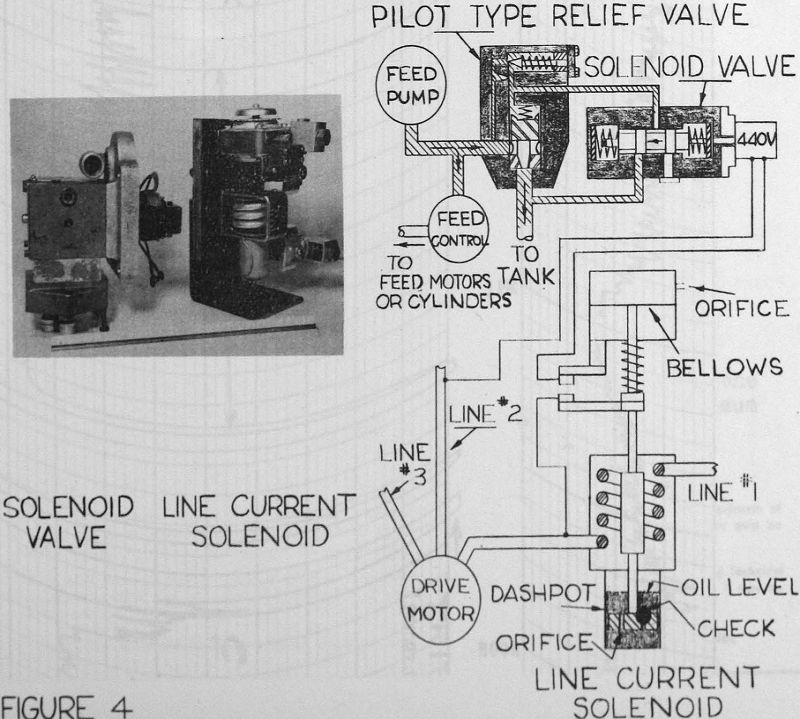

Maintenance and Operation of Mining Machinery

Modern high capacity underground mining machinery is a complex of mechanical, electrical and hydraulic components which have greatly increased capability over similar components of mining machinery of ten and even five years ago. Looking into the future I feel certain in stating that there will be changes equally great in the coming five and ten […]

