Grinding Coal Water Slurry

The pilot mill used was 44 cm i.d. and 60 cm i.l. with a volume of 91,250 cm and was fitted with six one-half inch

The pilot mill used was 44 cm i.d. and 60 cm i.l. with a volume of 91,250 cm and was fitted with six one-half inch

To study the effects of collector and hydrogen ion concentrations on the floatabllity of sulfide minerals, a series of flotation experiments were conducted in which

Over the last few years there has been an intense effort to identify lixiviants other than cyanide for gold and silver leaching. Bromide and iodide also

Table of ContentsProduction Pellet ComparisonMetallurgical Tests by SizeBench Scale Pelletizing TestsEffect of SilicaBentonite EliminationImproved Organic Binder PelletsIncreased Porosity PelletsFlux Addition RateMaking Fluxed PelletsInstallation of Roller

Table of ContentsFlotation Rate ApproachesFlotation Cell ModificationsKinetics of FlotationReview of Previous TheoriesDevelopment of Modified, First Order EquationLaboratory Experiments Froth flotation of minerals is one of

Dust measurements in mines clearly indicated that the major mineral dust exposure is due to loading and transport of the ore from the mining areas.

Ball mill shape factors in the period prior to 1927 averaged 1.1/1 for 29 center discharge mills and 1.0/1 for 30 peripheral discharge mills. With

Table of ContentsRTD ModelModelling of the residence time distribution data We present the results obtained in a study of the residence time distributions of solids

Table of ContentsThe Decision to Sell the Mining PropertyPackaging the PropertyMarketing the PropertyInvestigation and Due DiligenceNegotiating a PriceAgreementClosingsPost ClosingSOLD Very few mineral properties spend their entire

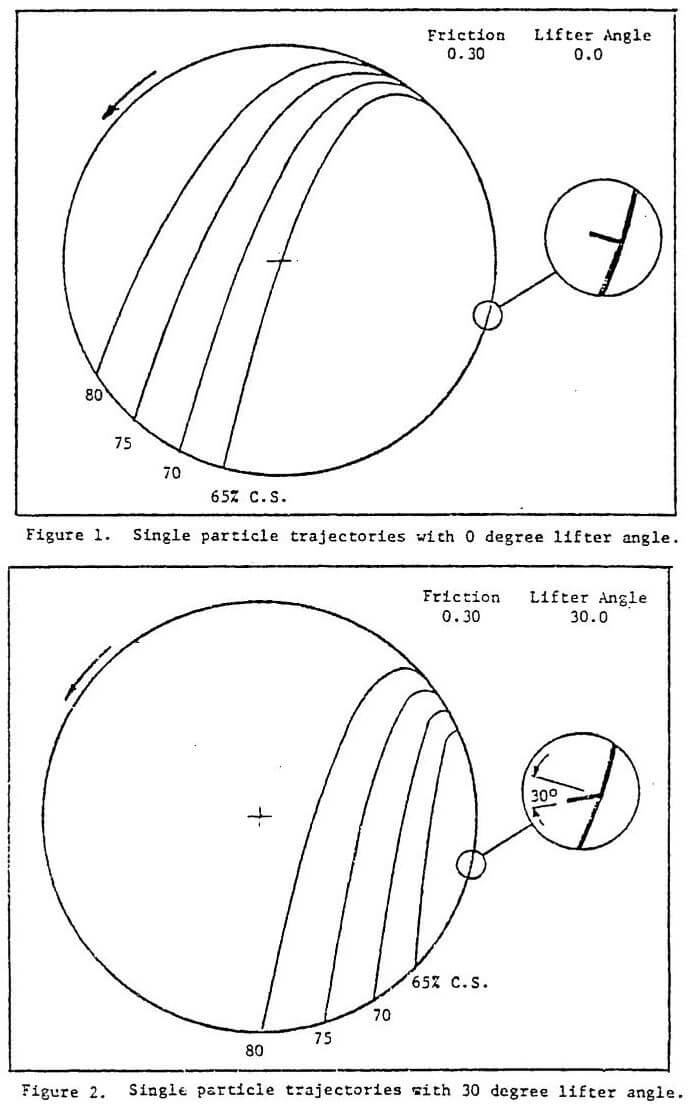

The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed