Table of Contents

Much research has been carried out on biohydrometallurgy over these last 25 years and is still being actively conducted all over the world. The interdisciplinary nature of this young branch of science and technology is reflected by the variety of experts involved: microbiologists, mining engineers, hydrometallurgists, physico-chemists, mineralogists, solid-state physicists and bio-chemists. This intensive research effort has provided a solid background on the fundamentals of this technology, although many important is-sues have still to be solved, amongst which the enzymatic mechanisms controlling biocatalysis of mineral sulfides dissolution, the influence of bulk- and surface solid-state physics of metal sulfides on dissolution mechanisms, the interaction of the various strains composing natural microbial floras. Their elucidation should permit the rationalization of biohydrometallurgical techniques and the optimization of commercial processes.

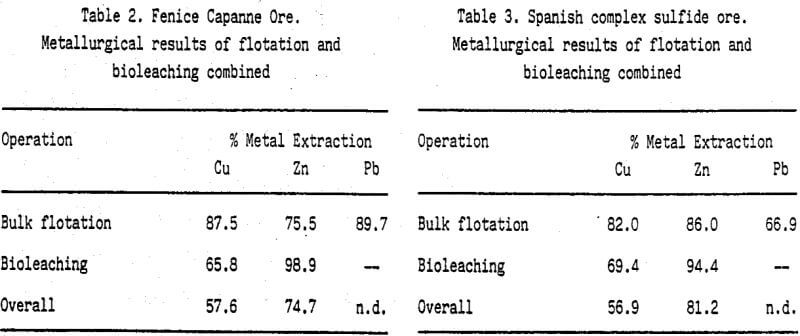

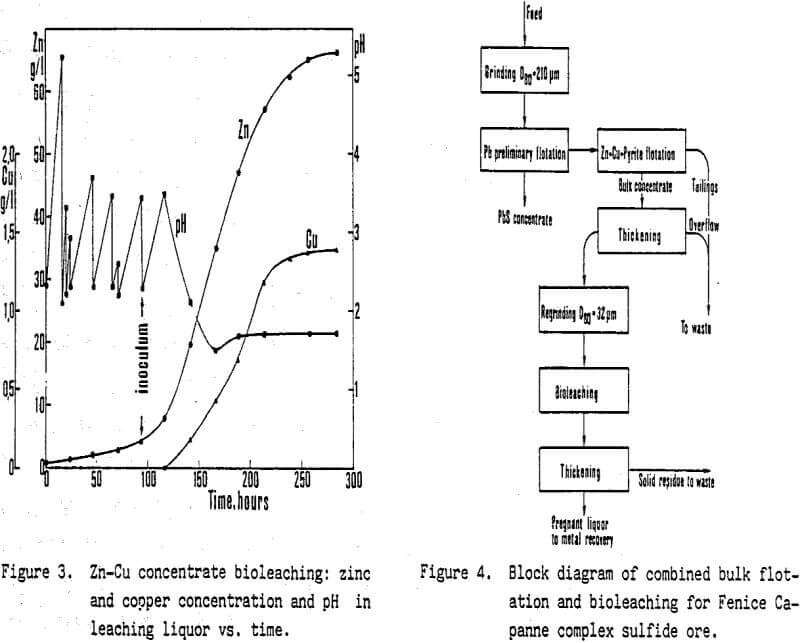

Biological Leaching of Sulfides Bulk Flotation Concentrates

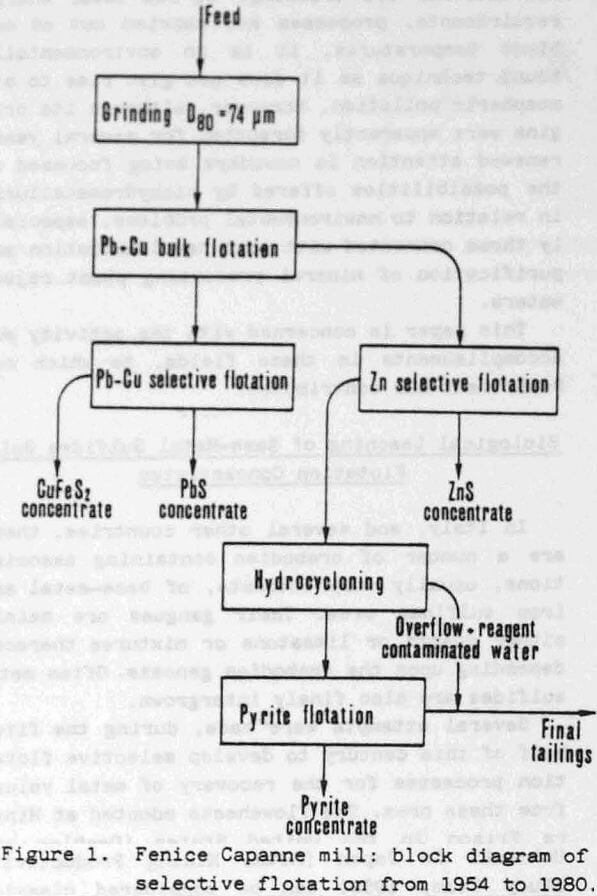

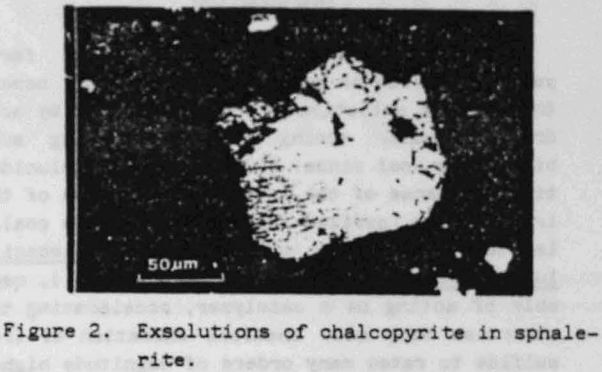

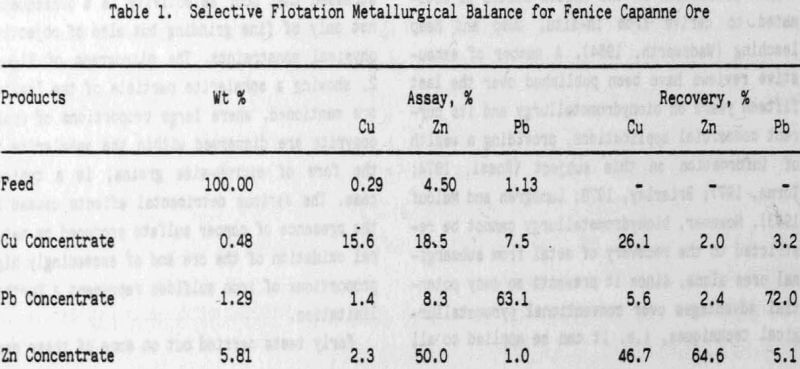

In Italy, and several other countries, there are a number of orebodies containing associations, usually very intimate, of base-metal and iron sulfides ores. Their gangues are mainly either quartz or limestone or mixtures thereof, depending upon the orebodies genesis. Often metal sulfides are also finely intergrown.

