The permitting for the copper project required time beyond what was initially anticipated and stand alone gold reserves were exhausted. While leaching of the gold heaps continued, it was recognized that to continue active leaching into start up of the copper project, some actions had to be taken to increase production.

The leach pads were built to an overall height of approximately 100 feet, and constructed in lifts increments of 20-25 feet. In order to evaluate additional leach potential, the pad was drilled to a depth of 25 feet. At this depth one complete lift could be evaluated and protection of the liner system would be insured. It is also believed that if new solution channels are developed in the upper 25 feet of the heap, additional leaching will occur at lower levels.

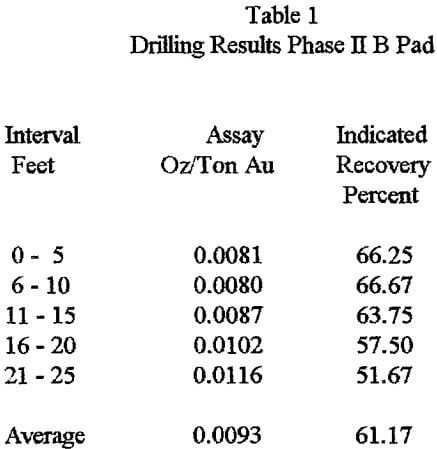

For approximately 25 % of the drill holes, samples were taken on 5 foot increments to provide information related to leach pad’s performance. A summary of the data collected is shown as Table 1.

The data in Table 1 shows that adequate leaching did not occur at depths greater than 15 feet. In the bottom 10 feet, of a 25 foot lift, recoveries averaged about 11 percentage points lower than the upper 15 feet of the lift.

The blasting of the leach pads was set up to increase percolation into the leach pad and achieve higher gold recoveries from the pads. The pads were over drilled and under shot. When the pads were blasted the surface movement, heaved or dropped, did not exceed 3′ to 4′ and most of the time the movement was far less. However in all cases severe surface cracking did occur.

The drilling was performed on a 15′ x 15′ pattern. Seven inch blast holes were drilled to a depth of 27 foot. These holes were loaded with slurry, 5″ by 30 pounds. The holes were loaded with a powder factor of 3.75 tons/pound powder. The shot was designed with delays so that no more than 2 to 3 rows, 15-20 holes per row, would detonate at the same time. A typical blast would contain approximately 150 -200 holes.

Facilities Drilling and Blasting Sequence

Based on the assay results generated in drilling of the phase II B pad, and on a significant spike in solution grade after the pad was placed under leach, the decision was made to continue with the program. The program was sequence so the majority of the work would be completed prior to winter condition setting in.

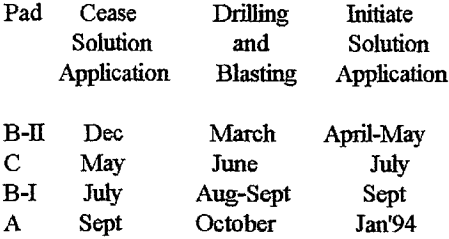

While the five leach pads, A, B-I, B-II, C, and D, the solutions are combined and processes by three carbon column plants. The solutions from the A, B-I, and B-II, are combined in a single pregnant pond and processed through a common set of carbon columns. The C and D facilities have their own processing plants. The A through C facilities are located on the eastern side of the district, and the D facility is on the western side. The operation is capable of solution transfer between facilities on the eastern side, and the blasting sequence was set up to take one pad at a time down, on the eastern side, for solution containment. Drilling and blasting was not performed on the D pad. The drilling and blasting sequence followed in 1993 was as follows:

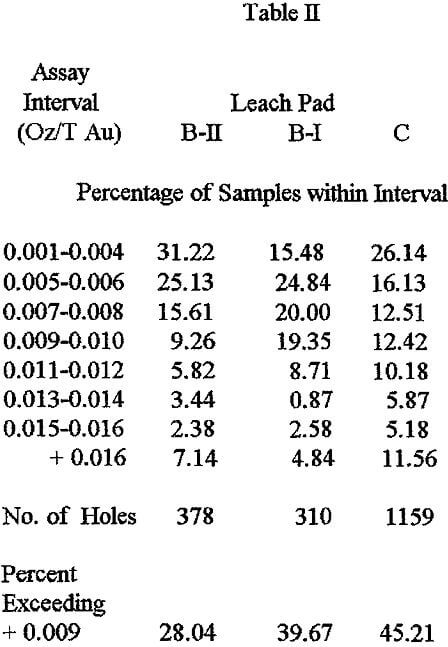

Drill cutting were collected throughout the program. Analysis performed on the pulps clearly show that a significant amount to unleached, or partially leached areas existed within the heaps. The data collected indicated that up to 11.5 % of the ore on the C pad could be classified as being unleached, assays exceeding 0.016 Oz/T Au, and that 45.2 % of the ore could be classified as only partially leached, assays values of 0.009 Oz/T Au or greater. Assays on the 25 foot composite are shown by assay intervals in Table II.

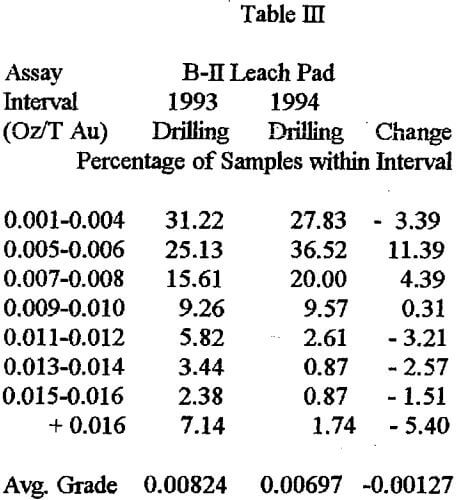

In early 1994 a drilling program was performed on the B-II as a follow up to the 1993 program. The 1994 program drilled to a depth of 50 feet. A comparison of 1993 drilling results and 1994 is as follows in Table III.

The data shown in Table III shows a significant reduction of residual gold on the leach pad between 1993 and 1994. One significant item is the percentage of samples that exceeded the 0.016 OZ/T Au. In the 1993 drilling 7.14 % of the samples Were above the 0.016 grade. This assay interval decreased by 75.6 %. to 1.74 % in the 1994 drilling. This reduction indicates improved percolation arid solution contact after the drilling program.