Table of Contents

Several categories of storage are used depending on capacity. Operational storage, which is small in comparison with the market, facilitates handling surges of a few hours’ or a few days’ duration. Seasonal storage, usually larger, permits accumulation of product during seasons when demand is low, for delivery when demand is high. In producing areas, large storage may permit production at a uniform rate, without waste or distress sale. Near large markets such storage increases the efficiency of transportation, allows a more extensive or higher grade market to be served, and affords protection against interruption in delivery.

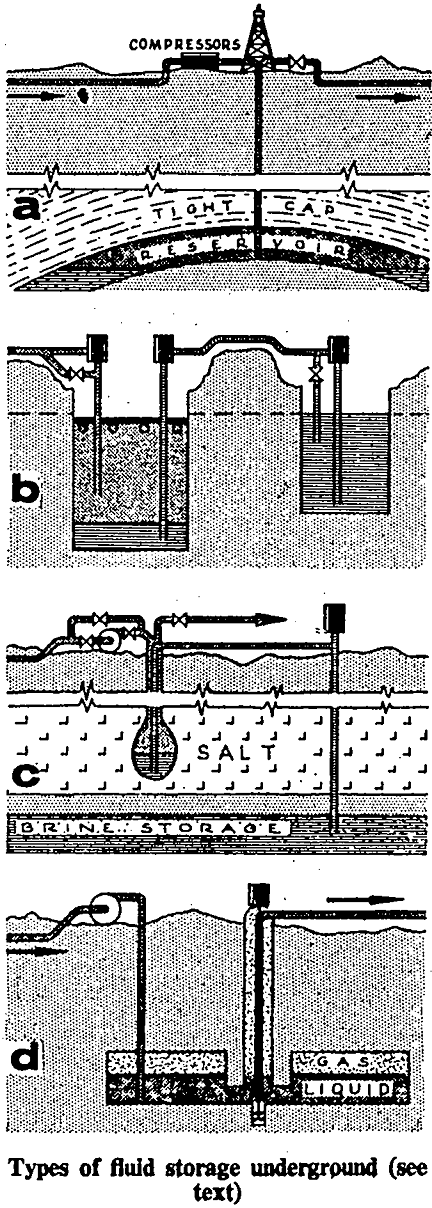

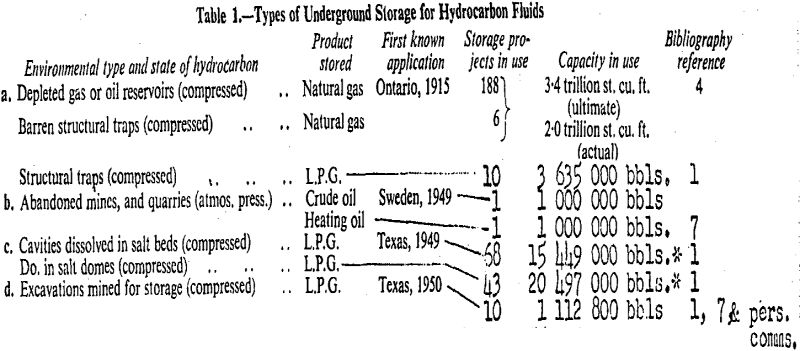

As the term is used by petroleum and gas industries, underground storage may be classified into the four types outlined in Table 1 and illustrated diagrammatically in Fig. 1. Application of any type at any location depends on the existence of rock conditions favourable to that type. Some types are intrinsically suitable to the storage of products whose physical properties or cost, at the time and place of storage, fall within a certain range.

Non-excavated storage

Type a. Storage in depleted gas or oil reservoirs has the longest history, the greatest number of projects, and the greatest capacity, whether measured by volume or B.Th.U’s. Such storage has been used principally for natural gas but helium, coke oven gas (near Paris), refinery gas (near Hamburg) and L.P.G. are or have been stored in this fashion.

Type b. Regrettably, few abandoned quarries and mines meet the requirements even for storage of hydrocarbon liquids at atmospheric pressure. Where they are suitably located and do meet these requirements, their use may enable the construction of storage at capital costs which are low indeed. Ingenuity has been employed in the design of the two storages in use.

Type c. From Table 1 it may be calculated that 84% of liquid hydrocarbon storage capacity is in cavities dissolved in salt domes or beds. Except where salt is very deep, where permeable rock is interbedded, or where salt has been disturbed by mining or brining operations, salt may be assumed to be structurally strong and impermeable.

