Ruble Hydraulic Elevator Ribble Laddler

In many of the old placer-mining districts are still to be found large tracts of gold-bearing gravel not suitable to be worked with a dredge, because the bed is too shallow or the gulch too narrow. Frequently there is not enough grade to handle the gravel successfully by ground-sluicing or a bed-rock flume, or it […]

Mineral Assay & Testing Laboratory Services

After the completion, of the Hammond Mineral Assay & Testing Laboratory of the Sheffield Scientific School, Yale University, it became necessary to secure and assay a large assortment of ore-samples, and to arrange the results in such a manner as to admit of use with the least amount of work on the part of the […]

Amalgamation Pan

The aim of instruction in a metallurgical laboratory is to make real the principles on which metallurgical processes and operations are based, and to foster the spirit of investigation. The materials with which experiments are carried out are ores, metals, and metallic compounds. The method varies with the end sought. A class may work as […]

Jigging Minerals: Galena – Sphalerite

Summarizing some of the principal points brought out in this laboratory Jigging of Minerals’ investigation, I believe the following may safely be accepted: The pulsion-reaction is by far the most important one in the process of jigging. During this period, with sized grains of different specific gravities, with proper pulsion-velocity, the separation between them will […]

Jigging

The jig, in one form or another, continues to hold a leading place among the machines designed to separate two or more minerals of different specific gravities. It is simple in construction, easily operated, capable of treating large quantities in a short time, and highly efficient under various conditions. The question, whether the material to […]

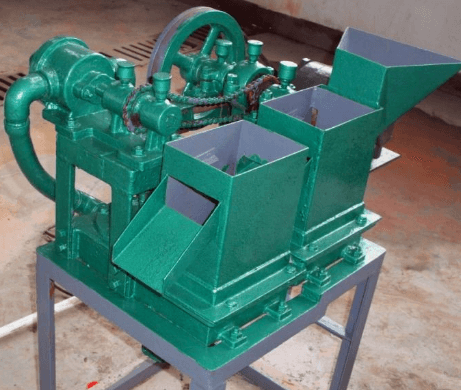

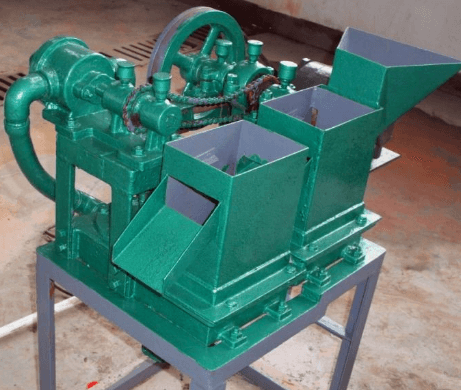

Hydraulic Jig Concentrator VS Shaking Table

Concentration of grains from 10 to 30 mm. is effected by hydraulic jigs with two compartments, and in the case of the smaller grains down to 2 mm. by jigs with five compartments. The construction of the jigs is the same in both cases. Fig. 3 gives the details of a jig with two compartments; it […]

Difference between Crushing and Grinding

When making comparisons of the efficiencies of different grinding and crushing machines it is desirable to be able to estimate the work actually done in crushing the ore from a given size of feed to a given size of product, the screen analysis of both feed and product being determined. Messrs. Klug and Taylor, in […]

Underground Gold Mine Development – Sampling

This paper is intended, in the light of recent investigations, to call attention to some of the essential features of good practice in sampling and mine-valuation. Mine sampling may be divided broadly into two classes: development-sampling and computation of ore-reserves; and, stope-sampling and estimation of stope-values. Development Sampling It is with development-sampling only that this […]

Assaying Gold & Silver from Copper Alloys

The so-called “combination method” is generally used in assaying bar copper for silver. It has been modified from time to time. Briefly outlined as now practiced, it is as follows: One A. T. of the borings is dissolved in dilute nitric acid. When solution is complete the liquid is boiled and then filtered to remove […]

How to Assay and Evaluate a Gold Bar

The Bureau of the Mint of the United States Treasury maintains offices for the purchase of gold-bullion, and this paper describes an investigation to establish the reasonable differences in the assay-results at the various institutions which may be commercially allowable in the settlements between them. Beginning with the comparative assay of proof-gold at the Philadelphia […]