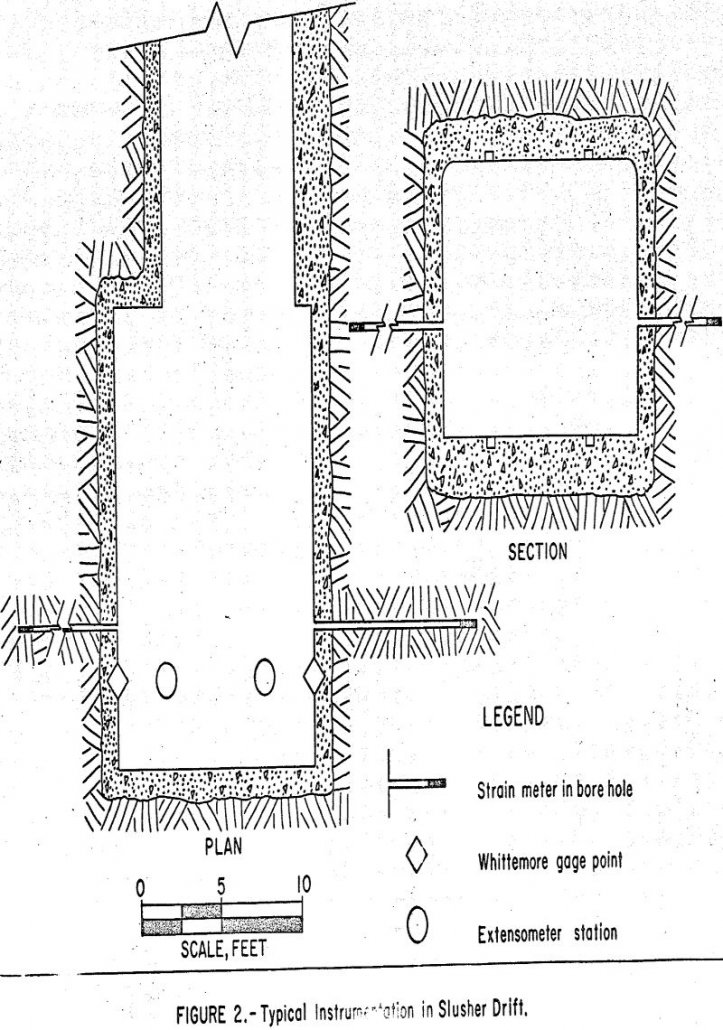

Influence of Block Caving upon Adjacent Mine Openings

The stress distribution around single and multiple underground openings has been determined both from theory and from photoelastic laboratory model studies. These determinations require certain simplifying assumptions: The rock is elastic homogeneous, and isotropic; the opening or openings are in an infinite medium, are subjected to plane stress or strain, and are not affected by […]

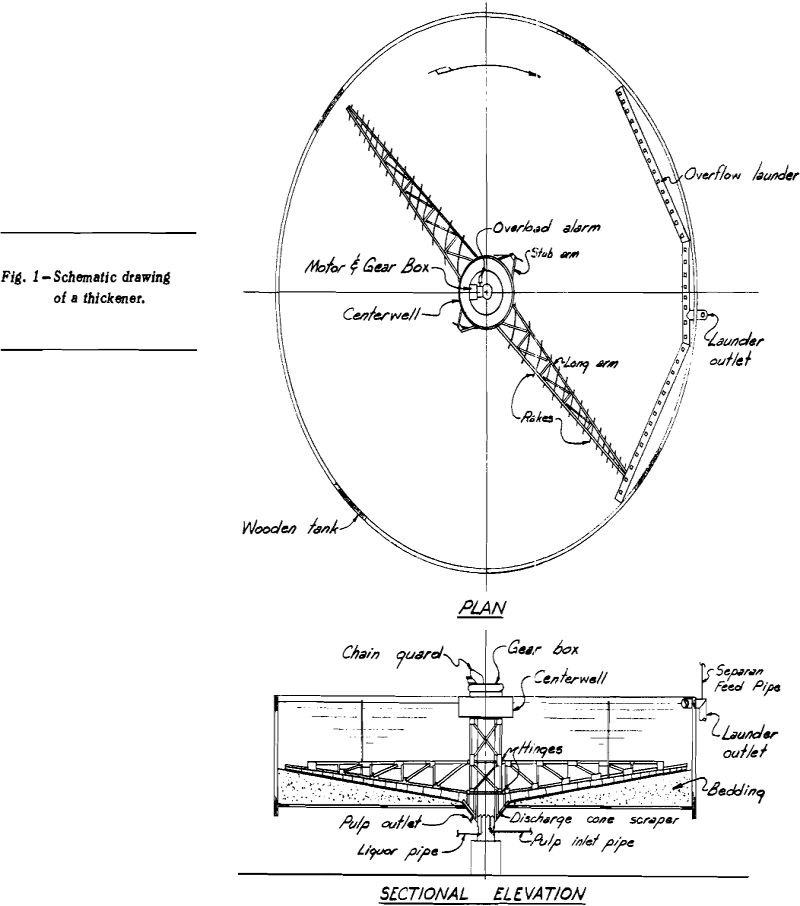

How to Handle Coarse Ore in a CCD Thickener Circuit

The use of a series of thickeners for washing of the slime fraction of a leached ore is not uncommon in the uranium industry; however, few ore processing mills have used a thickener circuit for washing leached total ore. The common practice is to wash the sand fraction in classifiers and the slime fraction only […]

