The bucket dredge may be described as a continuous dipper dredge, the material being raised by a revolving chain of dippers or buckets, which scoop or dig into the deposit. The principle and system of raising material in these machines are almost identical with those of harbour dredges. The favourite type of bucket dredge is that known as the endless chain centre bucket dredge.

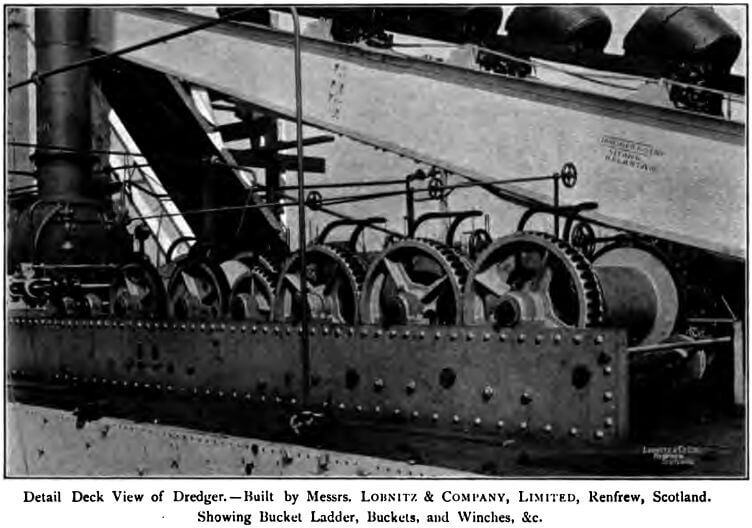

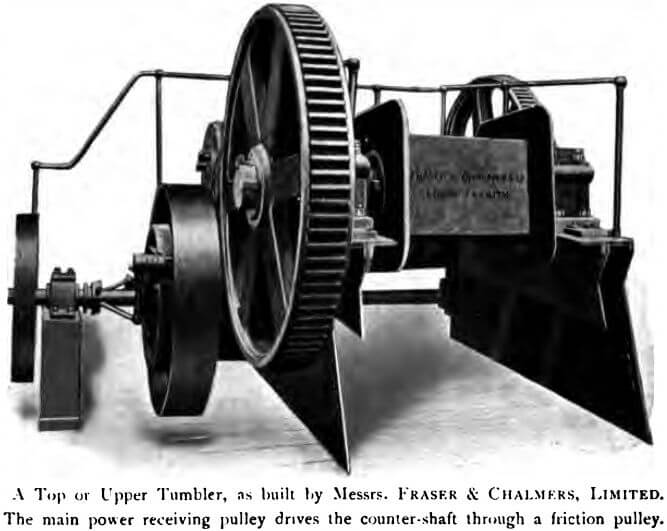

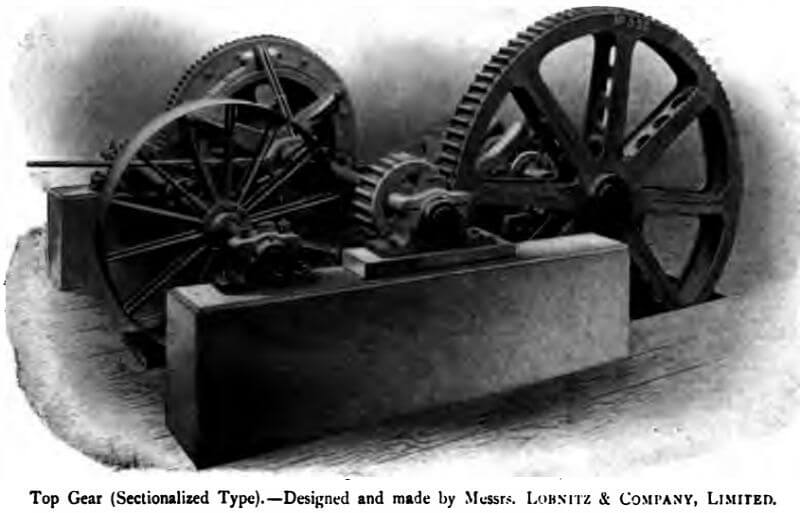

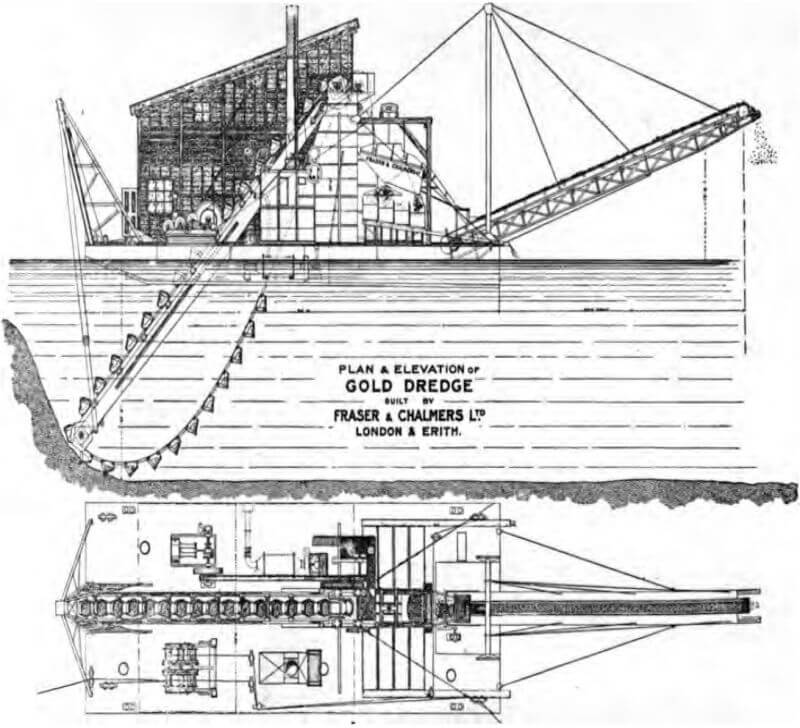

An endless chain of buckets is carried on rollers resting on a steel ladder. The upper end of this ladder is hinged on a gantry frame about 20 ft. above the deck of the dredge. The lower end of the ladder is suspended by cables, which pass over sheaves to a drum on a winch, so that the ladder may be raised or lowered to feed the buckets. The buckets pass over tumblers at the upper and lower ends of the ladder. The power to drive the bucket line is applied at the upper tumbler through gears. The material as excavated by the buckets is dumped into a hopper, and from this hopper is fed to revolving or shaking screens. Water under pressure is forced from spray pipes over the screens on to the travelling gravel. The gold-bearing material passes through the screens into a distributor, which feeds this material and water to tables provided with riffles. These tables in turn discharge into side or tail sluices, which deposit the fine tailings well behind the dredge. The coarse tailings, after being washed on the screens, pass from the screens to a conveyor, which carries these tailings 30 to 50 ft. behind the dredge and stacks them 20 to 30 ft. high.

The usual construction of such machines may be illustrated by the description of a dredge built by the Risdon Ironworks, San Francisco, to work on the Yuba River. The dredge consists of two large pontoons, each 86 ft. long by 9 ft. beam. These are connected at the stem by a small pontoon 17 ft. long and 5 ft. wide, the bow being connected by a heavy overhung beam. This practically makes one boat, 96 ft. long, 23 ft. wide, with a well-hole 5 ft. wide running through the centre for some 75 ft. As the name implies, the chain of buckets and the ladder round which it revolves works in this centre

