Table of Contents

These instruction sheets have been prepared in this form to take the place of mimeograph copies which were formerly used by students electing the course in fire assaying at the University of California. These notes are concise directions for the carrying out of certain laboratory work, and in no wise cover the ground of the lectures which supplement the instruction in the laboratory.

The purpose of the course is not to teach merely practical fire assaying, but also to familiarize the student with metallurgical principles which underlie smelting operations on the large scale; and in the lectures as much emphasis is placed on the underlying metallurgical principles as on the practical details of fire assaying.

The laboratory work is divided into twenty-five assignments, thirteen of which are intended to cover the work of the first half-year, and the remaining twelve, the work of the second half-year. In addition to the twelve assignments of the second half-year, there will be given, as time permits, assignments relating to the fire assays of mercury, tin, cobalt, and antimony, and the determination of carbon, sulphur, and ash in coal and coke.

ASSAYING LABORATORY REGULATIONS

Before commencing work, each student should be supplied with the following articles:

- Copy of Fulton’s Manual of Fire Assaying.

- Capsule-box containing six porcelain capsules, three un-glazed capsules, three Kennedy parting-flasks, three test tubes, needle and magnifier.

- Laboratory folder with centimetre-ruled paper, arranged for carbon copy.

- HHH lead pencil.

- Set of Becker (or equivalent) weights from 1 gram to 1/10 milligram.

- Pair of bone-tipped pincers.

- Pair of steel pincers.

- Pair of bead pliers.

- Blow-pipe.

- Laboratory suit.

Each student should report promptly for work at the appointed hour, and should stay the full laboratory period, unless excused.

All apparatus should be left in its proper place and in order.

Assay Sample Weighing

In this assignment you are expected to become thoroughly familiar with the construction, adjustment, use, and care of an assay balance. Read carefully all the references given at the end of this assignment.

An assay balance is similar to a chemical balance, except that the moving parts are made lighter, and instead of limiting the sensibility to .10 mg. it is made to weigh accurately to .01 mg. With the balance you use this is done entirely by the method of deflections. Later on you will be given a balance with a rider.

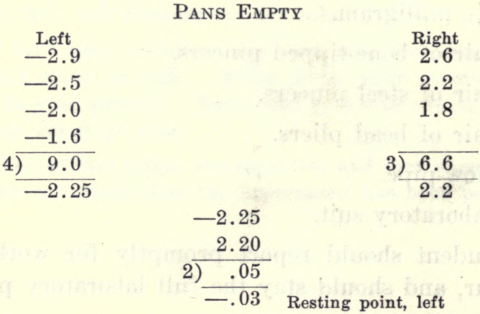

Calculate the sensibility of the balance assigned to use, as follows: After a couple of oscillations take readings, first on one side and then on the other—for example:

Repeat the readings until uniform results are obtained. If the resting points do not agree, increase the number of readings on a side. After a little practice, two readings on one side and one on the other will suffice.

In this assignment record all readings in your notes. After you have become skillful in reading, recording will not be necessary. In taking readings do not let the needle vibrate more than a total of five divisions.

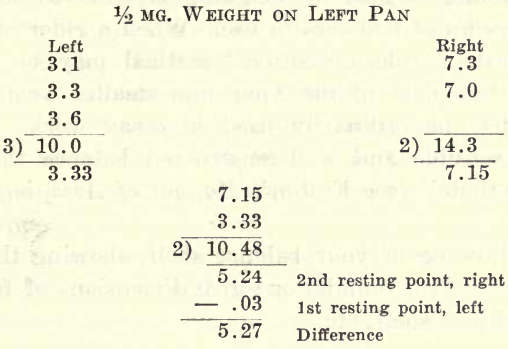

Now place your ½ mg. weight on the left pan, allow needle to swing as before, and determine the new resting-point—for example:

The difference between the two resting points is the number of divisions on the ivory index through which ½ mg. has caused the needle to be deflected.

The sensibility of a balance may be defined as the deflection caused by 1 mg.; or, expressed in another way, the sensibility is the weight in hundredths of a milligram which will cause the needle to be deflected one division on the index.

In the above example, the sensibility is 10.54 divisions, or .095 mg.

As you can readily read to tenths of a division, the balance will be sensible to .01 mg. Were the beam perfectly rigid, this sensibility would hold for much greater loads than are usually weighed on an assay balance; but for a load of even ½ grm. there is a perceptible change. To test this, place a load of 1 gram on each pan of the balance and determine the sensibility as you did when the load was zero. Compare results.

You are now ready to weigh by the deflection method. Obtain a number of pieces of gold or silver weighing from 1 to 10 mg. Weigh each separately and then all together. Add up the separate weights and compare with the total weight. Repeat until your results are consistent.

Make a full and complete record of your observations.

Before leaving the balance see that the beam is lowered and the case closed.

The foregoing method of weighing is specially adapted to the poorer grades of balances in use. “When a rider attachment is available, the “rider-deflection” method may be used, the rider taking the place of the 2 mg. and smaller weights. This method is the one ordinarily used in assay work. “With an exceedingly sensible and well-constructed balance the method of “no deflections” (see Fulton’s Manual of Assaying) may be used.

Make a drawing of your balance shelf, showing the method used to secure a firm foundation: give dimensions of foundation supports, width of shelf, etc.

Practice in Cupellation

A. Place half a dozen dry cupels in the muffle and build a fire in the usual manner. As coke is used for fuel, it is necessary to have a good coal fire started before adding the coke. Let the muffle heat up until a bright red is reached, then arrange the dampers so that the heat remains uniform. Before cupelling, see that the fire is solid around the muffle.

Now obtain six lead buttons, weighing approximately 15 grams each. Cupel in sets of two each in the following manner: Bring two of the cupels forward say within two inches of the front of the muffle. Place a lead button in each, using the cupel tongs, then shove the cupels back into the hotter part of the muffle. Close the muffle door for a few minutes. When the buttons have melted and cupellation has commenced, as shown by the fumes of litharge, open the door and arrange the dampers so that the fumes are drawn slowly off through the rear of the muffle. Try to keep the temperature constant, increasing it only when the lead has almost disappeared. The beat is too low when the fumes become heavy and dark, and a scum forms around the edge of the molten lead. The heat is too high when the fumes of litharge rise rapidly to the top of the muffle and the lead appears to be boiling. The heat is just right when crystals of litharge form in the cupel. Practice will enable you to fix upon the proper conditions.

Cupel the remaining four and as many more as you have time for during the period.

Make a full and complete record of your observations.