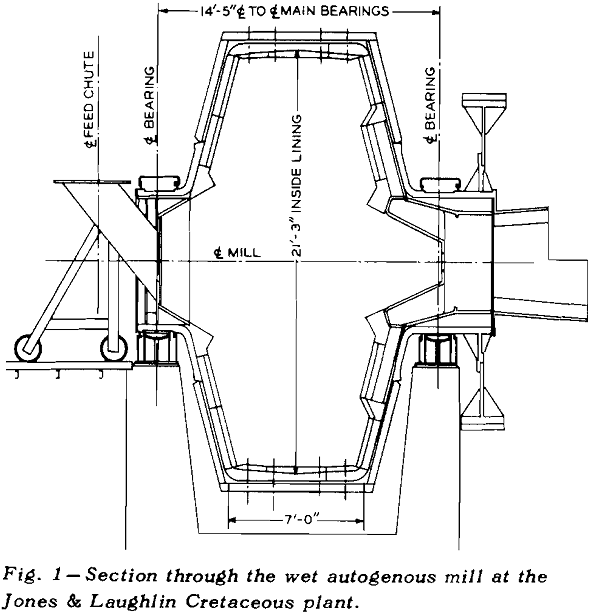

Grinding Iron Ore in a Wet Autogenous Mill

The Cretaceous plant at the Hill Annex mine of the Jones & Laughlin Steel Corp. was designed with a wet autogenous mill for grinding low grade iron ore so that it could be concentrated by spirals and flotation cells. The plant, on the west end of the Minnesota’s Mesabi Range, went into operation in June […]

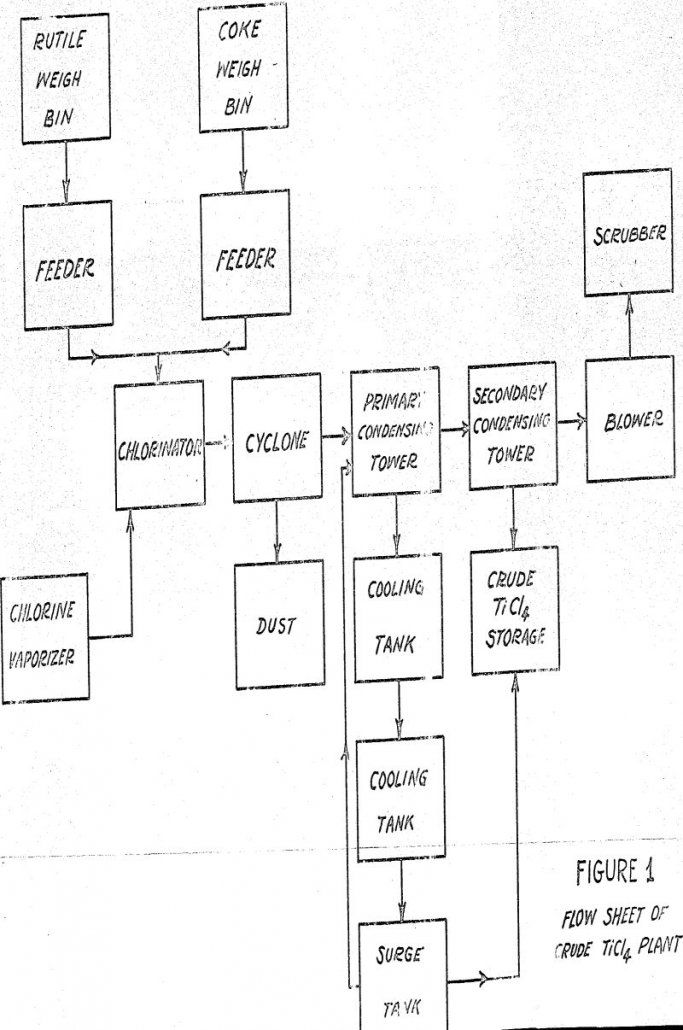

Fluidized Bed Chlorination of Rutile

Starting with rutile, containing more than 95% TiO2 and of the proper particle size, the commercial production of titanium tetrachloride via fluidized bed chlorination is relatively very simple and economical. As compared to shaft chlorination, it operates at a much higher capacity for given sizing of equipment, and appears more foolproof, requiring less attention. At […]

