Ultrasonics can be used to deslime and upgrade ores, such as tungsten and tin, which slime excessively with high losses of value in the tailing and are difficult to deslime with conventional methods. Experimental work has been performed with a test-tube size ultrasonic classifier. Larger equip-

ment and further testing would be necessary to ascertain the applicability and economics of this method.

When high frequency sound waves are propagated upward through the bottom of a cylindrical tube containing an ore pulp, the mineral particles are subjected to the peptizing action of cavitation, to the stratifying action of the progressive waves, and also to the accumulating action of the standing waves. All actions originate from the radiation pressure of the sound waves. The accumulating action, however, embodies additional effects of reflection and refraction. The proposed method of ultrasonic desliming depends primarily upon the stratifying and peptizing actions and is somewhat hindered by the accumulating action.

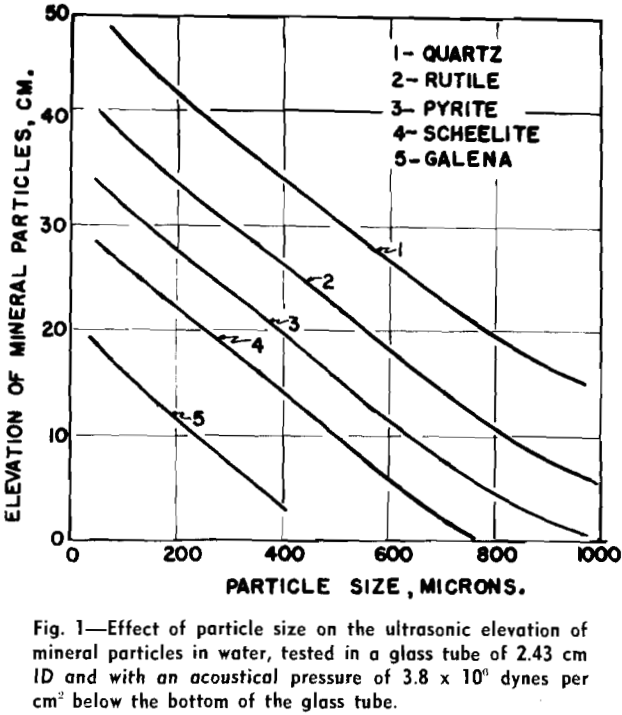

Ultrasonic Stratification of Mineral Particles in Water: The peptizing and accumulating actions of ultrasonics have often been studied and need no explanations. In contrast, the stratifying action is new and had to be experimentally ascertained. Before each test was started, a glass tube 120 cm long was filled with water to the 75-cm mark. Then 0.1 to 0.3 g of mineral particles were added and allowed to settle to the bottom.