B. Roll out a silver coin to the thickness of an ordinary visiting card. Anneal the coin repeatedly during the operation. Clean with sandpaper. Now weigh out on your bead balance six assays of this coin, three weighing 25-30 mgs. each, and three weighing 90-100 mgs. each. Weigh each bead accurately. Wrap each assay in 15 grams of sheet lead, weighed approximately on the pulp balance. Arrange these six assays in sets of two each, so that each set will contain one 25-30 mg. assay and one 90-100 mg. assay. Cupel one set at a time, as in “A,” only using more care on account of the resulting silver bead. Try to feather the cupels and at the same time brighten the beads.

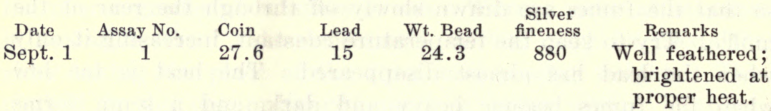

Remove the beads from the cupels and clean thoroughly by brushing. Place them in their respective capsules, and take to the balance room. Weigh, and report in this form:

The term silver fineness, as used above, refers to the number of parts of silver found in 1000 parts of the coin.

Compare the results, and note the average percentage silver losses for the 25-30 mg. assays and for the 90-100 mg. assays, taking into account, of course, the known fineness of the silver coin used.

Dissolve a piece of coin silver in nitric acid and test with ammonium hydroxid for copper; also test a well-brightened bead in the same manner. What deductions do you make ?

C. Obtain from the storeroom, six lead buttons or packets, having, respectively, the following compositions:

- Lead and silver.

- Lead, silver and gold.

- Lead, silver and antimony.

- Lead, silver and copper.

- Lead, silver and tin.

- Lead, silver and iron.

Cupel in sets of two each. Endeavor, in each case, to make a perfect cupellation. Observe, carefully, in each case, the heat, time and manner of brightening; observe the formation of any scoria, its color, etc.; note, in each case, the color and general appearance of the cupel after brightening.

Make a full and complete report.

Parting Gold and Silver

To be a successful assayer one must be able to part correctly and rapidly. Nicety of manipulation is required, and the only way to acquire this is to practice conscientiously. Do not take anything for granted. There are three steps in an assayer’s work where he must be sure, viz: (1) That the sample is what it represents; (2) that nothing but gold is weighed as such; (3) that the weighing is done accurately. With these points looked to carefully, the rest will be comparatively easy. Perform carefully the following experiments:

Weight out six pieces of gold foil on your bead balance to .01 mg.; each piece should contain about 5 mgs. Alloy the pieces of gold with 1, 2, 3, 4, 5, and 8 times their weight of silver, respectively. Weigh the silver also on your bead balance, to .10 mg. only.

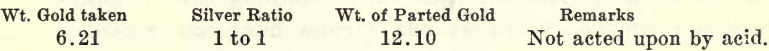

To alloy, wrap the gold and silver in about 1 grain of sheet lead and cupel in the muffle, taking care to have the cupel smooth, dry and hot. The muffle should be slightly hotter than for ordinary cupellation. After alloying remove the bead from the cupel by means of the bead plyers, brush thoroughly, and place in the porcelain capsule used for parting. Treat each of the five beads thus and remove to the parting room. Now flatten each bead, using the small blowpipe, hammer and anvil. Return them to their respective capsules, which should then be tilled with hot, weak parting acid; heat slowly on the hot plate, and when all action has ceased, replace the spent acid with strong acid and heat for three minutes at boiling point. Then remove from the plate, pour off the acid, and wash three times with distilled water (preferably warm). Dry over the hot plate, then anneal by heating to redness over the Bunsen flame. Cool and weigh. Report results in this form:

What do your experiments determine?

Describe minutely the action of the acid on the several beads.

Note.—Flatten all dore beads unless they are known to contain more than eight parts of silver.

Fire Assay of Lead Bullion

Chip or saw off four ½ A.T. samples from the bullion given you, and assay according to the directions given in Fulton’s Manual of Assaying.

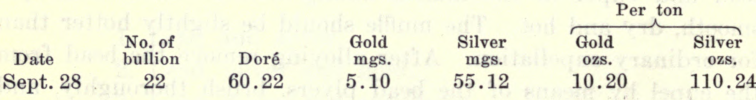

Report both gold and silver values in this form:

To get correct results in this assignment the cupellation must be done perfectly, so in a measure this assignment will test your ability to cupel.

Explain the term A.T.

Scorification

In this assignment you are expected to get a general idea of the scorification process as far as can be done by reading.

A brief outline of the work in scorification is given below:

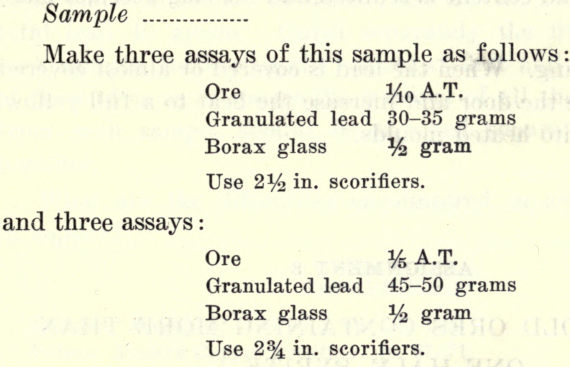

Scorification assay of silver ores

(а) Silver-lead ores.

(b) Those containing no lead, but quartz, metallic silver, and silver compounds.

A general charge for ores of the above class is:

Ore 1/10A.T.

Granulated lead 30-35 grams

Borax glass ½ gram

Use 2½ in. scorifiers.

This charge, with slight modifications, will treat any silver ore; if the ore contains more than 50 per cent of pyrite, the lead may be increased up to 45 grams. And if much lime, zinc or antimony is present, the borax glass must be increased up to as much as three grams in exceptional cases. Where the sample is rich and at the same time homogeneous the weight of the sample taken may be decreased to 1/20 A.T.

Scorification assay of rich gold ores

As will be noticed from your reading, the ” scorification assay ” is primarily adapted for silver ores and rich gold ores, for evident reasons. To get the required amount of sample for a medium or poor gold ore, it becomes necessary to make several scorifications and then scorify the resulting buttons together, or cupel separately and part together.

(a) Quartz gold ores consisting largely of quartz.—The charge given for silver ores can be used equally well for quartz gold ores containing less than 50 per cent pyrite, though in most cases it is better to take more than 1/10 A.T. and consequently more lead and a larger scorifier if necessary.

When 1/10 A.T. of ore is used 30 grams are sufficient, and with 1/5 A.T. 50 grams of lead had better be used.

