Recent experiments indicate that the usual type of gold concentrating-table is not only poorly adapted to produce the desired results, but also is based upon an incorrect principle, namely, the use of riffles to perform the work of stratifying the various minerals.

We have heard a good deal about riffles for concentrating-tables; exhaustive experiments have been made to discover the proper form of riffle, or to prove the superiority of this or that form; disputes and patent-litigation have arisen over the matter of riffles, and thus many have been led to believe that the riffle is the saving-device upon which the process of concentration depends.

In the present paper it is proposed to show that the riffle is greatly overrated as to the part it performs in the concentration of minerals, and that, in the near future, it may possibly be eliminated entirely from that process.

The experiments in question have shown that the troublesome riffle can be considered of secondary importance at the most, and should be so classed in the construction of a concentrating table built upon the right lines.

The action of any form of riffle on a concentrating-table is such as to upset and retard the process of settling and stratifying the various minerals on the table-deck.

From the deck of a riffled table no concentrates can be delivered until the deck is “ bedded,” that is, until a sufficient amount of metallic values has been fed to the table to spread over a large portion of the deck, forming a substratum of the heavier minerals. This substratum must be maintained by the feed within quite narrow limits, and directly proportional to the rate of discharge from the table, in order that the bed shall not be lost. On the other hand, the riffles having a very limited carrying-capacity, considerable care must be taken not to overfeed a riffled table, in which case the table proceeds, in mill parlance, to rob itself. As soon as the space between the riffles becomes filled to and above the riffle-tops, the values then pass off the table with the tailings or lighter material, before they can he delivered by the table-motion to their proper discharge-point.

It can readily be seen that to regulate a feed that will keep a riffled table properly bedded, namely, between the points of not sufficiently bedded and over-bedded (which are not very far apart), is no easy performance from a mechanical point of view, and it is rendered doubly difficult by the varying metallic content of the pulp fed to the table.

It is not often that favorable conditions for feeding a riffled table-deck can be secured in practice; and when they are, the riffle proceeds to upset the whole business in hand. As the pulp reaches the first riffle it is forced over it by its own momentum; and this process is repeated at each succeeding riffle. In passing over each riffle, the entire mass of the pulp is disrupted and shaken up. Whatever settlement and stratification of heavy particles has taken place between the riffles, is to a large extent destroyed. Each time the pulp is forced over a riffle it is an even chance whether the lighter or the heavier particles reach the deck first. They may drop from the top of the riffle and reach the table together, in which case the lighter particles become mixed with and imbedded with the heavier, in such a manner that they are unable to stratify themselves according to their specific gravities before they again meet an obstacle to their proper settlement in the form of another riffle. In other words, the work of settling and stratifying by themselves the various mineral contents of the ore in hand, is upset and retarded as many times as there are riffles on the deck of the table.

Another serious defect in the construction of many concentrating tables is that the line of motion of the table is parallel to the riffles upon the deck of the table, hence there is no action to counteract the downward flow of the heavier minerals and aid in their separation from the gangue matter by the dressing-water.

A series of experiments extending over a period of six years and conducted by U. S. James, of Newark, N. J., to obtain the best means of concentrating gold minerals by the use of a wet reciprocating-table, has resulted in a table differing radically in construction from the riffled table with parallel motion. A view of the table is given in Fig. 1.

The deck of Mr. James’s table is composed of a plain, non-riffled surface, and what might be termed a slightly-riffled surface. The plain, non-riffled portion of the table is formed by two planes of different inclinations to each other, meeting in a line diagonal to the line of motion of the table. Hence Mr. James has named it The Diagonal-Plane Table-Deck. The planes in question form a basin in which the minerals of the greatest specific gravities are settled and stratified previous to their discharge upon the riffled portion of the deck.

Referring to Fig. 2, which is a plan of the table-deck, A and Bare the stroke-adjustments, and C is the tilting-lever. The pulp, which enters the launder through pipe D, is fed along the upper edge of one plane and on a line parallel to the table- motion. During the travel of the pulp down the gentle incline of this plane, G, G, which may be called the receiving- and settling-plane, the heavier minerals in the pulp settle and slide gently on the surface of the plane, to the line of intersection, H, H, of the planes forming the basin. Along this line the most important action of the whole operation takes place, namely, the stoppage of the metallic portion of the pulp-flow by the rising plane, K, K, forming the lower section of the basin, and the carrying onward of the lighter or tailings portion of the pulp by the wash-water out of the basin. All these actions take place simultaneously with the discharge of the concentrates from the settling-basin by the motion of the table.

The degree of inclination of the settling-planes to each other, and the angle of their intersection to the line of the table- motion, is of the greatest importance in securing the above results.

The practice of settling and stratifying by means of a settling- basin provides for the disposition of a very wide range in quantity of metallic contents. There are no confining limits other than the limits of the basin itself. The basin does not require “bedding” and is very difficult to overfeed. It settles and discharges automatically whatever quantity of metallic particles the ore may furnish.

