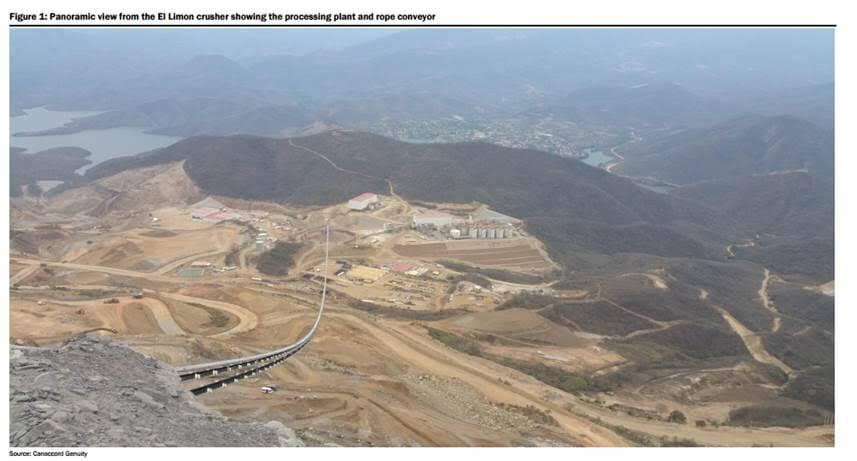

Rope Conveyor

Gold and Silver Metallurgy Technology

An ore may be treated experimentally with cyanide solution and 90 per cent, of the gold or silver dissolved. This may be quoted as an extraction of 90 per cent., but it is preferable not to do so, since it is, at best, only an experimental extraction; and by no parallel method of operation in […]

Diagonal Plane Shaking Table Design

Recent experiments indicate that the usual type of gold concentrating-table is not only poorly adapted to produce the desired results, but also is based upon an incorrect principle, namely, the use of riffles to perform the work of stratifying the various minerals. We have heard a good deal about riffles for concentrating-tables; exhaustive experiments have been […]

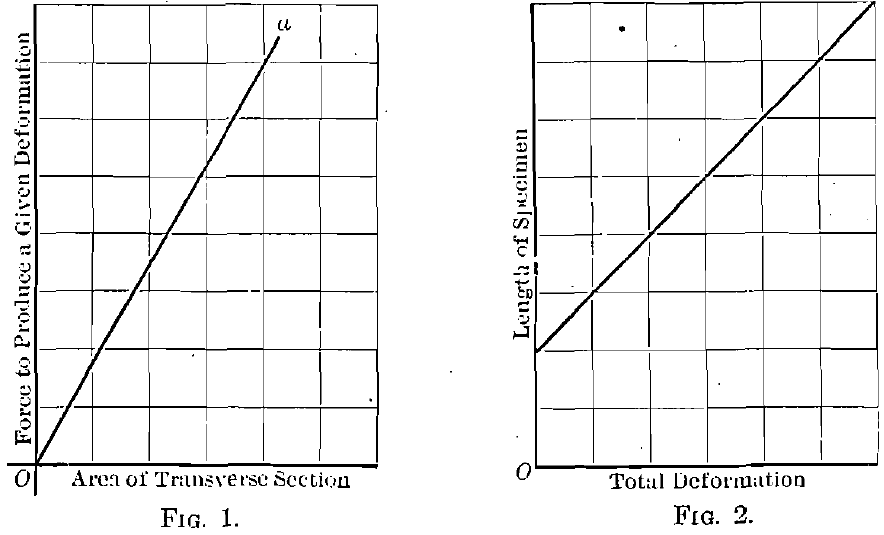

Crushing Energy & Work of Crushing Machines

A general awakening of interest among mill men concerning the mechanical efficiencies of their crushing machines is evident from a perusal of the recent files of mining publications. Considering the large part of the power bill which must be debited to the crushing department, such interest is natural. When, however, the articles on the subject are […]

Ammonia-Carbon Dioxide Ore Treatment

Most metallurgists appreciate the great need of a process for the extraction and recovery of valuable metals from complex ore, where the presence of one metal increases the cost of extracting the other metals to such an extent that not any of the metals can be extracted at a profit. We need only refer to some […]

Fine Grinding in Cyanide Plant

This plant, near Marysville, Montana, was planned to treat the ore from the Piegan and Gloster mines, the latter being one of the early and famous producers of the Marysville district. When the mill was closed, treatment consisted of stamp milling, followed by pans and settlers for pan amalgamation. The extraction was evidently poor, because, a […]