(b) Quartz-pyrite gold ores consisting largely of pyrite.— Owing to the large amount of lead required to scorify ores of this class, it is impracticable to use more than 1/10 A.T. of ore in one scorifier, so to accomplish the same result it becomes necessary to unite the lead buttons as suggested above.

The usual charge is :

Ore 1/10 A.T.

Granulated lead 40-45 grams

Borax glass ½ gram.

Scorification assay of samples containing large % of copper

In samples of this class it is necessary to use a small amount of ore and at the same time a large amount of lead; this is due to the retention of copper in the lead and the difficulty in removing it unless a sufficient amount of lead is used. If any great amount of copper is retained in the lead button, a high heat will be necessary to remove it during cupellation. This will produce a high loss in silver value; so it is almost imperative to add enough lead during scorification to insure the removal of the copper, when the silver loss will be small in comparison.

The usual charge is:

Ore 1/10 or 1/20 A.T.

Granulated lead 45 or 50 grams

Silica and borax.

Scorification assay fusible with difficulty

Ores containing tin, zinc or antimony will come under this head. A large amount of borax glass and a high heat are necessary.

Scorification Assay of Silver Ores

Preparation of the charge:

On all assays the following method of selecting the portion of ore to be assayed (assuming that the sample is correct and ground to pass a 100-mesh, or finer, sieve) should be rigidly followed. If there be any doubt as to the uniformity of the sample, pour out on a piece of glazed paper and remix, then replace the sample in the bottle or bag. Assay charges are then to be taken direct from the bottle or bag by means of a spatula.

Consult your lecture notes for an explanation of this method of selecting the portion of ore to be assayed.

Copper spoons are provided for measuring the granulated lead.

Measure one-half the lead required into the scorifier, add the ore, mix with the spatula, spread the remaining half of the lead over the charge, and sprinkle with borax glass over all.

Sample……………………………A silver-lead ore.

Prepare six charges as follows:

Ore 1/10 A.T.

Granulated lead 30-35 grams

Borax glass ½ gram

Use 2½ in. scorifiers.

Make the six scorifications at one time in the muffle assigned to you. Have the muffle at a bright red before placing the charges in it; when the charges are in, close the muffle door. In a few minutes draw the door aside slightly, and if the lead is melted, remove the door completely and arrange the drafts so that there will be a strong current of air through the muffle. During the scorification the heat should be maintained at a medium orange, or a little above a good heat for cupelling. Increase toward the end to a full yellow. As soon as the “bull’s eye” has disappeared, pour into a warmed scorification mould. When all the charges have been removed from the mufille, place six cupels in so they may be ignited by the time the buttons are slagged and ready for cupelling.

Cupel the six buttons at one time, feathering them all. Weigh each bead separately; part the beads together in sets of three in Kennedy parting flasks, and weigh the gold.

Sample……………………………………….A silver ore containing a quartzose gangue.

Sample……………………………………….A quartz-silver ore.

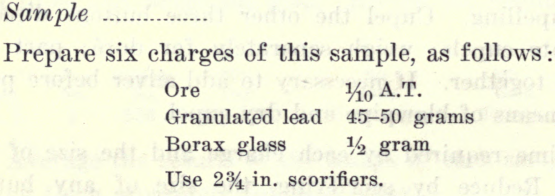

Prepare six charges of this sample, each as follows:

Ore 1/10 A.T.

Granulated lead 30-33 grams

Borax glass ½ gram

Use 2½ in. scorifiers.

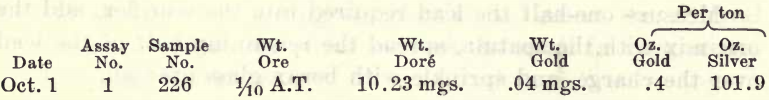

Cupel the six buttons at one time, feathering them all. Weigh each bead separately; part the beads together in sets of three in test tubes and weigh the gold. Record the results in this form:

Average the results of the assays of each sample after calculating them separately for each assay.

Under remarks give composition of the ore, manner of scorifying and cupelling.

If there is any reason to doubt the accuracy of the assay the results should never, under any circumstances, be accepted.

Describe in your notes the appearance of the scorifiers and the character of the lead buttons. Weigh out 1/10 A.T. of the ore and wash on a batea, making yourself familiar with the constituent minerals and the approximate percentage of each. Use the blowpipe if necessary. Make a detailed report in your notes.

Follow the above directions in all future assignments.

Quartz-Gold Ores Containing Less Than One-Half Pyrite

Unite the three buttons from the first charge by re-scorification before cupelling. Cupel the other three buttons directly and in separate cupels; weigh separately for dore; part one alone and two together. If necessary to add silver before parting, alloy by means of blowpipe and dry cupel.

Note the time required by each charge and the size of the lead button. Reduce by scorifying, the size of any button weighing over 20 grams. Observe the following periods in scorification of sulphide ores (consult your lecture notes) :

- Melting. Have muffle at a low yellow heat. Introduce the scorifier and close the muffle door.

- Roasting. When the charges have thoroughly melted, open the door carefully and allow as much air as possible to pass through the muffle; if they begin to bubble, close the door so as to decrease the air supply. The heat during the roasting period should be kept at about a medium orange. A high heat will cause mechanical loss by too rapid oxidation.

- Fusion, or formation of the “bull’s eye.” When the roasting has ceased, close the door and fuse down the charge thoroughly.

- Scorification. When the charge has thoroughly fused, as shown by the formation of the “bull’s eye,” open the door and allow a good current of air to pass through the muffle. During this period the lead content is reduced and the slag becomes more fluid.

- Final heating. When the lead is covered or almost covered by the slag, close the door and increase the heat to a full yellow, and then pour into heated moulds.

Quartz-Gold Ores containing more than One-Half Pyrite

Scorify as directed in previous assignment; cupel separately, feathering carefully. Clean the beads carefully, combine in sets of three, weigh and part; weigh again. Report both gold and silver.

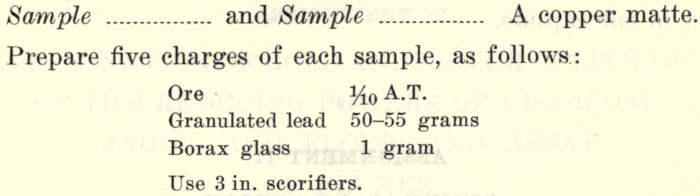

Scorification Assay of Samples High in Copper

For copper matte add 1 gram of silica with borax glass. Control the furnace as in assaying ores rich in pyrite. Buttons from matte must be rescorified; use 2½ in. scorifiers and have total lead 40 grams. Cupel separately the five, buttons from each sample, feathering the cupels at first and raising the heat at the end so as to ensure the removal of all the copper. Beads from each sample should be weighed separately, but parted together.