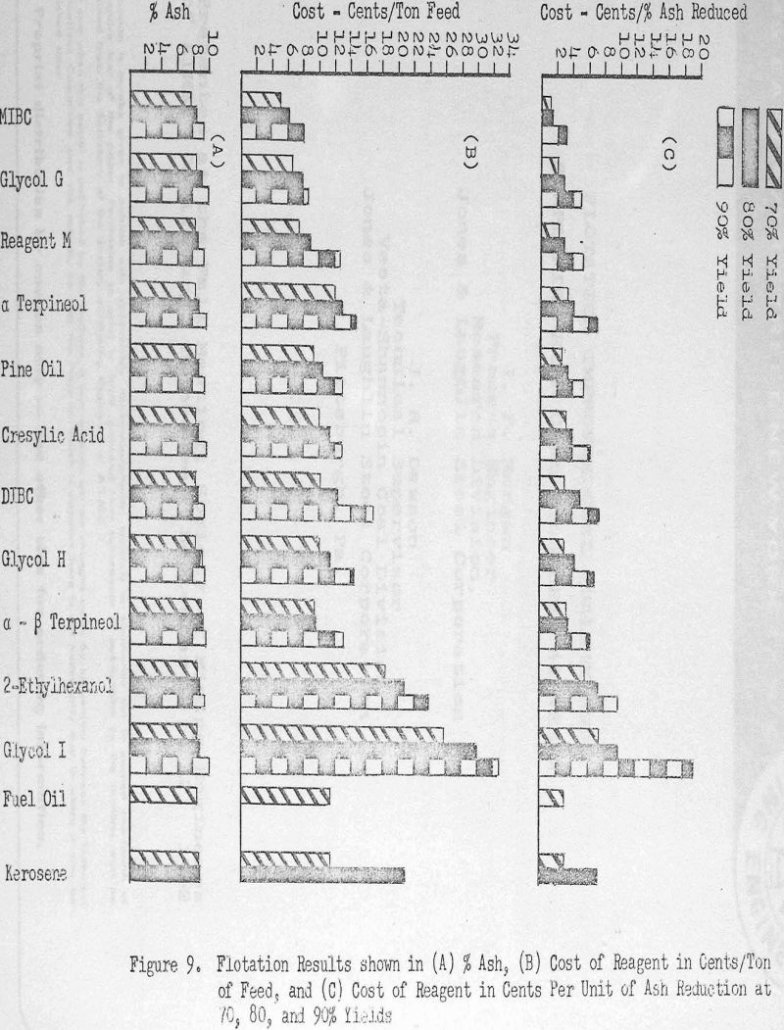

Coal Flotation Frothers – Yield Selectivity VS Cost

This paper presents the results of a study in which commercially available forms of various reagents were used as flotation frothers. Flotation procedures which would conform in general to those employed in a large number of commercial coal flotation plants were utilized. The reagents employed have been grouped into the following chemical classes; aliphatic alcohols […]

