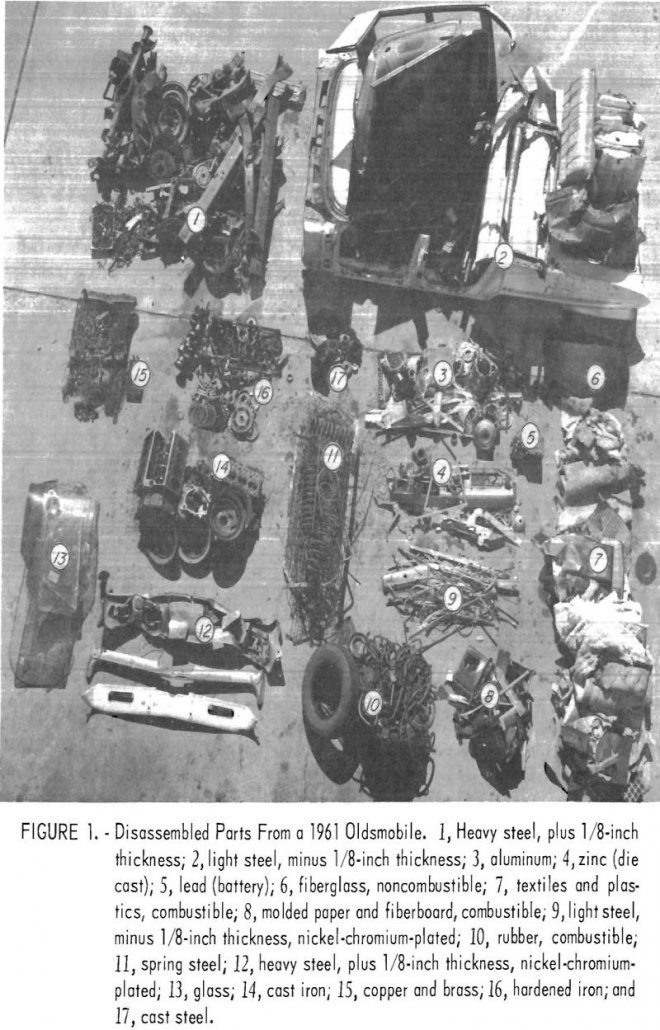

How to Dismantle Junk Cars for Scrap

The proposed complete dismantling of the car removes all copper-containing parts; hence, the bales prepared from the clean ferrous metals should contain only the 0.07 percent copper that is in solid solution in the steel. As the baled steel weighs 2,614 pounds, it contains about 1.8 pounds of copper. If the upper limit of high-quality […]

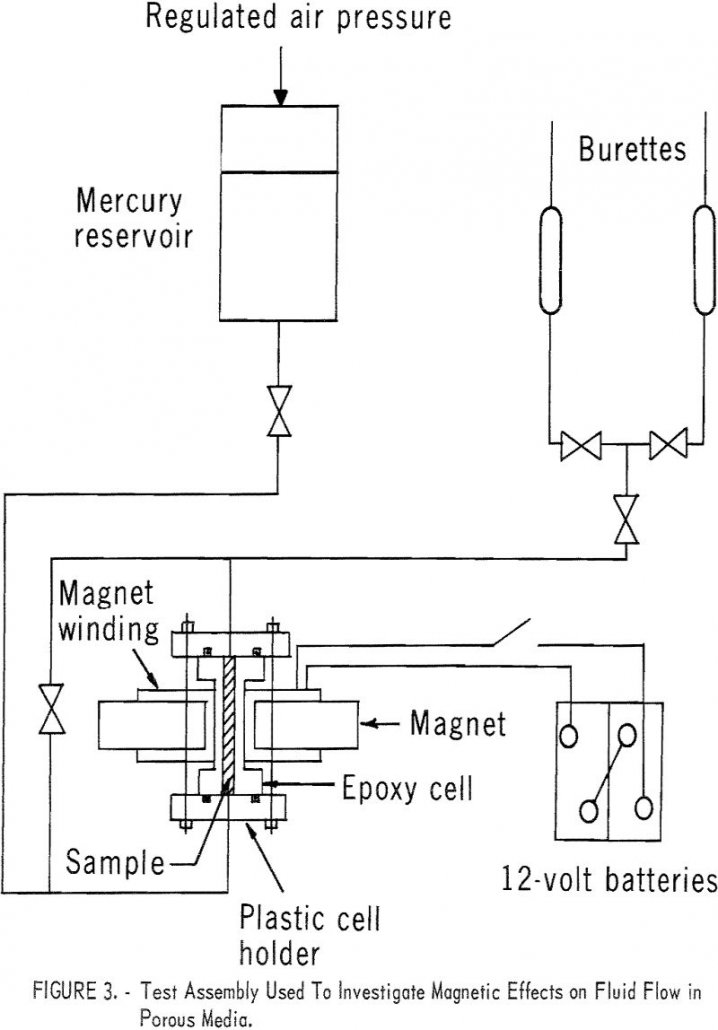

How Mercury Flows in Porous Media

After studying the factors which influence oil recovery from petroleum reservoirs and since the flow behavior of fluids in petroleum reservoir rock depends to a large extent on the properties of the rock, techniques of core study that yield new or additional information on the characteristics of the rock would contribute to a better understanding […]

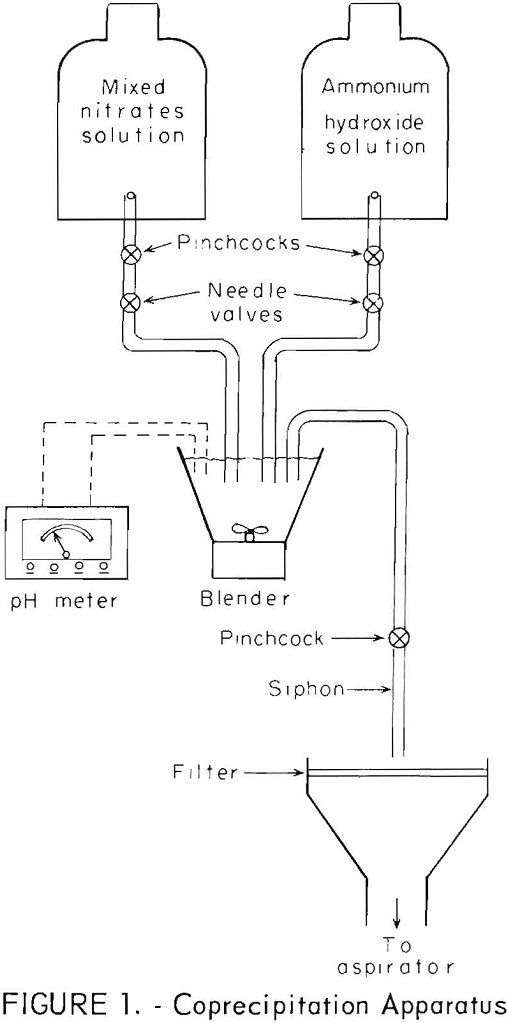

Dispersion Strengthened Copper

In accordance with a program for developing new materials required for emerging technologies, an investigation was undertaken to determine the properties of dispersion-strengthened copper. The copper contained either alumina or yttria as a dispersoid and was prepared by coprecipitation-a potential method for commercial production. Although the coprecipitation method had been used previously to prepare dispersion-strengthened […]

Scrap Tire Distillation

Destructive distillation was demonstrated to be a technically feasible method of disposing of and obtaining potentially valuable products from scrap automobile and truck tires. The relative amounts of the various products were shown to be highly dependent on the temperature of carbonization. Highest yields of liquid products were obtained at 500° C and highest yields […]