What are the difficulties encountered in assaying ores rich in copper?

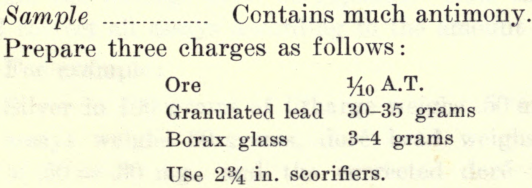

Scorification Assay of Ores Fusible with Difficulty

Scorify in the usual manner except at the end, when the heat must be raised to a full yellow. The buttons should be perfectly malleable; if they are not, rescorify with an addition of test lead. Cupel, feathering carefully; weigh the beads separately. Part in one capsule.

General Practice

Take the sample given you and reduce by methods suggested until you have at least two pounds passing a 100 mesh sieve; bottle this and keep for assay.

In this assignment you will be given three or more ores, in addition to the one sampled. You are to determine their composition and then decide on charge you would use for assay by scorification method.

Make a detailed report, indicating the composition of each sample, the charge used, etc. Give both gold and silver values.

Crucible Assays

Determination of Gold and Silver in Litharge

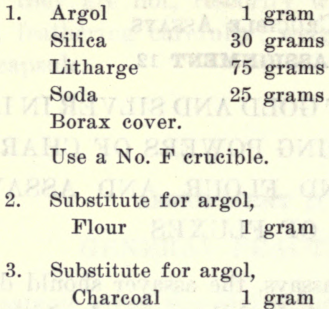

Reducing Powers of Charcoal, Argol, Flour, & Assay of Fluxes

Before making any assays, the assayer should determine the precious metal content of the litharge used. Litharge containing more than a trace of gold should be rejected. The presence of a small but uniform amount of silver is rather an advantage than otherwise, as the silver serves to help collect the gold.

The assayer must also determine the reducing powers of the various reducing agents; and an assay of all the reagents used should be made in order to detect any “salting” of the fluxes.

First. To determine the precious metal content, of the litharge, prepare two charges as follows:

Litharge 100 grams

Argol 2 grams

Salt cover.

Use a No. 7 crucible.

To one charge, add a small amount of test silver. Fuse quickly both charges in a hot fire until thoroughly liquid, then withdraw and pour; cupel the resulting buttons. Determine gold and silver by weighing the unalloyed bead for the dore, and parting the other for gold. If more than a trace of gold is found, the litharge must be rejected. Note the silver content, and correct all assays according to the amount of litharge used.

For example:

Silver in 100 grams of litharge weighs .50 mg., litharge used in assays weighs 60 grams, dore bead weighs 2.24 mg., then .60 x .50 = .30 mg., and the corrected dore is 2.24 — .30, or 1.94 mg.

Second. To determine the reducing powers of the reducing agents, argol, flour and charcoal, prepare charges as follows:

Reducing agents, only, should be weighed carefully. Fuse, at one time, the above charges; when quiet, pour into clean, warm slag moulds. Clean and weigh the resulting lead buttons. Weigh, using pulp scales, to the nearest 10 mg.

Note that the above determinations are made under normal working conditions.

Third. To make an assay of the fluxes used, prepare one charge, as follows:

Silica 30 grams

Litharge 75 grams

Soda 25 grams

Borax glass 5 grams

Reducer for 18-gram button.

Salt and Borax cover.

Use a No. F crucible.

Add a weighed amount of test silver to the charge, and fuse in the usual way Determine gold and silver, if any.

Quartz Ores

In ores of this class are included only those whose principal constituent is quartz, with the addition of 0-15 per cent of iron pyrites. Any exception will be noted below. The following charge will treat any ore of this class:

Ore 1 A.T.

Litharge 75 grams

Soda 25 grams

Borax glass 5 grams

Salt, borax glass, or ground borax cover.

Reducer, preferably flour, to reduce 18-22 gram button.

Observe first, that 1 A.T. of ore is used. This is the standard amount for ordinary crucible assays. When the ore is rich in gold it is advisable to take less, say ½ or ¼ A.T.; when the ore is poor in gold, as in stamp mill tailings, it may be advisable to take as much as 4 A.T.

The amount of litharge in a charge for ore of this character should be such that every particle of the ore is oxidized. For an ore containing minimum amount of pyrites, 60 grams of litharge will suffice. Any great excess is to be guarded against, as the crucible is apt to be corroded and the assay lost.

The third element of the charge is soda (sodium carbonate) ; this flux is used in every crucible assay. To some extent it may replace the litharge; so that if the soda in the above charge is increased, the litharge can be decreased, thereby making a more economical charge, although the slag would not be so clear.

Borax as borax glass is a most useful flux. If the ore to be treated contains, besides the quartz, any great amount of infusible oxides, the borax may be increased up to 20 grams.

A cover of salt or borax (hydrous) should be used on all assays; it acts as a wash and prevents an overflow.

Sufficient reducer should be used to produce an 18-25 gram lead button. If the ore is oxidizing, several grams of reducer may be necessary. If the ore contains more than about 10 per cent pyrites and no oxidizing agent, reducer will be at a minimum and a small amount of oxidizer as nitre may be necessary. An ore containing more than about 15 per cent pyrites cannot be properly treated by this charge.

Other reducing agents which may be used instead of flour are argol, charcoal or sugar.

Prepare three charges of Sample, using the charge given before and an F crucible. This sample consists mainly of quartz with less than 5 per cent of sulphides of iron, lead and copper, and reduces grams of lead per one assay ton of ore.

Unless the proportion of silver to gold in an ore is known to be at least five to one, test silver should be added to all charges except one. Weigh the test silver added to one of the charges.

This illustrates three methods of working, and we have two checks on the gold and two on the silver. The amount of silver in the litharge will of course be deducted from the weight of the dore.

On one charge use a salt cover, on the others a borax cover.

Heat the charge until in quiet fusion, then increase the heat to low yellow for about five minutes, or until the charge, becomes smooth on top. Pour into clean, warm slag moulds, and when cool break away the lead button; clean, hammer into cubes, and then cupel in the usual manner.

Report results in the following form:

Under remarks indicate everything that has a bearing upon the results. Describe the appearance of slag, buttons, etc. Which cover do you prefer, and why ?

Make a vanning test of the ore, using about 1/10 A.T. of ore and a batea. Report this test also.

If necessary to use ½ A.T. of ore or to make the fusions in a muffle, the following charge will be found suitable:

Ore ½ A.T.

Litharge 60 grams

Soda 20 grams

Borax glass 5 grams

Reducer to give a 20-gram button.

Ground borax cover.

Use a No. F crucible.

