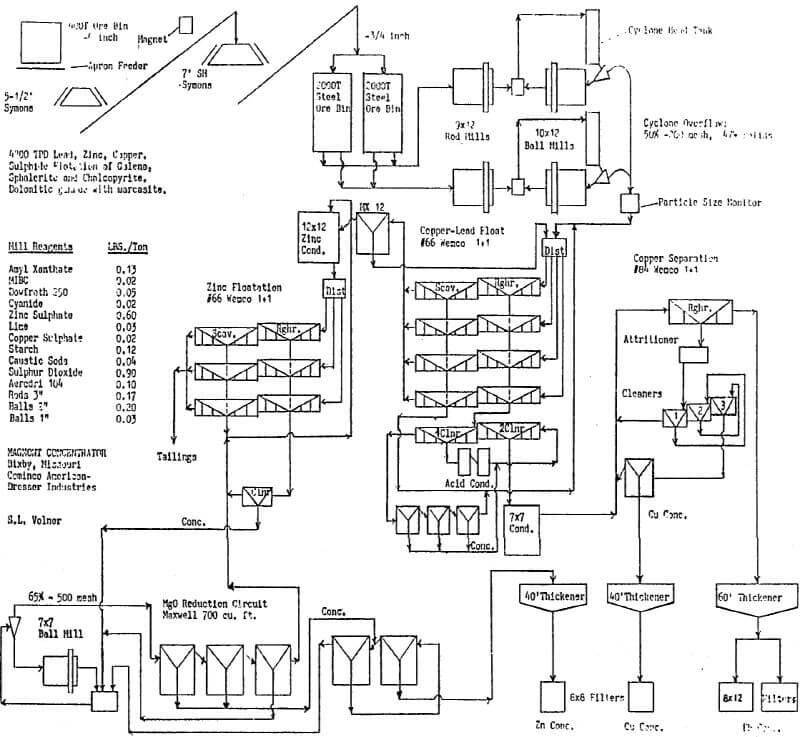

The flotation section starts with a bulk concentrate float for lead and copper using four rows of eleven cells each as roughers and scavengers. The froth taken off the roughers is then pumped to a two stage cleaner circuit. Scavenger froth and cleaner tails are returned back to the head of the rougher circuit. Froth from the cleaner circuit goes to a conditioner where sulfur dioxide and starch are used to depress the lead. The copper is then floated using four rougher cells and four stages of cleaning cells to produce a final copper concentrate. The final lead concentrate is the copper rougher cell tailings.

Zinc circuit feed is the tailings from the bulk copper-lead circuit. It is pumped into a conditioner and treated with copper sulfate for activation of the sphalerite (zinc). The zinc flotation circuit consists of three rows of eleven cells each as roughers and scavengers. The rougher froth is cleaned once and pumped to the zinc regrind circuit. Scavenger froth and cleaner tails are returned to the conditioner at the head of the circuit.

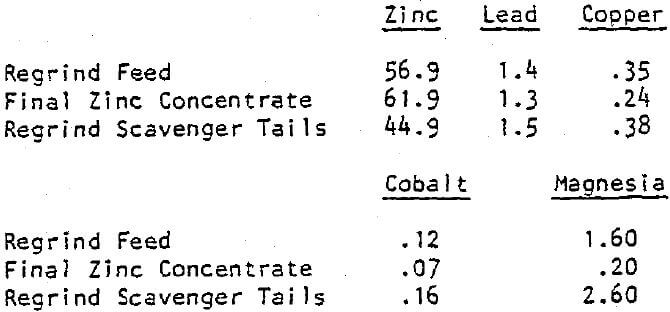

The zinc regrind circuit consists of a 214 cm x 214 cm (7 ft x 7 ft) ball mill in closed circuit with four 15 cm (6 in.) cyclones. Cyclone overflow goes to two 20 m³ (700 cu ft) rougher cells and a 20 m³ (700 cu ft) scavenger cell. Froth from the scavenger cell is returned to the regrind mill. Tailings from the scavenger cell is pumped back to the zinc conditioner at the head of the circuit. Froth from the two roughers is combined and then cleaned twice using 20 m³ (700 cu ft) cells to produce the final zinc concentrate.

