https://www.911metallurgist.com/tungsten-ore-extraction-processing-flowsheet https://www.911metallurgist.com/tungsten-gold-ore-extraction-processing-flowsheet

The purpose of the following research, as originally planned, was to investigate the influence of temperature upon the plate- amalgamation process. In order to consider

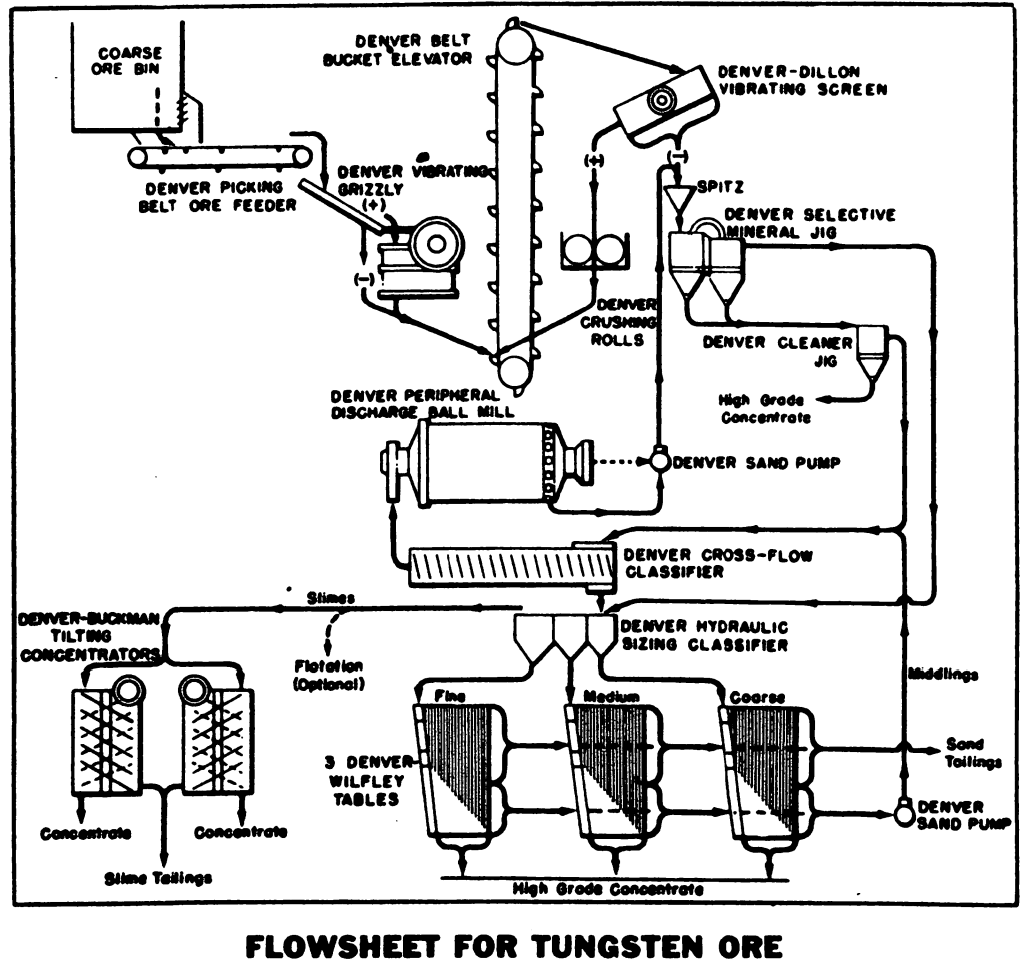

The Beneficiation flowsheet shown with this study is particularly adapted to the concentration of tungsten ore in small tonnages. Tungsten minerals are generally in the

PROCESS FLOWSHEET DESCRIPTION: Batch Gold Cyanidation-Leaching Plant. ORE TREATED: Small tonnages of high-grade gold-silver ores and flotation or Jig concentrates amenable to cyanide treatment, used

PROCESS FLOWSHEET DESCRIPTION: Continuous counter-current decantation cyanidation flowsheet. ORE TREATED: Gold and silver ores amenable to the cyanidation process and where economics justify plant outlay.

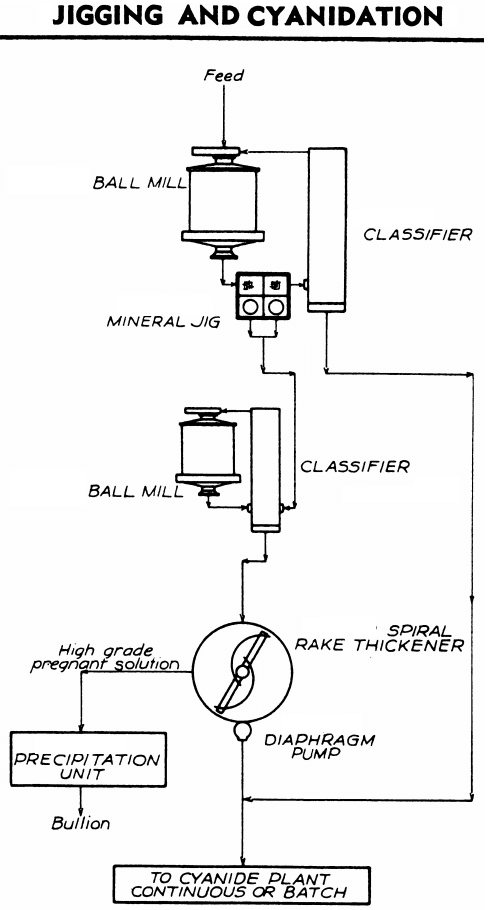

PROCESS FLOWSHEET DESCRIPTION: Jig gold concentrates reground and cyanide leached. Mineral Jig in ball mill-classifier circuit for removing sulphides for fine grinding and subsequent cyanidation

PROCESS FLOWSHEET DESCRIPTION: Gold Mineral Jig in cyanide circuit with amalgamation of the Jig concentrates. ORE TREATED: Practically all ores treated by cyanidation and especially all

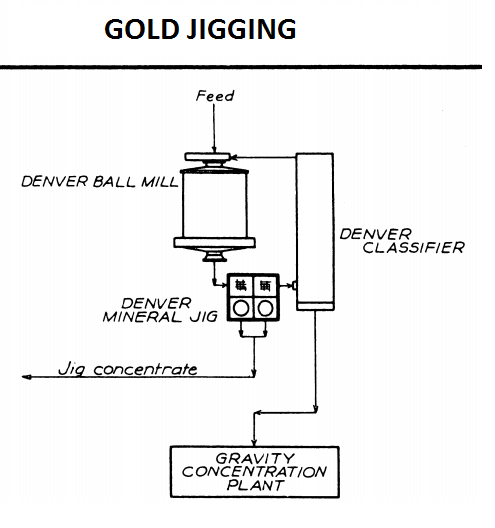

PROCESS FLOWSHEET DESCRIPTION: Gold Mineral Jig in grinding circuit (ball mill discharge) at center of gravity concentration plant. ORE TREATED: Various oxide and nonmetallic minerals