Table of Contents

Domestic mines account for a mere 2 pct of the manganese consumption in the United States. Although plentiful supplies of manganese are readily available from several foreign countries, the Nation’s vulnerability to sudden cessation of foreign shipments plus the current trade imbalance has stimulated a renewed search for economic methods of producing manganese from domestic deposits. The Bureau’s Minerals Availability Field Office recently published a study (Kilgore and Thomas, 1982) that manganese could not be produced competitively from 8 domestic deposits using various conventional mining and milling schemes. The long-run total costs for production from these domestic operations ranged from $8 to $35/long ton unit or 22.4 lbs ($.16 to S.71/kg) contained manganese as compared to 1982 prices averaging between $1.60 and $1.70/ long ton unit ($.03/kg) for 48 pct minimum grade manganese ore imported f.o.b. Chicago or Pittsburgh.

Clearly, significant new technology is necessary to enable domestic producers to produce manganese at competitive prices. From strategic material and market size standpoints, such new technology would have the greatest impact. If it provided manganese in the form that could be used directly by the steel industry. The chemical, battery, and superalloy industries, however, annually consume about 100,000 tons (10 x 10 6 kg) of manganese and it is these markets that seem attractive targets for the technology recently researched by the Bureau—in situ and/or heap leaching manganese with aqueous SO2. Although the products of leaching cannot be charged directly into steelmaking furnaces without expensive reprocessing, they can be readily incorporated into other industries as manganese sulfates, oxides, and carbonates.

In situ leaching has been very successful for uranium and, to a lesser degree, for copper. Heap leaching has become a very important source of gold, silver and copper. Leaching offers advantages of low capital cost, low operating cost, and short start-up times as well as environmental and safety improvements over conventional mining. The primary disadvantage—low recovery—favors consideration of the method for small and/or low grade deposits that would not otherwise be mined. Most domestic manganese deposits fall in that category.

Leaching manganese with SO2 was explored by the Bureau during the 1940’s (Wyman and Ravitz, 1947). Experiments demonstrated that a variety of manganese deposits could be leached with SO2 to produce manganese sulfate solutions. Laboratory leaching tests led to pilot plant experiments and eventually to commercial production of manganese from a vat leaching operation during World War II. Although heap leaching experiments were conducted in the 1950’s, (Bender and Rampacek, 1957), in situ leaching was not seriously considered until Mr. James Lake presented several ideas on leaching the Artillery Peak deposits to the Bureau. A contract subsequently awarded to a private firm to evaluate feasibility of in situ leaching various metals concluded that in situ leaching of massive oxide manganese deposits offered potential for commercialization for specialized manganese markets (chemical products) (Potter, et al., 1982; Potter, Chase, Chamberlain, 1982).

The favorable consideration given to leaching manganese triggered an in-depth evaluation of leaching potential, summarized in this paper. The approach was basically to: 1) rank deposits based on geologic, hydrologic, and geographic factors; 2) collect samples from a variety of the types of deposits that were highly ranked; 3) conduct laboratory leaching tests on the samples with aqueous SO2; 4) analyze technical feasibility and economics of leaching several typical types of deposits; and 5) conduct field tests to verify laboratory results and certain assumptions in the economic analysis. Budgetary constraints have, however, prevented any field testing to date.

Early in the investigations, a special circumstance of leaching manganese presented interesting possibilities—leaching silver ores that are refractory to ordinary cyanidation because of their manganese content. A dual leaching system consisting of leaching the manganese out of the ore with aqueous SO2 followed by leaching the silver with cyanide (after flushing with NaOH or lime to remove any acid) appeared promising for greatly increasing silver recovery as well as providing salable manganese. Results of experiments with such a method are presented separately (Rhodes, Pahlman, Chamberlain, 1984).

Evaluation of In Situ Leaching for Manganese

Background data were gathered on as many manganese deposits as possible. To provide an objective rationale for selecting deposits to be used in the laboratory testing program and to establish “typical” conditions as a basis for conceptual designs and cost analysis, an arbitrary ranking process was implemented. Ranking factors included geologic, hydrologic, and geographical considerations. A variety of highly ranked deposits were selected for the testing program and subsequent evaluation of leaching potential. An attempt was made to ensure representation of different manganese minerals (oxides, hydroxides, carbonates, silicates), physical characteristics, geologic origins, and geographic locations in the selected list.