Flotation Controlling Factors

The object of this paper is to offer some suggestions to assist metallurgists to supervise the operations of flotation plants. We do not yet thoroughly understand what “flotation” is, or “why minerals float,” and all attempts that have been made to explain the phenomena have been based on theory or imagination, and have not been capable […]

Conical Mill Grinding Tests

In the laboratory work described in the following pages, a 4 ½-ft. Hardinge mill with three removable cylindrical sections, 16 in. each in length, was used. Fig. 1 shows the mill with three cylindrical rings in place. This combination allows a mill 4 ½ ft. by 0 in., 4 ½ ft. by 16 in., 4 ½ ft. […]

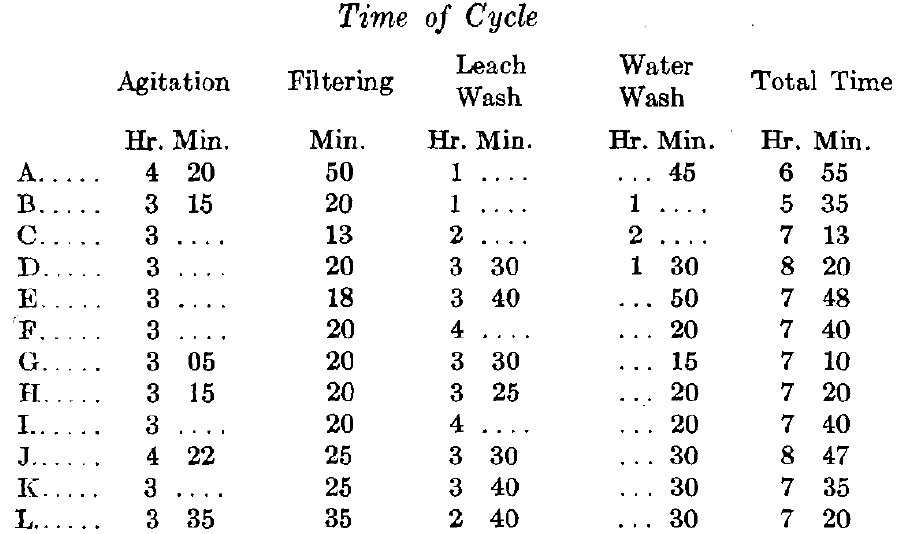

Calculate a Settling Tank’s Capacity – Thickener

During construction work at a mill, the metallurgical engineer in charge, ran a series of experiments on settling. His tests proved that deep settling tanks were not ordinarily necessary. The use of tanks 2 or 3 ft. in depth was suggested. Later experiments demonstrated that the following principles of settling applied to Tigre pulp. In settling dilute pulp, […]

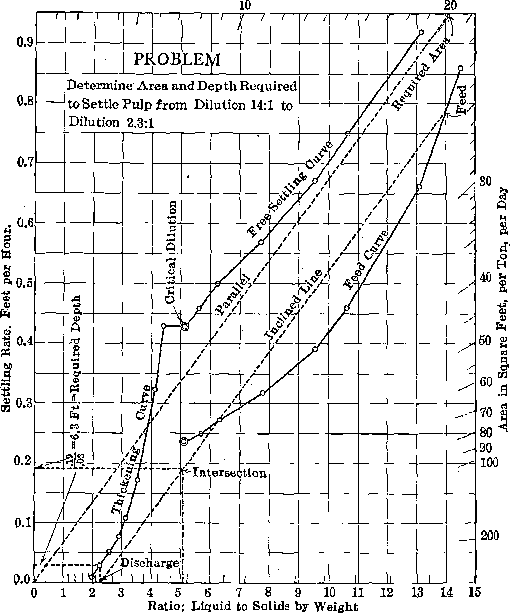

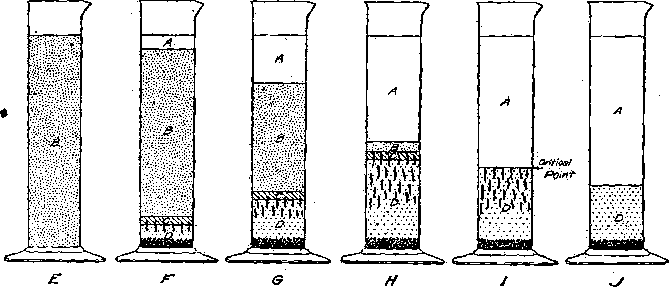

Measuring Settling Rates and Calculating Thickener Capacity

In order to develop rational methods of measurement and laboratory testing, it becomes necessary to study the general phenomena of settling rates. Since it was desired to give the public the benefit of these methods at as early a date as possible, together with the knowledge of the general principles of slime settling necessary for a […]