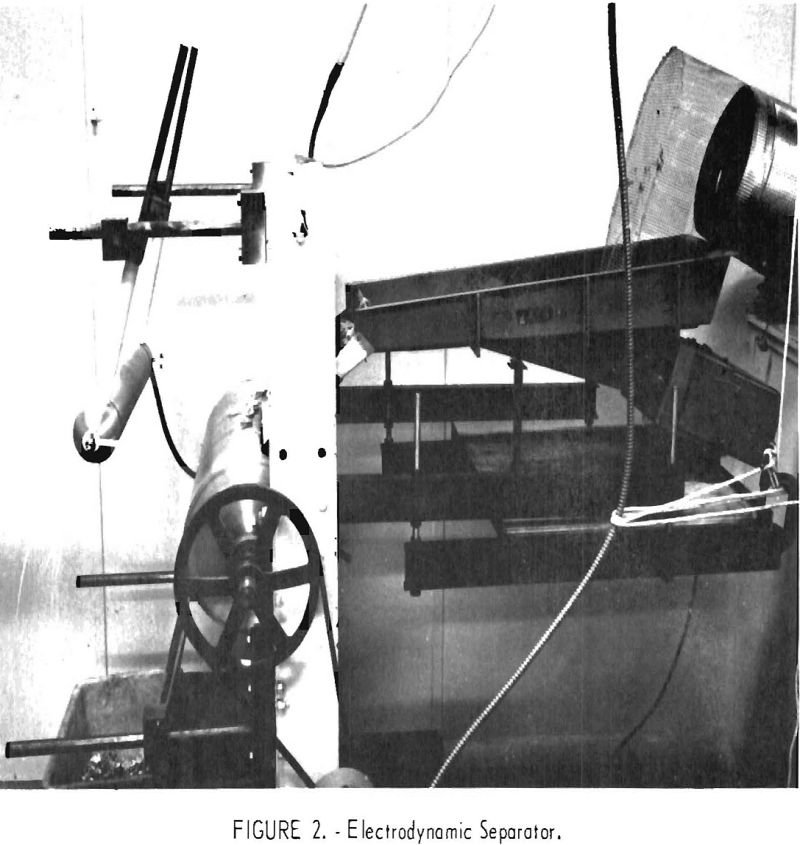

Electrodynamic Separator

Several years ago, the Bureau of Mines initiated a program to develop effective methods for reclaiming and recycling metal and mineral values contained in urban solid waste. The Bureau’s initial work at its College Park (Md.) Metallurgy Research Center dealt with establishing reliable methods for sampling and characterizing the residues left from the incineration of […]

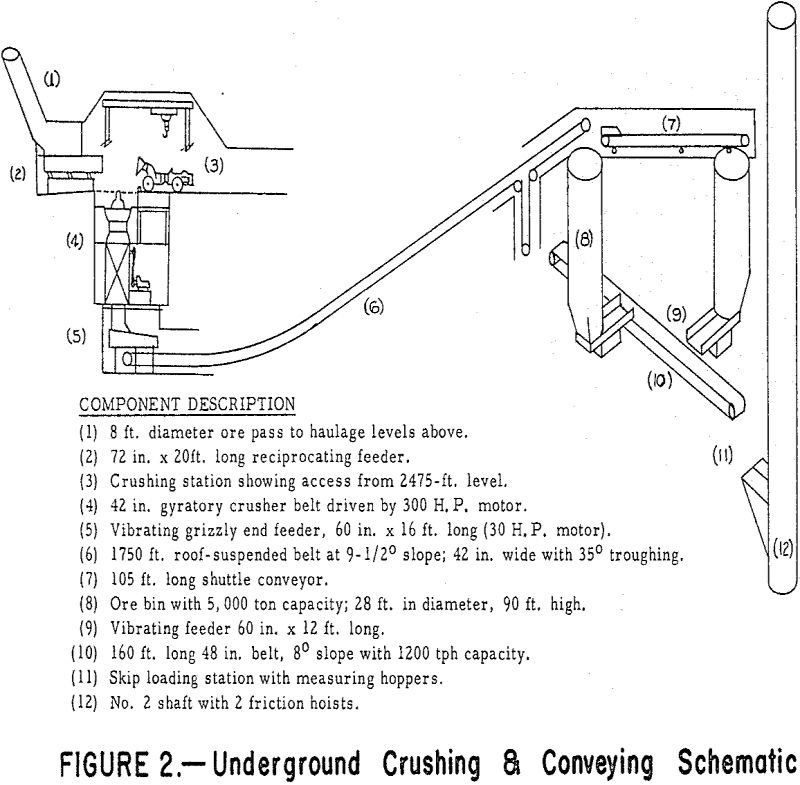

Installation of an Underground Crushing System

Meramec Mining Company, a joint venture by Bethlehem Steel Corporation and St. Joe Minerals Corporation, is engaged in the mining, concentrating, and pelletizing of iron ore from the Pea Ridge Mine located near Sullivan, Missouri, about 70 miles southwest of St. Louis. Crusher and Conveyor System Layout The heart of this system is a 42-inch […]