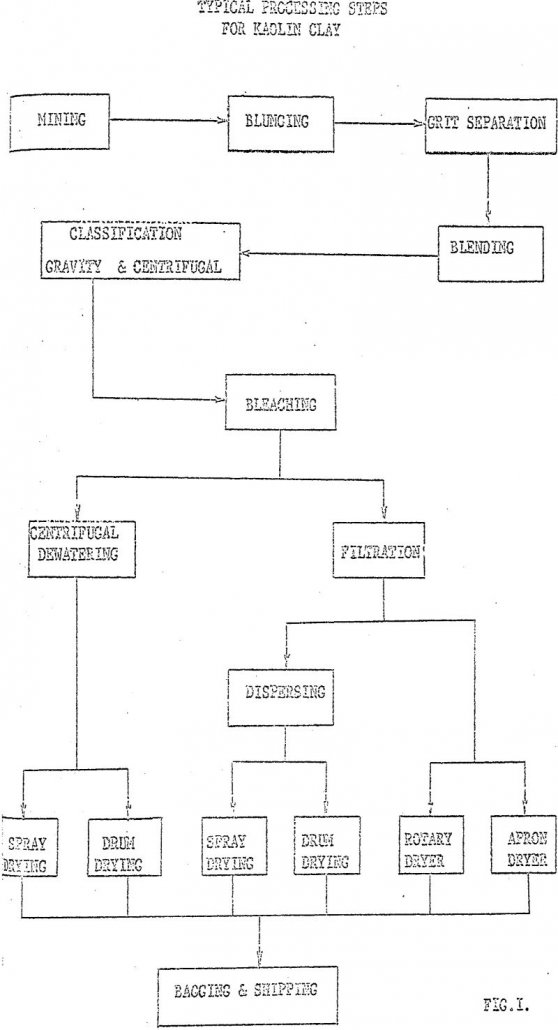

Dewatering and Processing Kaolin Clays

The dewatering steps discussed will include gravity settling, centrifugal dewatering, vacuum filtration, and thermal drying. Of these dewatering steps particular attention will be given to vacuum filtration and the variables affecting filtration of these kaolin clays. Kaolin consists essentially of the mineral kaolinite, which is a hydrated aluminum silicate (Al2O3·2SiO2). Commercial deposits of kaolin occur […]

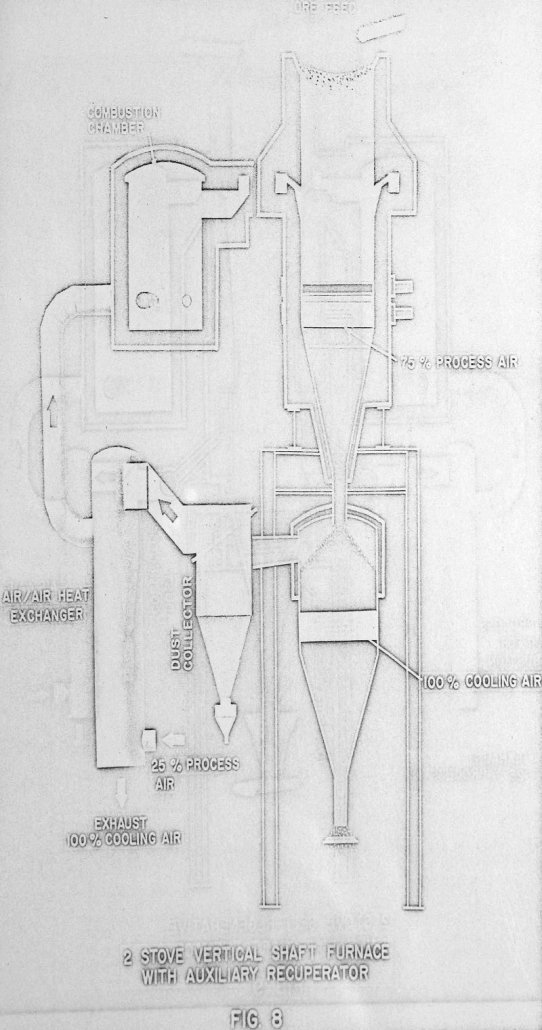

Vertical Shaft Furnace Design

Vertical shaft furnace design and operation have their roots deep in antiquity. There is substantial evidence to indicate that iron was reduced from its oxides to serve mankind’s needs long before recorded civilization actually prior to 3500 B.C. For at least 5500 years man has been matching wits with Nature to find better methods of […]

