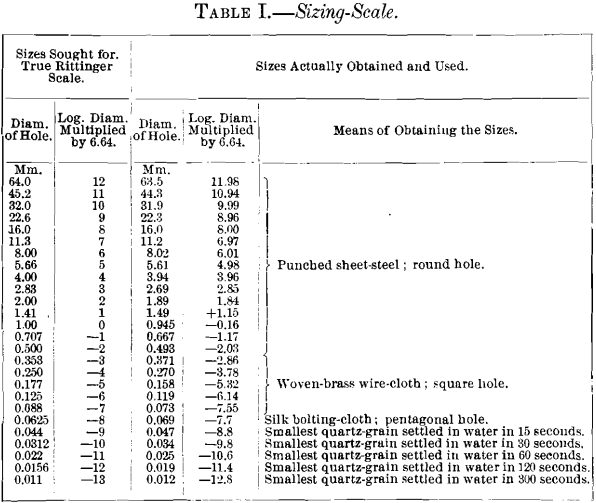

The sizing of coarse products was done by sifting on screens of sheet-metal with round punched holes. These holes ranged in size from 64 mm. to 0.5 mm. in diameter. Below the smaller limit, punched metal, suitable for this work, was not obtainable, and the sizing was carried on by sifting on woven wire-sieves. The finest woven wire-cloth obtainable gave a hole 0.073 mm. square, and the finest silk bolting-cloth gave a pentagonal hole with an average diameter of 0.069 mm. Even these very fine screens served no useful purpose in sifting certain of the very fine classifier-products, of which all, or nearly all, passed through the finest screen. A new adaptation of a method of settling and decantation with water in beakers was therefore worked out, and by this means the sizing was carried down to grains of a diameter as small as 0.012 mm.

Description of Sieving Equipment & Operation

Sieves of sheet metal with round punched holes were used as far as practicable, chiefly because, as already explained, the primary object of the experiments was to test mill-work, and the mills had all used sheet-metal with round punched holes for coarse sizing and, further, because the diameter of a round hole is its only limiting dimension, whereas a square hole may limit the passage of a grain of ore, according as the grain approaches, to take advantage of the diagonal dimension or the side dimension. The Rittinger sieve-scale was adopted as a standard for these sizing- tests, and screens were secured which would match the sizes of the Rittinger scale just as closely as possible. The sizes of the Rittinger scale are in geometrical progression. Diameters of successive sizes have a constant ratio of 1.414, while the areas of holes of successive sizes have a constant ratio of 2.

The screens coarser than 2 mm. were measured with a scale, using a magnifying glass. Screens with holes 2 mm. in diameter and smaller, were measured under a microscope, using a micrometer. From 10 to 20 holes were measured in each screen, and the average of these measures was taken to represent the size of hole for that screen. Sizes of square holes were determined by the mean of the measurements of the two sides. Some of the holes in the woven wire, instead of being truly square, were trapezoidal. In this case the long and short parallel sides were measured, and their mean length taken for one dimension. The sizing-scale used is shown in Table I. The first column shows diameters in millimeters of the Rittinger sieve-scale, the third column shows the actual diameters of the holes in screens obtained for the work in these experiments.

The samples were sifted dry, and the shaking and jarring on the sieves were carried on for such a time that the resulting weight of any size, expressed in per cent., should be significant in the first place of decimals. By trial it was found that on the punched screens, a 4-minute shaking was usually sufficient, while often on the woven wire-screens two or three times as long was needed; the time depending on the size of the sample and the area of the sieve. In sizing the finer products, it was found that samples weighing 200 grams for 1 sq. ft. of screening-surface could be handled in a reasonable time, requiring somewhat less than 10 minutes vigorous shaking and jarring.

In selecting a method of sizing for the material finer than 0.069 mm., we considered several methods. The use of the assay spitzlutte was not practicable, because of the very small water-currents necessary, the tediousness of the work, and the difficulty of separating the products, for weighing, from the relatively large bulk of water introduced. Certain experiments made by Prof. W. O. Crosby in the sizing of samples of clay were considered. He introduced a weighed portion of material in the top of a 0.5-in. glass tube, 5 ft. long, filled with water. The depth of the sediment was then measured at the end of different periods up to one hour, and these depths were assumed

to represent proportional weights. The sediment was then excavated from the tube to the points where measurements were taken, samples removed and the grains measured with a microscope-micrometer. This method was discarded chiefly because the volumetric determination of quantities would be inapplicable to mixtures of minerals of different specific gravity.

Allen Hazen has described a method of sizing applied to the examination of sand used in filtration-plants. A beaker was used in which 5 grams of the fine material was agitated with water, allowed to settle 15 seconds and the water decanted. This was repeated by the addition of water three times, yielding a settled product which was dried and weighed, and the average size of grain determined by measurement with a microscope-micrometer. The amount of overflow-product was not weighed, but was calculated by difference.

Following this idea, experiments were tried by settling successively for 300, 120, 60, 30 and 15 seconds. Samples of the five settled products were examined under the microscope to determine their uniformity and sizes. These results were so gratifying, and the sizes so near those required for the Rittinger scale, that the periods of settling named were adopted and a series of tests carefully conducted. A beaker 70 mm. in diameter and 110 mm. deep was filled with distilled water to a depth of 90 mm., and 5 grams of ore, through a sieve with 0.069-mm. holes, was thoroughly stirred in. After standing quietly for 300 seconds, the water was quickly but carefully poured off without disturbing the settled material. The beaker was again filled to the 90-mm. mark and the process repeated. This was continued until the decanted water was clear. What remained in the beaker was similarly treated for periods of 120, 60, 30 and 15 seconds in succession. Distilled water was used at a temperature of about 20° Cent. (68° Fahr.), and was not allowed to vary beyond 18° Cent, and 22° Cent. (64.4° Fahr. and 71.6° Fahr.). Each product was allowed to settle, the clear water siphoned off, and the residues dried and weighed, except the finest product, which was determined by difference. It was found, in order to make duplicate tests agree, that each period of settling (300, 120, 60 and 30 seconds) should be repeated the same number of times in the separate tests, and that it was not safe to rely on the visual standard of the observer as to the clearness of the last decanted water. Five settlings seem to give good results, and do not take an unreasonable length of time; and while this plan was not adopted except during the latter part of the tests recorded in this paper, it is recommended as the most satisfactory method.

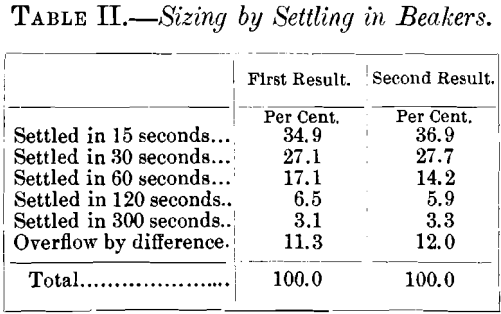

Table II. gives an idea of the degree of correspondence in results which are to be expected in sizing by settling in a beaker. Duplicate trials were made on the same sample, and the work done on different days.

