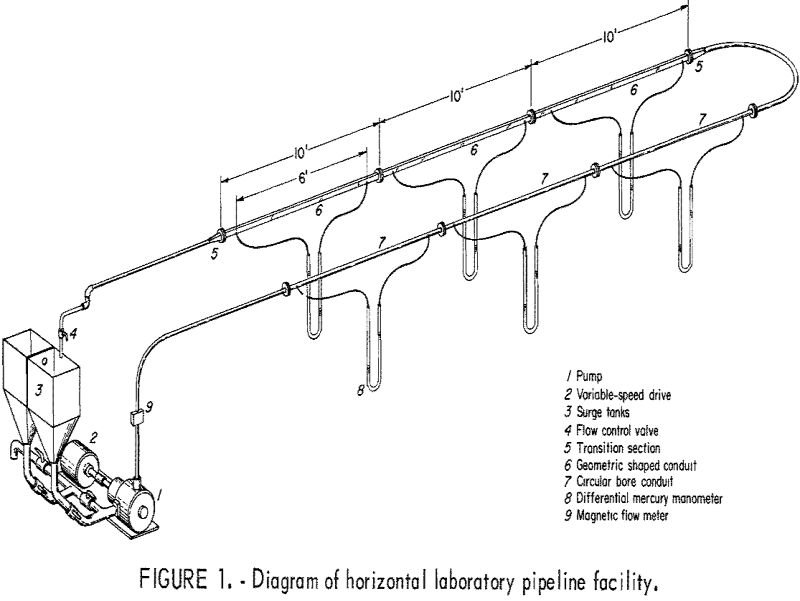

How Pipe Geometry Affects Flow Velocity & Head Loss

Transporting solids in pipelines generally is considered economical in the mining industry as well as in other industries. For example, the procedure has been used successfully in the iron ore slurry pipeline of the Savage River mines and the coal slurry pipeline of the Black Mesa mines. Even under conditions in which this mode of […]

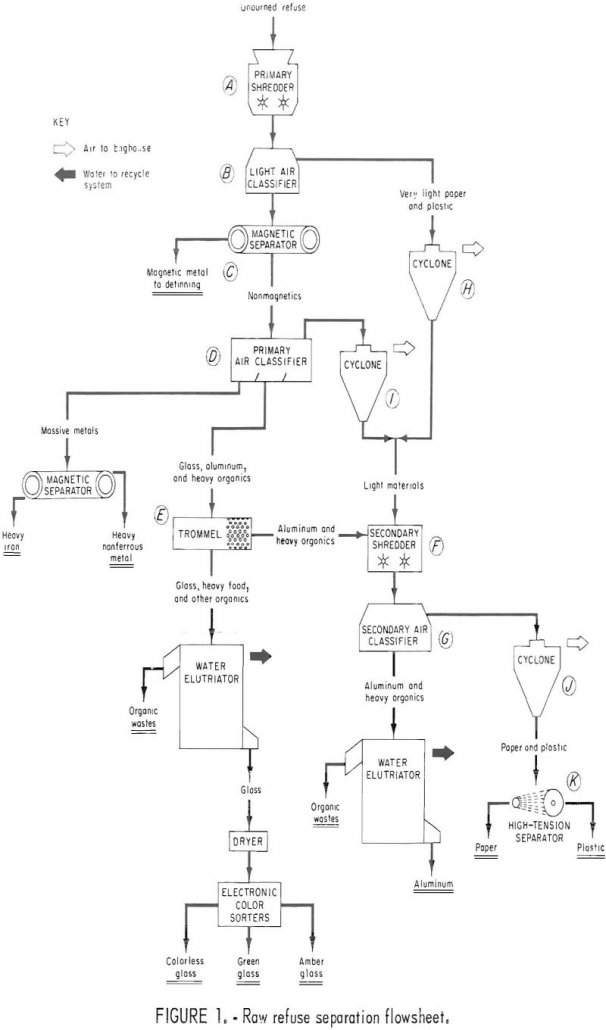

Small Scale Metal Recycling Plant & Equipment

Of the 220 million tons of refuse collected annually in the United States, it is estimated that about 30 million tons are incinerated, generating about 7 million tons of residues. In previous work, the Bureau of Mines developed a continuous mechanical process capable of converting 85 percent of municipal incinerator residues into potentially useful products. […]

