Molybdenum Roasting

Table of ContentsMolybdenite Roasting with Sulfuric Acid Plant VS Looping Sulfide Oxidation (LSO) with Sulfuric Acid PlantCurrent Multiple Hearth RoastingMolybdenite MHR – AdvantagesMolybdenite MHR –

Table of ContentsMolybdenite Roasting with Sulfuric Acid Plant VS Looping Sulfide Oxidation (LSO) with Sulfuric Acid PlantCurrent Multiple Hearth RoastingMolybdenite MHR – AdvantagesMolybdenite MHR –

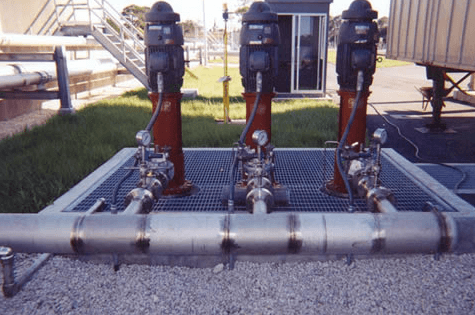

Process air is supplied to the process by two 150 HP, 1200 nm3/hr, 250 kPa compressors. Each compressor is a totally self-contained package. Each compressor

Introduction to an EXAMPLE Fresh Water System Water is pumped from the fresh water well to the camp tank which provides pressure and storage capacity

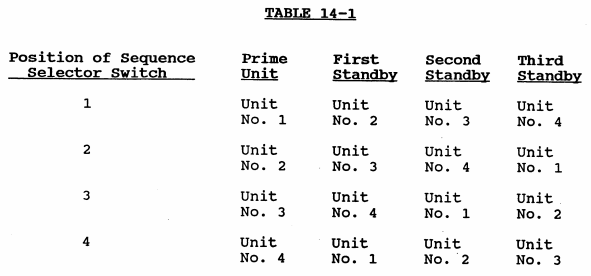

On our EXAMPLE mining operation, the power generation and distribution system consists of four components: Diesel electric generation Diesel fuel system Heat recovery system Power

EXAMPLE Operation and Preparation for Start up Ensure the mill is prepared to start up at the design throughput and range of solids content. Walk the

EXAMPLE Tailings System Tailings from the processing plant are collected in a common tails box and flow by gravity to the tailings pond. The tailings

An un-monitored (un-assayed) tailing from a vibrating screen was exiting the system. Operators would eyeball the Zinc content from a handcut while true assays were only

The following flotation reagent mixing system is typical for the flotation reagent mixing systems: A-208, Xanthate and Sodium Silicate. The reagent mix tanks, for the above

Images for illustration purposes only. No rights can be delivered from the illustrations.

911METALLURGY CORP. can not be responsible for errors in typography or photography.

Copyright 2012-2024 911Metallurgist | All Rights Reserved