Quicksilver Ore Mining & Reduction Method

The low cost of mining was the principal consideration, since, with mercury’s price per pound, the total gross value of the ore did not exceed too much per ton. Square setting and filling was out of the question, so various attempts with cheap methods were made, among them a shrinkage system. None gave satisfaction on account […]

Quicksilver Deposits

Quicksilver deposits are of special interest because they are confined to shallow depths and their origin is comparatively clear. The absence or scarcity of cinnabar and the less common quicksilver minerals in deposits whose features point to deposition at high temperature implies that these minerals are not stable at such temperatures, and the fact that […]

Amalgamation of Gold & Mercury

Any amalgamation test is found to possess most merits and fewest limitations when reduced to the smallest possible dimensions permitting uniform action and certain treatment. A limit is always reached at some point in this reduction in size, where some condition no longer can be fulfilled. In many continuous mechanical tests the limit is set […]

Chemical Precipitation on Mercury

The Chemical Precipitation on Mercury of the Gilmour – Young Process is a method that has been employed at the Santa Francisca Mine, Nicaragua. The ore contains a very large percentage of clay, the slimes amounting to 70 per cent, of the ore. The ore is crushed by a No. 5 Krupp ball mill through a […]

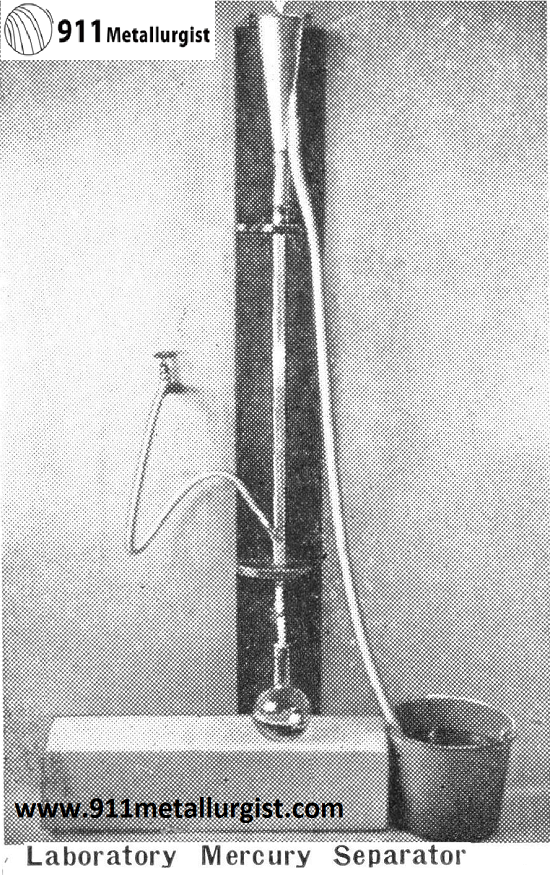

Laboratory Mercury Separator

Laboratory Mercury Separator is extensively used to separate floured mercury or amalgam from the tailings of any amalgamating unit. Pulp is fed into the tube through the funnel in the top, and water is forced in at the lower part of the tube, creating a sufficient up-current to overflow the sands out of the discharge […]

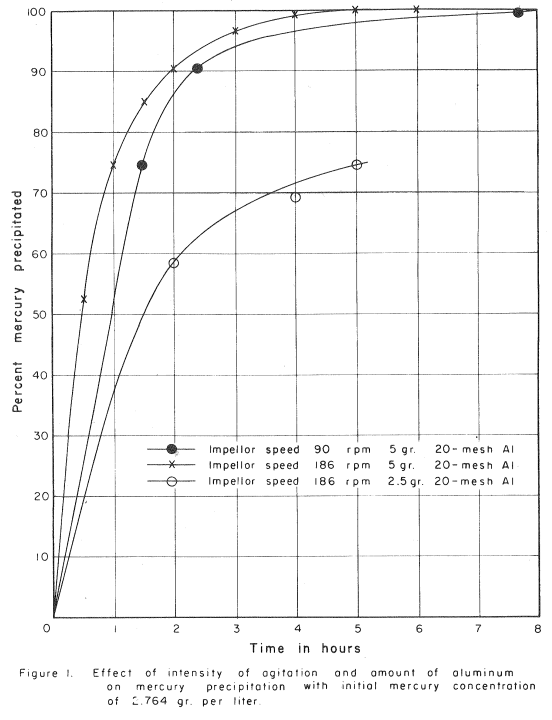

Leaching Mercury Sulfide

Hydrometallurgical methods have received increased attention for the treatment of many ores in recent years. Whereas, direct furnacing has been regarded as the standard process for mercury (cinnabar) ores, hydrometallurgical methods offer an alternate consideration. The chemistry of this process is not new, but with the impetus to hydrometallurgical methods, it is only logical that […]