Excavated storage

(a) Liquefied Petroleum Gas

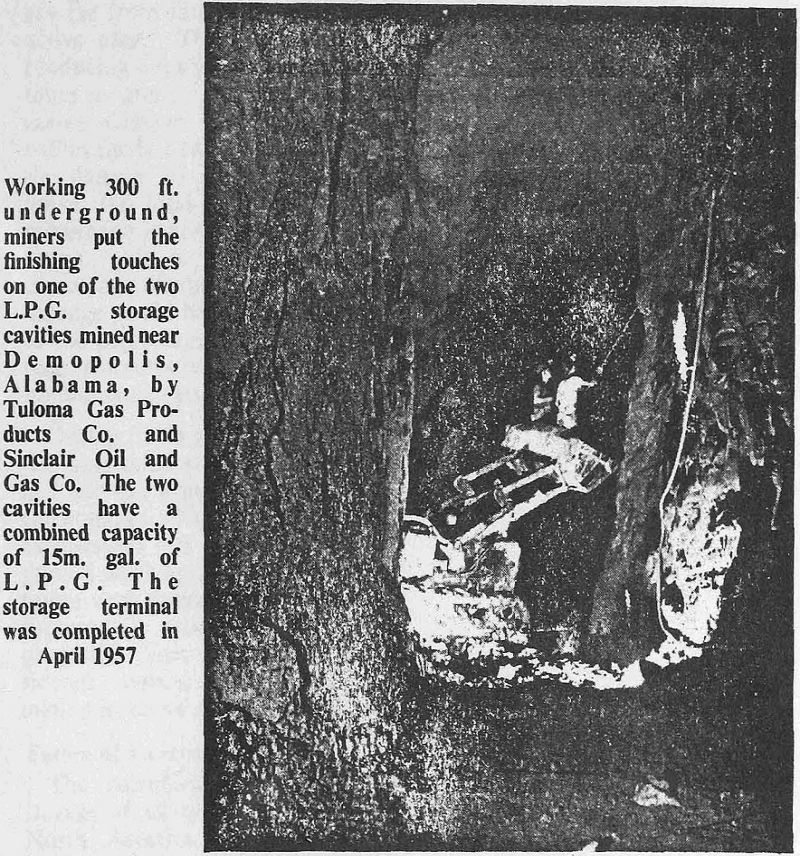

Ten excavated installations are in use for storing liquefied propane, butane and mixtures grouped under the terms liquefied petroleum gas (L.P.G.) or liquefied refinery gas of similar properties. Excavated storages under construction are expected to be used for the same products.

(b) Crude Oil

Crude oil storage in an abandoned feldspar mine (Sweden) and heating oil storage in a slate quarry (Pennsylvania) are of Type b. Where rock is favourable, estimates indicate that large volumes of storage could be excavated for crude oil, heating oil and other “non-volatile” products at capital costs comparable with those of covered tanks. Some requirements for storing these products are not so exacting as for storing L.P.G.

(c) Natural Gas

It should be possible to store natural gas in excavations, as gas and perhaps as liquid. Storage of natural gas appears to be feasible where there are, at appropriate depth, large stable masses of naturally tight rock, or rock which can be made tight. To be economical, gas would have to be stored at relatively high pressure many cu. ft. of standard gas being squeezed into each cu. ft. of excavation. To retain this pressure safely, storage chambers would have to be much deeper than those for propane. This implies shaft costs which are likely to be justifiable only for storage of at least moderate capacity.

Physical conditions

Physical conditions necessary or desirable for storage in rock excavations are:

- Rock in contact with the stored product must either be impermeable to it or to any fractions which may separate within the range of storage pressures, oi be capable of being made impermeable.

- The mass of rock in which the storage is excavated should be sufficiently large so that work can be designed to permit low unit cost and be completed within a reasonable time.

- Rock should sustain permanently good-sized openings without support.

- Access openings must be closed impermeably to the stored fluid and its fractions.

- Rock exposed to the product should contain nothing which will contaminate it.

- Chambers must be at sufficient depth that rock will not be harmfully deformed by the greatest pressure in them at any time.

- The slope and relative elevations of chamber floors should alloy substantially complete recovery of product, and facilities must be provided to recover the product at rates desired.

Cost factors

Contractors may choose from a great assortment of equipment and methods, to which additions appear almost continuously. The constant effort is to make labour ever more productive. Yet methods and equipment highly productive in one job may be only partly effective on another where working conditions are different. As the size and cost of equipment increase, it becomes more necessary to design and organise appropriately for conditions under which work will be done. Adequate appraisal of rock conditions and planning based on it are at least as essential to underground construction as foundation testing and sound architecture are to surface construction.

The variety of means permits efficient work under a variety of conditions. On a substantial job, appropriately planned and capably organised, in sound and reasonably uniform rock, high efficiency can generally be attained whether rock is sedimentary or igneous, hard or soft.

Rock stability and tightness

Since stability and tightness are most important, they merit further attention here. Permanent usefulness requires stable openings, and chambers must of course be safe for construction crews. In strong rock tremendous openings stand permanently without support. Large caves are examples.

Stability affects costs directly in that the cost of supporting an excavation in an unstable rock may be as much as the cost of the excavation itself. In rock which is less than desirably stable the cross-section of chambers may be reduced and the chambers may be shaped to minimise the need of support. But both expedients generally increase unit excavation costs.