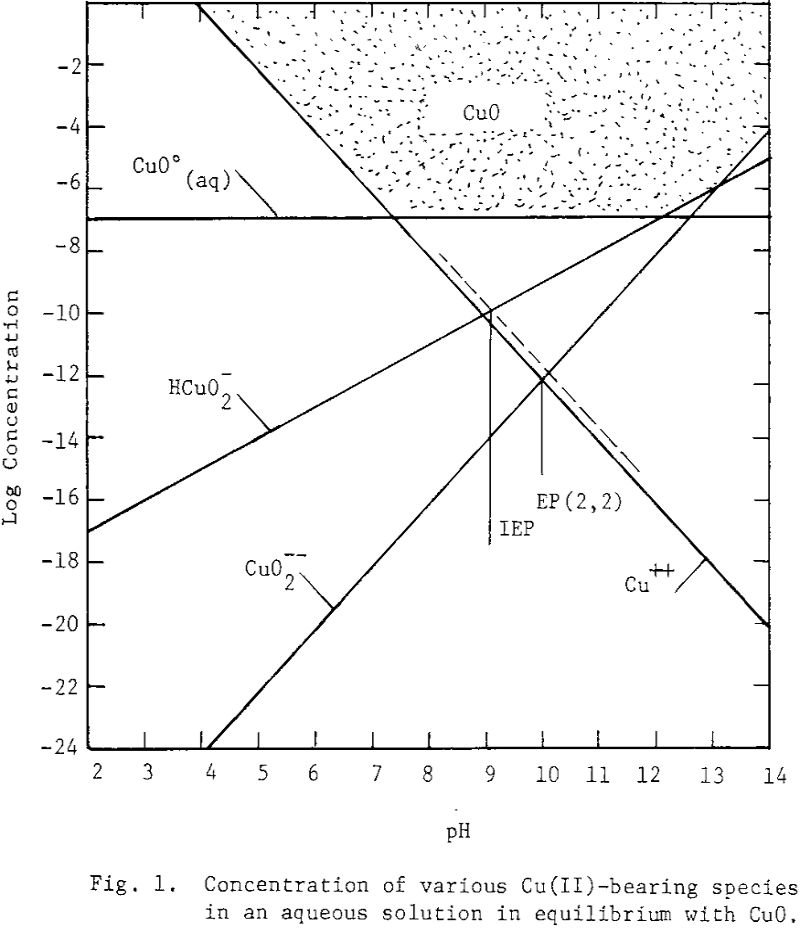

Surface Oxidation of Chalcocite

For sulfide minerals, the presence of dissolved oxygen in the water phase is an influencing factor for separation by flotation, Klassen and Mokrousov distinguish three stages of oxygen adsorption; namely, reversible adsorption, activated adsorption and, finally, surface oxidation. While contraversial, limited adsorption of oxygen is believed to improve the interfacial reactivity between collector and mineral. […]

Use of Simulation Models to Design, Optimization and Control of Wet Grinding Circuits

Mineral comminution is an important and expensive industrial process and modern comminution circuits are complex. There is considerable economic incentive to optimise circuit design and performance and to operate circuits at maximum efficiency, and these aims may be achieved by setting up mathematical models of the volts in a circuit on a digital computer and […]