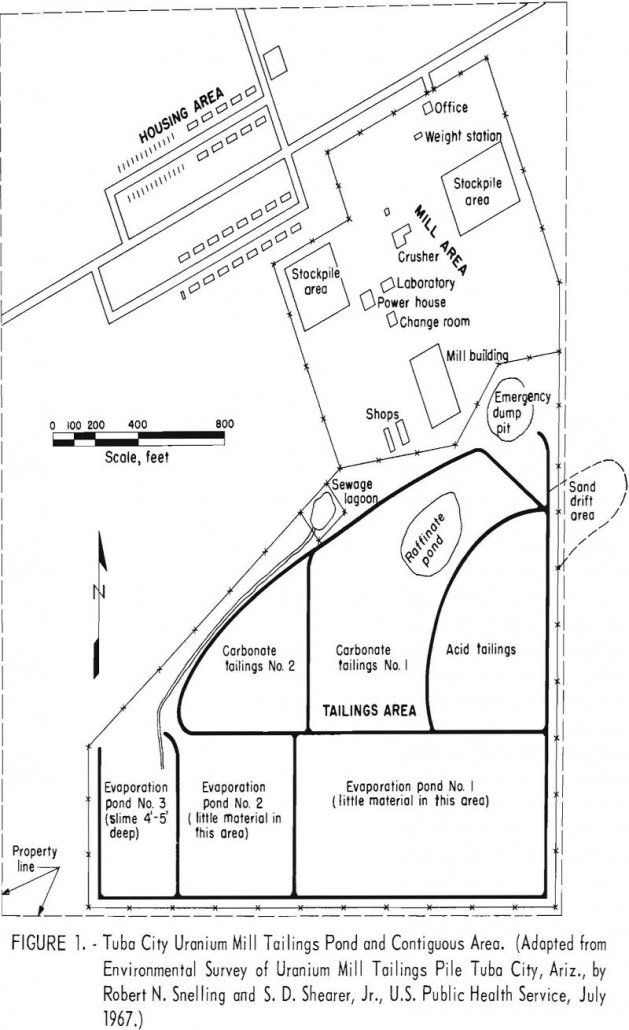

How to Stabilize Uranium Tailings

An environmental radiological survey was conducted on the El Paso Natural Gas Co. uranium tailings pile at Tuba City, Ariz., in May 1967, by the South-western Radiological Health Laboratory of the Public Health Service, U.S. Department of Health, Education, and Welfare (HEW). As the abstract of the reports of the survey summarizes the pertinent facts […]

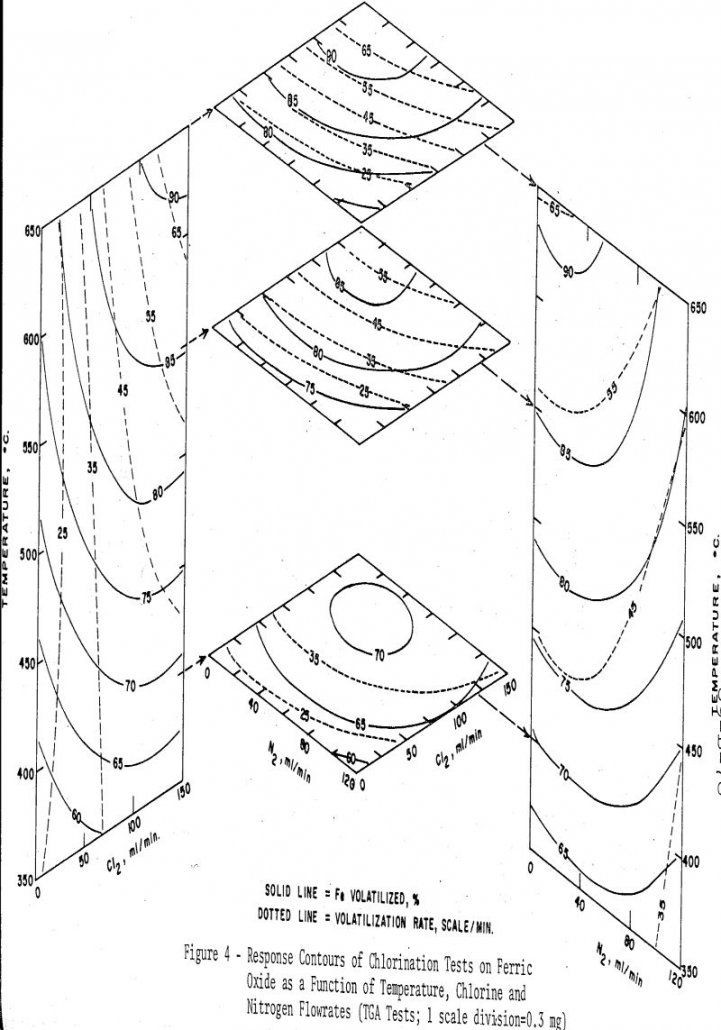

Manganiferous Iron Ore Chlorination

The chlorination behaviors of pure iron and manganese oxides were investigated by combining a thermogravimetric analysis (TGA) technique with batch-boat roasting followed by leaching. Ferrous and manganous oxides could be chlorinated readily, but, in the absence of a reductant, the higher oxides of both iron and manganese were difficult to chlorinate. Thermogravimetric analysis curves were […]

