Table of Contents

Bulk sampling is define as the “process of extracting a small fraction of material from a large bulk sufficiently representative for the intended purpose”. Today’s pressing need for simple, effective and reliable sampling systems is intensified by the growing demand for quality control as a means to cope with inflation, competition and rapidly increasing consumption of raw materials.

The classical 4-step sampling technique

If only a cursory check of bulk quality is required, sampling can be quite simple. A flip-gate installed in the head

chute of a conveyor belt junction can collect a plant-run sample in two seconds and still satisfy operating needs. However, if more precise and reliable information is required, a 4-step sampling technique must be considered.

Step 1. Sampling Plan Development

Step 2. Sample Collection

Step 3. Sample Preparation

Step 4. Sample Analysis

Armed with a thorough understanding of the purpose of the sampling, and the knowledge or the characteristics of the material, one can then proceed to develop a sampling plan using, whenever possible, the latest applicable codes or theories in statistics and probability.

Material Variability – A Major Consideration in Sampling Plan

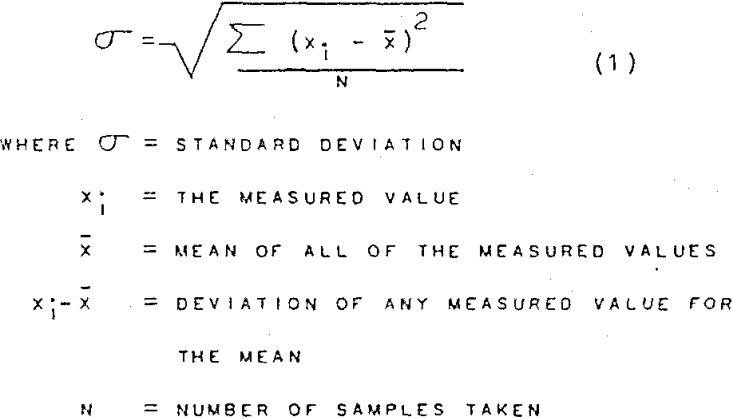

A major prerequisite for any sampling plan is a study of the variability of the material to be sampled. In general, there are three measures of variability; namely, range, mean deviation, and standard deviation. By definition, range is the difference between the highest and the lowest numbers in a set of data and gives the maximum spread of the data. Mean deviation is the average of the absolute deviation. Standard deviation is the “root mean square” deviation as defined by formula (1) which follows. Because of various shortcomings inherent with other measures of variability, standard deviation is generally regarded as more capable of accurately depicting the variation pattern of a set of values, it is by far the wore preferred and widely used.

Standard Deviation (or “root-mean-square deviation”) is defined as “the square root of the mean of the sum of the squares of the individual arithmetical deviations from the mean”. The standard deviation has the same unit as the quantities measured. Expressed mathematically, it is

In bulk sampling, to obtain a representative sample of a consigned lot within a defined precision the more variable the material, the greater number of samples would be required.

On the basis of certain fundamental laws of probability and statistics, the minimum number of samples (called “increments”) required for a consigned lot is expressed as a function of the variability (standard deviation) of the material and acceptable error as follows:

N90 = (1.64 σ/E)²…………………………………………….(2)

where: N90 = minimum number of sample increments required at a confidence level of 90

σ = estimated standard deviation of the material

E = acceptable error in %

As an example, for a 60,000 ton shipment of iron ore pellets, at a confidence level of 90% and allowable error of 1% if the variability of the cargo in terms of standard deviation is found to be 6, by eq. 2, the minimum number of sample increments required would be

N90 = (1.64 x 6/1.0)² = 97

If the allowable error is reduced to 0.5% the required number of samples will increase to

N90 = (1.64 x 6/0.5)² = 388

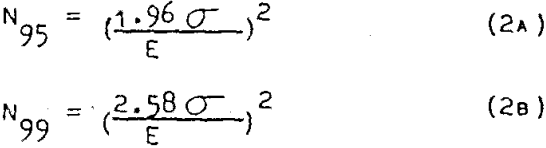

when more certainty is desired, as expressed by increased confidence limits, more increments will have to be taken from the same lot. Accordingly, at confidence levels 95 and 99%, formula (2) becomes:

The Collection of Samples

Mine face samples are normally taken by hand along premarked vertical and horizontal channels. For each channel, the samples are taken either in subsections for geological observation, or along the entire length to form the gross sample which is then sub-divided and later reduced for analysis, the results of the mine face samples are used for long range ore reserve calculations as well as for short range layout of the mining plans. One of the common problems in the collection of channel samples is the loss of fines which tend to fall off or be blown away. The samples thus collected could be biased and misleading.

A “Thief Sampler” is essentially a metal tube with a sharp, angled point at the end and a single or multiple slot along its length. The “Thief” is inserted into the material and withdrawn with the desired sample in the tube. Various modified versions of the thief sampler are available for different specific purposes.

Due to the relatively consistent pattern of material flow, the most reliable method is collecting bulk samples when the material is in transit, in particular, at the junction of conveyor belts. Samples may also be collected on a stopped belt at predetermined tonnage rate intervals. the belt is stopped at a preset location and a fixed amount of sample is removed, in a prespecified length, completely across the belt width.

Equipment and Component Design

The equipment selected for a sampling system must have sufficient capacity to perform the desired operation under a variety of conditions without affecting the acceptable degree of accuracy, yet remain simple to operate and service. Since it would be impossible to design a sampler so that it may have the same degree of accuracy for all types of feed, it must be designed for the worst conditions. Furthermore, most sample cutters are biased in favor of the smaller particles; it is particularly important that the opening of the sample cutter be more than adequate to accommodate the worst conditions. A combination of high flow rate of material with high cutter travelling speed can create such turbulence in and around the cutter as it enters the ore stream the material may tend to bounce and scatter, with the result that only smaller particles would enter into the cutter. Consequently, a cutter opening far greater than the conventional “2-½-times largest particle size” is often required.