Table of Contents

Floatable and non-floatable particles follow different sequence for transport from the pulp to the froth and from the froth out of the cell. For floatable particles, the principal mechanism is true flotation (i.e. bubble attachment and levitatlon). Non-floatable particles arrive to the slurry-froth interface by hydraulic entrainment (i.e. wake carry over), mechanical entrainment (due to turbulence), and/or slime coating, all non-selective processes.

Gangue transport in the froth is carried out by the inter-bubble water. There are three mechanisms whereby pulp water with the fine gangue is transferred into the froth.

a. water is dragged along with the bubble walls (i.e. hydraulic boundary layer entrainment around each bubble).

b. water is entrained in the wakes of bubble clusters, and

c. water entrapment as successive layers of bubbles rise to Join the froth column (i.e. bubble swarm theory).

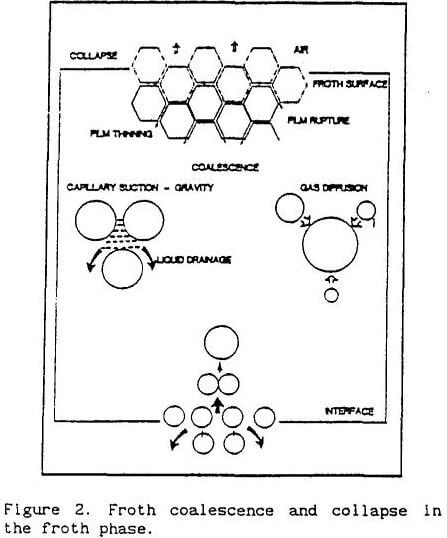

After particles have been transported into the froth, two of the mechanisms by which they may return to the pulp are coalescence and collapse followed by particle drainage (Figure 2). These mechanisms are responsible for secondary concentration (i.e. removal of gangue particles in the froth phase). The interrelationship between these mechanisms determines the froth cleaning.

Froth Drainage

Froth drainage is one of the fundamental irreversible process occurring in all froths. The capillary suction created by the pressure difference and gravity tends to drain liquid towards the regions of greatest curvature. Pleateau borders contain 80-95% of liquid in the froth phase. The thinning and rupture of bubble walls are followed by coalescence. The rate of thinning is inversely proportional to viscosity and directly proportional to the square of film thickness. Liquid drainage is influenced by particle size, shape, and density, bubble size and spatial distribution, and upward water velocity.

Gangue Rejection Mechanisms In the Froth Phase

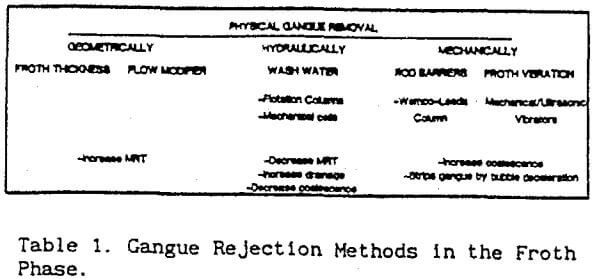

Gangue rejection in the froth phase of mechanical flotation cells is largely achieved by physical means (Table 1): geometrically, hydraulically, or mechanically. Gangue rejection can be maximized by controlling froth residence time, bubble coalescence, or drainage rate. An increase in residence time or in probability of coalescence increases drainage rate.

Increasing froth thickness and the use of flow modifiers lead to a longer particle stay time in the froth phase. Wash water addition decreases the particle residence time and the probability of coalescence, but increases water drainage between bubbles. Mechanical gangue rejection can be achieved by using rod barriers in the froth phase (e.g. Wemco-Leeds Column) or using mechanical or ultrasonic froth vibration. Mechanical gangue stripping increases bubble coalescence and slows down bubbles in the froth phase.

Effect of Wash Water Addition Location

Figure 6 shows the effect of wash water addition location on gangue and water recovery. Gangue recovery without wash water is maximum. Adding water above the froth decreases gangue entrainment at a higher water recovery while adding wash water below the slurry-froth interface decreases gangue entrainment more, but at a much lower water recovery, which in normal plant operation may decrease valuables recovery. The minimum gangue recovery was achieved with both types of additions. Above-froth additions stabilize and expand the froth and increase the water recovery, increasing froth carrying capacity (i.e. higher valuable recovery). Wash water trickles down the froth and washes out loosely held gangue particles, which increases the concentrate grade. Distributors are maintenance free and easily installed and monitored. The disadvantages of above froth addition is the froth disturbance and wash water short-circuiting to the concentrate. The higher the distance between the distributor and the froth surface, the higher the impact velocity of water droplets on bubbles.

Role of Wash Water in Froth Cleaning

Froth washing in mechanical flotation cells improves metallurgical performance for two reasons. First, wash water increases water drainage between bubbles and washes out hydraulically and mechanically entrained/entrapped gangue particles. Second, wash water breaks bubbles in the top froth layer causing them to shower their load on to the bubbles below. A crowding effect is produced in which mineral particles compete for sites on the reduced bubble surface yielding a heavily loaded clean froth. The thickness of the inter-bubble film, the rate of water drainage, and the probability of reattachment of valuable particles play an important role in the froth phase. The thicker the inter-bubble film, the larger the amount of water draining from the froth and more effective is the secondary concentration.

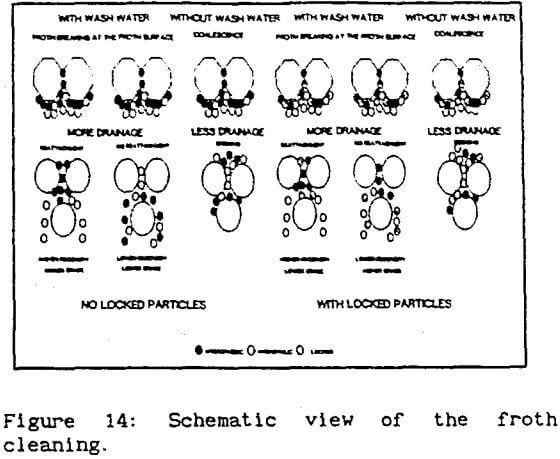

Figure 14 shows a schematic view of froth cleaning with wash water in the presence and absence of locked particles. Here, it is assumed that valuable particles strongly attach to the bubbles due to the presence of surface active agents, locked particles are weakly attached, and gangue particles do not attach to the bubbles. Free gangue particles can easily be rejected; but, locked and/or partially hydrophobic particles may be rejected depending on the nature of solid, froth stability, froth wetness, and wash water pattern.

In the absence of locked particles, concentrate grade and recovery increase if the valuable particles washed on the froth surface reattach to the rising bubbles and gangue particles washed away. If the probability of reattachment is low due to shallow froth, concentrate grade and recovery may decrease. In the presence of locked particles, concentrate grade may not Increase if both free and locked valuables reattach to the rising bubbles (at higher recovery rates). If only free particles reattach to the bubbles while locked ones wash away, grade increases at a lower recovery.

Concentrate grade increases largely due to the increased rejection of the entrained/ entrapped or weakly attached gangue particles. Concentrate recovery can also increase because of froth stabilization, increased water recovery, and increased coarse particle recovery.

Wash water forces feed water, which contains gangue particles, down to the slurry phase, and stabilizes froth by compensating water loss and reducing coalescence. With wash water, bubbles remain spherical and are further apart from each other. Wash water can also prevents overloading, which inhibits drainage, by lightening the froth and allows the concentrate to be pulled harder.