Table of Contents

The need to move large tonnages of slurry has grown as mines have become larger. As existing tailing depositories are filled up, new mines developed, or environmental requirements dictate, it becomes necessary to transport tailing particularly over longer distances.

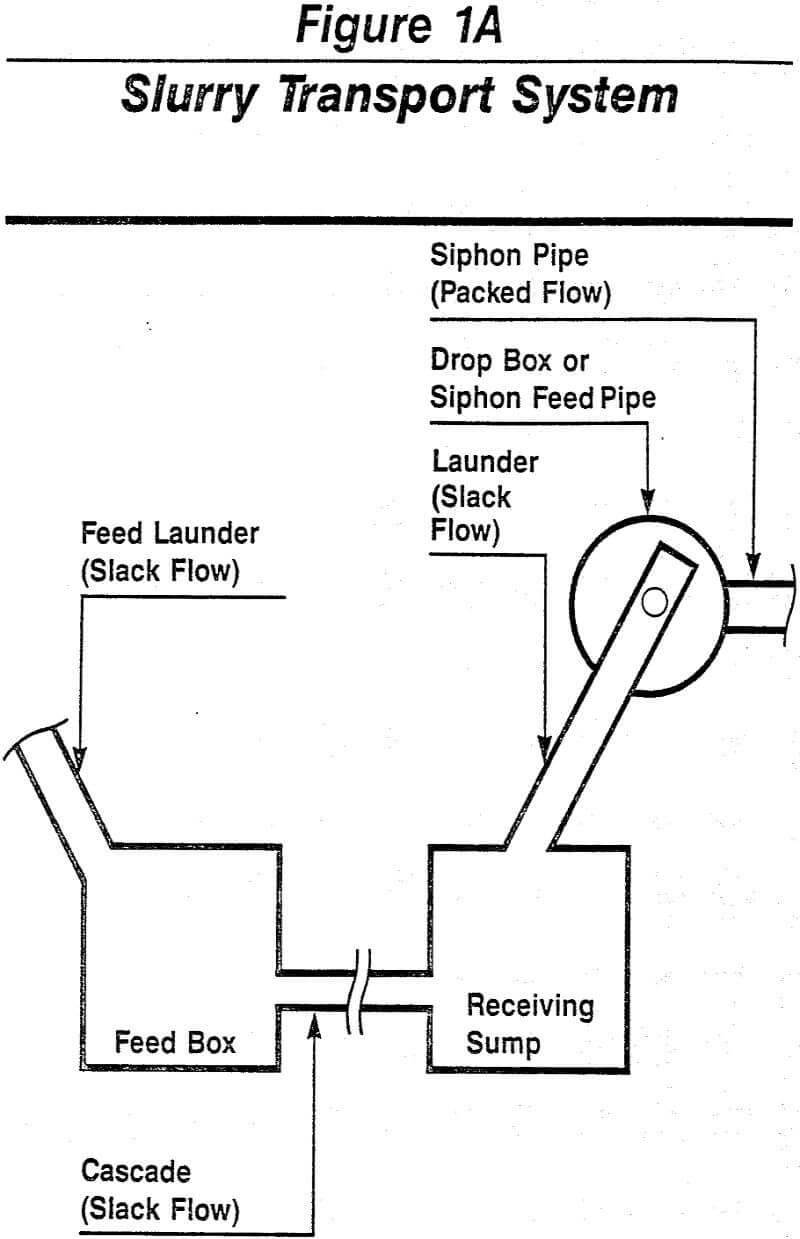

There are two basic types of slurry transport systems, packed flow and slack flow. Packed flow is typified by a pipe running full; slack flow by a launder or pipe running less than full. Slack flow in launders or channels is also referred to as open channel flow. Generally slack flow slurry transportation involves a flow with less than 65 per cent solids, and there is an upper limit on particle size, depending on the slope of the system.