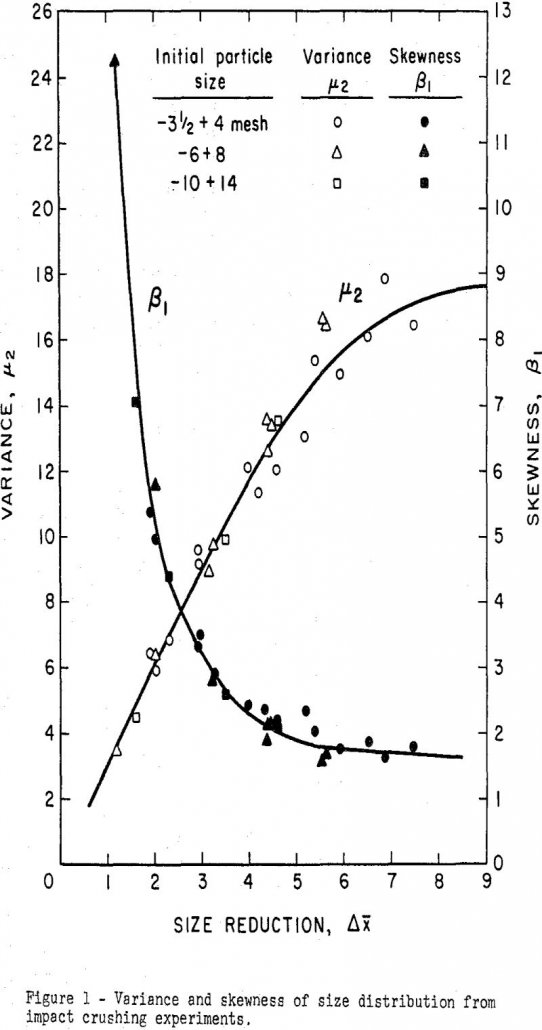

Particle Size Distribution of Grinding Mill Products

This report briefly reviews the essential features of moment analysis and describes extension of this method to size reduction by ball mill grinding. Method of Analysis of Size Distribution Data Size analyses of mineral products are usually made by screening with a set of sieves having mean apertures arranged in the Tyler scale, which is […]

Optimizing Grinding and Regrinding Capacity in Mill Design

The intent of this paper is to try to answer the complex question: “How much grinding capacity should be designed into a new mining – milling project?” Much work has been devoted to the technical aspects of grinding, the “how” of grinding. But, in the writers’ opinion, the economically important subject of optimizing grinding capacity in […]

Open Storage Piles and Dust Control

In discussing the open storage dust problem and possible solutions, one obvious question arises – what are the economics of placing large bulk storage under cover? Several known, practical, workable solutions to the open storage dust problem are described. These include the following which will be dealt with in some detail: A. Open pile surface crusting […]

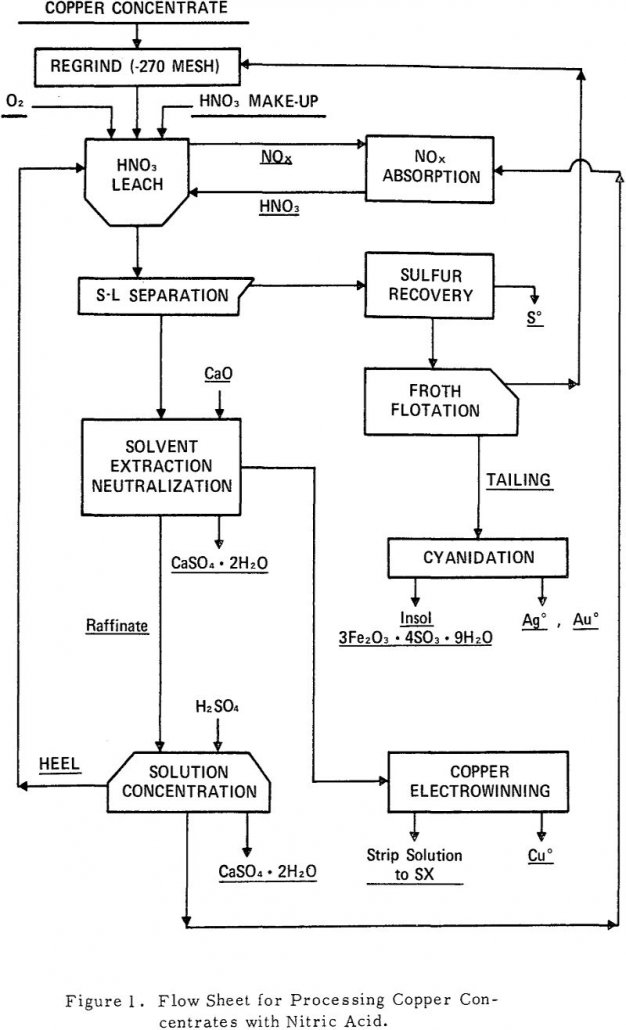

Nitric Acid Processing Copper Concentrates

The process parameters for effective utilization of nitric acid as an oxidant for copper-iron sulfides have been developed. Leaching variables found to be important were acid concentration, temperature, time, atmosphere, pressure, mineral type, particle size, and percent solids. Particular attention was devoted to analysis and control of fumes evolved during the oxidation. Numerous references have […]

Magneto-Gravimetric Separation of Nonmagnetic Solids

Stable colloidal solutions of ferromagnetic or ferrimagnetic materials are called magnetic fluids. About two generations ago, suspensions of relatively large micron-sized ferromagnetic particles in oil proved useful in clutches, brakes, and dashpots. They were called magnetic clutch materials, and their viscosities were highly dependent upon the applied magnetic field. Magnetic colloids, by contrast, are especially […]

Design Start-Up and Operation of the Hygas Pilot Plant

The HYGAS Process is one of several coal conversion processes now under development within the United States and is the most advanced in development. It is based on the overall reaction of coal and water to produce methane, which is the major constituent of natural gas,and a by-product, carbon dioxide, which is exhausted to the […]