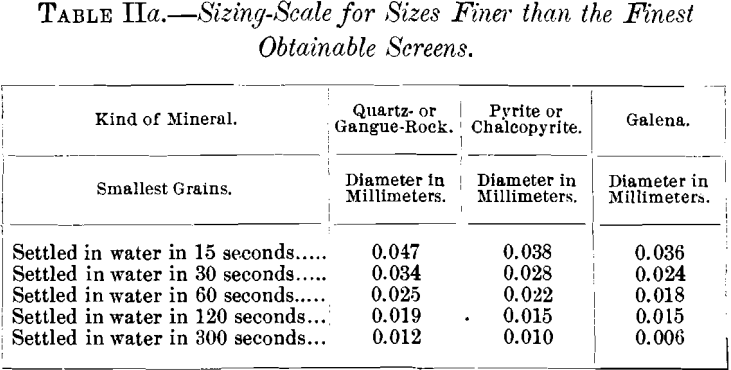

The sizes for the series of settled products were determined on the assumption that if the material were mostly quartz, practically the same quantities would have been obtained by screening and settling, if the screen-holes had the same diameters as the smallest grains of quartz in each of the settled products. If the material were mostly pyrite or mostly galena, the settled products would correspond in quantity to what would be obtained by different screen-sizes determined by measuring the smallest grains of pyrite or galena. If a sample under examination were made up of a mixture of quartz and a heavy mineral, in which neither greatly predominated, the product would be sorted rather than sized, and it is possible to express only an approximation to results which would have been obtained from sifting, by averaging the sizes of the minerals according to the judgment of the observer.

In sifting, it is evident that the two lesser dimensions determine the ability of grains to pass a square or a round hole; whereas, when measuring the same grains under a microscope, they never present their shortest diameter for measurement. This is illustrated by some measurements of the largest grains in the 15-second settled products. These grains had all been through a pentagonal hole with average diameter of 0.069 mm., but one sample showed the average diameter of the largest grains of quartz to be 0.100 mm., and of galena, 0.092 mm. The other sample showed the average diameter of the largest quartz-grains to be 0.105 mm., and of the chalcopyrite 0.096 mm. In the first of these determinations the average largest dimension presented was 0.120 mm., and the average smallest dimension was 0.080 mm.

The justification of the plan of measuring the smallest grains, in order to determine sizes, rests partly in the fact that their sizes give results which harmonize with the data secured by sifting, and with them yield smooth curves in plotting. As no other plan seemed more practical, it was adopted.

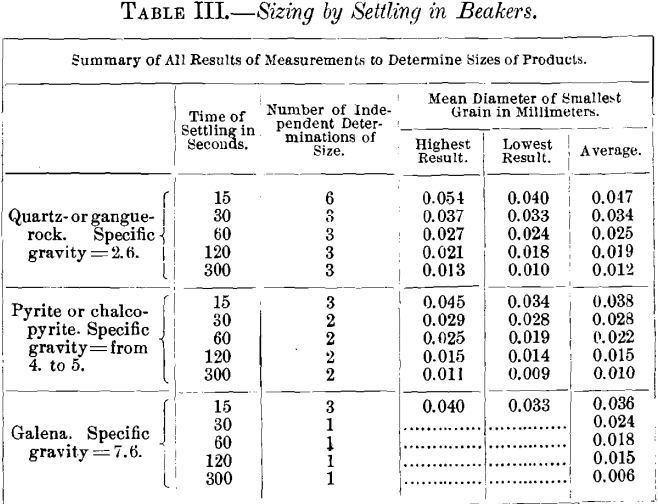

The diameter of the smallest particles in each settled product was determined as follows: A sample was placed under a microscope with a micrometer-measuring attachment, and the length and width of the smallest particle in the field of the microscope was measured. This was done with twenty or more separate fields for each sample, and the average of all measures was considered to represent the smallest particle in the sample. Separate measurements were taken on quartz- or gangue-rock, pyrite or chalcopyrite, and galena. On quartz- products, samples were measured independently by two different observers, so as to eliminate the personal equation as far as possible. A summary of all these measurements appears in Table III.

The quartz-sizes are used in the sizing-scale, Table I., and in the tabulated records of tests, because the major part of each sample consisted of quartz- or gangue-rock. The sizes for chalcopyrite or pyrite and galena are given in Table IIa. Chalcopyrite and pyrite are recorded together, because it was impossible to identify them in the samples so as to measure them separately.