Characteristics of Selected Deposits

The deposits that were sampled and tested in column leaching experiments are characterized in table 1. The higher order oxide minerals predominate—pyrolusite, psilomelane, and wad (an amorphous assembladge of oxides). Hydrothermal vein deposits are the most numerous although the sedimentary deposits are larger and may represent more viable leaching targets. The sedimentary deposits are generally massive, low grade, and high volume compared to the higher grade, small volume, vein deposits. With the exception of the Cuyuna deposits, the sedimentary beds were horizontal while most of the vein deposits are steeply dipped.

Laboratory Tests

Although many laboratory tests have been conducted on leaching manganese ores with aqueous SO2 (summarized in Chamberlain, 1981), the testing program established at the TCRC had several key differences from those earlier tests. For evaluating heap and/or in situ leaching possibilities, relatively large size ore pieces (compared to the more common 100 mesh size) were tested since they are the ones that control leaching rate, recovery, and profitability. Percolating leach solutions through ore columns rather than immersing samples in beakers was the preferred testing method because it more closely simulated operating conditions. A final difference from earlier programs was the use of low concentration of SO2 in solution. Tests conducted on sea nodules (Khalafalla and Pahlman, 1981) earlier had demonstrated that at low concentrations, SO2 was more selective in the metals it leached than it was at high concentrations. At a 5 pct solution, most of the would be leached but very little of the iron and other metals would be co-leached.

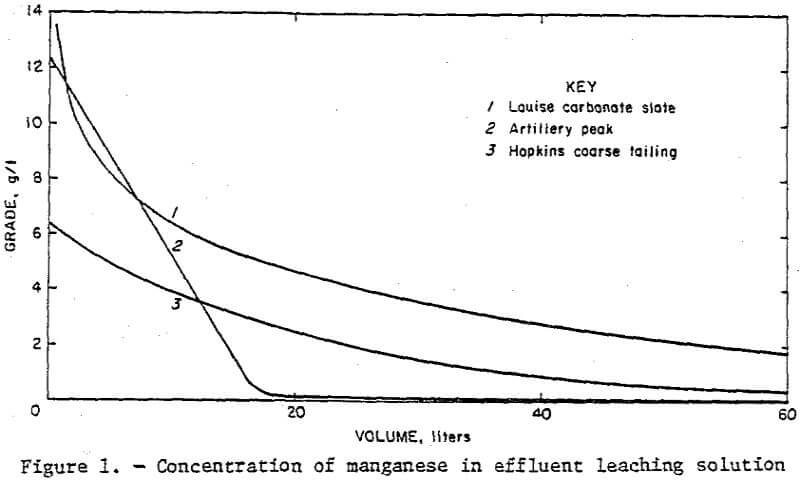

Column leaching tests were conducted in 4 in (10 cm) columns that were 3 ft (3m) long and contained 3.5 kg of -1 in +½ in (2.5 x 1.3 cm) pieces. A 5 pct SO2 solution was dripped into the column at 1 ml per minute. This rate was fairly close to the application rates in gold/silver and copper heap leaching operations. At that rate the entire column remained unsaturated. The tests were usually run until the manganese in the effluent from the column dropped to about 1 g/L (figure 1). During any one test at least 50 L of solution was applied except for the columns of Artillery Peak ore in which 25 to 30 L of solution extracted most of the manganese.

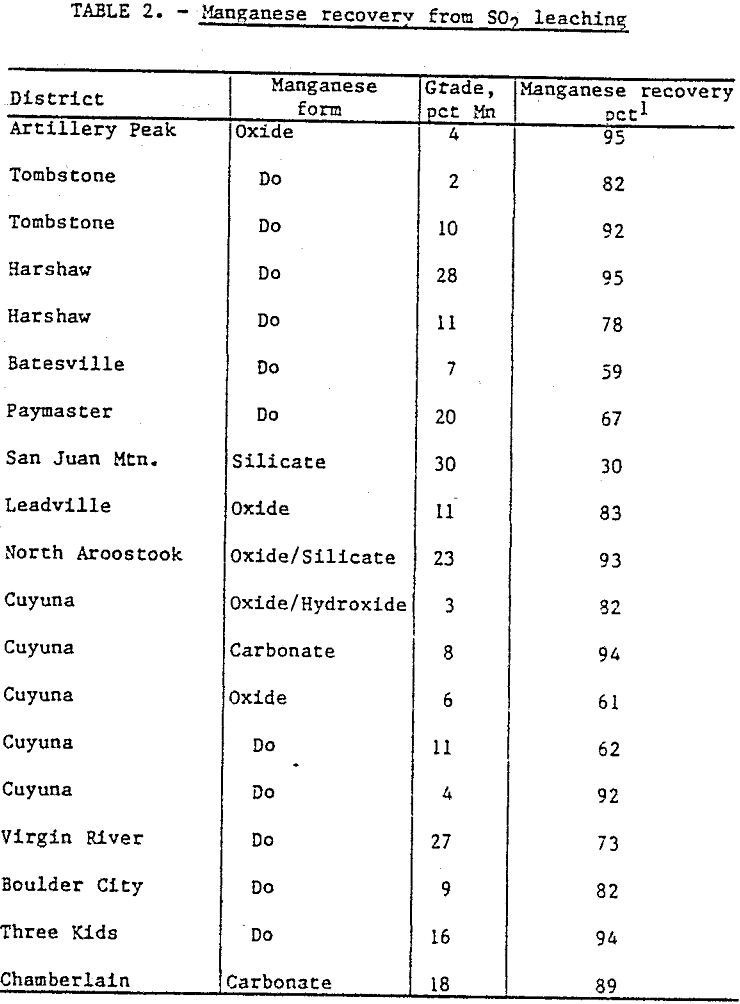

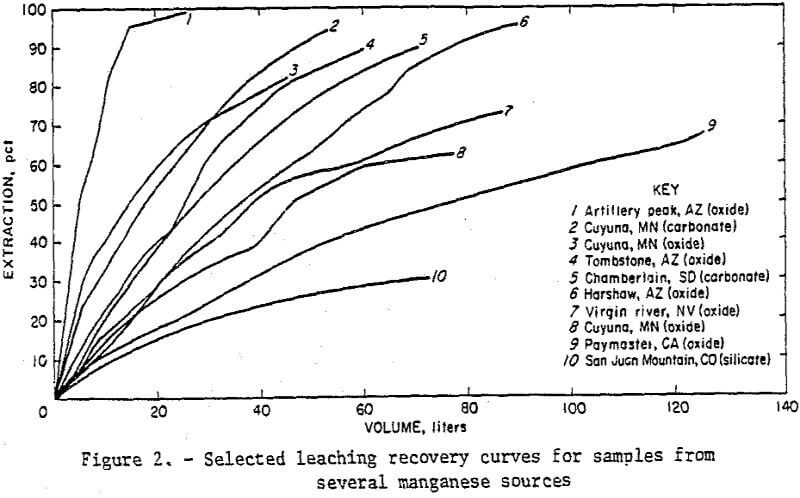

Manganese oxides, carbonates, and even silicates were all leachable in column leaching tests (figure 2, table 2). Although the leaching rate was highest for Artillery Peak samples, the higher grade of materials from other sites may provide effluent solution grade equal to or greater than that obtained from Artillery Peak. Greater than 80 pct extraction was obtained for most manganese oxide ores. Although batch tests on finer particles of ore conducted in flasks had earlier indicated minimal manganese leaching from carbonates and silicates, the percolating action of solutions in column leaching yielded recoveries from carbonate samples of greater than 90 pct. Leaching of manganese silicates, although slow, resulted in solubilization of 1 to 2 g of manganese per liter of leach solution applied.

Several generalizations can be stated about leaching manganese ores in the columns. First, the leaching rate of most ores tested is not dependent upon the solubilization reaction between the manganese and aqueous SO2, but instead upon the rate of solution ingress and egress from ore particles. Batch tests on several oxide samples demonstrated that, if ground to minus 60 mesh, more than 90 pct of the manganese was leached within a few minutes compared to the several days required of the large pieces used in the column leaching tests.

Second, the leaching rate of manganese is affected by gangue minerals present in the ore. Calcium for instance, is readily solubilized by SO2 solutions which diminishes the opportunity for manganese dissolution. This was evidenced by the results of leaching tests on two ores with similar manganese and iron contents, but different calcium contents. After passing 90 L of 5 pct SO2 solution through the column of each ore, the one with 5.7 pct calcium showed 73 pct manganese extraction while the one with only 1.0 pct calcium demonstrated 95 pct manganese extraction. Also iron as goethite or carbonate in an ore competes with the manganese for the SO2. Although SO2 has more affinity for manganese than iron, when the top layers of ore in the column are depleted of manganese, the SO2 will still pass in and out of these ore pieces leaching the next available metal.

Third, although there was a spectrum of manganese minerals in the samples tested, the majority of samples that contain either pyrolusite, psilomelane, wad, or rhodochrosite yielded manganese recoveries in the 80 to 95 pct range.

It is also interesting to note that rhodonite, a manganese silicate that is supposedly inert to SO2, appears to be leachable, although at a slow rate. This ore continued to leach at 1 to 2 g of manganese per liter even after application of 70 L of solution to the column.

Evaporation tests were made to identify the manganese species in the leach solution. Research in the 1940’s indicated that the manganese in solution would be predominantly as a sulfate with some dithionate, which x-ray analysis of the evaporation residue from the column leaching tests confirmed for deposits that contained high-valence manganese. Manganese in leach solutions obtained from manganese in the plus 2 valence, was primarily a bisulfite which decomposed to sulfite and SO2 upon heating.

Tests were also conducted on techniques for extracting manganese from the leach solutions. The easiest technique was to simply evaporate the solution to obtain manganese sulfate that is directly marketable as a fertilizer component. By raising the pH of the leach solution to 6 and filtering it prior to evaporation, ferrous and ferric iron were precipitated while manganese remained in solution. As an alternative to evaporation, the filtered solution was reacted with a base to precipitate the manganese as hydroxide that upon drying oxidized to either Mn3O4 or MnO2. This product could be used as feed for further processing by battery and chemical industries. In yet another alternative, the iron-free solution was sparged with CO2 to precipitate manganese carbonate that, upon heating, decomposes to an oxide. These products are of interest to battery and chemical industries or can be redissolved for electrowinning metallic manganese.

Conceptual Design and Cost Analyses

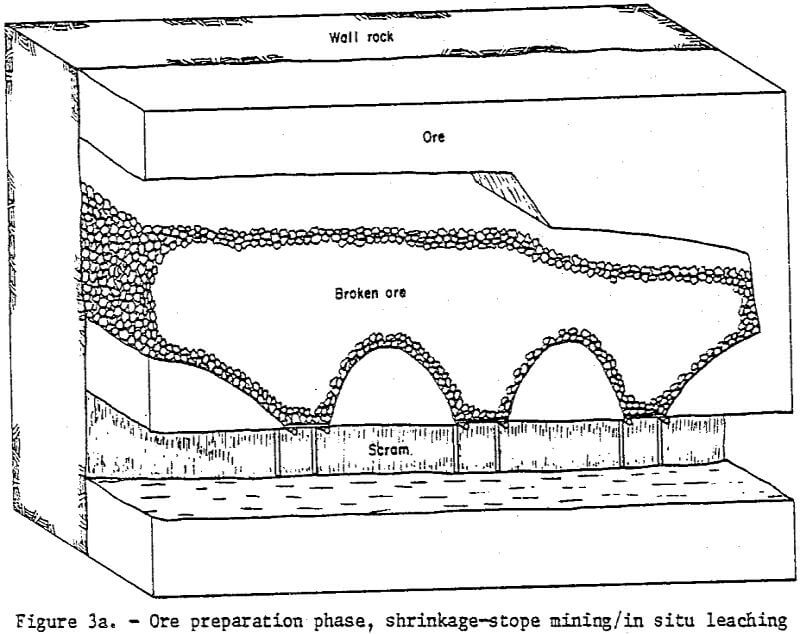

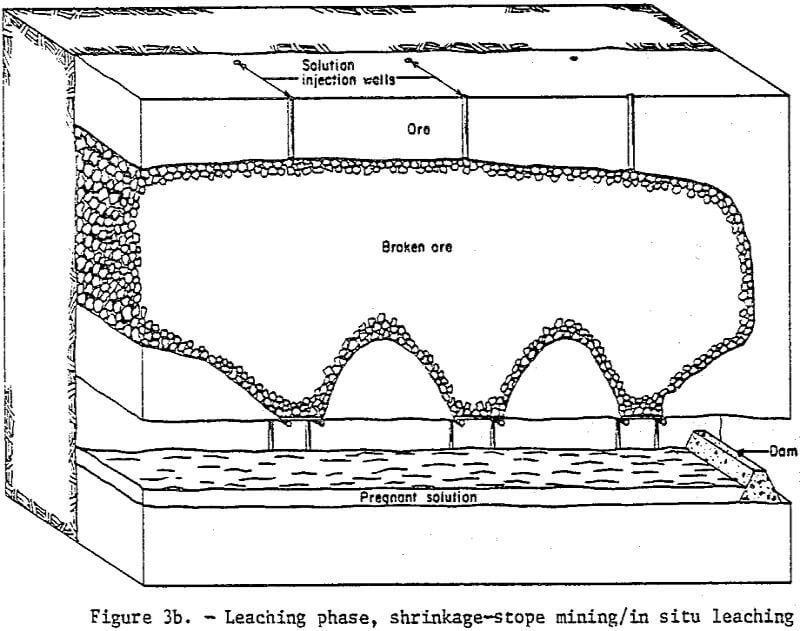

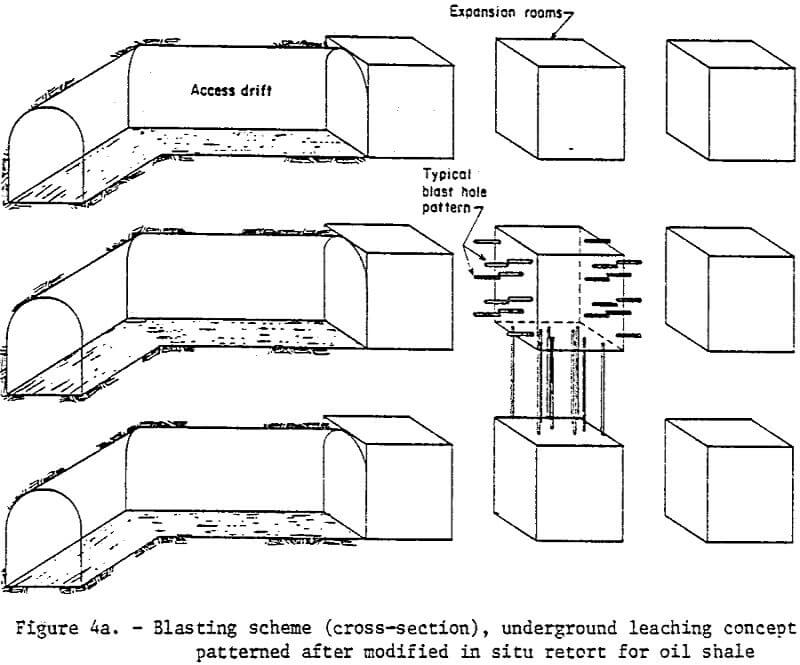

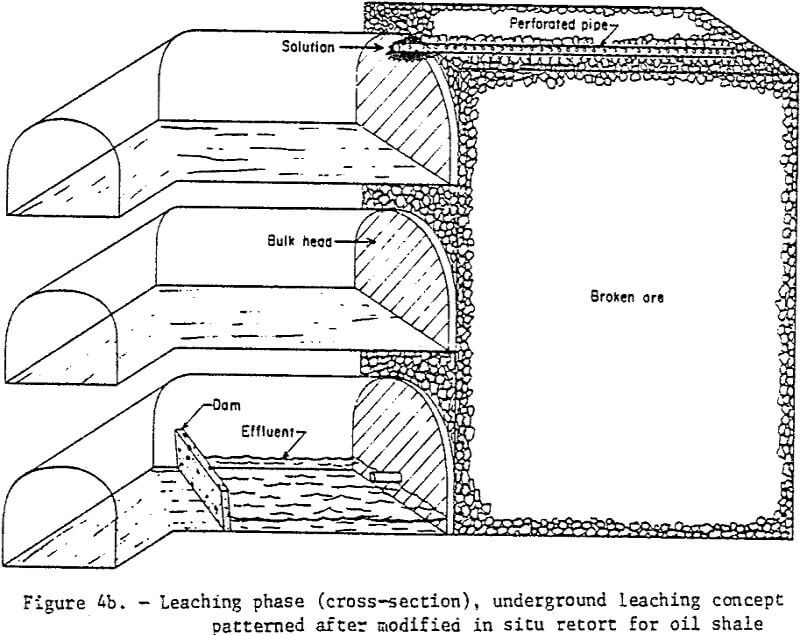

With the wide variety of manganese deposits in this country that are potentially leachable, an equally wide variety of mining/leaching schemes can be considered. Basically any system that is or would be developed for mining an orebody of certain configuration and physical properties becomes a prime candidate system for preparing a manganese orebody of similar configuration and properties for leaching. For instance, a shallow orebody that would be mined from an open pit for milling would, for a leaching system, be mined from an open pit and heap leached. Deeper deposits could be broken for leaching by shrinkage stoping (figure 3), long-hole open stoping- stoping, sublevel stoping, other overhand stoping, or by block caving methods exactly as they would be mined for conventional milling. The prime difference of a leaching system from a conventional system is that only enough rock would be hauled to the surface to provide room for the