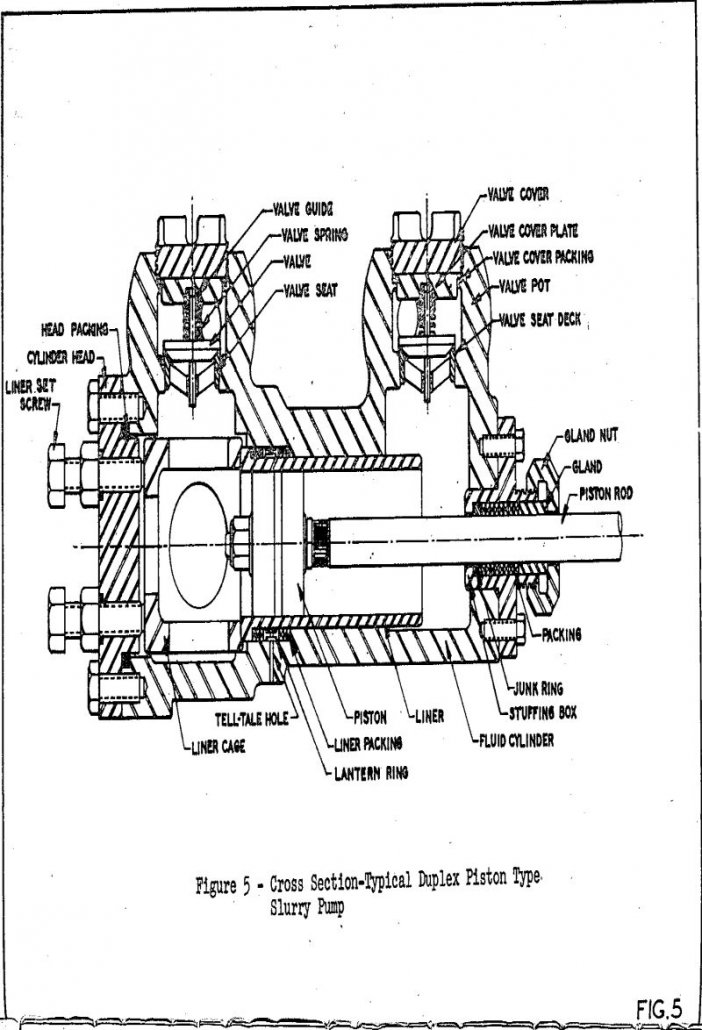

Slurry Pumps for the Long Pipelines

Since time immemorial, Mother Nature has been transporting slurries with both air and water serving as the carrier medium. Consider for example the formation of the continental shelves off our coast lines which are being formed by rivers emptying erroded land surface and depositing it into bays and gulfs. As the erosion processes take place, […]

Separation Efficiency

The technical excellence of separation achieved in a mineral concentration process, or any other process where two constituents of any kind are physically separated from each other, is expressed uniquely and quantitatively by the Separation Efficiency: Es = (R – Rg) where R is the percentage of the valuable constituent and Rg the percentage of […]