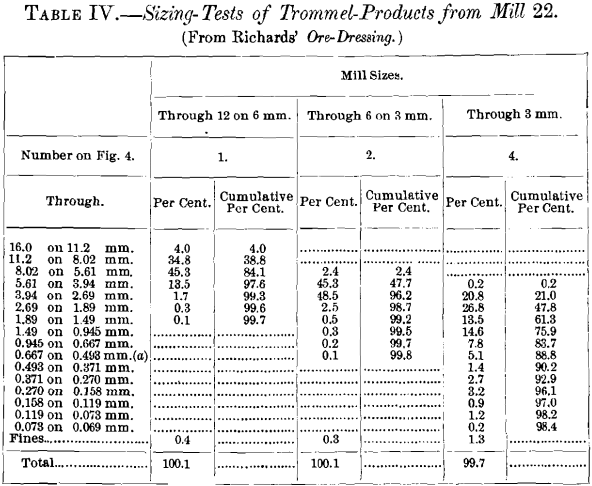

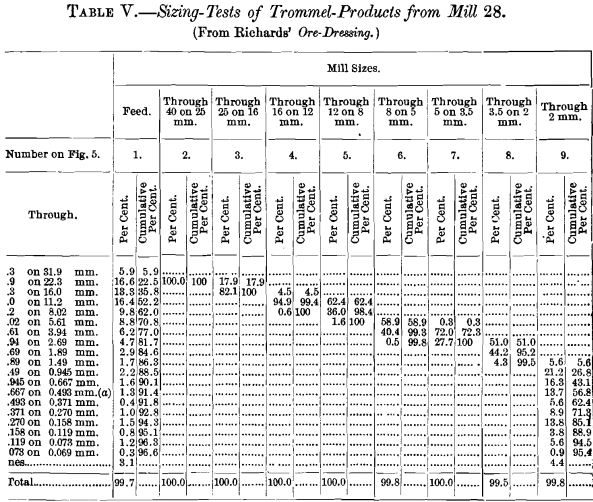

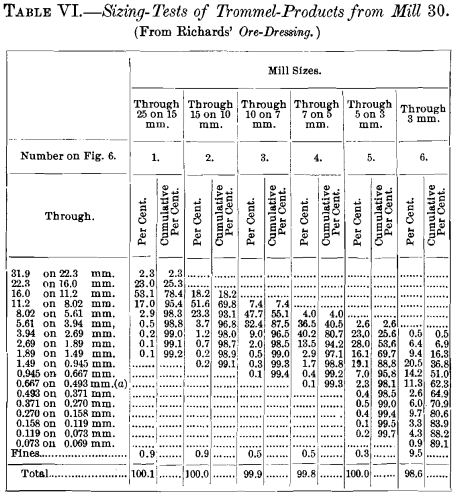

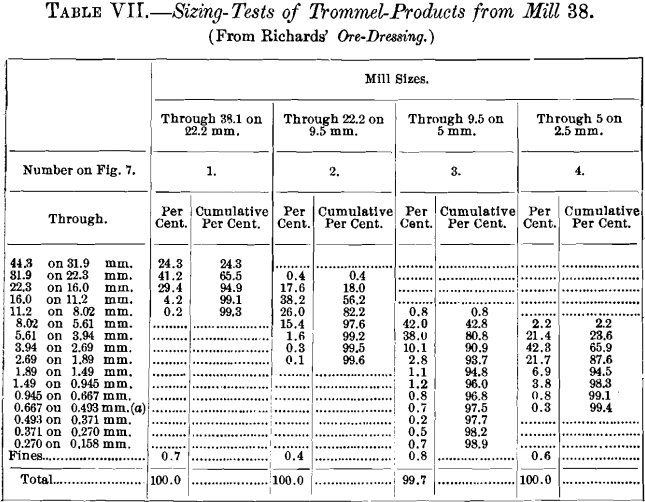

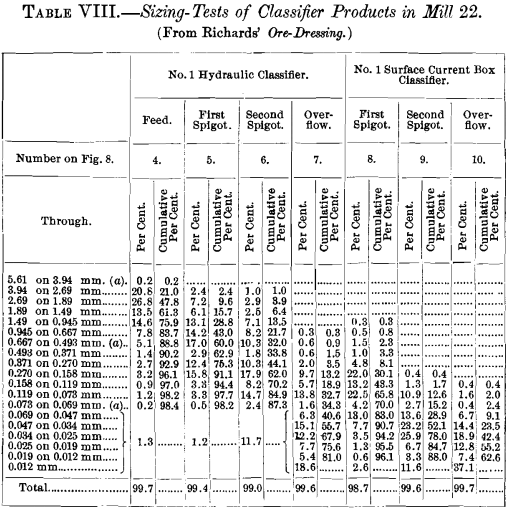

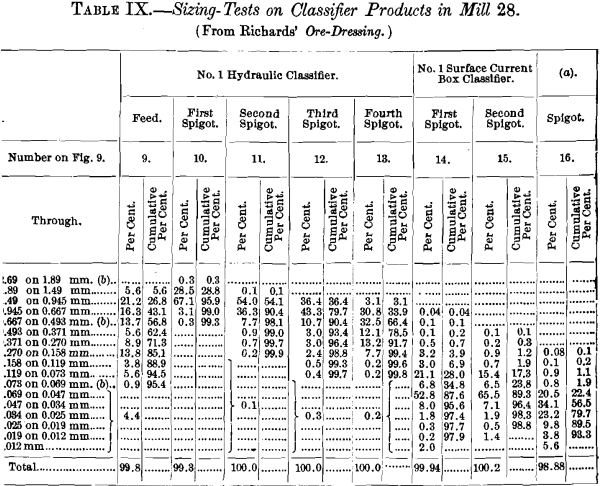

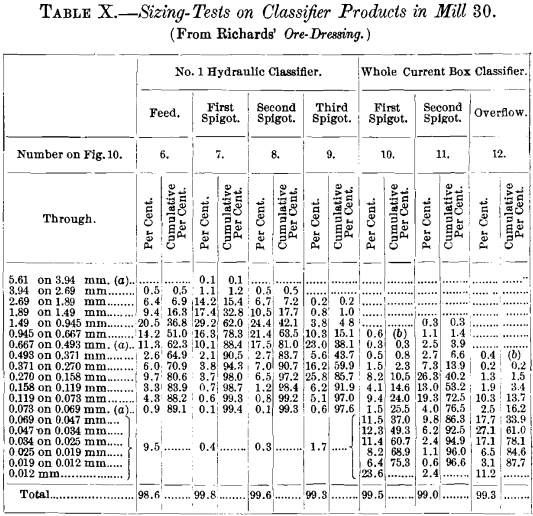

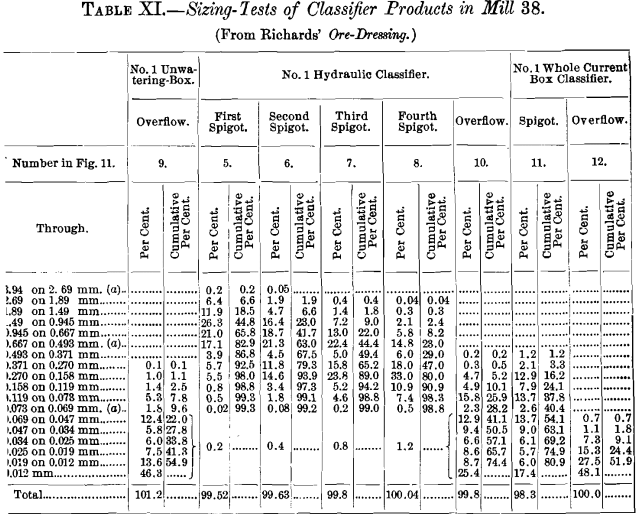

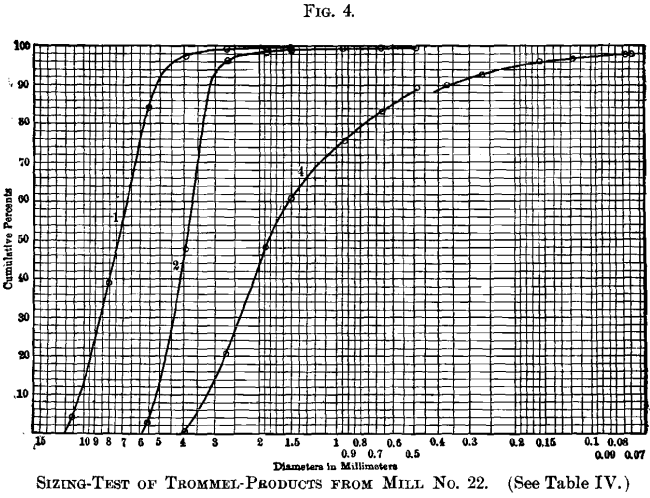

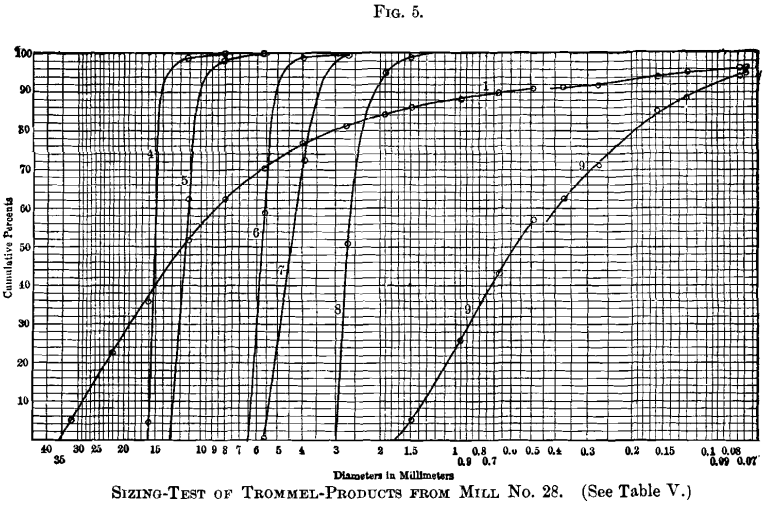

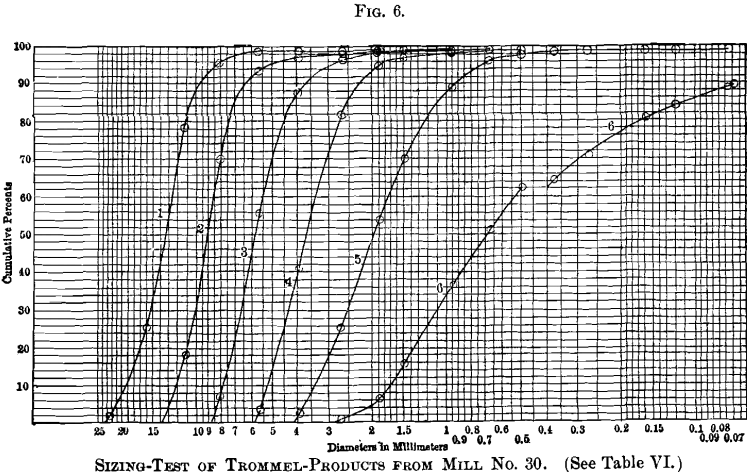

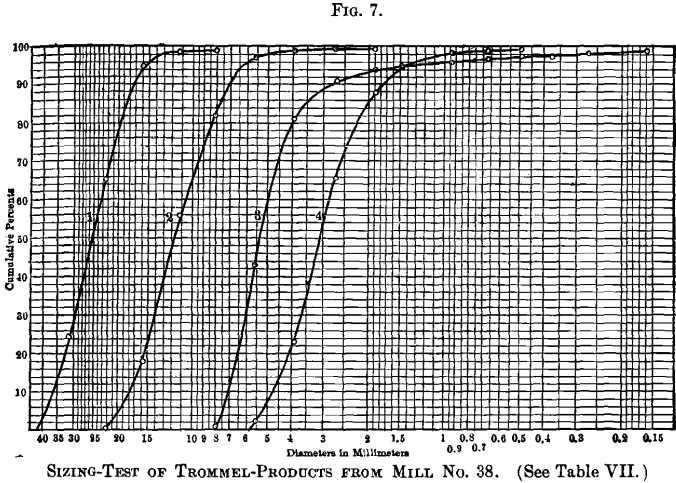

Complete tabulated results of the sizing of the mill products are shown in Tables IV. to XI.

(a) Round-hole sieves were used down to and including 0.493-mm. size, and square holes for finer sizes.

(a) Round-hole sieves were used down to and including 0.493-mm. size, and square holes for finer sizes.

(a) Round-hole sieves were used down to and including 0.493-mm. size, and square holes for finer sizes.

(a) Round-hole sieves were used down to and including 0.493-mm. size, and square holes for finer sizes.

(a) Round-hole sieves were used down to and including 0.493 mm,; then square holes down to and including 0.069 mm. Below 0.069 mm. settling in water was used, and the sizes given are diameters of quartz which settled a depth of 90 mm. in 15, 30, 60, 120 and 300 seconds. All of the settled products contained some grains of mineral heavier than quartz, and these grains were smaller than the quartz-grains.

a) No. 1 whole current box classifier.

b) Round-hole sieves were used down to and including 0.493 mm.; then square holes down to and including 89 mm. Below 0.069 mm. settling in water was used, and the sizes given are diameters of quartz which tied a depth of 90 mm. in 15, 30, 60, 120 and 300 seconds. All of the settled products contained some grains mineral heavier than quartz, and these grains were smaller than the quartz-grains.

(a) Round-hole sieves were used down to and including 0.493 mm.; then square holes down to and including 0.069 mm. Below 0.069 mm. settling in water was used, and the sizes given are diameters of quartz which settled a depth of 90 mm. in 15, 30, 60, 120 and 300 seconds. All of the settled products contained some grains of mineral heavier than quartz, and these grains were smaller than the quartz-grains.

(b) This was all foreign material, such as chips, etc.

(a) Round-hole sieves were used down to and including 0.493 mm.; then square holes down to and including .069 mm. Below 0.069 mm. settling in water was used, and the sizes given are diameters of quartz which settled a depth of 90 mm. in 15, 30, 60, 120 and 300 seconds. All of the settled products contained some grains of mineral heavier than quartz, and these grains were smaller than the quartz-grains.

Sieve Analysis Data Worksheet Download

How to Plot Grain Size Distribution Curve

In Tables IV. to XI. two columns of figures are given for each product. The numbers in the first column show the percent, by weight of each size. The numbers in the second column, headed “ Cumulative per cent.,” show the total per cent, of the size and all coarser, and represent the percentage of the whole sample which would rest on the screen, were it used alone. The cumulative per cent, is particularly useful in the preparation of some of the graphic diagrams explained later.

A graphic method of representing sizing-tests, to be of value, should present the results in a form more readily interpreted and understood than the tabulated figures. The following six conditions are desirable in the graphic record:

- The relative quantities between the testing-screens should be clearly shown.

- The relative quantities between screens of any set of sizes other than that represented by the testing-screens should be apparent, and the actual quantities should be easy of determination by the use of a scale.

- The entire range of screen-sizes should be capable of representation in one figure.

- The predominating grain-size of the sample should be prominently apparent.

- The form of the plot should be unaffected by, and independent of, the sizing-scale used in making the test, thus affording, if desired, a means of direct comparison with data secured by a different sizing-scale.

- The method should be simple, and the figures easily understood.

A number of methods have been used by other writers, and some of them will be discussed.

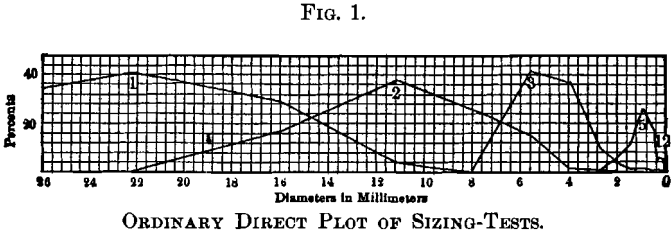

Prof. Courtney De Kalb, in his paper, Graphic Records of the Screening of Crushed Materials, presents a series of drawings prepared by a method whereby the screen-sizes are plotted by measuring the diameters directly on a horizontal line, while the percentage of ore resting on each of the testing-screens is plotted vertically at the proper points.

Samples Nos. 1, 2, 3, 5 and 12 from Tables VII. and XI. are adapted to a discussion of the various methods of graphic representation, and Fig. 1 shows a set of five curves prepared by this method, yielding what may be called an ordinary direct plot. These curves fulfill none of the requirements for graphic records except the first and last; and these they fulfill no better than the tabulated figures. The omission of one of the sieves

in making a test will greatly change the form of the curve, which is considerably dependent on the sizing-scale used. While the method is all right for some kinds of data, it is not suited to represent sizing-tests, and is positively misleading in some particulars: For example, curve No. 1 might be supposed to indicate that if a 20-mm. screen had followed the 22.3-mm. screen, it would have retained 37 per cent, of the ore; but that

is absurd, for the 16-mm. screen retained only 29.4 per cent., and the 20-mm. screen would, of course, fail to retain certain sizes that were caught by the 16-mm. screen. Other forms of plot show that a 20-mm. screen would have retained 12.5 per cent, of the ore, a fact which this curve affords no means of determination.

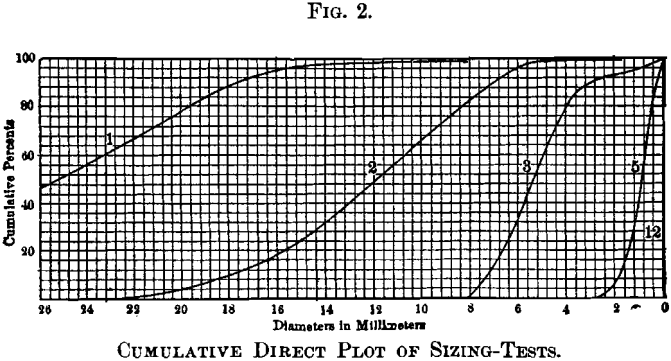

Luther Wagoner, in a paper, The Theory of Ore-Crushing, uses a method wherein the scale of sizes is laid off on a horizontal line just as in the first described method, but the quantities are represented by indicating cumulative percentages on the vertical scale. The curves in Fig. 2 are drawn by this method, and this form of plot may be called a cumulative direct plot. Its use is illustrated by reference to curve No. 2, from which may be read that 18 per cent, of the material under test is coarser than 16-mm., 50 per cent, coarser than 12-mm., and 82 per cent, coarser than 8-mm. size.

This method of graphic representation answers most of the requirements, but it possesses one serious fault, in that it does not permit the representation of the entire range of sizes in one diagram. This is illustrated by Fig. 2, in which, at the scale adopted, curve No. 2 shows to good advantage, but this scale is too large to permit curve No. 1 to appear on the sheet without extending it as far again to the left, and at the same time, the scale is so small that curve No. 12 appears only as a vertical line. The cumulative direct plot recommends itself for its simplicity, and it will serve excellently for the study of data secured from the sizing of single samples in which the range of sizes does not exceed a ratio of 4 to 1 between diameters of coarsest and finest grains. Beyond these limits the curves are distorted to such an extent that the method is of little use.

The ratio of the openings in successive sizes of screens, as near as can be determined, is about 1 to 1.41 for both fine and coarse screens; but, of course, the actual difference of the area of openings represented by this ratio is greater for the coarse than for the fine screens.

How to Plot Semi Log Graph for Sieve Analysis

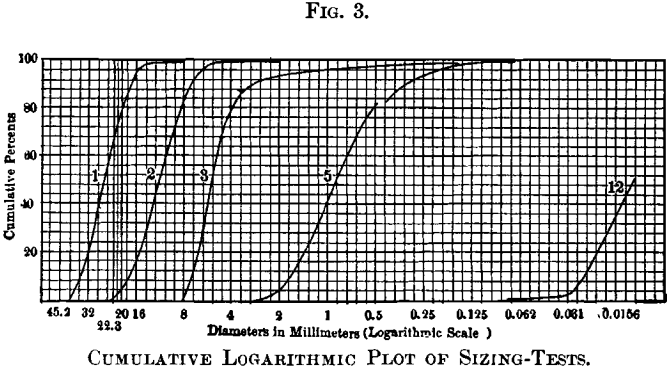

It is desirable to have a method of plotting, in which equal distances on the plot represent equal, ratios of diameter, or, if we had been able to match the Rittinger scale precisely in getting the various sizing-screens, the data would be plotted at equal intervals on the horizontal scale, thus compressing the curve at the large end, and stretching the distances out on the small end. The same result is secured automatically by plotting the logarithms of the diameters on the horizontal line, and Fig. 3 represents this method applied to the same data already presented by the other methods. If the logarithms of the diameters are multiplied by the constant 6.64, numbers very convenient for plotting are secured, because they are whole numbers for the diameters of the Rittinger scale, and these multiples of the common logarithms are given in Table I. for convenience in plotting. The negative quality of the logarithm of all numbers less than unity must be kept in mind, and since the logarithm of unity is zero, the original point for the scale of sizes will be at the unit diameter, and smaller sizes will be scaled to the right and larger sizes to the left from that point. This form of plot may be called the cumulative logarithmic plot. It has been used by the Massachusetts State

Board of Health for plotting sizing-curves of filtering-materials.

The curves resulting from this method fulfill every requirement for graphic representation. Its compliance with the first two requirements is easily shown by reference to curve No. 1 in Fig. 3. We read that 78 per cent, of the sample is coarser than a 20-mm. screen, and that 65.5 per cent, is coarser than a 22.3-mm. screen, therefore 12.5 per cent, of the material will fall between these sizes. It is also evident that the steep portions of the curve show the range of predominant sizes. Referring again to curve No. 1, we see that 95 per cent, of the sample falls between 16 mm. and 40 mm., and by curve No. 5, it appears that 75 per cent, of the sample is quite uniformly distributed between 0.5 mm. and 2 mm.; also, that while some of the sample is probably as coarse as 2.8 mm.; also, 4 per cent, is coarser than 2 mm., and although some grains are as fine as 0.062 mm., only 20 per cent, is finer than 0.5 mm., and but 6 per cent, finer than 0.25 mm.

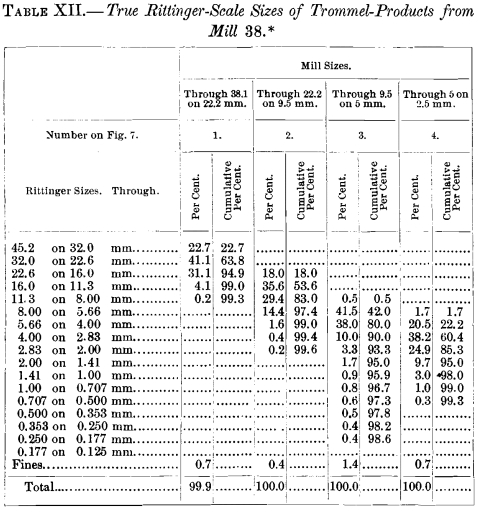

This method of graphic representation also affords a means of translating the records into tabular form to any scale of sizes which may be desired. The screens used in these tests conform only approximately to the Rittinger scale, but if it is desired, these results may be translated so that the tabular record will show the results which would have been obtained if screens conforming precisely to the Rittinger scale had been used. Such a translation of Table VII. has been made and is shown in Table XII.

Tabular records are probably easier of comprehension to most readers than are the graphic diagrams, and it may be desirable to translate all sizing-records to one standard, thereby making possible, direct and easily understandable comparisons. Such a translation of any sizing-record is possible, provided the dimensions of the holes in the testing-screens are known.