remaining rock to expand during the breakage process; the 20 to 25 pct hauled to the surface would be heap leached while the remainder would be leached in place underground. The underground oil shale retorts created by Occidental Oil Shale at their test facility in Colorado also seem reasonable patterns for creating underground chambers in which massive manganese deposits could be leached (figure 4). The primary cost savings with any of these systems becomes obvious: reduced haulage/hoisting requirements and no expensive milling operations.

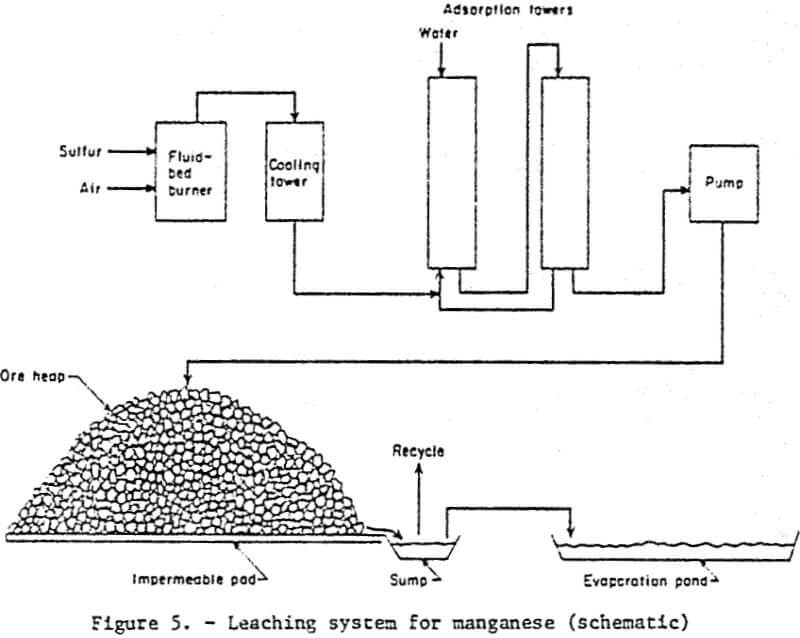

Leaching systems would employ aqueous SO2 created by burning pyrite or elemental sulfur in a fluidized bed and bubbling the combustion gases through water (Potter, et al., 1982) (figure 5). This latter step could be done adjacent to the sulfur burner and the aqueous SO2 pumped to the broken ore or the gas could be piped under the broken ore where it would rise to mix with water percolated downward from the top of the ore pile. Mining consultants estimate that costs for this system would run $0.01 to $0.03/lb ($.005 to $.014/kg) of manganese produced by leaching.