These flowsheets presented numerous drawbacks, the majority of which originated from the need for a very fine mesh-of-grind, say minus 400 mesh Tyler, in order to achieve at least an acceptable liberation of the mineral species from each other and from the gangue.

For these reasons in-situ, dump or heap leaching are not applicable to ores of this type.

Since the liberation size of the metal sulfides associations from the gangue is usually much coarser than that of the single sulfides from each other, it was decided to apply a combination of flotation and bioleaching, exploiting the advantages of both techniques and at the same time bypassing their limitations.

Furthermore, it should be added that the relative proportions of each mineral species may decisively affect process performance. It has been demonstrated, for instance, that where-

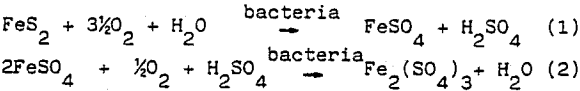

as pyrite usually has a favorable effect on metal sulfides biosolubilization, since the ferric sulfate produced by its bioleaching (Equations 1 and 2)

7Fe2(SO4)3 + FeS2 + 8H2O → 15FeSO4 + 8H2SO4…………………………………………………..(3)

CuFeS2 + 2Fe2(SO4)3 → CuSO4 + 5FeSO4 + 2S………………………………………………………..(4)

ZnS + Fe2(SO4)3 → ZnSO4 + 2FeSO4 + S………………………………………………………………….(5)