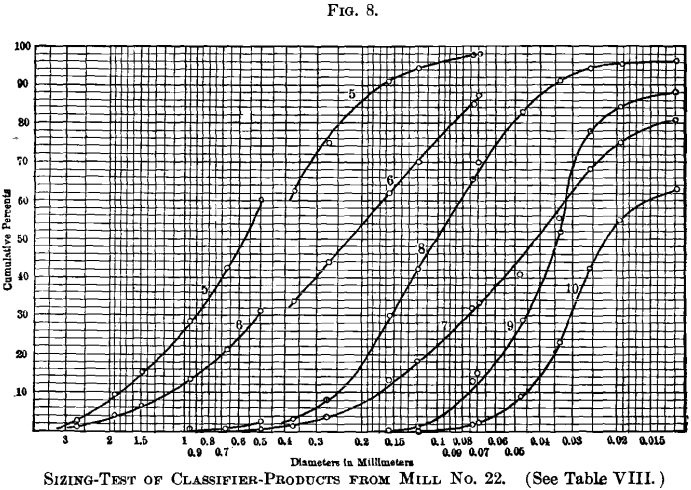

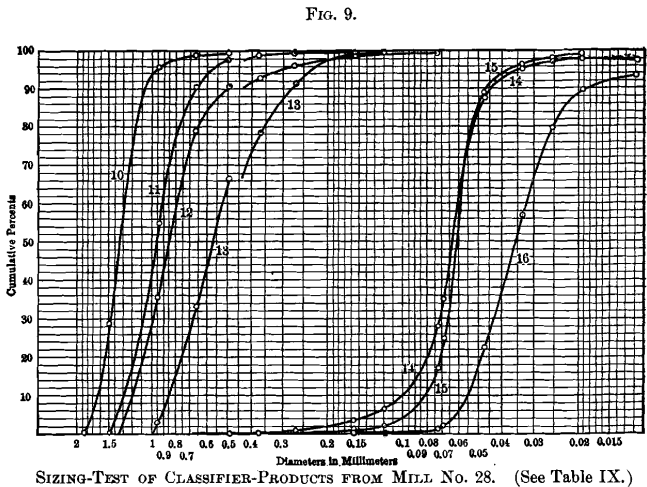

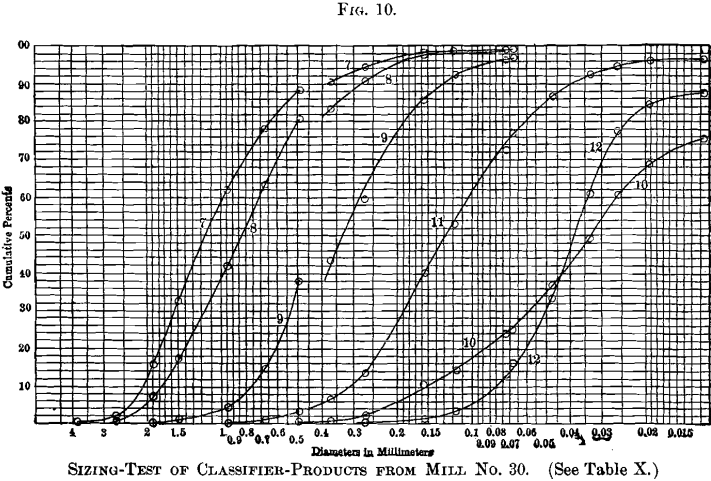

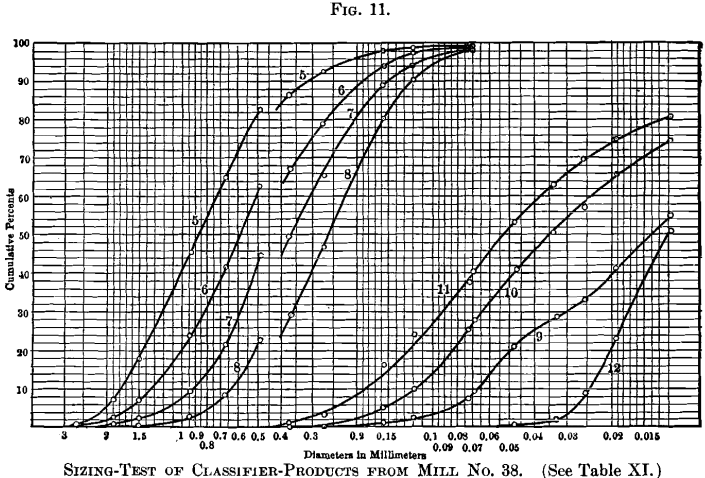

The cumulative logarithmic method of graphic representation was used by Prof. Richards to represent all the tests recorded in this paper, and the plotted curves are reproduced in Figs. 4 to 11, inclusive. These curves-differ from those in Fig. 3, used

for illustrating the method, in that they are plotted on logarithmic paper ruled for the purpose. Diameters in millimeters may be read directly from the horizontal scale. The original drawings showed the position of each size of the Rittinger scale by vertical colored lines, but they could not be reproduced in these engravings without confusion.

It will be noticed on Figs. 4 to 11, that for every sample containing material between 0.493- and 0.371-mm. size, there is a break in the curve at that point. In explanation of this, attention is directed to the fact already stated, that the 0.493-mm.

and all coarser screens have round holes, while the 0.371-mm. and all finer screens have square holes. A round-hole screen will retain finer material and, therefore, more material, than a square-hole screen of the same nominal size; consequently, if the fine screens could have been obtained with round holes, or if the square-hole screens had been used throughout, the curves would be continuous and unbroken, without suffering any alteration of form or direction. It is, therefore, believed to be better to sacrifice whatever advantage pertains to the use of round-hole screens, for those cases in which sizes smaller

than 0.5 mm. enter into the problem; and it is then recommended to use square-hole screens for all sizes.

The distance which either part of the curve must be moved, parallel to the scale of sizes, to bring the two curves together, will represent the practical difference in effective size, regarding screening-qualities, between round and square holes of the same nominal size. By this means, the diagrams indicate that a square hole, to retain just the same proportion of the sample as a round hole 0.500 mm. diameter, will measure from 0.406 to 0.435 mm., the first dimension being deduced for Mills Nos. 22 and 30, and the latter dimension for Mill No. 28.

This difference is probably due to some persistent difference in the shape of the grains of the mineral. Flat grains retained by a round hole will be readily passed by the diagonal dimension of a square hole of the same nominal size; and a difference in the proportion of flat and splinter-shaped grains will explain the difference noted. Such a difference in the shape of grains in different mills is not surprising, and might be due to the cleavage of the ore, or, possibly, in part, to some difference in the methods of crushing.

It will be noticed that no curves appear on Fig. 5 corresponding to Nos. 1 and 2 on Table V. These tests were on samples of very closely sized trommel-products, and the data furnish only one plotted point for No. 1, and but two points for No. 2, neither being sufficient to yield a curve. A more closely spaced sizing-scale, or intermediate screen-sizes, should have been used for these, also for tests Nos. 5, 6, and 8, Table V. and Fig. 5, in each of which more than 50 per cent, appears in the first size, yielding, therefore, no plotted point near the line of zero per cent.

