Application of value engineering techniques to grinding process modelling led to the identification of two basic functions of the ball mill-classifier circuit. In terms of a specified circuit product size which is used to differentiate between “coarse” or oversize material and “fines” or undersize material, these basic functions are (a) breakage of the coarse material and (b) removal of the fines. It was proposed that it may be useful to relate circuit design and operating variables to these basic circuit functions, which although related, are conceptually quite distinguishable. If each could be quantified by a suitable parameter, then either or the two together may be correlated to overall circuit efficiency, and hence used to link individual design and operating variables to overall circuit performance.

Ball mill circuit classification system performance is considered here first because it provides the basis for subsequent characterization of ball mill breakage efficiency.

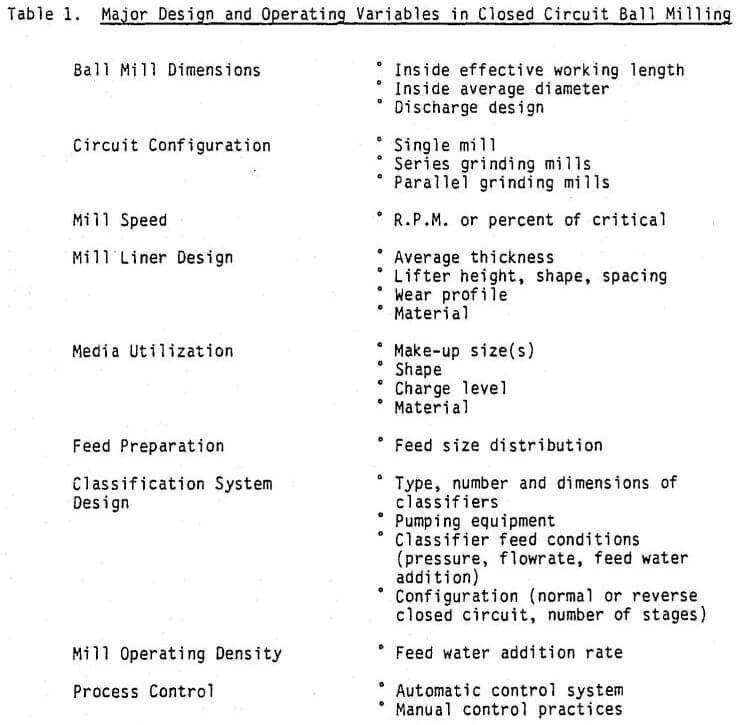

Major design and operating variables in closed circuit ball milling of a specified feed to a desired product size are summarized in Table 1. The purpose of process modelling is to establish cause and effect relationships between physical design and operating variables and the performance objectives of the circuit. Subsequently, output and efficiency can be maximized. The fundamental issue addressed by ball mill circuit modelling is thus depicted in Figure 1 (McIvor, 1989).

Steady state models provide the plant metallurgist with performance parameters which can be calculated and compared from two or more sets of operating data.

In the simplest form of plant experimentation, a key performance parameter (such as the fineness of the final product) is measured with and without a specific change to the circuit. Within the constraints imposed by the accuracy of measurements and assumptions about the constancy of other inputs (including the ore characteristics), the relative values of this parameter are used to evaluate the effect of the change on circuit performance.

Bond work index analysis takes this method of experimentation several steps further. During comparative testwork, variations in the ore grindability, grinding energy input, and feed and product sizing are measured and accounted for through the grinding circuit “model” embodied in the work index formulation. For each set of data, both the circuit operating work index and the laboratory test work index of the circuit feed are determined. Relative work index efficiencies with and without the change to the circuit can then be calculated and compared.