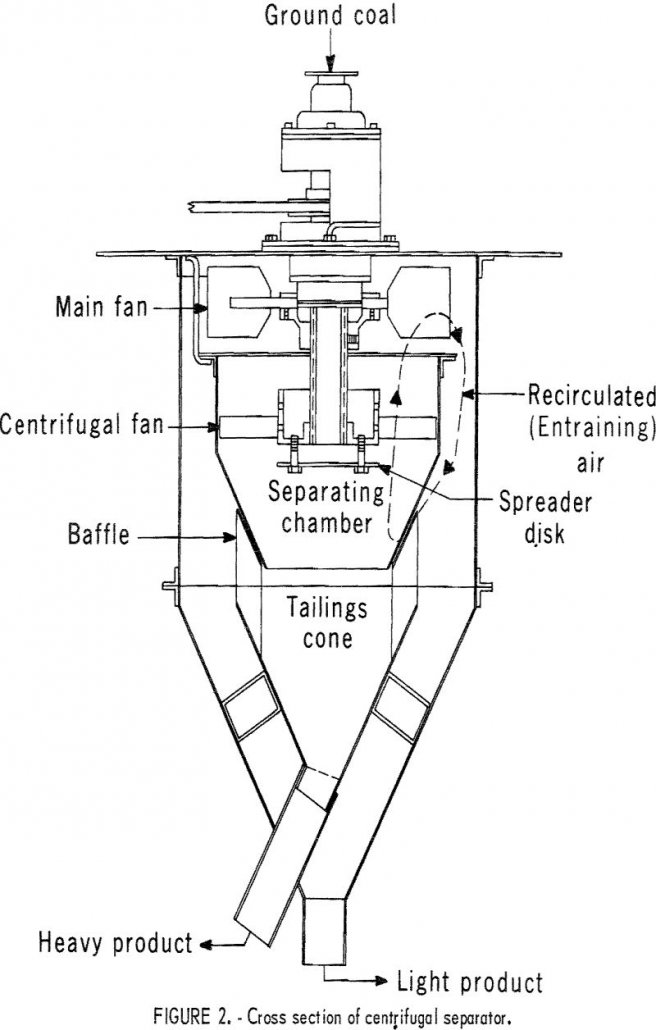

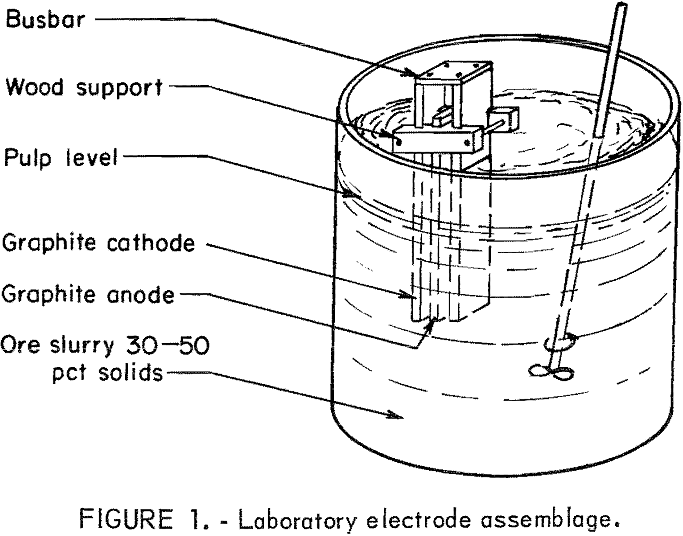

How to Remove Pyrite from Coal

In recent years, coal research has been directed toward environmental problems of the electric power generation industry. A major problem of coal-burning power-plants is reducing the air pollutants in stack gases. In most of these plants, the chief pollutant is SO2, which results from the combustion of sulfur compounds present in the coal. Stack-gas cleaning […]