The effluent from the leaching phase would be a solution containing a mixture of manganese sulfate, dithionate and (for carbonate ores) bisulfite. Effluent could be collected, recharged with SO2 and recycled to the heap if higher grade solutions were desirable. The easiest marketable product to produce from the effluent leach solution would be manganese sulfate commonly used as a fertilizer amendment or for other purposes by the chemical supply industry and recently selling for $250/ton ($.057/kg). The sulfate can be crystalized directly by evaporating the solution.

Another product interesting to the chemical industry, manganese carbonate, can be precipitated by adding NaCO3 to the effluent solution. Alternatively manganese hydroxide can be precipitated by neutralizing the solution with lime and heating the precipitate to form useful manganese oxide. Electrowinning to produce metallic manganese is also possible.

In determining the economic feasibility of mining and leaching domestic manganese deposits, four different mining scenarios were chosen to represent the ore preparation systems that would be suitable for leaching a majority of the domestic deposits: surface mining, block caving, sublevel stoping, and shrinkage stoping. Costs for these systems were estimated using equations from a handbook prepared by STRAAM Engineers under contract with the Bureau of Mines (Clement, et. al., 1977) for feasibility estimates of capital and operating costs for mining non fossil-fuel mineral deposits. Capital costs include roads, utility sources, buildings, town site, drilling equipment, loaders, haulage equipment, SO2 generation equipment, solution distribution equipment, engineering and construction fees, and 60 day’s operating expenses. Operating costs include land clearing, overburden removal, core drilling, drilling and blasting, shaft sinking, ore excavation and hauling, SO2 generation, solution distribution, evaporation pond maintenance, restoration, general operations costs, water supply, drainage waste disposal, transporation and administrative costs. An operating life of 10 years was assumed. Since reasonable cost estimates require selection of representative geologic, geographic, and physical parameters, two deposits were chosen to provide input data for the cost estimates. One was a low-grade massive deposit —the Artillery Peak deposit; the other was a thin vein deposit typical of many western ores—the Paymaster district.

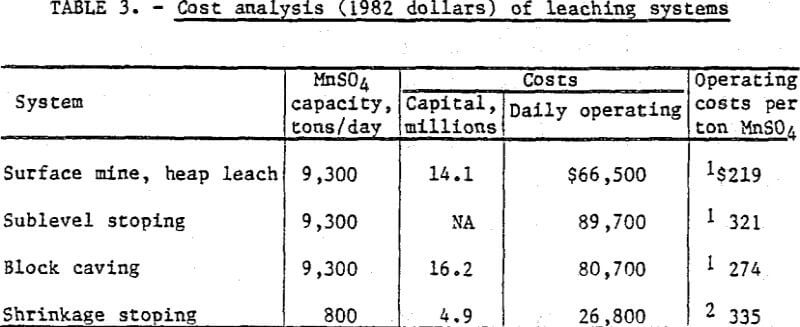

Details of the economic analysis are provided in a forthcoming Bureau of Mines Report of Investigations. In summary surface mining and heap leaching would be the cheapest method for leaching wherever it would be possible. Costs (based on 1982 dollars) for an exposed massive deposit 100 m thick of 3 to 4 pct manganese would run $219/ton (5-050/kg) for MnSO4 if 60 pct of the manganese was leached in an operation sized to produce 9,300 tons/d (8.4 x 10 6 kg/d) of MnSO4 for 10 years (table 3). This product has recently sold for $250/ton ($.057/kg) for agricultural fertilizer. Massive deposits typical of the Artillery Peak, Cuyuna, and Aroostook districts plus several of the larger vein deposits would appear amenable to such a system.

Deeper massive deposits that could be mined and leached in block caving system would generate operating costs $274/ton ($.062/kg) for MnSO4 produced, assuming that 60 pct of the manganese in the caved zones could be leached and that the deposit had an ore grade of 3.5 pct manganese. This would dictate that an ore grade of around 5 pct would be necessary to cover all of the operating costs plus pay back the capital costs with reasonable profit. Of the deposits evaluated in this study, selected portions of the Artillery Peak district are the only ones with the physical characteristics that would favor caving and have the required ore grade.