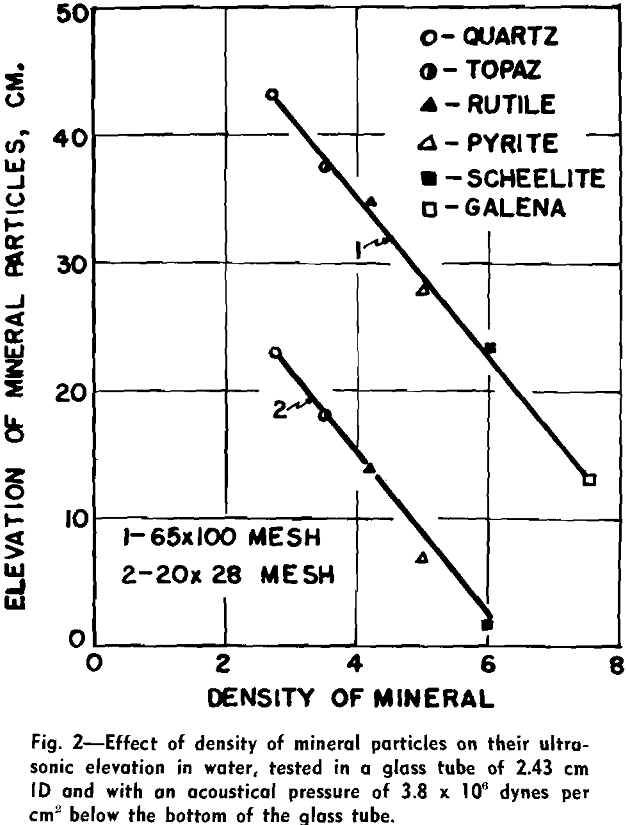

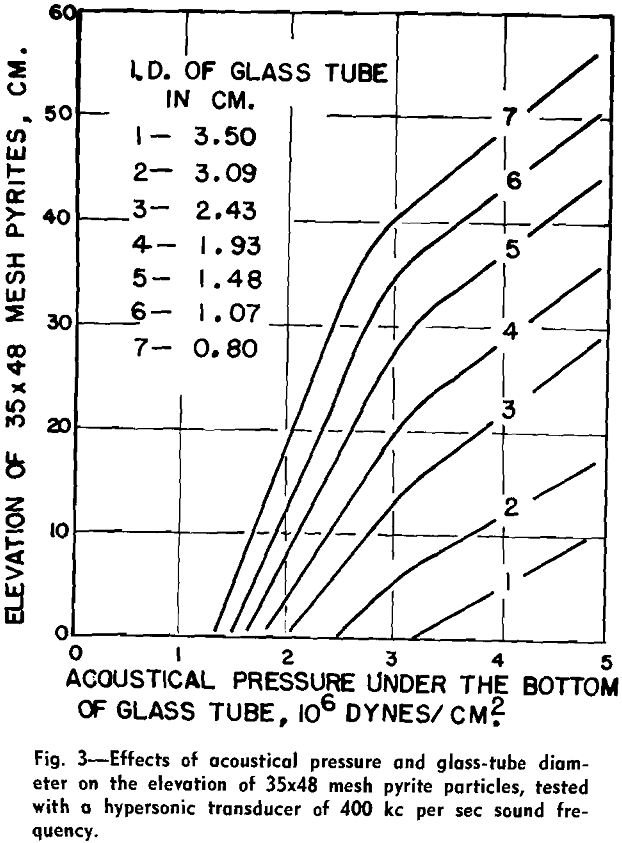

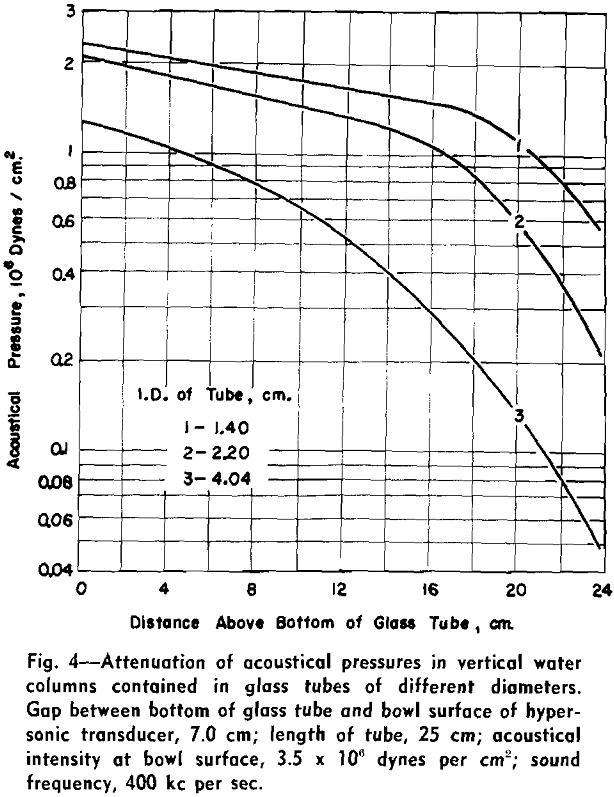

The upward forces, consisting chiefly of radiation pressure and partly of acoustical streaming, increase directly with the intensity of the incident sound waves. Owing to the attenuation of sound waves in the pulp, the upward forces are dampened from bottom to top. The downward forces, consisting chiefly of gravity and partly of fluid resistance, increase with an increase in the density and/or size of the particle. Elevation of any particle occurs only when the sum of the upward forces is larger than that of the downward forces and continues until these two sets of forces reach an equilibrium. For any given sound source, the equilibrium elevation of the fine-light particles is higher than that of the coarse-heavy particles, thereby producing stratification.