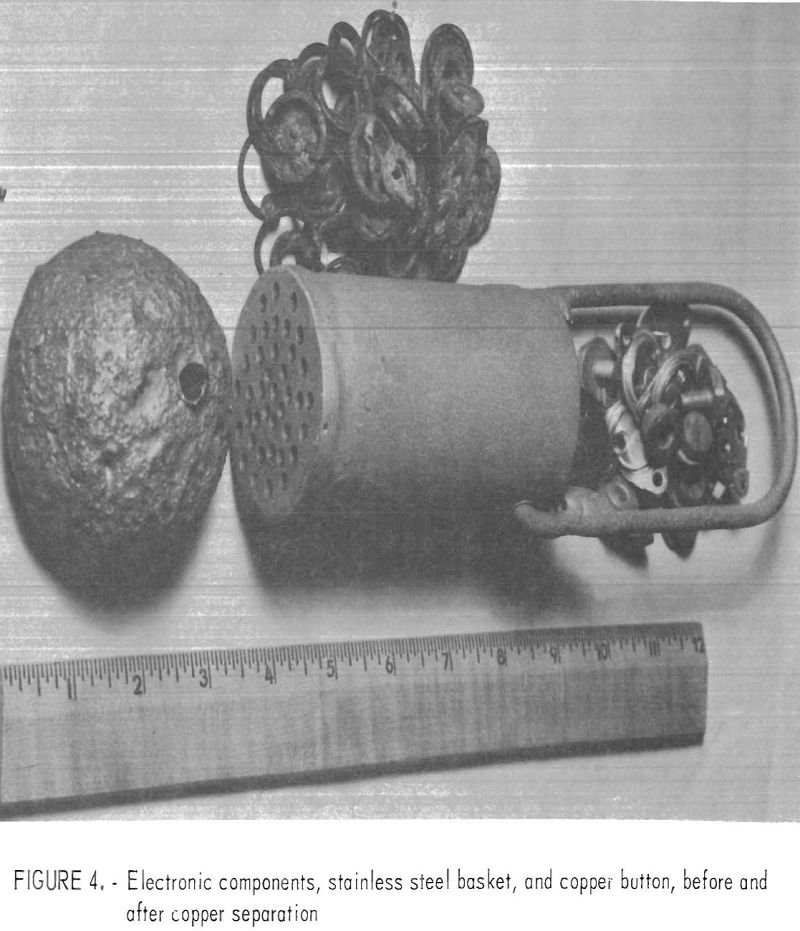

How to Separate Copper from Scrap by Melting

The secondary metals industry has been a major segment of the domestic economy for years. Many secondary commodities (heavy melting steel and lead storage batteries are familiar examples) have become so well established and recycled so promptly that industry commitments for metal would be impossible without them. Although some recovery and refining processes developed for […]

