The clear abstraction of application specific knowledge from computer instructions is fundamental to all expert systems. This property greatly simplifies the encoding of knowledge and allows expert systems to describe their line of reasoning. Provided first that a human expert can articulate his skills, the expert system can mimic his decision making.

The label “expert system” is a somewhat ill defined term, i.e. not everyone accepts the same general definition. As an example, one of the more popular self-tuning controllers is said to be based on an expert system. Granted, it performs the self-tuning function using the same knowledge as a skilled control engineer, but it can be argued that it is not a true expert system because, for one reason, it cannot be interrogated. One essential characteristic of an expert system is that it has an interrogation facility. All useful computer programs contain specialized knowledge, but only expert systems are readily interrogated.

The Grinding Circuit

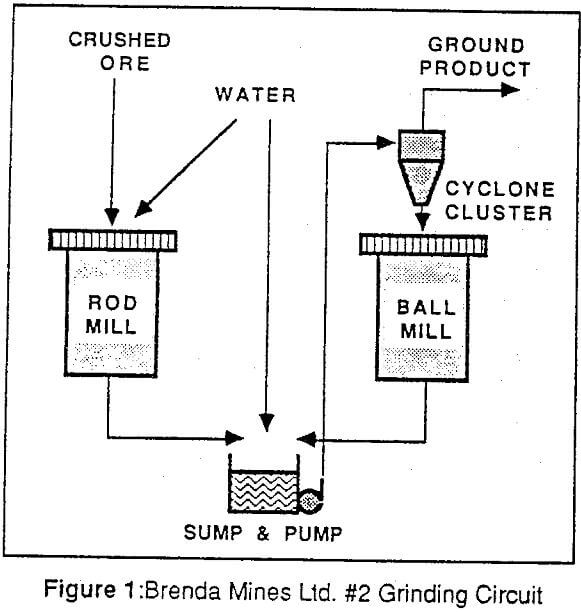

A proper evaluation of expert systems for process control must consider the process. The grinding plant is typical of many mineral concentrators. It consists of four parallel circuits each of which has four unit operations: rod mill, ball mill, slurry pump and hydrocyclone. These are illustrated in Figure 1.

Crushed ore is conveyed to the rod mill. Water is added to the rod mill in proportion to the ore in order to maintain a constant slurry density within the mill. The rod mill discharge flows into a pump box where it is diluted by a second water flow and by the discharge from the ball mill. The mixture is then pumped to hydrocyclones which separate the fine and coarse particles. The underflow reports to the ball mill for additional grinding, while the overflow leaves the circuit as flotation feed.

Expert System Control Strategy

Grinding is a process by which ore is comminuted to better liberate and hence recover the valuable mineral. All else being equal, the greater the ore feed rate the coarser the grinding product and the greater the metal losses. A concentrator must, therefore, balance the production rate with the metal losses. At Brenda Mines, the metal losses, due to coarser grinding, are out-weighed by the increased revenue due to the higher production rates. Brenda’s strategy is, therefore, to always process the ore at the highest possible rate.

The highest production rate is achieved by running the grinding circuit within its constraint conditions. A grinding circuit overload is defined as an overload of either the rod mil! or the ball mill. (The cyclones have never overloaded, or roped, under any operating condition encountered and are not considered a constraint). A rod mill overload is vaguely defined as the condition where the amount of rod mill reject becomes excessive and where an increasing amount of broken rods are being rejected (the ultimate overload is a rod tangle). The mill motor power draught and the discharge trunnion vibration signals are used to indicate this condition. A ball mill overload is defined as the condition where the mill holdup slurry density (viscosity) reaches a level where steel chips are rejected in significant quantity. The mill motor power draught is used to indicate this condition.

The operators have learned, however, that the cyclone feed density can also be used as an indication of the mill loading, despite the significant time lag inherent in controlling with this signal. The control strategy achieves and maintains the high production rates within these constraints through the adjustment of the manipulate variables.

