Table of Contents

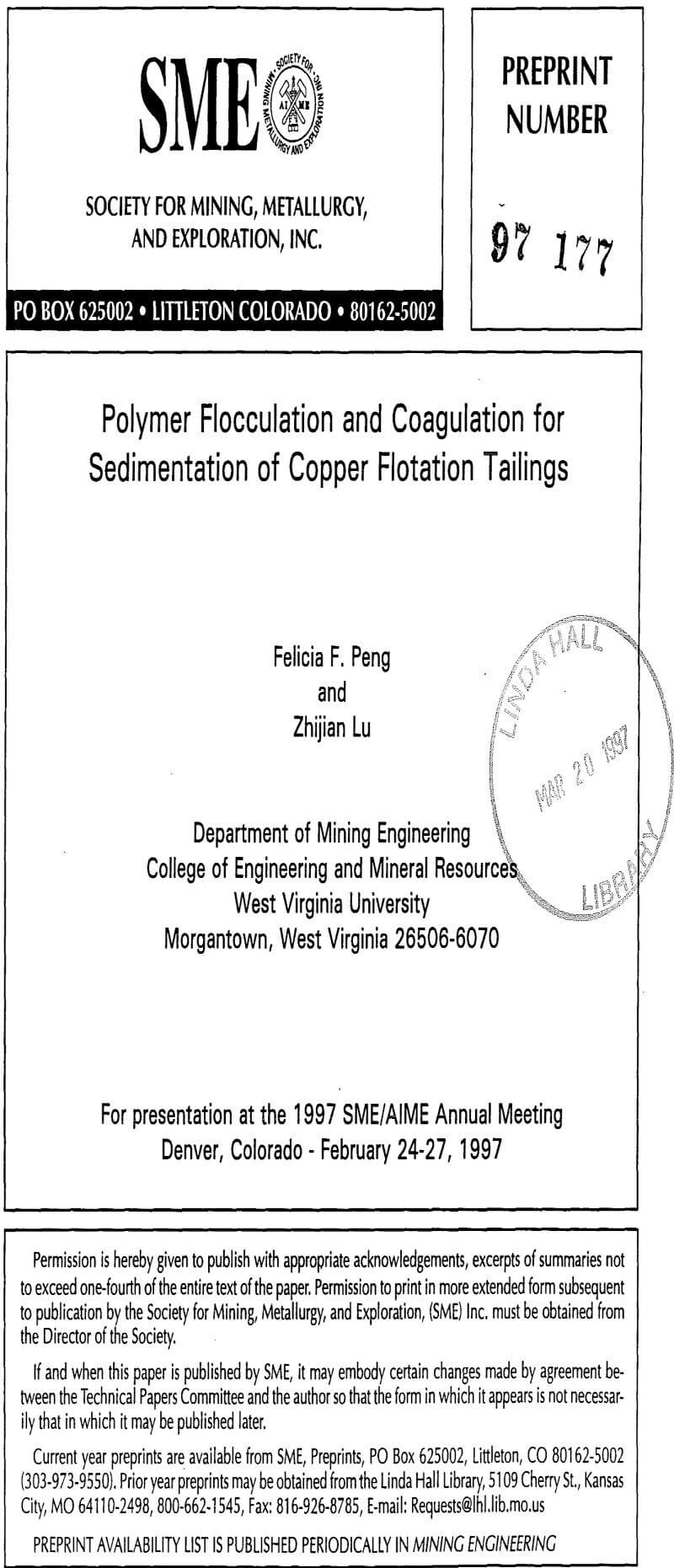

Dynamic tests were conducted in a laboratory continuous thickening system. This system, shown in Figure 1, consists of a 3½ in. (89 mm) ID and 20 in. (508 mm) height lab thickener/clarifier equipped with feed, polymer and underflow pumps, bed level sensor and controller. Rake speed, the gap between the deflector plate and feed pipe, and pump speeds may be regulated to alter the operating conditions. The bed level sensor transmits the signal to the controller which automatically controls the operation of underflow pump in order to maintain a suitable bed level. Bed level can also be operated manually by adjusting the speed of underflow pump. Samples of the underflow and overflow were taken every 15 minutes after the system reached a steady state. Overflow quality was determined by a Clarity Wedge and calibrated to TSS. Feed solid concentrations used were 14.6 and 28.2 percent at pH 8.8 using a dual polymer system. Feed rates were varied from 440 to 1,150 mL/min (1.45 to 2.04 t/h/m²) to determine the maximum thickener capacity at the required overflow quality and underflow density. Polymer dosages were varied from 7.6 g/ton to 19.6 g/ton anionic polymer using 0.0125 percent solution and up to 15 g/ton cationic polymer using 0.0125 and 0.00625 percent solution, respectively. Rake speeds were regulated from 4.1 to 16.0 rpm.