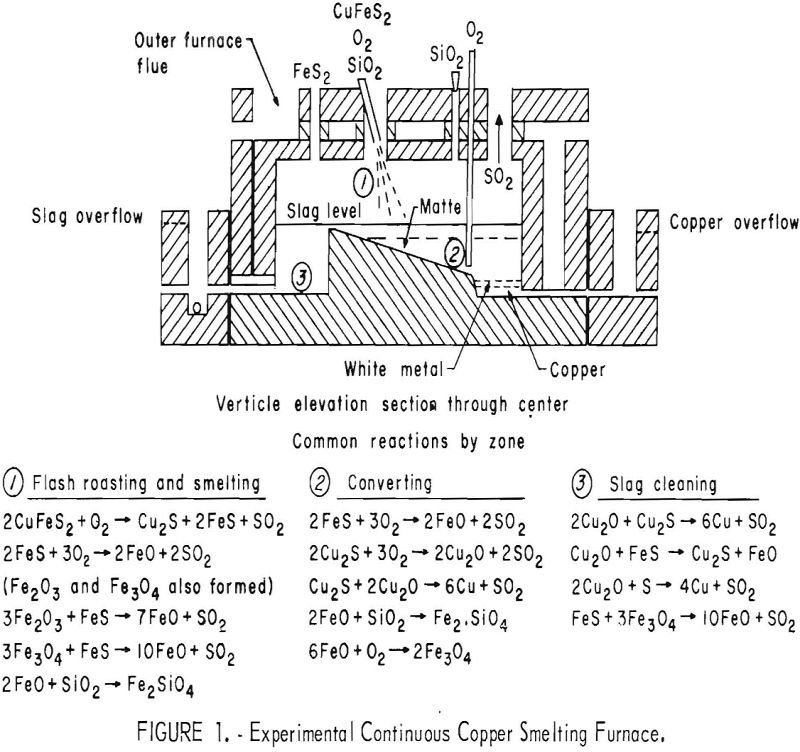

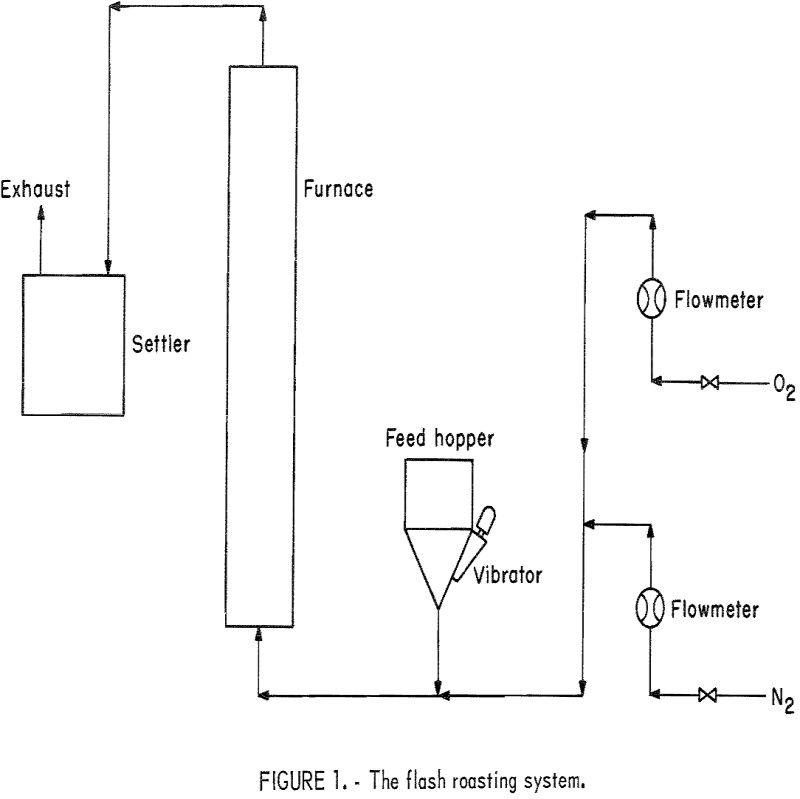

Copper Smelting

Throughout this century the major production of copper (as it relates to Copper Smelting) and most other nonferrous metals has been through pyrometallurgical methods, treating sulfide ores by various batch processes. The predominant copper process is reverberatory furnace smelting of sulfide concentrates to produce matte and slag, followed by treatment of the matte in converters […]