Prepare two charges of Sample , using the above charge. Add a weighed amount of test silver to one charge, and an unweighed amount of test silver to the other. Make the usual tests, and fuse as before.

To mix any charge, put the soda into the crucible first, then the litharge and other fluxes, lastly the ore, and mix all together with a fork; sprinkle salt or borax over the top. Make certain the ore and fluxes are thoroughly mixed.

Nitre Assay for Ores Containing Moderate Amounts of Pyrite

Ores of this class are usually richer in gold and silver than those of the previous class, and consequently less material may be taken in assaying them.

The following charge will be found suitable for ores of this class:

Ore ½ A.T.

Litharge 90 grams

Soda 20 grams

Silica 10 grams

Borax glass 5 grams

Nitre according to preliminary.

Cover.

Use a No. 7 fluxing pot.

Fusion of the charges should be carried on as before.

Calculate the amount of nitre (see below) to add so that a 20-gram button will be produced from ½ A.T. of ore.

Make three assays of Sample, using the charge given above. Sample contains about sulphides.

Add test silver to all charges but one. Before commencing work on this assignment, be sure that the previous one is thoroughly understood.

The reducing agents which are commonly present in ores are antimony, zinc, arsenic and sulphur. Iron pyrites, the sulphide commonly met with, reduces as follows:

Fifteen per cent of pyrite will reduce about nineteen grams of lead, and there will be no excess. More than 15 per cent of pyrite, using ½ A.T. of ore, will reduce too large a lead button. Nitre, an oxidizer, is used to control the size of the lead button, and is usually stated in terms of lead; that is, one gram of nitre oxidizes four grams of lead, more or less, according to conditions.

In order to know how much nitre to add, so as to reduce, within a few grams, a 20-gram lead button, we must determine, or guess correctly the amount of lead which will be reduced before making an assay.

The reducing power of a sample may be determined by making a preliminary, thus:

Sample 1/20 A.T.

Litharge 75 grams

Salt cover.

Use a No. 7 fluxing pot.

Have the fire hot when the charge is put in, and fuse quickly; when in quiet fusion, remove, and pour. Clean and weigh the button.

Calculate the amount of nitre which must be used on a basis of one gram of nitre to four grams of lead.

In preparing charge of Sample , add to one charge ½, gram more nitre and to the other ½ gram less nitre than the calculated amount. Weigh the resulting lead buttons, and calculate the oxidizing power of nitre under these conditions. Compare this result with the amount used above.

Nitre Assay for Ores Containing Large Amounts of Pyrite

Material of composition as indicated above, is in general, assayed in the same way as that of the previous assignment. The increase in the amount of iron pyrites calls for an increase of litharge to complete the oxidation; and as the amount of silica in the ore is decreased and the charge becomes more basic, more acid in the form of silica or window-glass must be added.

The following charge will suffice:

Ore ½ A.T.

Litharge 120 grams

Soda 20 grams

Silica 15 grams

Borax glass 10 grams

Nitre according to preliminary.

Salt or Borax cover.

Use a No. F or 30-gram crucible.

Calculate for 20 gram button.

When the material to be assayed is a pure concentrate or nearly so, the amount of nitre to be added can usually be placed at about 25 grams for ½ A.T. of ore. For material of unknown percentage of pyrites, a preliminary assay must be made.

In general, ores of this type are richer than the type treated in Assignment 14, and a smaller amount of ore can be assayed, thus effecting a saving in time and fluxes; when a sensitive balance is available and the values are uniformly distributed, the results obtained by using a smaller amount, ¼ A.T., will be even more accurate than those from ½ A.T.

The following charge will do when ¼ A.T. is used:

Ore ¼ A.T.

Litharge 75 grams

Soda 15 grams

Silica 5 grams

Borax glass 5 grams

Nitre according to preliminary.

Salt or Borax cover.

Use a 20-gram crucible.

Calculate for 16-20 gram button.

The ore to be assayed in this assignment is a concentrate obtained from one of our mill runs, and is a typical coneentrate.

Prepare three charges of Sample using ½ A.T., and three using ¼ A.T.

Time required for fusion about thirty minutes, ten minutes yellow heat at the end. Avoid heating too rapidly, as a sudden, uneven heating may cause the assay to boil over.

Report the mean of the several assays as the correct value, first discarding any assay that appears to have been abnormal in any manner.

Roasting Method for Ores Containing Large Amounts of Pyrite

Obtain two 4-inch roasting dishes with covers. Line each dish thoroughly by rubbing a blackboard crayon over its interior.

Weigh out ½ A.T. of Sample into each dish. Place the dishes, covered, in the muffle, which should be heated to low redness only around the edges and corners. The material to be roasted should be spread out in the roasting dishes and ridged across, so as to expose as much surface as possible to the air. After one-half hour, take out the roasts, letting them cool a little before removing the covers; then turn the ore over with a wire provided for the purpose, leaving it spread about and ridged, as before. Return the dishes, without covers, to the muffle, if the heat is still low. After one-half hour take out and stir again. Continue this treatment, gradually increasing the heat, till no odor of sulphur dioxide is perceived on stirring. Finally, increase the heat to a bright red for about ten minutes, to decompose any iron sulphate which may have formed.

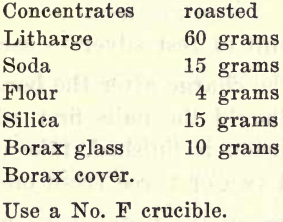

Smelt the roasted concentrate with this charge:

After the concentrates have been transferred to the crucible, the roasting dish should be “dry-washed” out with a little soda, which is added to the charge.

Compare results with those obtained from the nitre assay.

Assay of Sulphide Ores by the “Nail Method”

The “nail method” is adapted to gold ores containing varying amounts of sulphides, although it may with certain modifications be applied to all gold ores. Ores containing appreciable amounts of arsenic and antimony cannot be assayed by this method, with this exception: arsenic frequently occurs in vanner concentrates and may then be removed in the first stages of the assay by oxidation with nitre, part of the sulphur being oxidized at the same time.

In general, gold values will be higher by this method and silver values lower.

Prepare two charges of Sample as follows :

Ore ½ A.T.

Litharge 30 grams

Flour 2.5 grams

Soda 45 grams

Salt or borax cover.

Three twenty-penny nails.

Use a No. F crucible.

Add a weighed amount of test silver to each charge.

Stick the nails into the charge after the borax cover has been added, points down. Should the nails first added be eaten up by the charge before fusion is finished, take out what remains of the old ones and add two or three fresh ones.

First fuse the charges in the usual way; when foaming has ceased, give a very bright yellow heat for ten or fifteen minutes, continuing the heating until, on removing the nails and rinsing them in the slag, they are seen to be free from adhering globules of lead.