Today, however, flows and the required structures can be large and expensive, and a more reliable design procedure is necessary. Also, several conditions such as maximum, design, and minimum flow are often recognized and must be accommodated. It should be noted that a system may work well for a design or maximum flow, but may not function correctly for a minimum volume, sometimes as low as one third of the maximum.

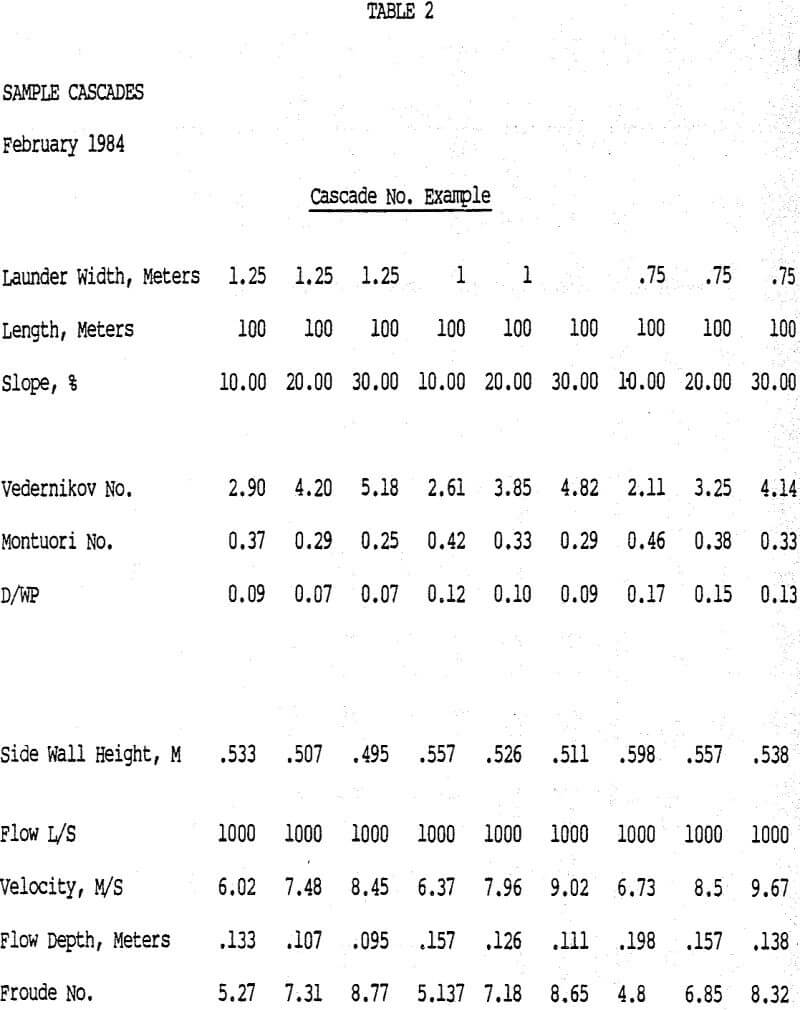

Cascades

Cascades are used for conveying slurry down steep terrain, where maintaining lesser slopes would be impractical. Velocity in cascades can be over 10 meters/sec (33 ft/sec), and can cause high rates of wear.