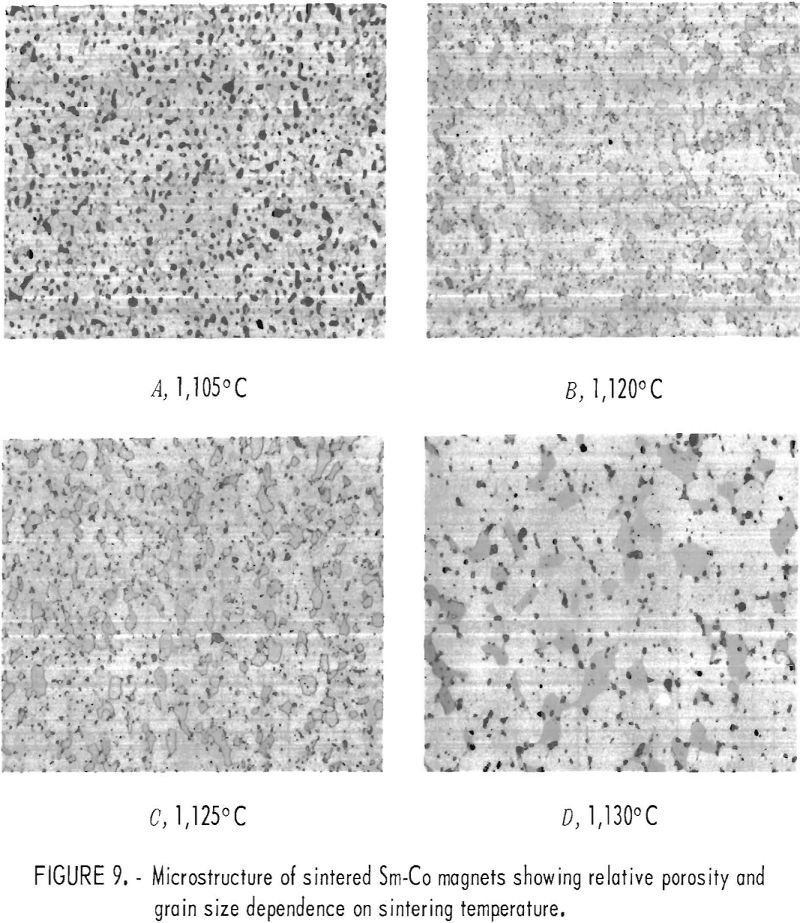

Permanent Magnets

The magnetic properties of rare earth-cobalt intermetallic compounds have been studied by various investigators. It was not until Strnat and Hoffer investigated single crystals of YCo5 and reported an extremely high magnetocrystalline anisotropy that systematic studies of the magnetic properties of rare earth-cobalt alloys were undertaken. These studies determined that RCo5 compounds (R = one […]