Effect of Polymer on Overflow Clarity

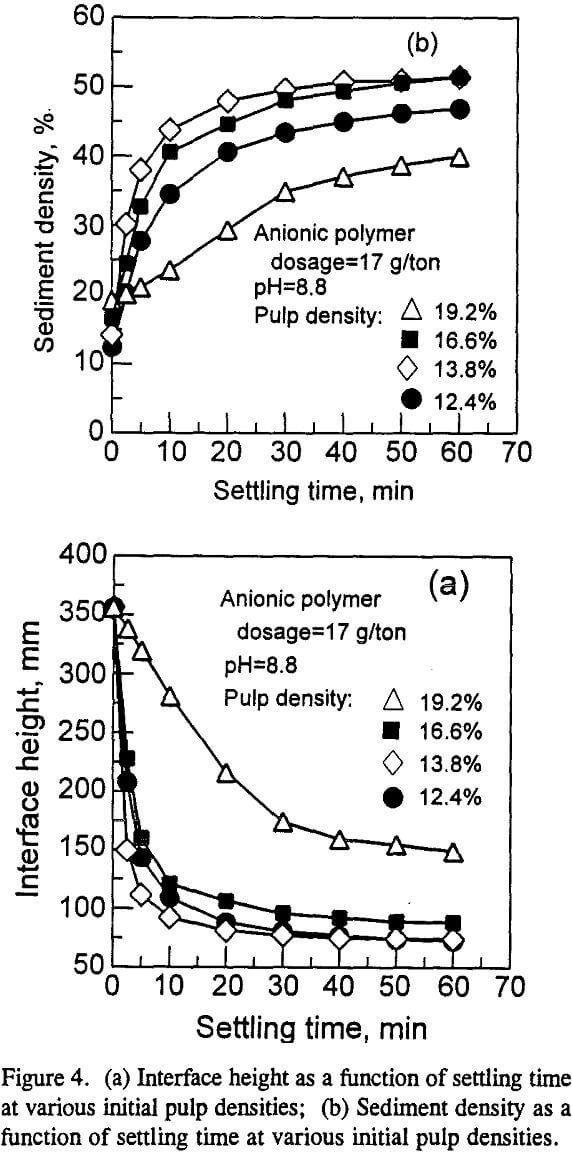

Dynamic test results are presented in Table 4. In the dynamic test, when a pure anionic polymer is used, the interface does not appear at the polymer dosage as high as 20 g/ton and 2,300 mg/L TSS is reported in the overflow. This value is higher than the TSS measured in the supernatant (996 mg/L) of the batch test using 10.65 g/ton of anionic polymer. For a dual polymer system, if anionic polymer is insufficient (less than 11 g/ton), a very high TSS in the overflow is also observed. When the anionic polymer dosage is 12.1-16 g/ton, the TSS in the overflow decays exponentially with the increase in cationic polymer dosage, as shown in Figure 5. When the cationic polymer dosage is increased to 3.3 g/ton, TSS in the overflow sharply decreases to 160 mg/L. A very sharp interface occurs at the cationic polymer dosage of 7.7 g/ton and less than 80 mg/L TSS is reported in the overflow. With further increasing in cationic polymer dosage the TSS in the overflow reaches less than 50 mg/L. Two important differences between the batch and the dynamic tests are observed. One is that overflow in the dynamic test is more turbid than the supernatant of the batch test when the cationic polymer is absent or at a low dosage (less than 1.5 g/ton) for a given anionic polymer dosage. In other words, the higher anionic polymer dosage is required in the dynamic test than in the batch test for the same water clarity. The other is that when the compact sludge blanket is formed, the required cationic polymer dosage to achieve the same water quality is much less for the dynamic test than the batch test. Once the compact sludge blanket is formed, the very clear overflow can be maintained with very low dosage of cationic polymer, e.g., 3.8 g/ton for lasting about 30 minutes as long as the compact blanket is maintained.

When a pure anionic polymer is used, the sludge blanket is formed by large and loose flocs. The fine particles which are not flocculated move up with upward flow through the sludge blanket and enter to the overflow. When a dual polymer system is used, cationic polymer coagulates the fine particles to coagula which is enmeshed and trapped into the loose blanket to form a compact sludge blanket. Consequently, a sharp interface is formed and a very clear overflow is obtained. Since the sludge blanket in the dynamic thickener operation is forming and settling continuously, if the compact blanket settles below

the feed injection position, newly formed blanket, due to lack of cationic polymer to form the coagula, is in a loose state, and the overflow turns turbid. In dynamic test, it is found that the consumption of the cationic polymer is about the half of the dosage used in batch test, the anionic polymer is about 110 percent of the dosage used in batch test. This results indicate that the overall consumption of polymers in the dynamic test is less than that in the batch test.

