In giving this subject the “broad-brush” treatment, it will be necessary to generalize on the major points which at the same time will permit me to avoid, to a great extent, any involvement in the purely technical and theoretical aspects of blasting. The practice of theorizing before a new idea is tried has practically been discontinued in our organization simply because experience has shown that, almost without exception, theories have fallen aside as some new development takes its place.

Our venture into the use of low-cost blasting agents resulted in an immediate threefold benefit. Years of experience with fixed-type explosives indicated that the best fragmentation was obtained by the use of six inch diameter holes on an 18 foot burden and an 18 foot spacing pattern. In retrospect, we see no reason to believe that this pattern of drilling was wrong while using fixed explosives. Initially, believing that there was a critical mass condition involved in the use of the low-cost agents, it was necessary to Increase the hole diameters.

The second benefit was in the area of a reduction in the cost of explosives. In a normal or average season about 16,000,000 tons of limestone is quarried at Calcite. As pointed out earlier, the cost of powder is a major consideration in the overall cost of production, and with the high volume of explosives used in a year, any fraction of a cent reduction in the cost per pound of powder yields high dollar returns.

After experimenting with several types of carbonaceous materials in varying percentages, good results were obtained from a compound of fuel oil and ammonium nitrate mixed in a ratio of 8 pounds to 100 pounds respectively. This compound, crudely mixed at blast hole site by sprinkling the fuel oil from a can while the nitrate was being manually poured into the hole, appeared to be properly balanced. After firing there was some evidence of nitrous oxide but the fragmentation results were excellent.

In order to attain the above goals, development was started on a machine which would thoroughly mix the compounds and at the same time reduce the manpower requirements. As you will see in the colored slides which will be shown later, a three-ton stake-body truck was used as a basic machine for transporting and mixing. The truck was equipped with a 50-gallon tank for fuel oil and an air compressor. A hopper built of aluminum for its non-sparking characteristics was mounted on the rear end of the truck platform.

It is realized that many quarry operators do not feel that it is necessary to mix the material so thoroughly, and in this light, it is conceivable that our machine loader is too elaborate. However, it is our firm belief that thorough mixing is important, and further, we can justify the loader on the basis of a reduction in manpower requirements.

It is hoped that a system of delivery of commercial grade nitrates can be worked out to permit bulk shipments either by rail or by truck. If such deliveries become a reality, a procedure would be developed whereby the nitrates would be transported to the blasting sites in bulk and loaded in a manner similar to our present method.

Obviously a question arise as to why the relatively low velocity agents can be successfully used in a stone that is so difficult to blast. It is our belief that because the dolomite stone is hard and brittle, the energy from a high velocity fixed explosive has a tendency to pulverize and shatter the stone in the immediate area surrounding the blast hole. Thus much of the energy is absorbed and dissipated rapidly in this area, which sharply reduces that which is available for fragmentation in the outlying areas.

Blasting with Prilled Ammonium Nitrate Fertilizer

The National Lead Company operates its MacIntyre Development at Tahawus, New York for the production of ilmenite and magnetite. The heavy ore of titanium and iron is mined from the open pit mine at an average rate of 7,000 tons per day, and the development waste is removed at an average rate of 10,000 tons per day.

The mine working benches are spaced at 35-foot vertical intervals, and 6½ inch blast holes are drilled 39-feet deep with 18-foot burden and spacing by down-the-hole drills.

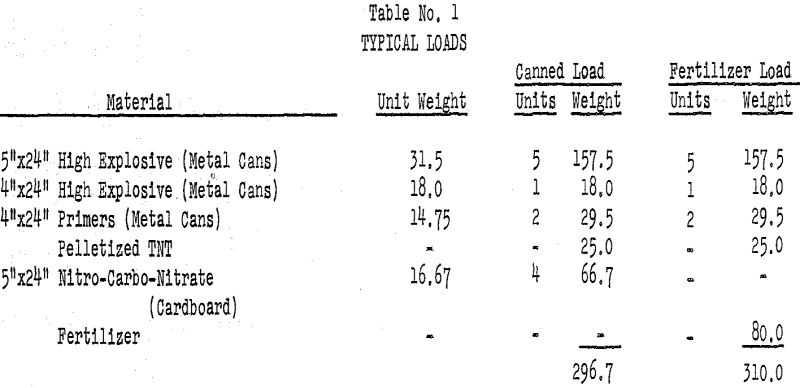

The following Table shows the comparison between a typical canned powder load and a canned powder and fertilizer load, now being used:

The holes are loaded with 5-inch cans in the bottom, then the 4-inch cans, then the top load. The primers are usually the second, unit from the bottom and the last unit before the top load is put in.

These loads, in waste having a density of 11 cubic feet per long ton, result in powder factors of 0.284 and 0.297 pounds of explosive per long ton of material broken.