well. The ladder, varying according to the depth of the river, and in this case 67 ft. long, is built up as a heavy lattice girder, and hung at the stem end by a bar fixed across a heavy wooden frame. The lower end of the ladder carries a five-side tumbler, and is suspended by blocks and tackle to a cross-beam. By means of wire rope and blocks, the winch can raise or lower the bottom as required. The top tumbler is carried by the timber framing some 3 ft. above the top end of the ladder. The continuous bucket chain comes up the top side of the ladder on rollers round the top tumbler, and back in a catenary curve to the lower tumbler. The top tumbler is driven by belt or rope transmission and heavy gearing from the engine. In a later dredge, on the gearing between the engine and the buckets there is a friction clutch, which not only allows the buckets to stop when they come in contact with anything too firm or heavy to lift, and start again when the pressure is relieved, but enables a mere movement of a lever to instantly stop the buckets without stopping the engine or interfering with any other part of the machinery. The winchman has his lever close at hand, and can control his buckets independently and without communicating with the engine-driver. A vertical compound condensing engine of 35 indicated horsepower is used; this also drives the centrifugal pump, throwing 3,000 gallons per minute for washing purposes. This water thoroughly washes the material, which is delivered from the buckets into a revolving screen or grizzly, from which the finer dirt, which is here usually not more than 10 per cent, of the amount raised, together with its gold, falls into a distributing box, and thence on to gold-saving tables 11 ft. wide, discharging into a flume.