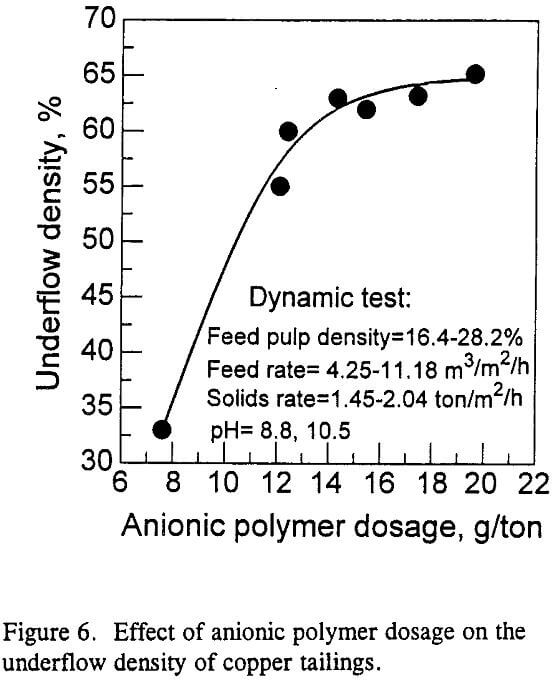

Effect of Polymer Addition on Underflow Density

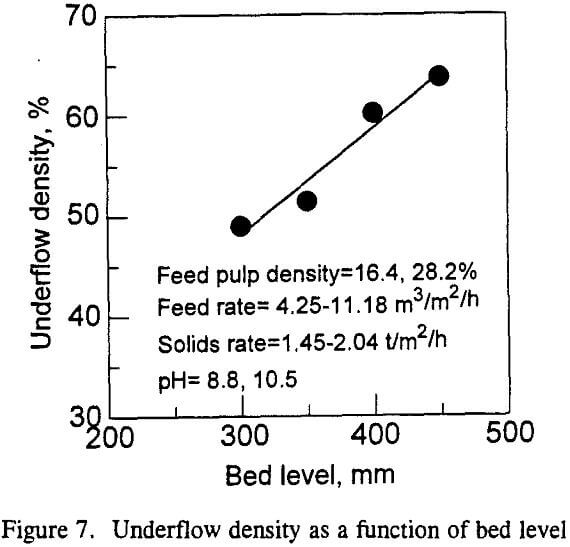

As shown in Figure 6, under various operating conditions, the underflow density increases exponentially and reaches an plateau, and remains relatively constant when P727 dosage is increased to 15 g/ton solids. The polymer is increased 60 percent (from 12.4 g/ton to 19.6 g/ton), 5 percent increases in the underflow density was observed (from 60 to 65%). Further increase in underflow density will primarily depend upon the increase in the retention time and the depth of compression zone. Although underflow density increases exponentially with the increase in the anionic polymer dosage, the requirement of excessively high underflow density is obviously not economical.

Effect of Polymer Addition on Thickener Capacity

Thickening capacity is expressed in terms of feed rate as shown in Table 4. To obtain 60 percent underflow solid density and less than 50 mg/L TSS in the overflow the minimum polymer dosages of 7.7 g/ton cationic polymer (Figure 5) and 13 g/ton anionic polymer (Figure 6) are required for the feed rate at 2.04 ton/h/m² (Run No. 19). Once the compact sludge blanket is formed and the required overflow clarity reaches with an adequate amount of dual polymers, the overflow quality is no longer the limiting factor for the thickener capacity. In this case, an increase in cationic polymer dosage has little effect on the thickener capacity, while anionic polymer dosage should be increased as the feed rate increases. Since the high feed rate also means a high upward flow velocity, a higher settling rate of flocs is required. It is worth noting that the prerequisite with optimal dosage of polymer molecule adsorbing on the particles and successfully forming the flocs is necessary to ensure the vacant sites existed on the particle surface and molecule stretching sufficiently. Excessive polymer addition easily results in lacking of vacant sites on particle surfaces and molecule curving.

Effect of Feed Concentration

Two feed concentrations are used in the dynamic test including 28.2 and 16.4 percent. Dynamic test results show that the thickener capacity is higher by using 16% than 28% solid feed concentration.

Effect of Rake Speed

The test results show that rake speed has no effect on the underflow density or overflow clarity at the range of 7.0 to 16.0 rpm for the continuous lab clarifier/thickener.