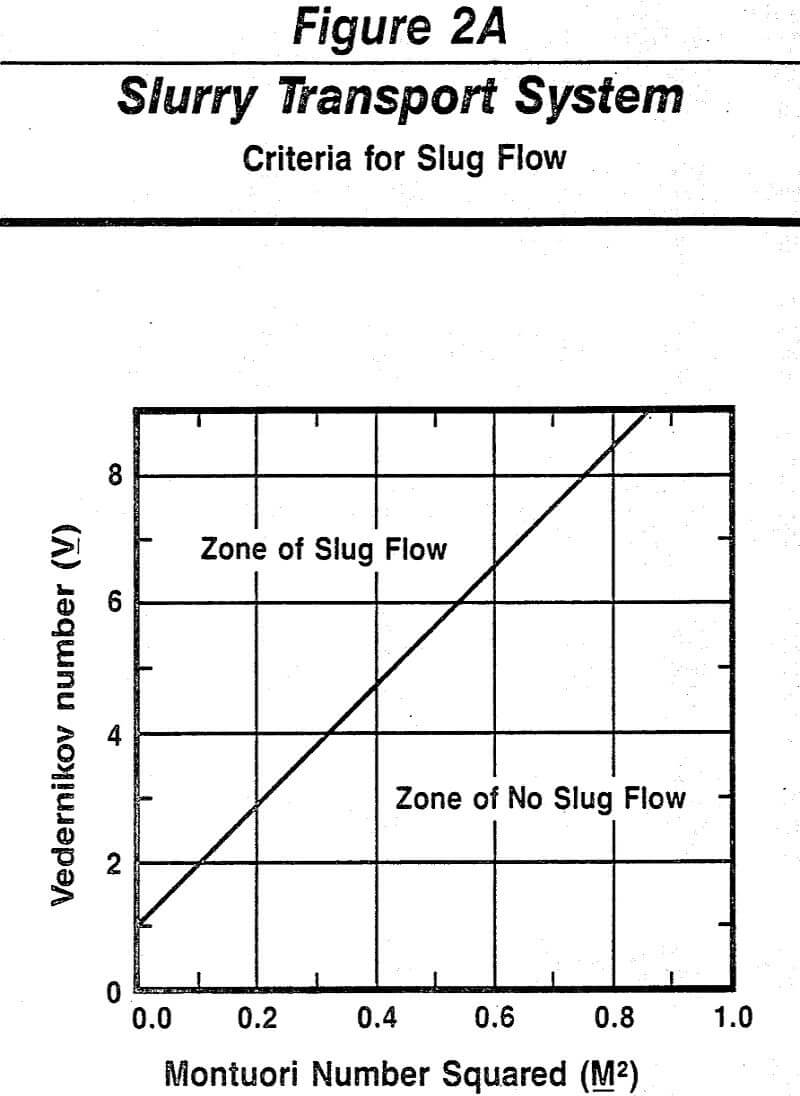

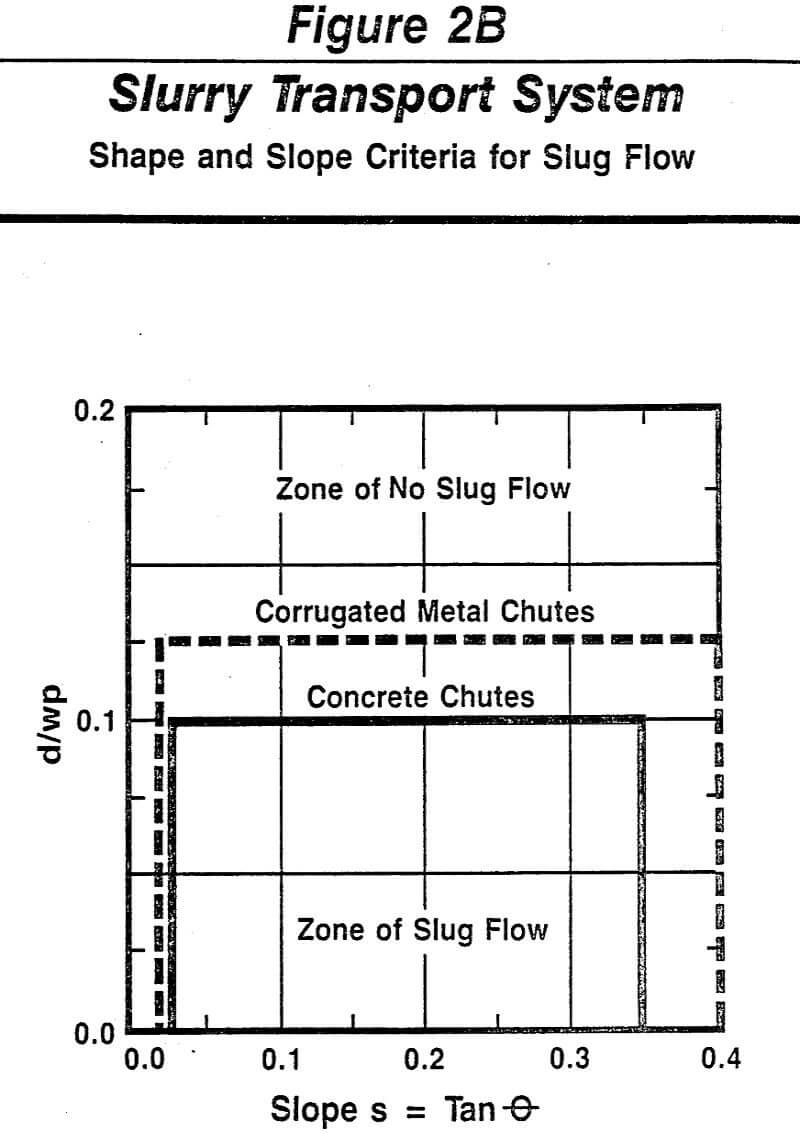

Work on slug flow was first done on water distribution systems in mountainous or hilly terrain. This data has been used to predict erosion potential in cascades for slurry transportation.