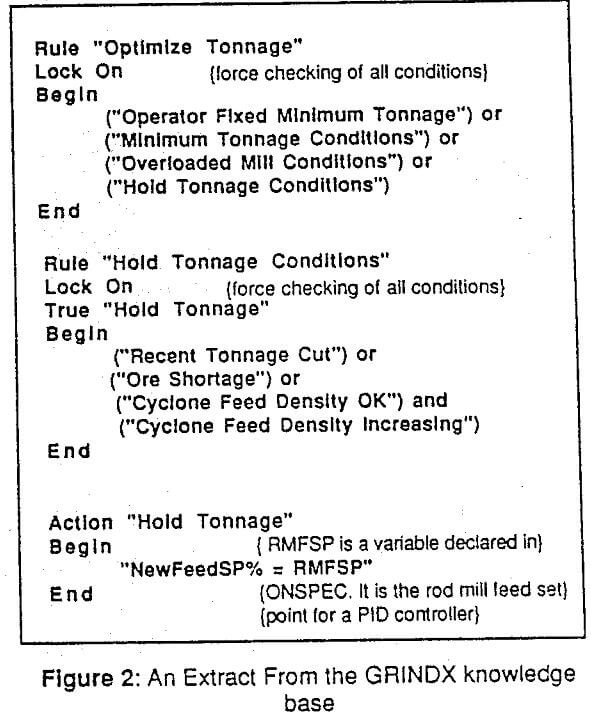

In the grinding circuit the manipulate variables are the rod mill feed rate, the rod mill water addition rate, and the cyclone dilution water addition rate. Through previous in-house experiments at Brenda, however, the rod mill operating density was found to have little affect on the grinding efficiency of the rod mill. Thus, rod mill water addition rate is ratioed to the rod mill feed rate to maintain a constant rod mill discharge density, independant of production rate. The rod mill feed rate and the cyclone dilution water addition rate (also referred to as the pump box water addition rate) are thereby the only two manipulate variables that may be used to control the grinding process. Both the current Brenda program and the expert control system must adjust the rod mill feed rate and the pump box water addition rate to keep the rod and ball mills below their overload conditions, yet at the maximum production rate.

The control routines for the current control program and the expert system are very similar, though one very significant difference does exist. Firstly, both routines are peak-seeking routines that maximize the circuit throughput by continually increasing the mill feed rate until one of the constraints is reached. The feed rate is then cut back to allow the constraints to clear, but is allowed to increase again once the circuit has returned to an unconstrained operating condition. A time trend of the mill feed rate would then have the appearance of a saw tooth.

Secondly, the routines use the same indicators to detect rod mill and ball mill overload conditions. And thirdly, both routines rely heavily on the cyclone feed density and its operator entered set point to maximize the production rate. Typically it is the cyclone feed density and the ball mill constraints that restrict the increases to the throughput. Historically, however, the rod mill was the overriding constraint, but the mill has been sped up and now has capacity for all but the highest of production rates. Overall, the cyclone feed density constrains most often, the operator must be diligent and use his judgement to constantly select the optimum density set point to maximize the tonnage. Unlike the current CP250 supervisory control program, the grind control knowledge base includes an additional constraint on the cyclone overflow density. High overflow densities typically indicate poor cyclone efficiencies and hence poor particle size separation (which implies a coarsening in the overflow). The CP250 program allows coarser overflows, relying on the operator’s judgement to limit circuit throughput; hence, maintaining a reasonable overflow density. The expert system, on the other hand, takes action on this high overflow density by increasing pump box water which effectively dilutes the cyclone feed, dilutes the overflow, improves the cyclone efficiency, and increases recirculating load; thereby attempting to maintain the grind in the overflow. This action, however, can reduce the throughput of the circuit. Consider a situation where the ball mill is already near an overload condition, the additional water will cause more coarse material to report to the ball mill and, since it is already near its peak loading, could potentially cause an overload. Thus, by constraining and acting on high cyclone overflow density, the expert system (loosely) maintains the grind but at the cost of circuit throughput.