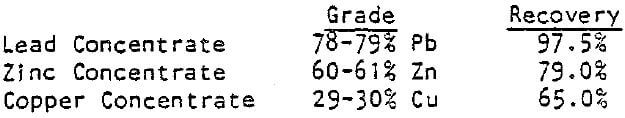

The concentrate grades and recoveries for the three products are:

Why Regrind Flotation Concentrate

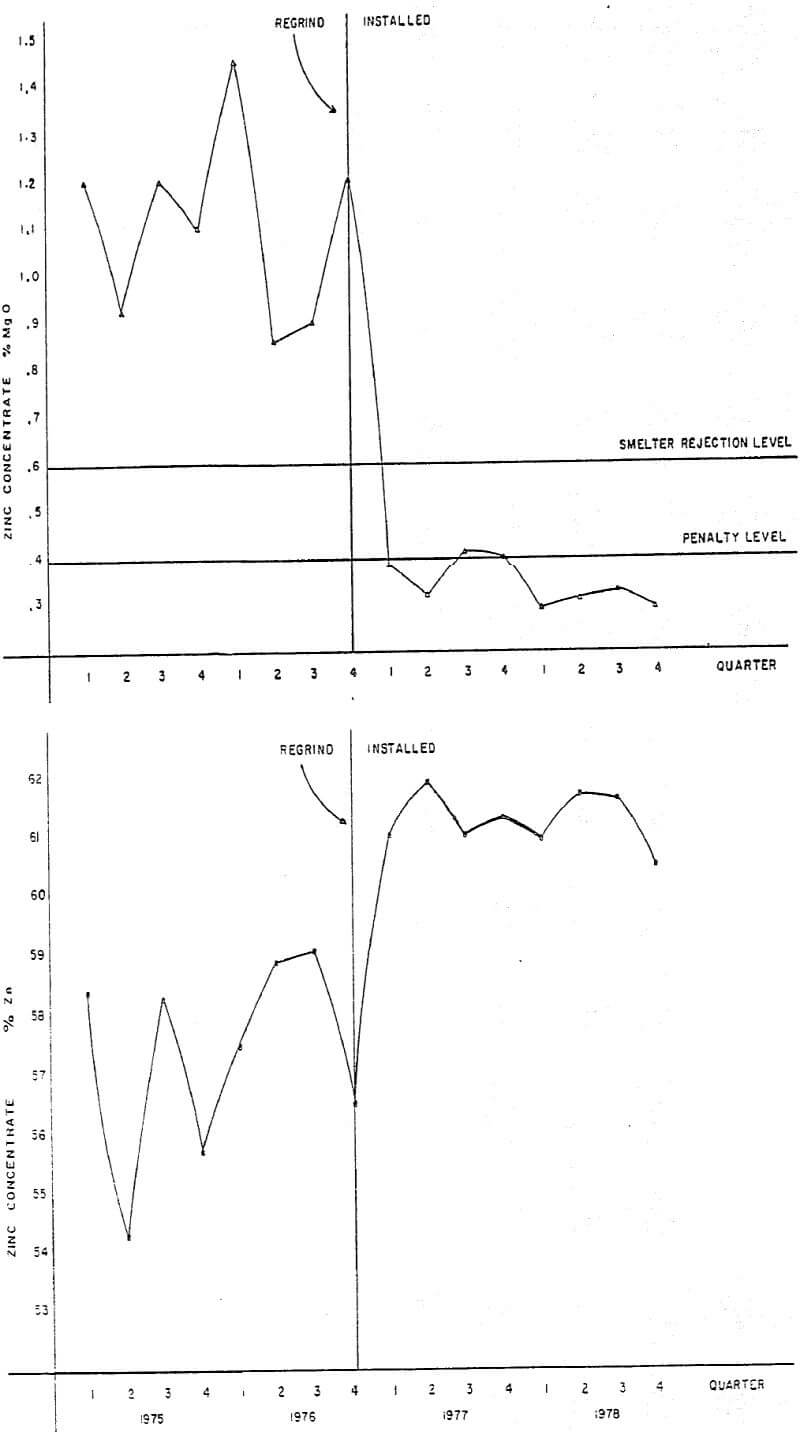

It was determined by the zinc smelter that a magnesia content of .6% MgO would be acceptable. The zinc concentrates were ranging from .7-1-5% MgO with an average of 1.2% MgO. It was determined from regrind tests that the minus 45 mm (325 mesh) fraction was substantially liberated to obtain a .5% MgO. With increased grinding and finer control of the particle size, it was determined the final content of magnesia would be less than 0.5% MgO.

Acid leaching of the concentrate was tested and produced magnesia contents below 0.1%. The major concern was the environmental aspects of acid treating. The magnesia in the zinc concentrate is dissolved with sulfuric acid, forming magnesia sulfate and carbon dioxide, which does not present a problem. In addition to dissolving magnesia, about 1% of the zinc sulfide is solubilized forming zinc sulfate and hydrogen sulfide (gas). Hydrogen sulfide is a toxic gas and zinc sulfate in solution would require a treatment plant for removal from the effluent before discharge.

The use of a regrind-flotation would not produce any environmental problems. Regrind also reduced other impurities – such as copper, cobalt, iron – appreciably and raised concentrate grade. Therefore, the decision was made to use the regrind-flotation process.