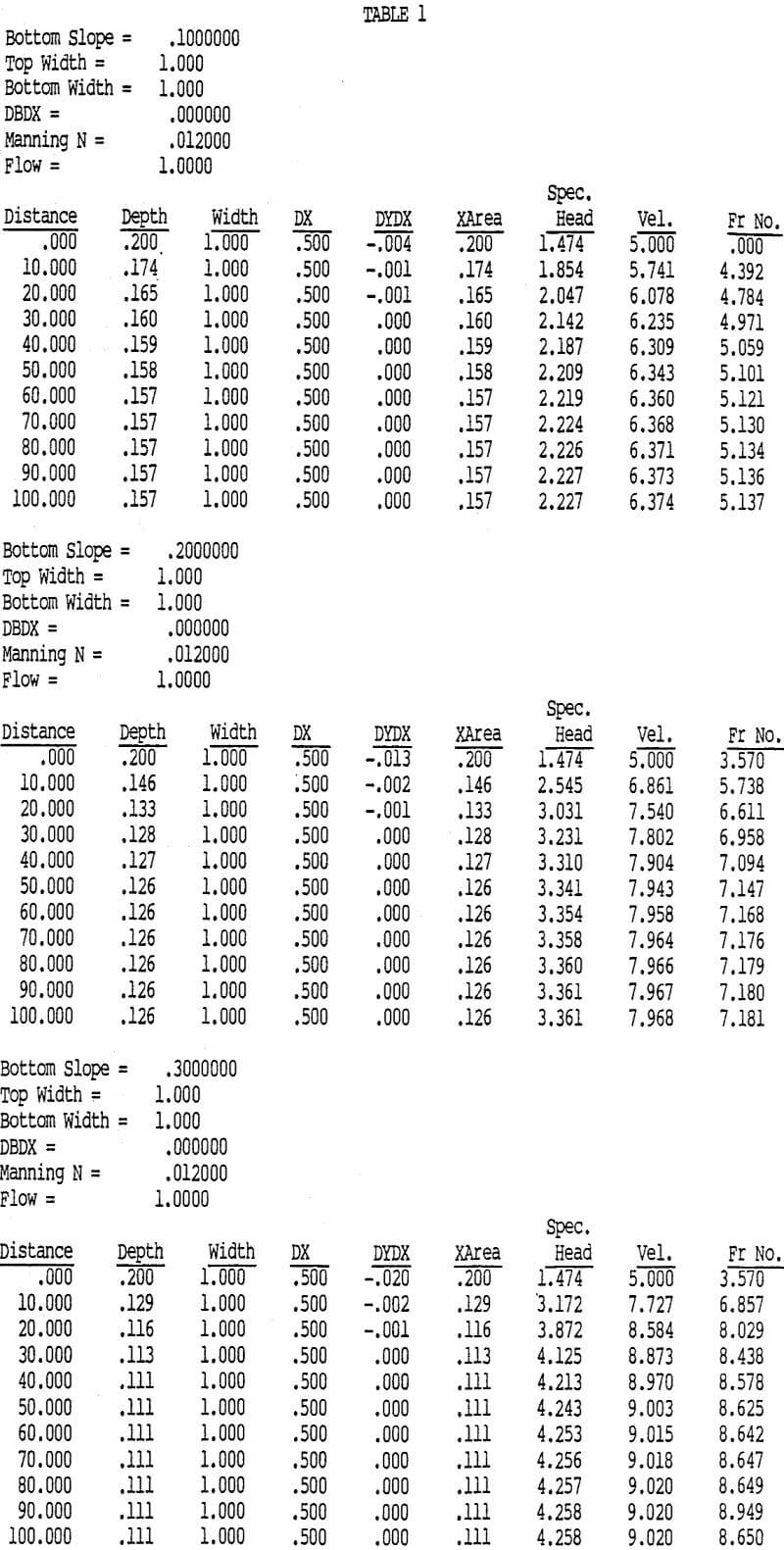

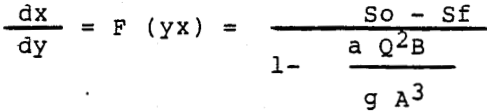

The mathematical theory of the program for the cascade flow is based on the equation:

Where,

x = channel length under consideration

y = flow depth

So = slope of channel

SF = energy gradient due to hydraulic friction

Q = flow volume

B = top width of flow

g = acceleration due to gravity

A = cross section of wetted channel area

a = velocity head coefficient

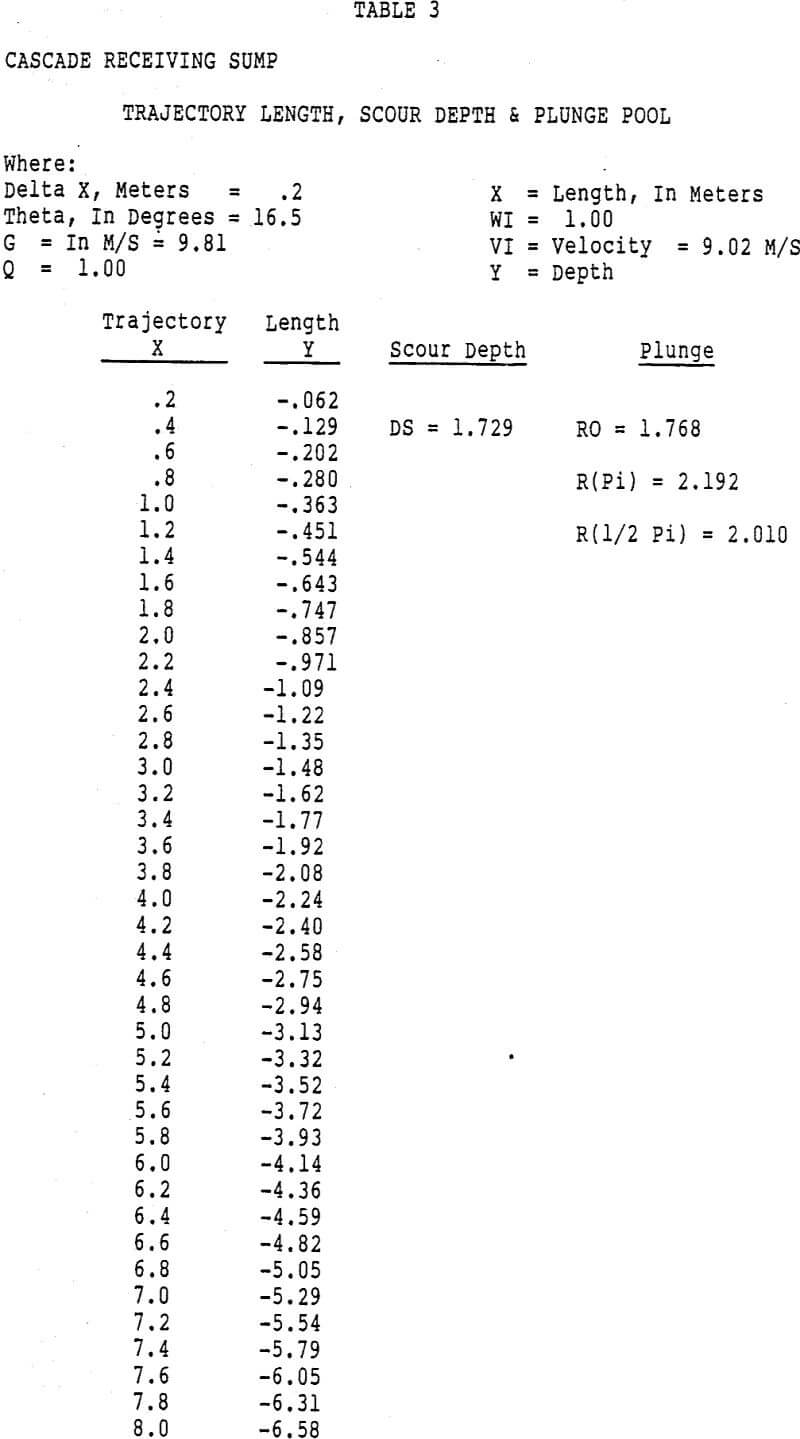

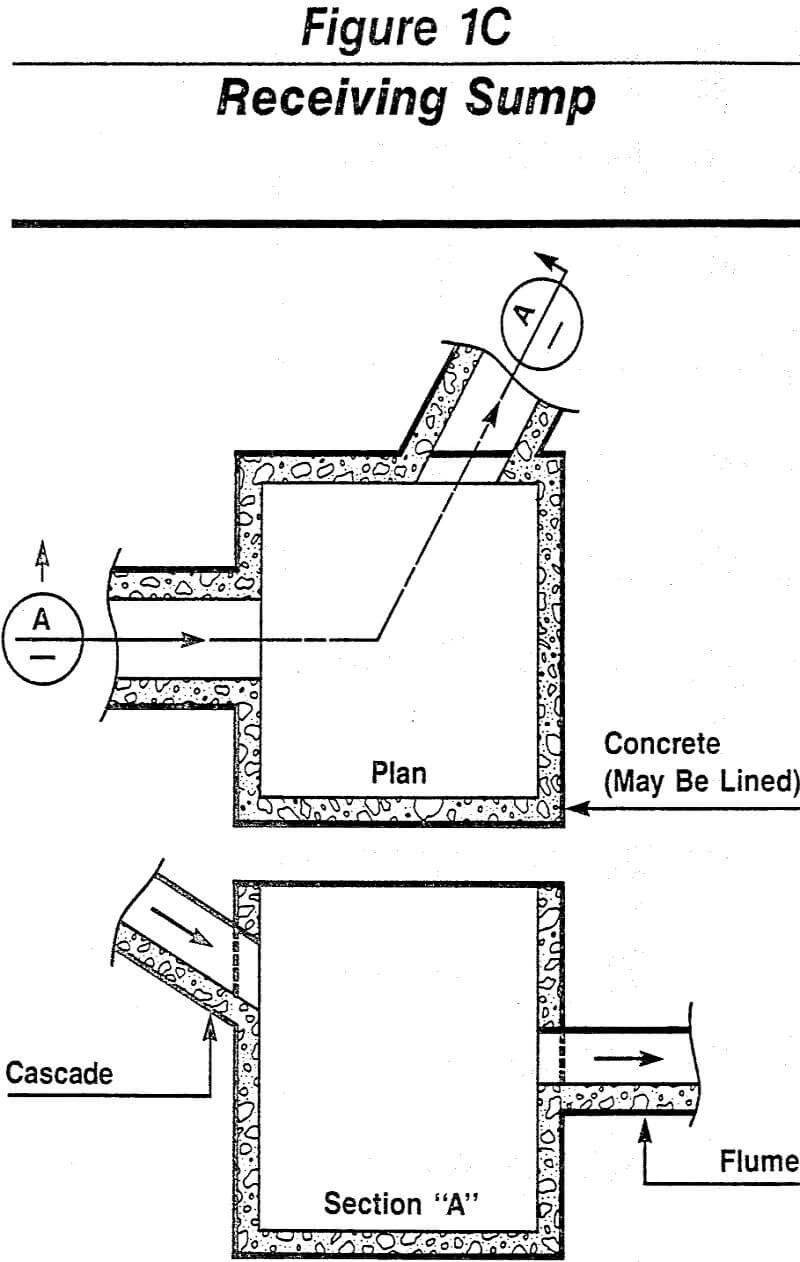

Receiving Sumps

The receiving sump at the bottom of a cascade acts as a stilling basin dissipating the kinetic energy of the incoming high velocity flow. Governing design criteria are:

- Incoming liquid should always impact on the surface of the slurry in the sump, introduction under the slurry surface tends to cause excessive turbulence in the pool.

- To prevent unwanted abrasion on the wetted sump surfaces, the sump should be sized such that enclosure walls remain outside of the computed turbulence pool.

- If slug flows are allowed to enter the sump, excessively long sumps are required to cope with the constantly changing flow pattern, and plunge plumes may reach excessive heights.

- Outlets from the sump into the subsequent launder section should be designed as penetrations through the face wall to guard against overfilling of the launder. As an additional precaution the first few meters of the launder should be covered.