Prepare one charge of Sample as directed for Sample, except add 5 grams SiO2, and add no test silver.

Prepare two charges of Sample as follows:

Ore ½ A.T.

Litharge 25 grams

Soda 45 grams

Borax glass 10 grams

Silica 15 grams

Five twenty-penny nails.

Salt or borax cover.

Use a No. F crucible.

Make the fusion as instructed before.

When arsenic is present it is well to omit the nails, add 10 to 20 grams of nitre, and “boil down” the charge; then add the nails and finish at a high heat as usual.

In each of the above cases compare results with those obtained from the litharge assay.

What do your results indicate ?

In what way is the nail assay convenient ?

Assay of Tailings

Mine samples usually consist of one or all of the following: quartz, quartz and varying amounts of sulphides, concentrates and tailings. You have had practice in assaying all the above except the last. Tailings are composed (i.e., stamp-mill tailings) mainly of quartz. No sulphide should be present.

It is often necessary to determine values in tailings as close as five cents per ton. This would require 4-5 A.T. to be taken at one time, or a number of smaller charges, and the resulting buttons combined. In the latter case 5-8 gram buttons could be reduced and cupellation effected without previous scorification.

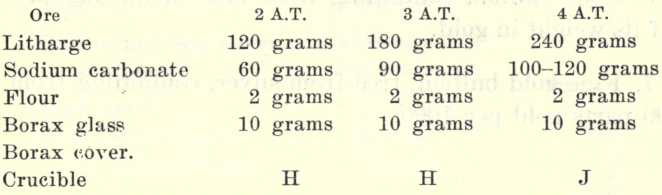

The following charges can be used to advantage:

Sample Prepare three charges, using 2 A.T., 3 A.T. and 4 A.T. Add one or two mgs. of silver to each charge.

Report in the usual way.

Bullion Assays

Bullion, in general, is classified as follows:

- Lead bullion, usually the product of the lead blast-furnace; 95 per cent and more lead, containing some copper, antimony, etc., silver and gold.

- Base bullion, containing from 100 to 925 parts of silver per 1000, gold in varying amounts, and a large percentage of base metals, chiefly copper, zinc, lead, etc. Produced most frequently by cyanide mills.

- Dore bullion, containing 925 to 990 parts of silver per 1000, some gold, and base metals, mostly copper, but also lead, antimony, zinc, etc.

- Fine silver bullion, free from gold, containing 990 to 1000 parts silver per 1000, but some base metals, usually copper.

- Silver bullion, containing little base metal and less than half its weight in gold.

- Gold bullion, containing little base metal and more than half its weight in gold.

- Fine gold bullion, free from silver, containing from 990 to 1000 parts gold per 1000.

You have had practice in assaying lead bullion (see Assignment 4). Gold bullion and fine gold bullion may be considered under a general case; likewise base bullion, dore bullion, fine silver bullion, and silver bullion.

Assay of Gold Bullion

The bullion that you are to assay in this assignment is made to represent as closely as possible that which comes from California mines.

The Preliminary.—In this class of bullion an expert can tell with sufficient exactness the fineness of a particular sample and so can alloy in the proportion of 2½ to 1, without making a preliminary survey. Ordinarily the base metal fineness is not taken into account, a small amount of copper being added to the proof center to prevent sprouting, and to toughen the head. But, for the general case, and for completeness, a preliminary assay must be made in order to determine the approximate fineness of gold, silver and base.

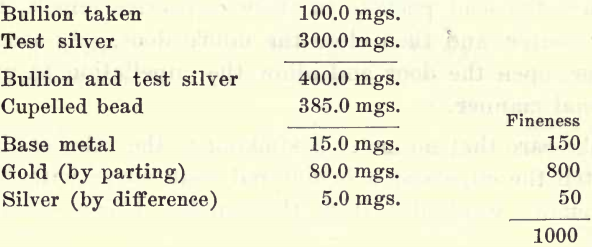

Weigh out 90-100 mgs. of the bullion given you; also 300 mgs. of test silver; wrap silver and bullion together in 3 grams of sheet lead, and cupel at a little above the feathering point. Brighten well; clean, and part the bead.

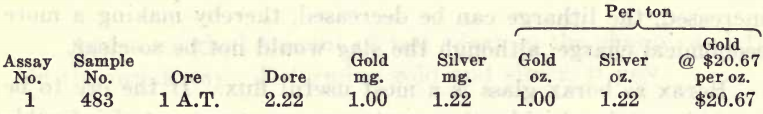

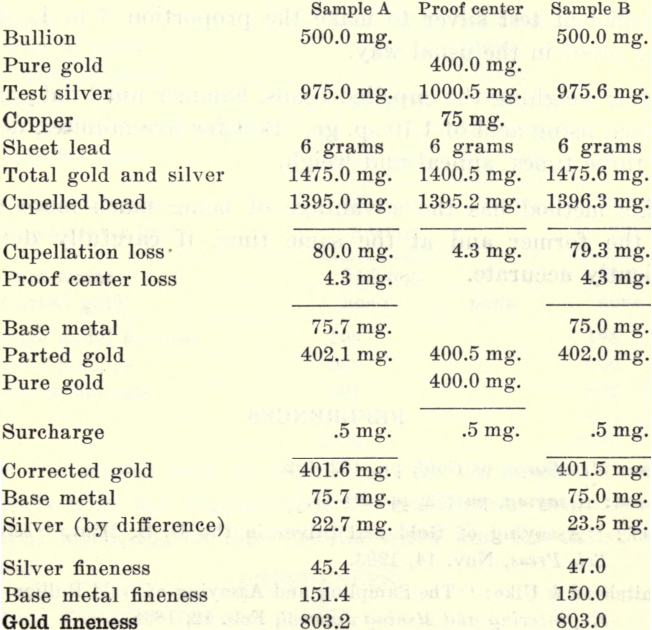

Report the results according to the following example:

These, results should be corrected by adding 15-20 points to the silver fineness and substracting the same amount from the base metal fineness. This is to allow for silver lost during cupellation.

Having determined the approximate fineness of the bullion given you, weigh out two samples of 500 mgs. each (within .05 mgs.); also weigh out test silver (within .10 mgs.) so that the ratio of silver to gold will be 2½ to 1.

Make a proof center of pure gold, silver and copper to correspond with the regular samples.