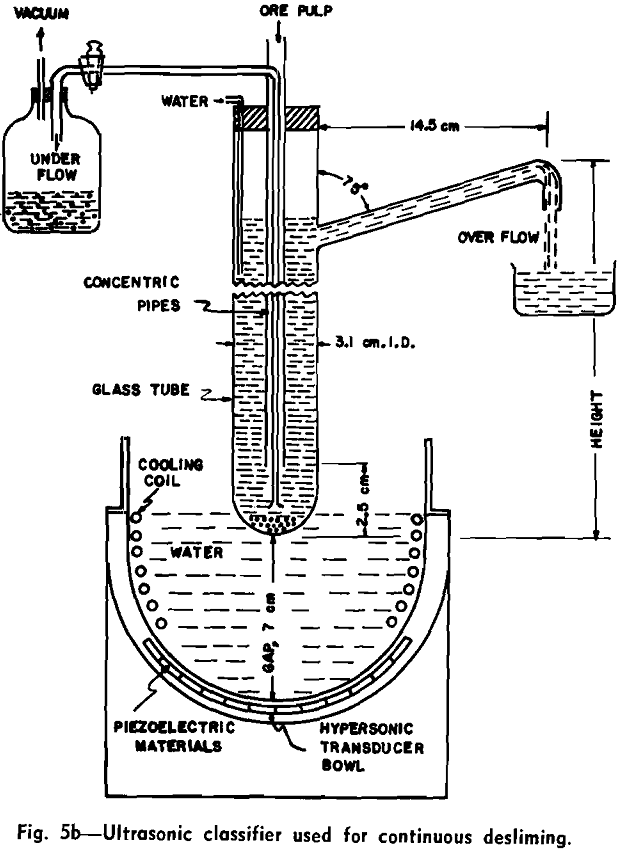

Apparatus and Procedure: the ultrasonic classifier used for intermittent desliming consists of a 400-kc hypersonic transducer, A and J; a feed preparing and regulating system, B-D; and a classifying system, E-H. The intermittent classifier can be converted into a continuous one by the addition of a vacuum system for evacuation of underflow.

Ultrasonic desliming was tested in the intermittent classifier by the following steps: 1) preparing the ore pulp to be tested in the graduated flask, C; 2) filling the glass tube, F, with water; 3) connecting the water inlet, E, to a water faucet by rubber tubing; 4) turning on the hypersonic generator, A and J; 5) opening the stopcock of the graduated flask and allowing the prepared ore pulp to flow into the glass tube, F, through the funnel tube, D; and 6) collecting both the overflow and underflow for subsequent drying, weighing, analyzing, and sizing.

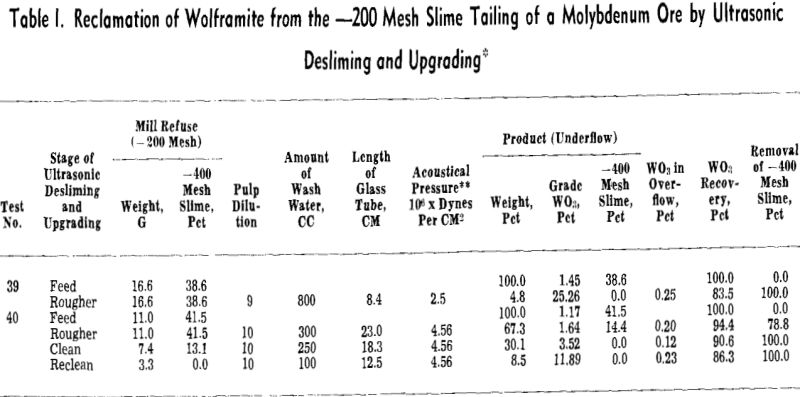

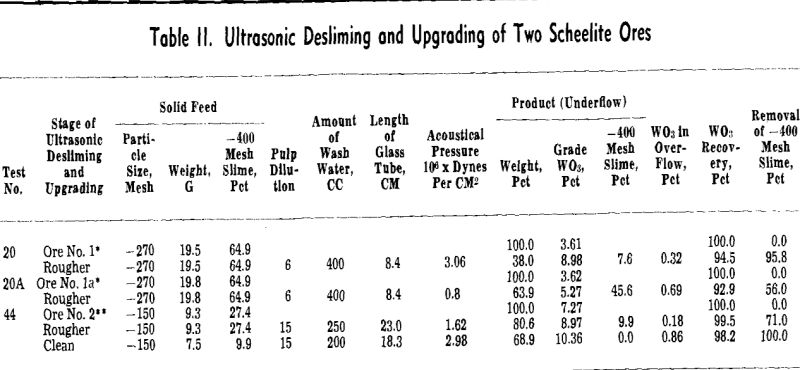

Desliming and Upgrading: The validity of the proposed ultrasonic method for desliming and upgrading of ores and tailings was checked by reclamation of wolframite from the —200 mesh slime tailing of a molybdenum ore. This slime tailing, containing 1 to 1.5 pct WO3 and 38 to 42 pct of -400 mesh material, is the overflow of the hydraulic classifiers of a milling plant and has plagued investigators interested in reclaiming the tungsten. For example, test 39 shows that, under suitable conditions, a one-step desliming is sufficient to remove all fine slime particles from the tailing, resulting in a product of 25 pct WO8 and 83 pct tungsten recovery.