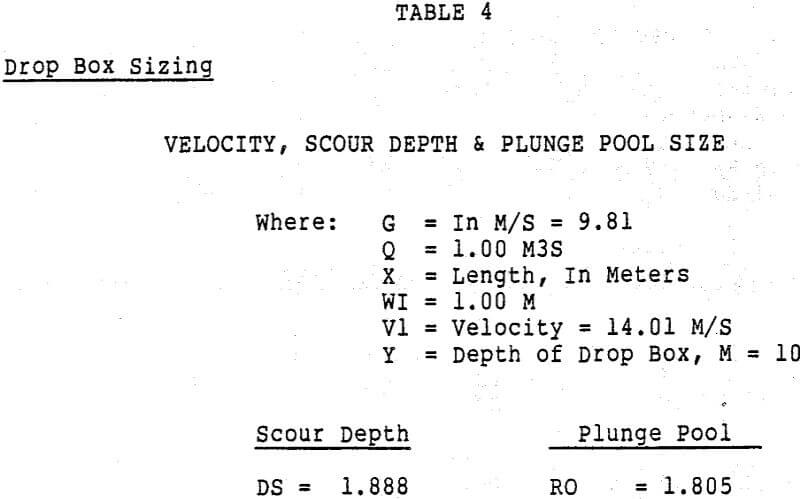

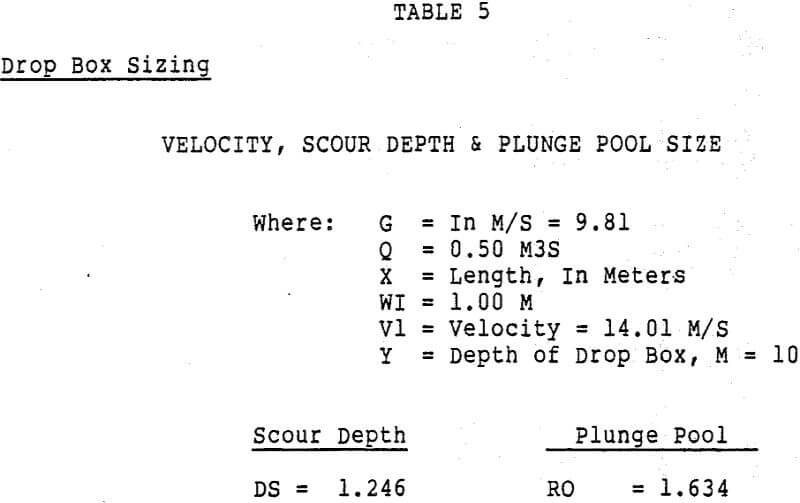

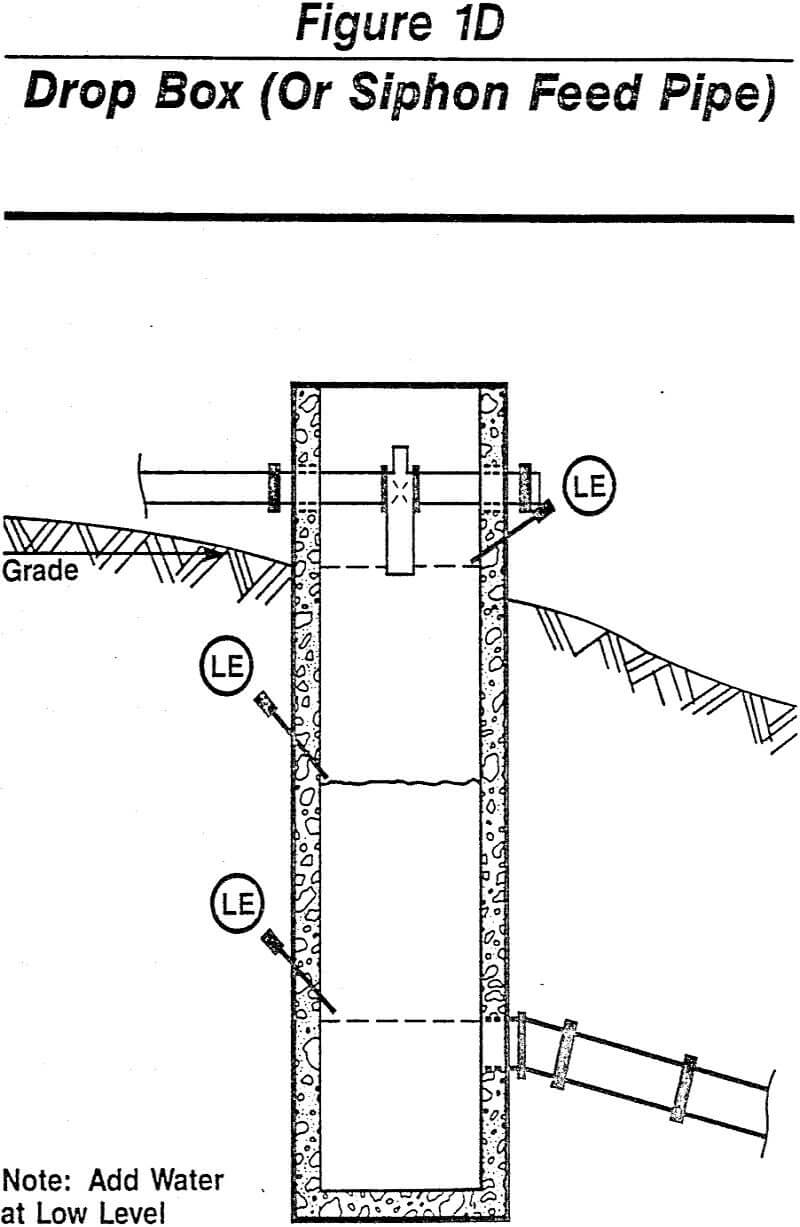

Drop Boxes

Drop boxes are used as devices to convey a slurry from one elevation to another vertically, considerations in design of drop boxes include inlet, diameter, height, outlet, and wear for a given flow.

Wear considerations affect the previous parameters. If the slurry does not present problems, not as much care in design is required, therefore the following will consider the slurry to be abrasive, such as would be encountered with a high silica content slurry.