Another method of graphic representation was considered and discussed in connection with these experiments; and while its nature does not recommend it for such general use as the cumulative direct plot, it has, nevertheless, some interesting and useful qualities.

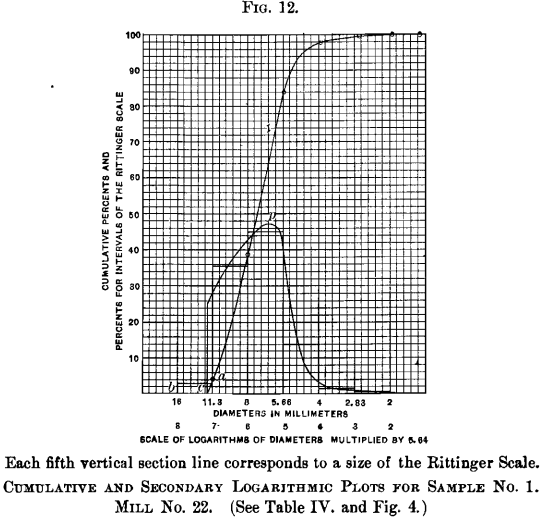

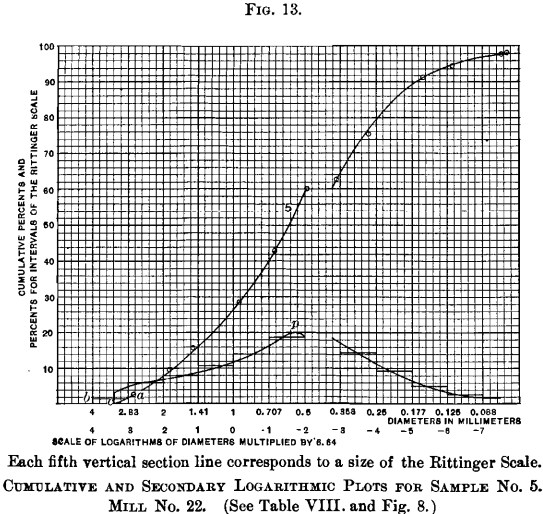

Referring to Figs. 12 and 13, the rising curves are identical with curves No. 1, Fig. 4, and No. 5, Fig. 8, for Mill No. 22, except that the diameters are plotted by the same method as in Fig. 3, but on a larger scale. The heavy vertical section-lines correspond to the sizes of the Rittinger scale.

The steps in the curve are made by plotting on the vertical scale the percentages which would have rested on each sieve of a precise Rittinger scale. These figures are deduced by the method explained for Table XII.; and the height of each step, measured by the vertical scale on the left, represents the percentage, if sized by the true Rittinger scale. On the scale of logarithms, the horizontal length of each step is unity, and the area of the rectangle between two adjoining Rittinger sizes, bounded by the step and the base line, is equal to the percentage of that size. These rectangles represent in a pictorial way the relative distribution of sizes in the samples, where the ratio between successive sizes is uniform.

A comparison of this stepped figure, with the primary curves from which it is derived, shows a certain inconsistency at the starting-point on the left, where the primary curve leaves the base-line at an abrupt angle. If these two figures are to be consistent, either the primary curve should curl up at the lower end and extend to the point b, or the step at that point should not extend to the left beyond the point where the primary curve touches the base line at c. The data furnish no means of determining just how the primary curve should proceed from the nearest plotted point a to the base line. We have, however, on curve No. 4, Fig. 4; curve No. 7, Fig. 5; curves Nos. 2 and 3, Fig. 7; and curves Nos. 10 and 11, Fig. 9; examples in which plotted points of data appear close to the horizontal base-line, and in these, the data imperatively indicate that the curve should approach the base-line at a steep angle. No exceptions to this rule appear in samples of sized materials in which the maximum grain is coarser than 4-mm. size. These curves are, therefore, followed as a pattern in the construction of the primary curve in Figs. 12 and 13.

Assuming that both primary curves in Figs. 12 and 13 are properly terminated, any series of rectangles which will represent by their areas, the distribution of sizes, must begin at the point c, where the primary curve intersects the base-line. On this new basis, by taking horizontal distances less than before, measuring the difference between ordinates on the primary curve at the points selected and dividing by the horizontal distance of the scale of logarithms, a many-stepped figure will be obtained, in which the area of each narrow rectangle represents the percentage of material between the two sizes taken. If this idea be carried to infinitely small horizontal steps, a smooth curve will result, of which the ordinate at any point will be proportional to the tangent of the angle which the primary curve makes at the point with the horizontal base line. The two closed curves in Figs. 12 and 13, following pretty closely the stepped figures except at the point of beginning, is such a curve; which may be called a secondary logarithmic plot. The area enclosed by the curve and the base line, between any two vertical lines, represents the percentage of material in the sample, between the two sizes corresponding to the vertical lines taken. The scale is so chosen for Figs. 12 to 14 and 16 to 18, that 25 squares represent 10 per cent.; and the percentage between any two adjoining Rittinger sizes is shown by the average height of the curve between them, measured by the vertical scale of percentages on the left of the plot.

This curve shows pictorially the relative quantities between any set of sizes, but the actual quantity is not easy of determination except by measurement with a planimeter. It cannot, therefore, fill the place of the cumulative logarithmic plot as a simple method of graphic representation. The pictorial quality of this diagram is its chief merit, as it shows the predominating

sizes by a glance at the vertical scale. Referring to Fig. 12, it is seen that no grains will be found in the sample coarser than the size represented by the point c. This point is at 7.15 on the scale of logarithms; divide this by 6.64 and we have 1.077, which is the common logarithm of the size; and a reference to a table of logarithms shows it to correspond to 12.0 mm.

Just as should be expected in a sized product, a considerable proportion of the coarsest grains is shown by the vertical height of the curve at this point. The predominating size is found, however, at the point p. The reading of the scale of logarithms at this point is 5.4, which corresponds to a diameter of 6.5 mm. This information is yielded, likewise, by the primary curve, the point of maximum steepness indicating the predominating size, but it is not pictured so clearly to the eye as by the secondary curve. Moreover, the construction of the secondary curve is helpful to an understanding of the significance of the primary curve and it is suggested to use them together on the same plot.

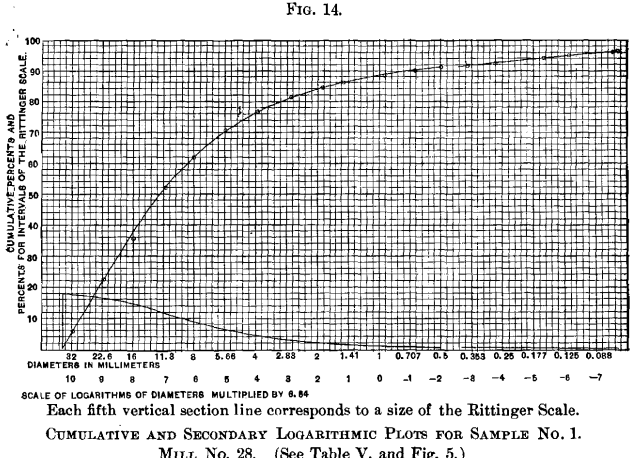

Another plot on a different character of material, Fig. 14, is presented, which represents crushed ore, as it is fed to the sizing- trommels in Mill No. 28. It might be supposed, by an inspection of the tabular record, Table V., that the predominating size would be between 22.8 and 31.9 mm. or between 11.2 and 16.0 mm. Referring, however, to the secondary plot, it appears

that the coarsest size predominates. This size corresponds to 10.32 on the scale of logarithms, which equals a diameter of 35.8 mm. From this size downwards, the proportion of material falling between any fixed ratio of sizes becomes progressively less and less.