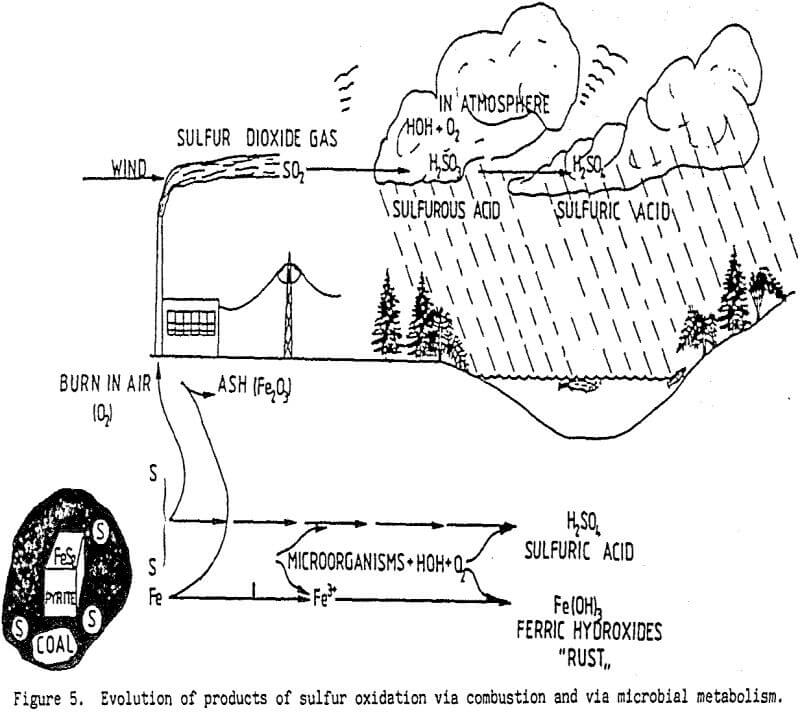

Microbial Coal Desulfurization

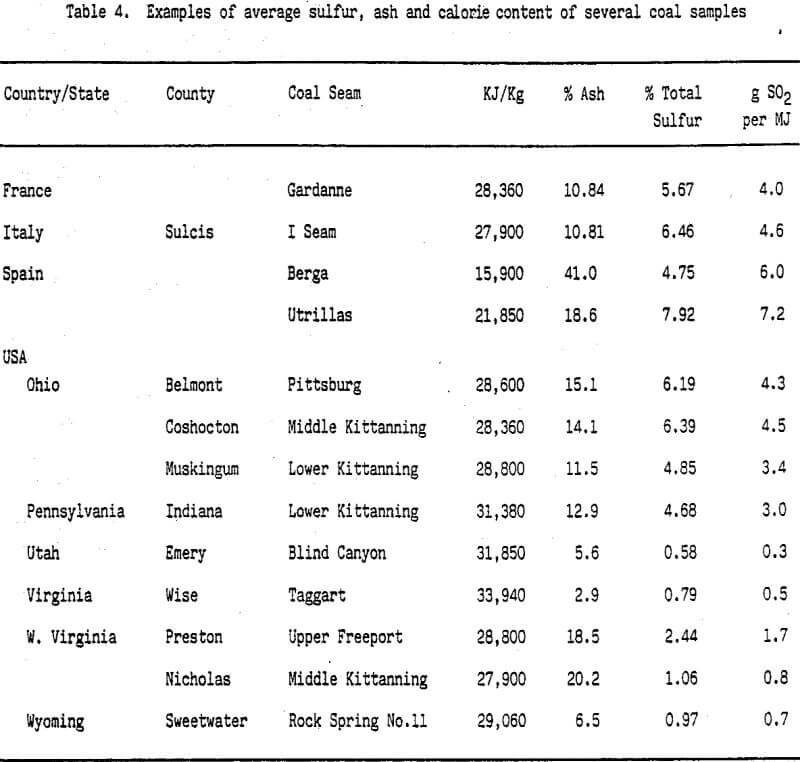

The 1972 oil crisis, together with the mounting anti-nuclear campaign, especially in the light of recent incidents, have revived interest

in coal as an alternative energy source. However many coals are characterized by sulfur contents well in excess of the limits imposed by current legislation, attaining as much as 6 to 8%. On combustion, SO2 is emitted with the flue gases, resulting in the fallout of acid rains, a serious threat to the environment in many parts of the world.

Coal contains sulfur in three forms: iron sulfide (“pyritic sulfur”) as crystals or clusters (“framboids”) of crystalline grains, which are physically separable from the coal matrix; sulfur covalently bound in the complex-structure matrix as thiols, mercaptans, sulfides, disulfides and complex thiophenic moieties (“organic sulfur”) and sulfate sulfur (usually in negligible amounts, say less than 0.1%).

The solution of the microbiological problem must, however, in this case too, be supplemented by an adequate development of the continuous process with a view to achieving a sufficient degree of sulfur removal from high (more than 50% w/v pulps) solld-to-liquid ratios pulps, so as to minimize residence times and consequently contain reactor volumes and power consumption to within acceptable limits.

Special Biohydrometallurgical Applications

Mineral dressing plant throughputs are constantly increasing chiefly because of the tendency to process r.o.m. ores with increasingly lower grades. Most mineral dressing plants concentrate the metal values or commodities contained in the r.o.m. ores by flotation, a wet processing method requiring up to 7 m³ of fresh water per ton of r.o.m. ore. Daily throughputs of several thousands or tens of thousands tonnes correspond therefore to large fresh water flow rates which are drawn from natural water bodies and have to be returned thereto after utilization. In arid areas high fresh water flow rates are frequently not available, but even in those areas where fresh water is abundant, restrictions are imposed on water supply for industrial purposes and in any case environment protection legislation requires that the quality of the reject waters comply with stringent specifications.

When pure microbial strains are used, biodegradation effectiveness increases from amines through carboxylates to alkylsulfates.

Inorganic contaminants can be effectively removed by biosorption, i.e. the phenomenon of selective retention of cations from aqueous solutions by microbial biomass.

The relatively recent discovery that biosorption can be effectively carried out also using dead microbial cells appears to be of major importance. This finding has led to the development of techniques based on the utilization of waste industrial biomass for biosorption.