The riffled surface of the deck is divided into two sections, one for the reception of the concentrates, I,I, Fig. 2, and the other, J, J, for the tailings. The riffles on the concentrates section are very thin, being but 1/32 in high. As the concentrates are discharged from the settling-basin on this portion of the deck, the low riffles allow them to spread out, which action enables such gangue as may remain in them to become free, forming a thin upper stratum, which is easily washed away by the dressing-water.

Fig.2- Plan of James Diagonal Plane Table Deck

As the metallic pulp emerges from the settling-basin upon the thinly-riffled section of the deck, it is, by reason of the line of table-motion being diagonal to its line of settlement, driven not only forward but upward against the inclination of the deck, thus counteracting the tendency of the dressing-water to wash the gold concentrates into the tailings-section.

https://www.911metallurgist.com/gold-shaking-tables

The tailings from the settling-basin do not come in contact with the riffles until they have been washed entirely free of values. These riffles act simply as a retarding influence, preventing the too rapid discharge of the tailings and the wash- water from the non-riffled section. They have nothing to do with the stratification of the minerals.

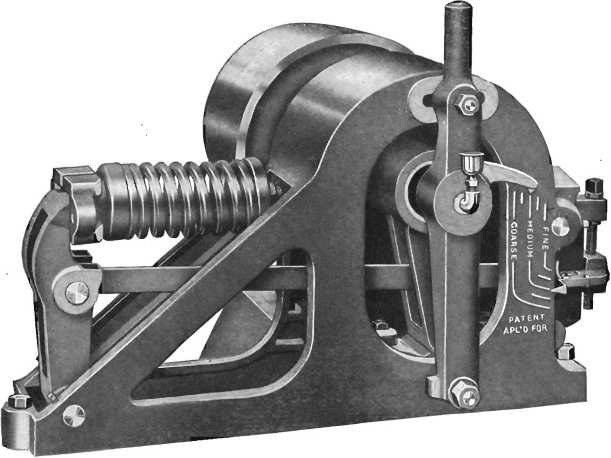

In order that the table-motion may be adapted to the greatest variety of metallic pulps, the eccentric actuating the table is

Fig.3- Head-Motion of James Diagonal Plane Table Showing Index-Plate for Regulation of Stroke

mounted upon an adjustable pin. Thus the eccentric may be placed more or less off center. This adjustment, combined with the regular stroke-adjustment, provides for more than 200 different movements, ranging from a very mild kick and long stroke to a very sharp kick and short stroke, or any combination of movements between these extremes. As a guide to the unskilled operator, an index-plate, based upon the size of the material, is provided, which is of great assistance in selecting a movement with which to start. Fig. 3 is a view of the head- motion, showing the index-plate for the regulation of the stroke.

An attempt is made to discuss some of the theory of wet tabling and the phenomena surrounding tabling action. The Deister diagonal-deck table is described. In discussing the performance of this table in the cleaning of the finer sizes of bituminous coal, a study was made of four tests run on un-classified feeds, each test being made on different types and sizes of coals. The author has attempted to be objective in his analyses, presenting the facts of the different studies based on actual table performance.

The separation of different minerals on a wet concentrating table is the result of their differences in specific gravities, size and shape of particles, and the phenomena of stratification and hindered settling. These factors can be controlled and aided by many possible table adjustments, including speed, stroke, side tilt, end elevation, deck area, riffle design, shape of deck, and water distribution.

A diagonal-deck type of concentrating table offers the advantage of a more effective deck area at the section of the deck where it is most needed. For most coal washing a riffle design where the riffles are parallel to the differential head motion appears to give the most satisfactory results. A desirable table for wet washing or concentration of coal is one that provides the flexibility of adjustments so that it can be operated to fit the particular coal being treated and produce the desired results.

Capacities of tables will vary with their size, shape, and other operating characteristics, as well as with the particle sizes being treated, the inherent washability of the coal itself, and the results desired by the operator.

A study of the four cases incorporated in this report indicates that a high degree of performance was achieved under a wide variety of conditions. In comparing the results of any process, it must be remembered that the inherent characteristics of the coal must always be taken into consideration and that a true comparison between different processes can be made only when treating the same kind and size of coal.

It is believed that the type of coal washing table herein studied will produce a satisfactory product from fine sizes of coals and fulfill most requirements while operating on an unclassified feed. Test data indicate that bituminous coal fines of size consist ranges of ½, 3/8, ¼ and 3/16 in. x 0 can be treated effectively. If a higher degree of separation accuracy is required, a closely sized or classified feed may become necessary. This latter course may be especially desirable if the primary purpose is sulphur removal.

Diagonal-Plane Concentrating-Table, by S. ARTHUR KROM, PLAINFIELD, N. J.[/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]