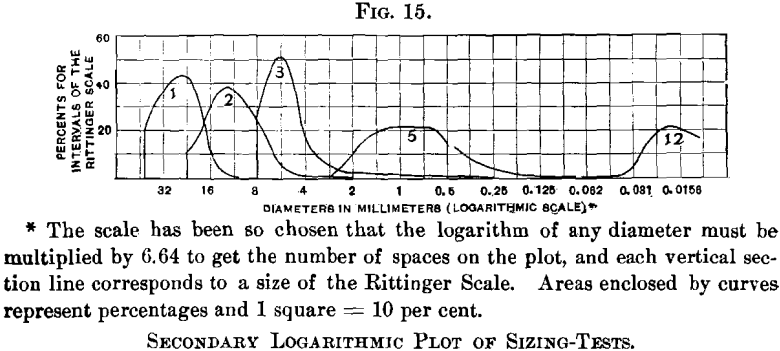

Fig. 15 is a secondary logarithmic plot of the same data presented in Figs. 1, 2 and 3, prepared for the purpose of comparison. It is interesting to note that, while in Fig. 3, curve 12 seems only to have been begun, Fig. 15 shows that its culminating point has been passed, indicating that the size 0.017 mm. predominates.

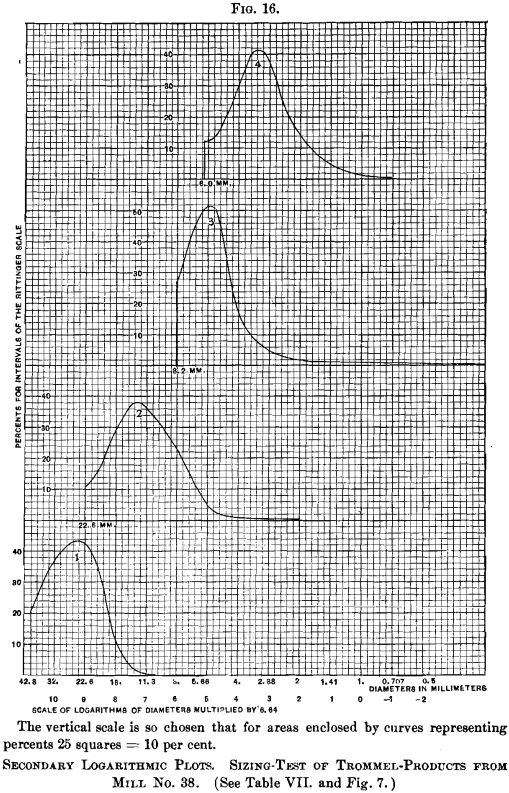

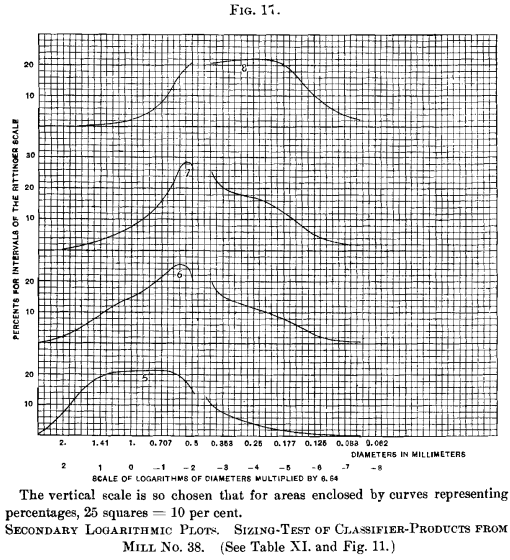

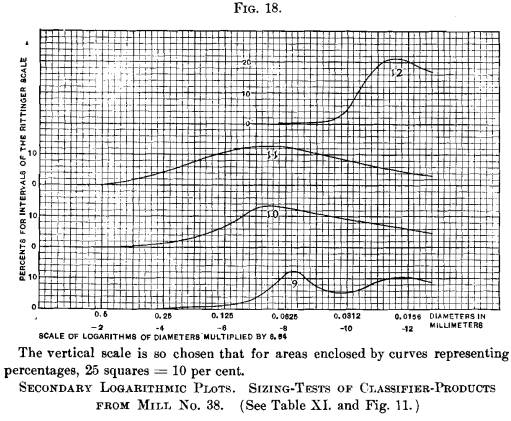

Figs. 16 to 18 represent the data in Tables VII. and XI. plotted as secondary logarithmic curves, evolved from the cumulative logarithmic curves in Figs. 7 and 11. Curves Nos. 1, 2, 3 and 4, representing trommel-products, show similar characteristics, and while they overlap somewhat, they show, as should

be expected, a narrow range above and below the predominating size. Curves Nos. 5, 6, 7 and 8 (Fig. 17) represent

spigot-products of the classifiers. No doubt there is some reason for the difference in form of these curves. Curves Nos. 5 and 8 present a flat top showing a wide range of predominating sizes, while curves Nos. 6 and 7 indicate a sharper definition of the predominating size. Probably the second and third spigots, represented by curves Nos. 6 and 7, are producing a more closely sorted product than the others. No. 9 (Fig. 18) represents the overflow of the No. 1 unwatering-box. It has a double hump, and is the only curve, prepared from the data presented, which shows any departure from what seems to be a type of secondary curve having one point of maximum height.

Sieve Analysis Lab Report Discussion & Conclusion

Four methods of plotting sizing-tests have been described in this paper. The ordinary direct plot is dismissed as unsuited for sizing-diagrams. The cumulative direct plot is simple and fulfills most of the requirements tolerably well, but it does not permit the representation of the entire range of sizes on one diagram. The latter difficulty is overcome by the use of the cumulative logarithmic plot, which fulfills all requirements. The secondary logarithmic plot is evolved from the cumulative logarithmic plot and presents the data for pictorial comparison as none of the others does.

When a sample has only a limited range of sizes, and the plot is desired simply to determine, by interpolation, the exact quantities between any set of sizes other than those of the sizing-scale, a cumulative direct plot answers the purpose. For general analysis and comparative study of results of sizing-tests, the cumulative logarithmic plot, supplemented by the secondary logarithmic plot, is recommended as the most satisfactory.

This paper is a development of ideas suggested by the experiments made for Prof. Richards’ new book, and in closing, I wish to express my indebtedness to Mr. C. D. Demond and Mr. C. E. Locke, assistants until lately to Prof. Richards, for suggestions and criticisms during the progress of the tests and the discussions of the data.

https://www.youtube.com/watch?v=-4qqqwzDWvI