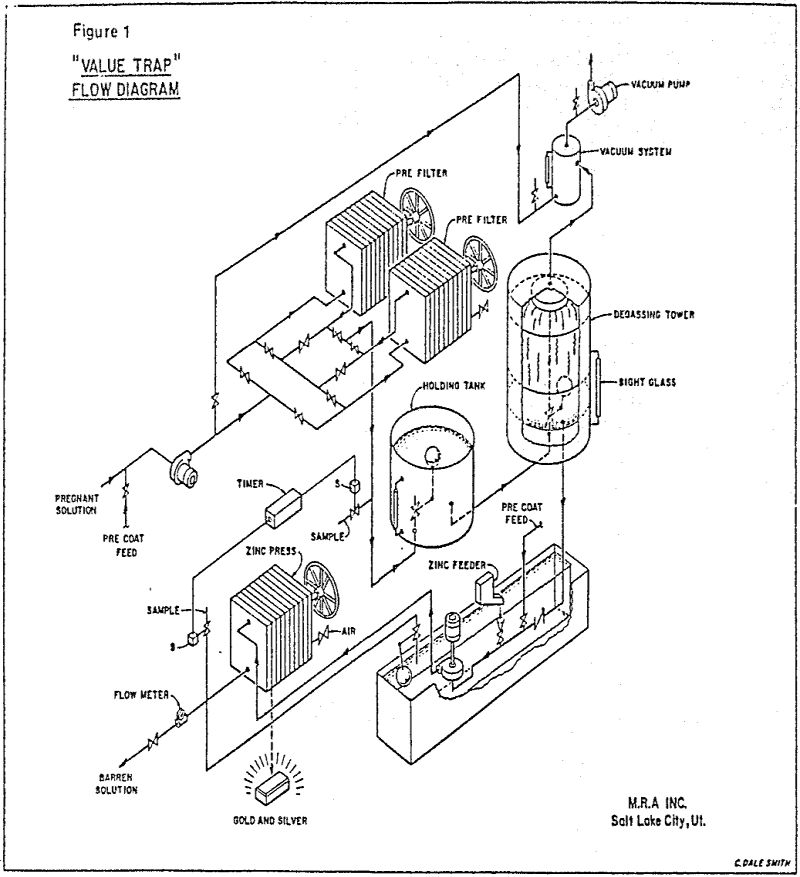

Design Merrill-Crowe Plant

The removal of metal values from cyanide solutions, fortunately, can be done in several ways. The oldest practiced method is, cementation with zinc, or Merrill-Crowe. Clarifying Filters Today the clarifying filtration is done with every kind of filter imaginable. Most of these filters are precoated with diatomaceous earth, DE, to produce extremely clear solutions. The […]

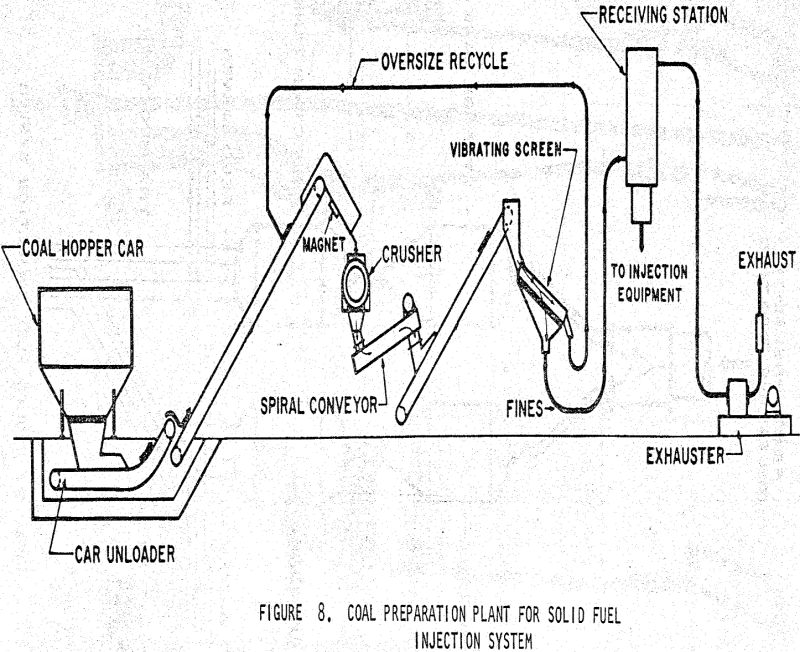

Coal and the Blast Furnace

During this period of evolution, man struggled with the only fuel he knew – charcoal. Some 5600 years passed before any attempt was made to use coal as a fuel for the blast furnace. Blast Furnace Practice No one factor can be pointed to as the prime cause of reduced coke rates and increasing production. […]