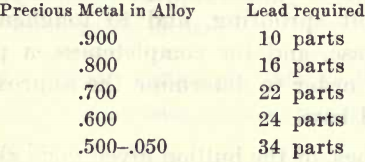

Wrap each sample in 6 grams of sheet lead, or as many as the following table calls for. For bullion containing over 900 points of precious metal 5 grams of lead are sufficient to remove all the base metal. The following table is valuable for determining the least amount of lead to use:

Cupellation

Before introducing the samples into the muffle, have the temperature at a bright red (higher than for ordinary cupellation), and the cupels, which should be smooth, hot.

Place the lead packets in their respective cupels, the proof in the center, and then close the muffle door. As soon as they uncover, open the door and allow the cupellation to proceed in the usual manner.

Take care that no metal is sticking to the sides of the cupels. Brighten the cupels at a bright red heat, cover with hot cupels and remove gradually from the muffle. Clean carefully and weigh.

Now hammer the beads into the shape of a rectangular bar, then roll out to the thickness of an ordinary visiting card by means of the rolls; or in the absence of rolls, hammering will do In rolling, anneal the alloy whenever it becomes hard and elastic and before it begins to get rough on the edges. The three beads should be of the same thickness after rolling. Great care should be taken to prevent mechanical loss.

Parting

Clean thoroughly three matrass flasks. Place 2 ozs. of 1.16 sp. gr. nitric acid in each; now introduce the flattened and annealed beads, first rolling them into a spiral coil, and heat to boiling.

Boil gently until action ceases (ten to fifteen minutes), then pour off the spent acid and add 2 ozs. of strong acid (1.26 sp. gr.). Boil gently with this acid for fifteen to twenty minutes. Place a piece of charcoal or burnt brick in each flask to prevent bumping. Pour off this acid and wash the gold three times in hot water. Transfer to annealing cups and anneal.

Weigh the gold carefully; and record the results according to the following example:

Remarks.—Gold results should agree within ¼ point. Silver results will depend on the care used in cupellation, as will the base metal fineness. Surcharge is the difference between gold lost during cupellation and parting (gold may be lost by volatilization, cupel absorption, or solution in the acid) and the amount of silver retained in the parted. It is generally positive. A negative surcharge is to be regarded with suspicion.

In order to get precise results it is necessary to have pure gold for the proof; parted gold from previous assays will do, but then an arbitrary surcharge will have to be used, say ¼ to 1 point.

When rolls cannot be obtained, the gold bullion assay may be made as follows:

- Make a preliminary assay as usual.

- Weigh out 250 mgs. of bullion, instead of 500 mgs., and add sufficient test silver to make the proportion 3 to 1. Make up the proof in the usual way.

After weighing the cupelled beads, hammer until flat; anneal and part, using acid of 1.10 sp. gr. Boil for five minutes, decant, wash three times, anneal and weigh.

This method has the advantage of being much more rapid than the former and at the same time, if carefully done, is sufficiently accurate.

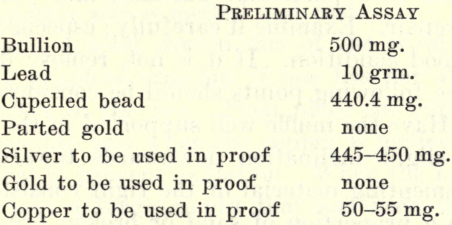

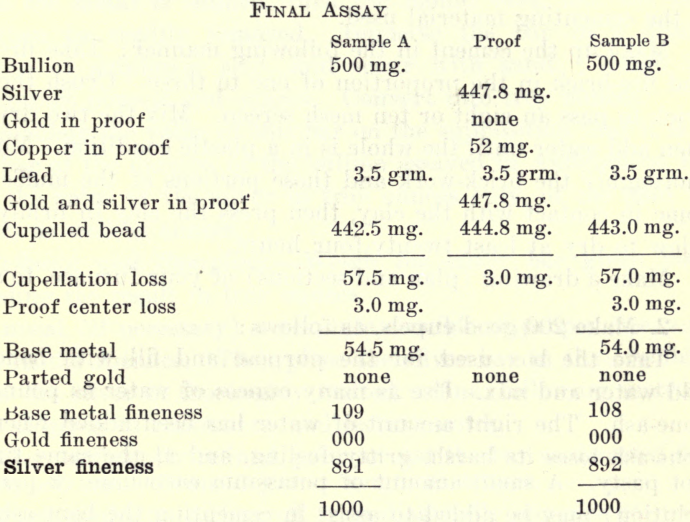

Fire Assay of Silver Bullion

Make an assay of the sample of silver bullion obtained in Assignment 22, following the directions given in Fulton’s Manual of Assaying.

Record results according to the following example:

Use the utmost care in cupelling. Do not neglect to cover the cupels with hot cupels when the beads have brightened; a bead that has sprouted must be discarded and the entire assay repeated.

Fire Assay of Lead Ores

Lead assays are usually made in the muffle; but, in the absence of such, a wind furnace may be used. The muffle is to be preferred because the heat can be more uniformly controlled, and there is less danger of loss by volatilization.

All our lead assays will be made in the muffle furnace.

The fire assays of lead ores may be placed under three heads, according to the kind and proportion of flux used:

- Fusion with sodium bicarbonate, borax, argol, and iron.

- Fusion with mixture of sodium bicarbonate and potassium carbonate, borax, argol, and iron.

- Fusion with potassium cyanide.

Sample Pure assayers’ litharge.

Prepare three charges as follows:

Ore 10 grams

Lead flux 35 grams

Salt cover.

Use Battersea P crucibles.

Manage heats as directed below; pour into scorification moulds.

Clean buttons by brushing and hammering. Weigh on pulp balance to .01 gram. Report to .10 per cent.

Sample Pure Galena

Prepare three charges as before, with the addition of four nails to each crucible, and five grams of borax glass on top of each charge before salt cover.

Assay Sample in the same manner.

Your results should check to within .5 per cent. Write your notes carefully.

The lead flux is a mixture of sodium bicarbonate (12 parts) potassium carbonate (12 parts), argol (3 parts).

The first method should be used only when potassium carbonate cannot be procured. The third should be used only on pure ores. The second is preferable in all cases.

Heats

The fusions are best managed by giving a low heat for about twenty minutes and then a high heat to finish. This is necessary for two reasons: (1) Lead and its compounds are volatile; and if the heat is so high that boiling takes place violently, some lead is almost certain to be lost. (2) Lead forms a double sulphide with sodium; and to reduce this by means of iron, a high heat is necessary.

The nails should not be removed until entirely free from lead.

Fusion with cyanide requires a very low heat.

Furnace Repairs

You are assigned to a particular furnace, and you are expected to keep it in repair. Examine it carefully; especially see that the muffle is in good condition. If it is not, remove it and put in a new one. The following points should be considered in placing a new muffle: Have the muffle well supported in the back and front, give it a slight inclination downwards toward the front, and have the cementing material of the right consistency. Fire-clay with a certain proportion of sand or broken fire-brick is the cementing material used.