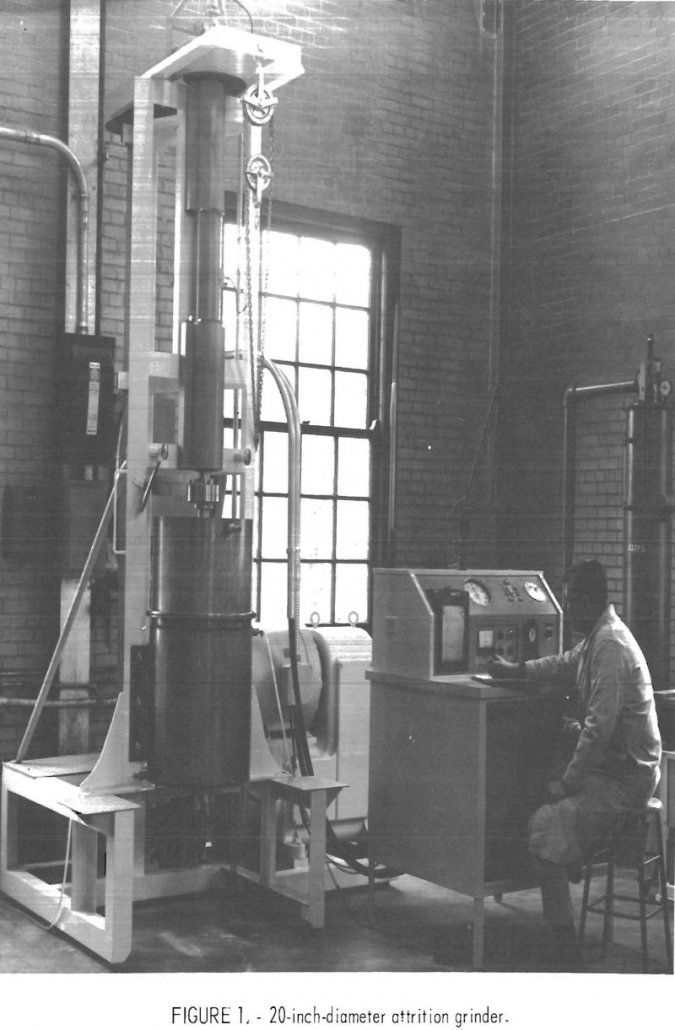

Kaolin Attrition Grinding

Fine grinding research has resulted in the development of an attrition grinding process: that has been successfully used for ultrafine grinding of various solid materials. The process was initially developed and patented by the Bureau at the Tuscaloosa Metallurgy Research Laboratory to grind coarse paper-filler kaolins to finer, paper coating-grade clay. The fundamental objective of […]

How to Extract Silver from Refractory Ores

The recovery of silver from ores by hydrometallurgical techniques changed considerably toward the end of the 19th and in the early part of the 20th century. Metallurgical techniques, such as amalgamation, chloride roasting followed by amalgamation, hyposulphite leaching, and the Patio process (amalgamation of silver formed by the reaction of silver minerals with sodium chloride […]

Copper Cement Oxidation

Cement copper production has been increasing steadily because more mine waste from open pit mining is being leached and the copper recovered by cementation on scrap iron. Current estimates indicate that about 13.1 percent of the Nation’s production of primary copper is from this source. Cement copper is usually a crude product containing elemental copper, […]

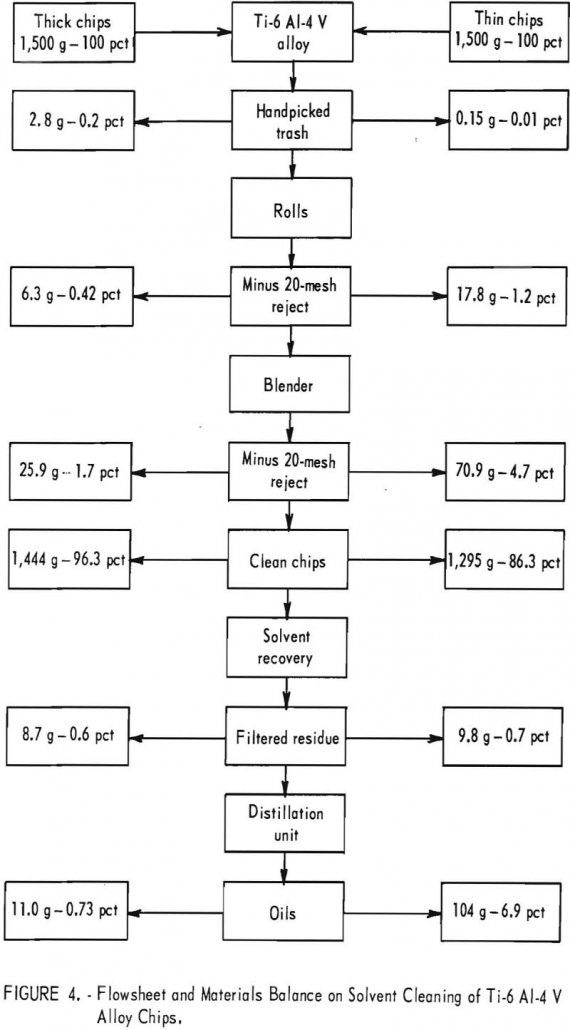

How to Clean Titanium Alloy Scrap

Recycled titanium scrap is mixed with titanium sponge for ingot production and, therefore, plays an important role in the production of mill products. Clean and segregated scrap is recycled fay producers that regard their scrap-recovery procedures as proprietary. Unless a rigorous procedure is observed for segragating titanium scrap by alloy content, the scrap is not […]