For massive deposits that would not cave readily, a leaching system encorporating sub-level stoping for ore preparation was conceptualized. Operating costs for such a leaching system would approach $320/ton ($.073/kg) MnSO4 for a 3.5 pct manganese grade deposit. Again, to cover all operating costs and repay a profit on the capital expenditures an ore grade of 6 or 7 pct would probably be required to develop an operation. High grade portions of the Artillery Peak district containing “hard” matrix-cementing minerals, the Aroostook, and perhaps several of the larger vein deposits would seem the most likely candidates for such a system.

Narrow vein deposits would be more expensive to mine and leach underground. For instance, our feasibility analysis indicated that if a 10 to 30 ft (3 to 10 m) thick steeply dipping vein containing 10 pct manganese were mined by shrinkage stoping methods (figure 3) and leached, the operating cost would be $335/ton ($.076/kg)l of MnSO4. The practical application of such a system, therefore, would probably be limited to 15 pct or higher grade deposits. Several such deposits exist in Colorado, Montana, and Nevada.

A unique and particularly interesting scenario could be developed for leaching manganese in the Cuyuna Iron Range of Minnesota. Significant manganese tonnages are contained in vast waste rock piles from the depleted iron mines scattered profusely throughout the district. Many of the piles could be moved short distances to prepared pads and heap leached (with or without crushing). Costs were not developed for such a system. Similarly, coarse tailing in the Leadville, Colorado, and Cuyuna districts contain significant amounts of manganese that could be directly leached without any additional ore preparation costs.

Another unique leaching situation is created by the vast horizontal, unconsolidated deposits of nodules containing manganese centered around Chamberlain, South Dakota. The low grade and impervious nature of the beds has thwarted all attempts to recover the manganese from the high grade nodules. An intriguing possibility would be to “leach farm” the beds, 1 ft (.3m) at a time. In leach farming (Lankenau and Lake, 1973) the top layer would be worked with rippers and farm machinery to mix the leach solution with the shale matrix containing nodules for a depth of 1 ft (0.3 m). After a “soak” period the layer would be removed by scraper or bull-dozer and washed into a settling pond. The pregnant leach solution would then be drawn out of the pond for extracting the manganese. No costs for this conjectural leaching system were developed.

Costs were not developed for any leaching product other than MnSO4. Although the technology is readily available, it is likely that precipitating manganese oxides or carbonates from the original MnSO4 solution would be more expensive than solar evaporation to obtain MnSO4.

Likewise, MnSO4 could be used as the raw material for electrowinning metallic manganese but determining the costs of such a process were beyond the scope of this study. One refinery purchases 74 pct MnO2 for $150/ton ($.034 kg) but since that material must be roasted before processing (while the MnSO4 from a leaching operation does not) and contain undesirable contaminants, a direct cost comparison cannot be made.

Conclusions

The heavy reliance of this country on foreign imports of manganese has stimulated the search for new and innovative methods of producing manganese from small and/or low grade domestic deposits. One method that appears to offer hope for fulfuilling some non-ferromanganese requirements is in situ/heap leaching. Laboratory column leaching tests on 19 samples from 13 mining districts indicate that manganese oxides, hydroxides and carbonates were leached to 62 to 95 pct extraction with aqueous SO2. The leaching product is a solution containing MnSO4 that can be precipitated by evaporation for direct marketing as an amendment for agricultural fertilizer. Alternatively manganese oxide or carbonate can be precipitated from the solution for sale to the chemical industry, battery manufacturers, or possibly to processing plants that produce metallic manganese by electrowinning.

A very preliminary cost feasibility analysis based on 60 pct recovery of manganese as MnSO4 valued at $250/ton ($.057/kg) from different mining/in situ leaching scenarios for oxide and carbonate deposits indicated that the following strategies were potentially viable: (1) surface mining of massive deposits containing more than 4 pct manganese, (2) block caving of massive deposits containing more than 5 pct manganese, (3) sublevel stoping of massive deposits containing more than 7 pct manganese and (4) shrinkage stoping of thin vein deposits containing more than 15 pct manganese. Although no cost analysis were developed for them, occurrences of manganese in iron mine waste rock piles in the Cuyuna range and in coarse tailings from several districts seem to offer particularly interesting possibilities for heap leaching with no ore preparation.