Make up the cement in the following manner: Take fire-clay and fire-brick in the proportion of one to three. Crush the fire-brick to pass an eight or ten mesh screen. Mix the two dry and then add water until the whole is in a plastic condition. Moisten thoroughly the brick-work and those portions of the muffle that come in contact with the clay, then press the clay in firmly and allow to dry at least twenty-four hours.

Make a drawing (plan and sections) of your furnace, to scale.

Melting, Refining and Sampling of Gold and Silver Bullion

Melting

The object of this experiment is to make you familiar with some of the conditions under which a gold bar of moderate size is melted and cast.

Build a solid fire in one of the wind furnaces. Anneal a No. 12 graphite crucible, if one has not already been annealed, and place in the fire. Then place the copper bar given you in the crucible, and when the copper is melted cover with powdered charcoal to prevent oxidation. When the metal is perfectly fluid, pour into a large mould that has been first heated and oiled. When the metal is solified, turn the mould over, and the bar can then be readily removed. Immerse the bar in a dilute solution of sulphuric acid, and scour with sand. Weigh in avoirdupois pounds and ounces. Convert into troy ounces.

Calculate the value of this bar on the supposition that it is a gold bar of the fineness of the bullion assayed in Assignment 19. Give the value of the silver in troy ounces only, of the gold in dollars as well as ounces.

Refining and Sampling

Weigh the silver bar given you, recording the result in troy ounces.

Anneal (if necessary) a graphite crucible of proper size, and place in the furnace. Then place the silver bar in the crucible. When the silver is thoroughly melted, refine, following instructions as given in references, and lecture notes.

When sufficiently refined, pour or cast the bar as directed for the copper bar. Clean, dry and weigh, as before.

Take samples by cutting off from diagonally opposite corners, two or three grams of metal. Keep these samples separate. Assay as directed in Assignment 20. Reweigh the bar. Make detailed report.

Comparison of Methods for Assay of Copper Ores and Copper-Bearing Materials

Scorification

The standard charge for the assay of copper ores and copper bearing material by the scorification method is as follows:

Ore 1/10 A.T. to 1/20 A.T.

Granulated lead 50 grams

Borax glass 1 gram

Silica 1 gram

Use 3 in. scorifiers.

Re-scorify lead buttons, using 2½ inch scorifiers and enough test lead to make total weight of lead not less than 35 grams. When the ore or copper-bearing material is poor in copper the silica and re-scorification may be omitted. As many assays may be run as are necessary to give accurate results.

Cupel and slag corrections, either or both, are sometimes required and may be made as follows:

The cupels are taken in lots of two each, the unused portion discarded, the remainder crushed to pass 100 mesh, and fused with 100 grams of litharge, 20 grams sodium carbonate, 40 grams borax glass, and 3 grams of argol.

The slag is merely ground to pass 100 mesh, and fused with the addition of, say, 40 grams of litharge, 20 grams of sodium carbonate and 3 grams of argol.

In both cases the resulting lead buttons are cupelled and the silver and gold obtained added to the first weights.

Crucible

A standard method for the assay of the above by the crucible method is as follows:

Ore 1/10 to 2/10 A.T.

Litharge 80 grams

Silica 12 grams

Sod. Carb. 16 grams

Boiax glass 12 grams

Reducer or oxidizer for a 20 gram button.

Use a No. F crucible.

For ores or other material containing less than 40 per cent copper, the amount used for assay may he increased up to ½ A.T. Some or all of the silica may be omitted.

Prepare eight charges of Sample, a copper matte rich in copper, according to the methods already outlined, four by scorification and four by crucible fusion. Use proper precautions in melting and cupellation.

Make a tabular report, showing comparative losses, etc.

Best Practice in Sampling, Panning and Amalgamating

Best Sampling Practice

Take the sample of ore given you, weigh, and then reduce in size (weight and mesh) by approved methods. Your assay sample should weigh at least ½ lb. and should pass at least a 100-mesh screen. Take care that all scales pass the screens used.

Reserve all discarded ore passing the 40-mesh screen and keep for the panning and amalgamating experiments.

Amalgamating

Weigh out five charges (100 grams each) of the 40-mesh lot, and place in bottles provided for the purpose with mercury (10 grams), and 150 c.c. of water; and agitate for thirty minutes. Separate the mercury by panning (see below) and transfer to a porcelain dish, dry with filter or blotting paper. Place the thoroughly dry mercury in a 20 gram or F crucible in which 20 grams of lead have been placed. Add to the crucible a charge consisting of 30 grams of litharge, 10 grams of soda, 5 grams of borax glass, and 0.5 grams of argol, and silver enough to part the gold.

Fuse, the charge very slowly, starting with a slow fire in the wind furnace or if using a muffle, one that has not yet become red and has a good draught through it to prevent the escape of fumes into the room. When fusion is quiet, pour and cupel the resulting lead button. Part and weigh the gold.

Best Panning Method

The contents of the bottles are to be panned separately and then together. Pour the contents of one bottle into a gold pan, add water if necessary, and wash by giving the pan a vibratory motion as in vanning, washing off the light particles of gangue and leaving only the mercury and the heavy portion of the ore, as black sand, sulphides, etc. The light portion of the ore should be washed into a pan or vessel of somewhat larger size than the gold pan. Repeat the panning of the mercury and concentrates in order to separate, the mercury. If the mercury is floured, add a small globule of liquid sodium amalgam.

Treat the contents of the other bottles in the same way. The light portion or tailings of the several bottles may be poured into the same vessel. Re-pan this material to make sure that no mercury or sulphides have escaped. If any is recovered, add to the amount recovered before.

Treat the collected mercury as directed above (see amalgamating).

Allow the tailings to settle, pour off the surplus water, and dry by any convenient means. When dry, weigh, pass through a 100-mesh screen, mix well and assay.

Wash the heavy material or concentrates into a small porcelain pan, or if more convenient on to a batea. Examine under a magnifying glass or low power microscope, and note the different kinds of sulphides or other constituent, and the approximate amount of each.

Dry, weigh, crush to pass a 100-mesh screen, and assay.

From your results calculate the following:

- Assay value of ore in ounces, and dollars and cents per ton.

- Gold amalgamated in ounces, and dollars and cents per ton.

- Assay value of concentrates in ounces, and dollars and cents per ton.

- Assay value of tailings in ounces, and dollars and cents per ton.

- Percentage of gold amalgamated.

- Total gold contents in comparison with assay value.

- Percentage and different kinds of sulphides or other heavy material.