Ball Mill Breakage Efficiency

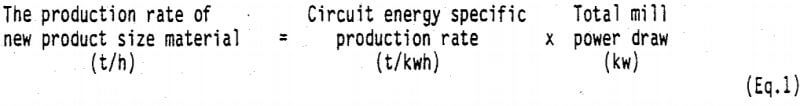

Consider a ball mill circuit processing material of a given feed size and at a given throughput rate to a target product size, the latter which once again distinguishes the “fines” from the “coarse” material. The production rate of fines or new product size material can be calculated from the circuit feed and product size distributions and the throughput rate of the circuit. Based on the energy expended in the ball mill, the production rate of new product size material (tonnes/h) equals the amount produced per unit of energy applied (tonnes/kwh) times the rate at which energy is applied (kwh/h). The rate at which energy is applied is the power draw of the ball mill. If we then define the production per unit, of energy applied as the “energy specific production rate” of the circuit, then we can write the following equation:

The circuit power specific production rate reflects the overall efficiency of the circuit on the particular ore over the particular size reduction range.

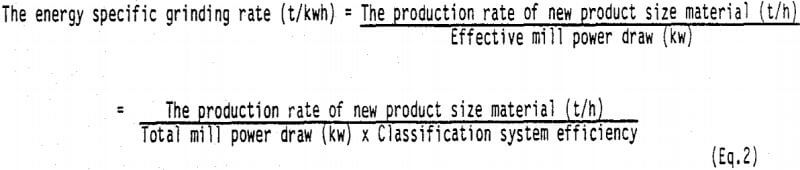

All the production of new product size material takes place in the mill as “coarse” is ground into “fines”. However, the proportion of the total mill power applied to size reduction of coarse particles is equal to the fraction of coarse solids inventory, or the so defined circuit classification system efficiency.

The energy specific grinding rate of the coarse material in the ball mill can then be defined as follows:

The mill specific grinding rate reflects both the efficiency of the mill environment in breaking the coarse particles, as well as the grindability characteristic of the ore over the particular size reduction range.

To arrive at a term which reflects only the efficiency of the mill environment, we must factor out the grindability of the ore, such as the net grams per revolution measured in a Bond work index test. This will yield the specific grinding rate in the plant ball mill relative to the measured specific grinding rate in a standard test mill, and may be termed the “grinding rate ratio”.

Grinding rate ratio = Plant specific grinding rate/Test specific grinding rate………………………….(Eq. 3)

The grinding rate ratio may be considered dimensionless because each revolution of the test mill requires a fixed amount of power. It is based on breakage of only the coarse material in both the plant ball mill and the standard laboratory test mill. It is therefore proposed that the grinding rate ratio is a direct measure of the relative overall breakage efficiency of the environment of the plant ball mill.

Ball Mill Circuit Functional Performance Equation

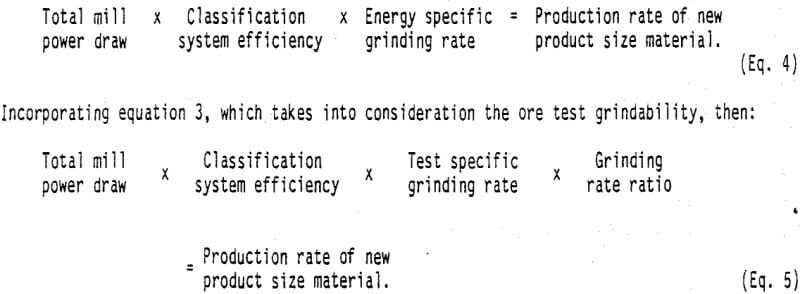

The above described parameters for system breakage and classification system efficiency factor the overall task of the ball mill circuit into its two distinct basic functions, namely, fines generation and fines removal. The effect of design and operating variables on each can be studied separately, and when the product of the two is maximized, maximum overall circuit efficiency will be achieved. Equation 2 may be re-written as:

This has been termed the ball mill circuit functional performance equation (McIvor, 1989). It states that the output of new product size material of a ball mill circuit with a given feed size is determined by:

a. the total mill power draw;

b. the classification system efficiency, which defines the fraction of the total mill power effectively applied to the grinding of coarse material;

c. the grindability characteristic of the ore over the size reduction range of the circuit; and,

d. the breakage efficiency of the ball mill environment on the coarse material.