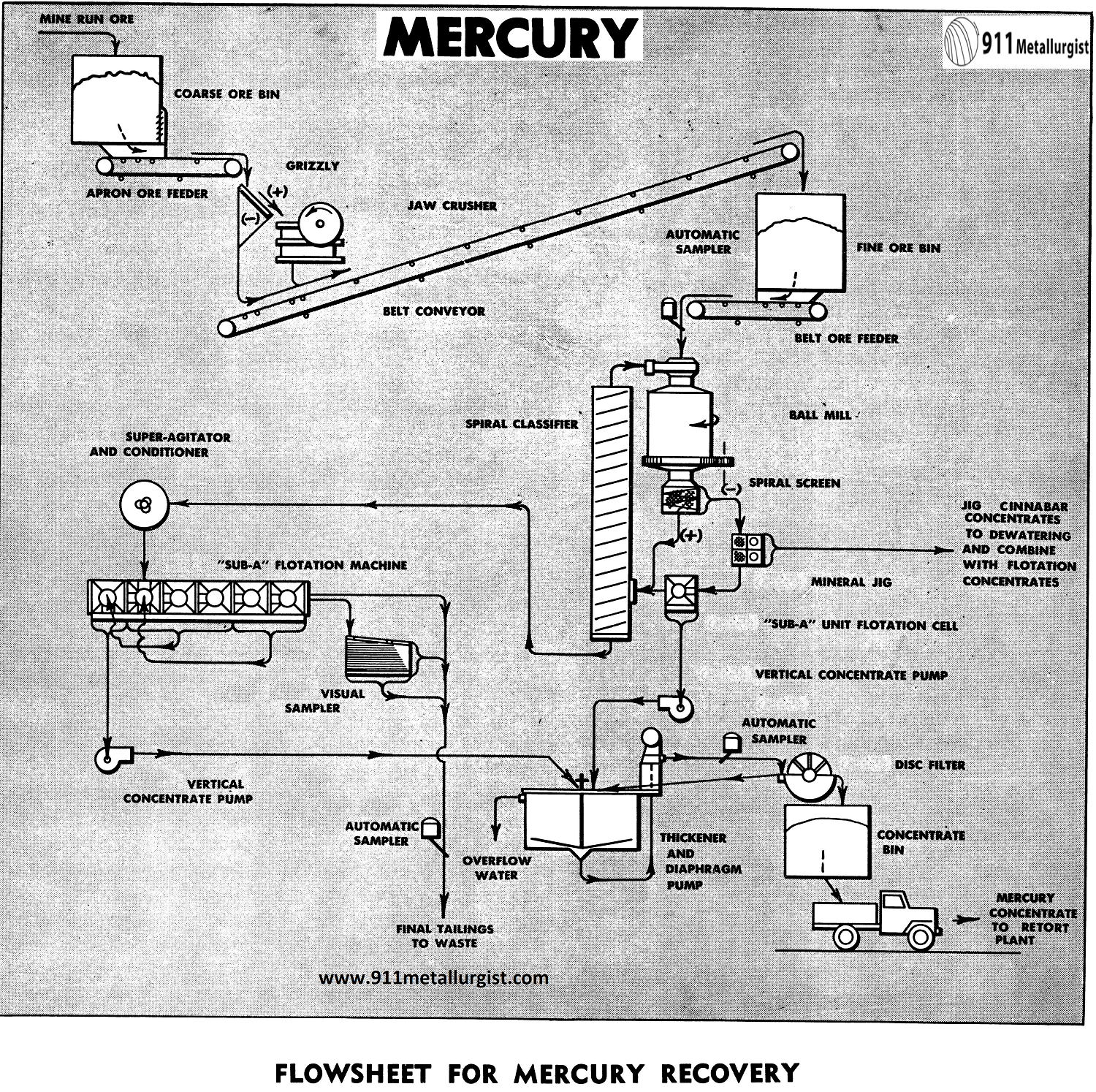

Mercury Ore Processing

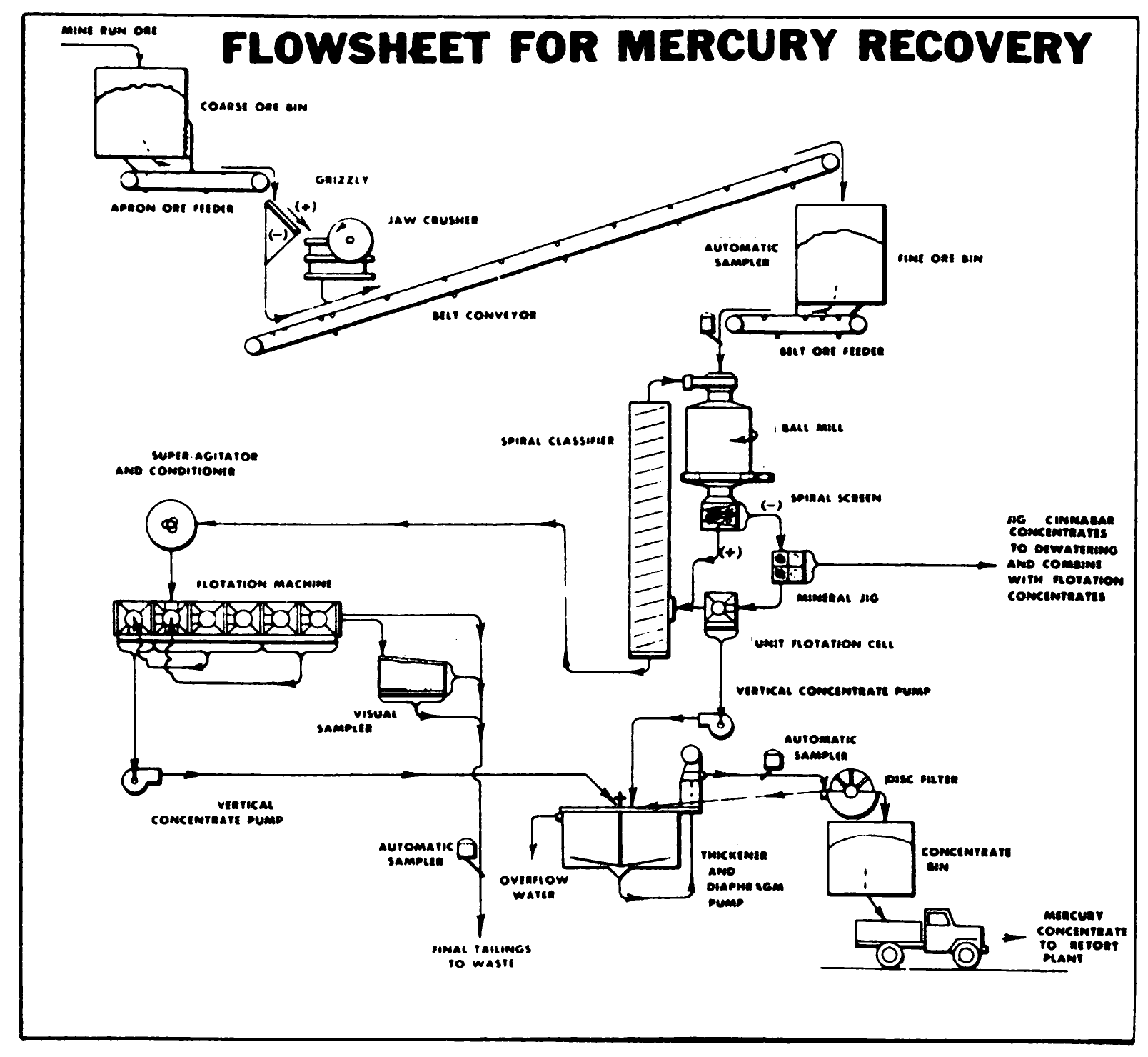

The concentration of low grade cinnabar, HgS, with a specific gravity of 8.0-8.2 is effectively accomplished by gravity and flotation methods. Cinnabar ores of relatively high mercury content can be retorted directly to expel the sulphur and condense metallic mercury, but for lower grade ores, preliminary concentration is advisable to reduce the tonnage for retorting. […]

How is Mercury Extracted from Cinnabar Ore

Mercury Process Recovery/Extraction Circuit Flowsheethttps://www.911metallurgist.com/mercury-extraction-process

Gravity Borax Method GBM Mercury Free Gold Recovery

The Gravity-Borax Method GBM is still unknown to most Artisanal and small-scale gold miners (ASGMs) worldwide as most still use mercury to extract gold. “Whole-ore amalgamation” is a technique that requires the use of 10–25 g of mercury to produce 1 g of gold. Within the last eight years, it has become evident that this technique is more […]

Illegal mercury used in small-scale damages lands

Many developed nations hope 2014 can finally be the year when a real fight against the use of mercury in gold mining across the world starts. However, until then, several countries like Indonesia will continue to suffer the consequences of this and other dangerous techniques. The small-scale, and many times illegal, gold mining operations spread […]