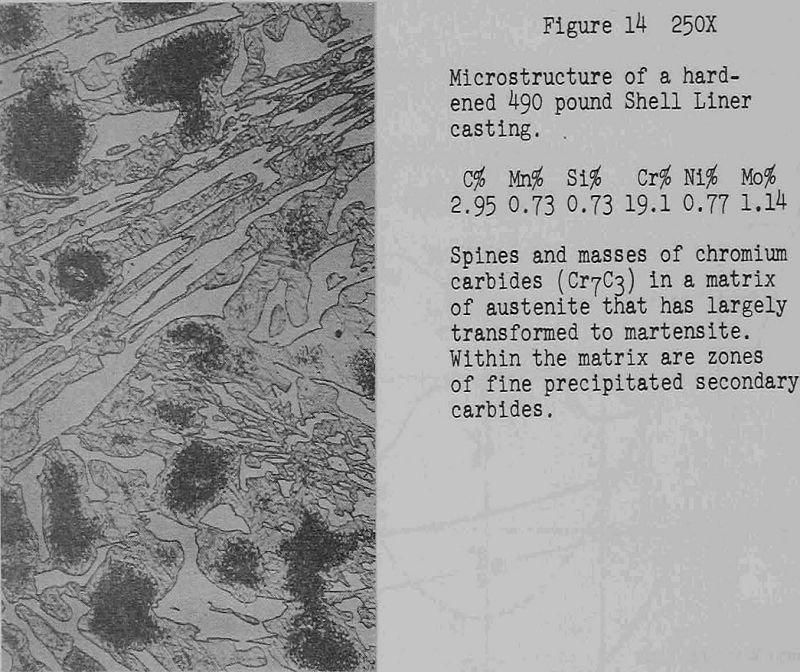

How to Select Grinding Mill Liner Alloys for Optimum Wear Resistance

The wear resistance of an alloy in heavy mill liner sections may be quite different from that of the same alloy in small balls and other light sections. This fact was established by means of a well standardized laboratory test that was validated for ball mill service. The salient properties of mill liner alloys, including […]

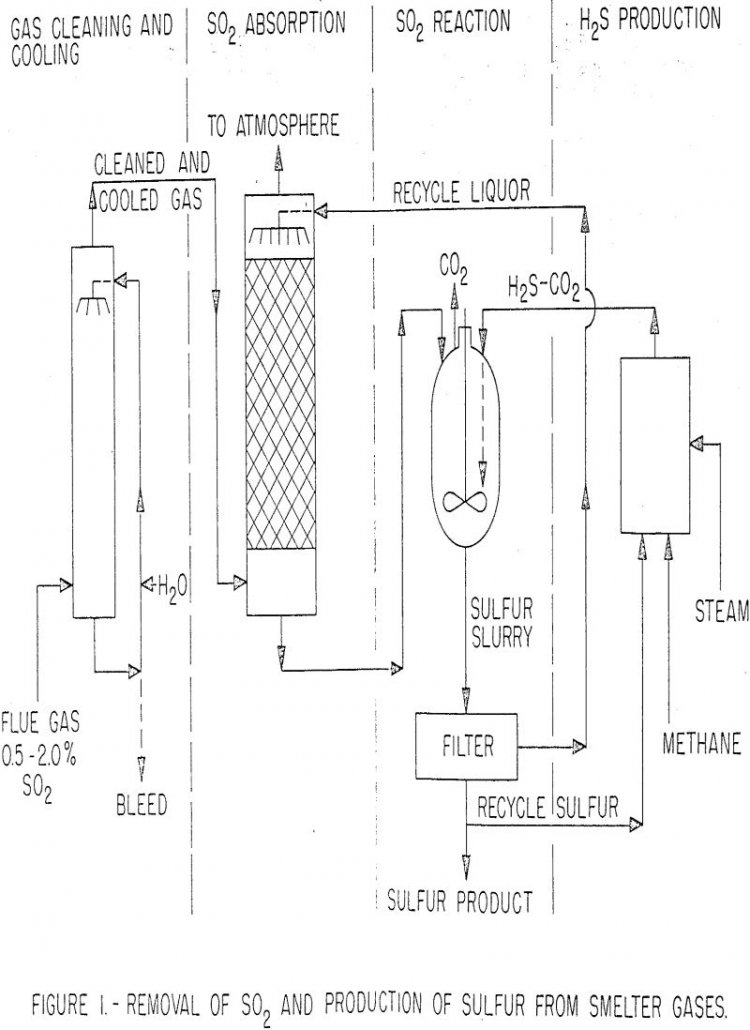

Removal of SO2 and Production of Sulfur from Smelter Gases

The economic removal of SO2 and production of elemental sulfur from stack gases discharged by base-metal smelters is a challenging-goal. Annually, in the United States, about 3.5 million tons of SO2 are discharged to the atmosphere by smelters. The SO2 concentration of the gases ranges from about 0.5 to more than 3 percent. As the […]