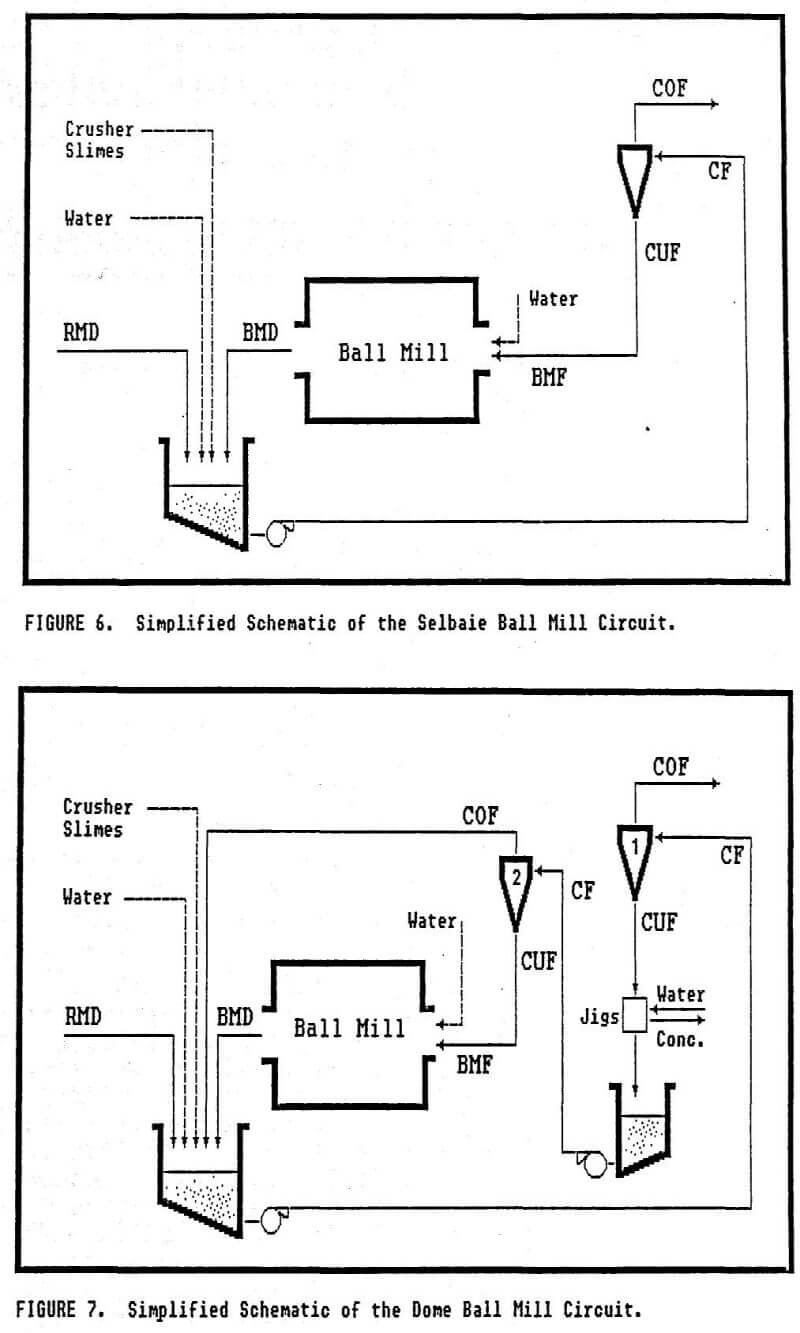

While all four factors clearly influence the circuit output, overall circuit efficiency will be determined by classification and breakage efficiency. Specific design and operating variables can now be considered in terms of their individual effects on classification and breakage efficiency, and subsequently on the overall efficiency of the circuit. This provides an intermediate level of ball mill circuit performance characterization, as shown in Figure 5.