A more recent dredge, designed by Messrs. Cutten Bros., of Dunedin, in 1903, for the Feddersen Gold Dredging Company, Limited, Three Channel Flat, Butler River, has a length of 86 ft., beam 29 ft., depth 7 ft. The ladder is 56 ft. long, and, when at an angle of 450, is capable of dredging to a depth of 30 ft. The buckets have a capacity of 5 cubic feet each. The elevator is rope driven, the power being applied to the top tumbler, and the tailings can be stacked to a height of 30 ft. Steam is generated in a multi-tubular boiler of 30 n.-h.-p. The main engines are of the compound type, rated at 16 n.-h.-p., and built by Marshall, Sons, & Co., Limited. The winches are worked by a pair of coupled vertical engines. A revolving screen is used, and the tables are covered with expanded metal above the matting. The Davis patent grapnel has been adopted on this dredge.

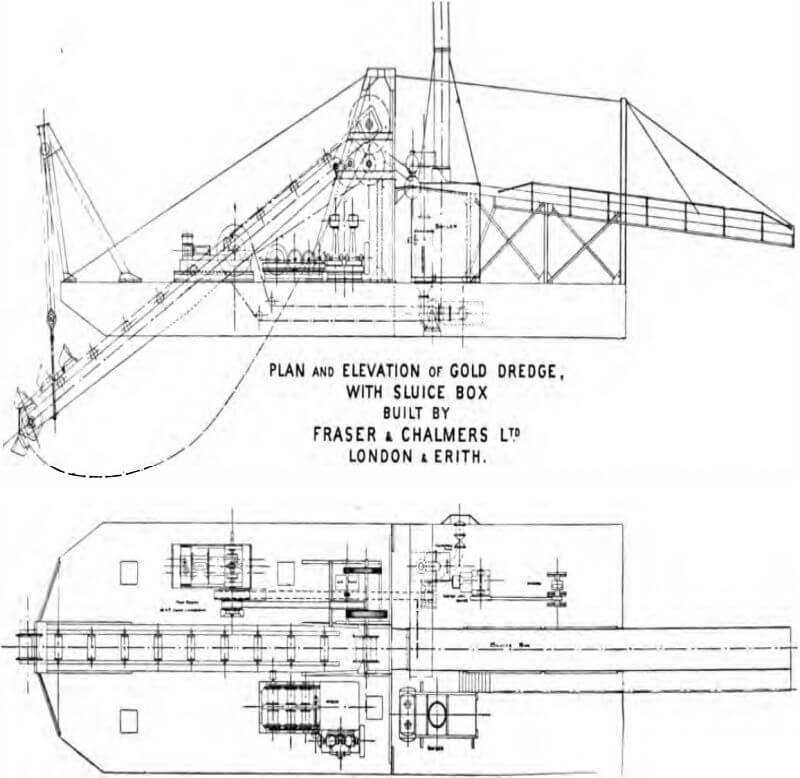

The following plans and elevations illustrate gold dredges, built and fitted by Messrs. Fraser & Chalmers, Limited.

The advantages of bucket chain dredges as a class are: Their suitability for handling either coarse or fine material, and for dealing

with the varying conditions on the river-bed or flat on which they may be operating; their power of dredging to 60 ft. and over in depth, of working into banks considerably above water level, and of stacking the tailings behind to a height of 30 to 40 ft.; their efficiency as an excavating apparatus, clearing the bottom, and handling the material with little agitation, while they slowly and continuously feed a tolerably regular quantity of material to the gold-saving appliances, thus fulfilling a condition essential to good extraction. Finally, they are relatively economical in their consumption of power. The chief disadvantage is that they are not very successful in lifting gold from a hard and rough bed-rock.