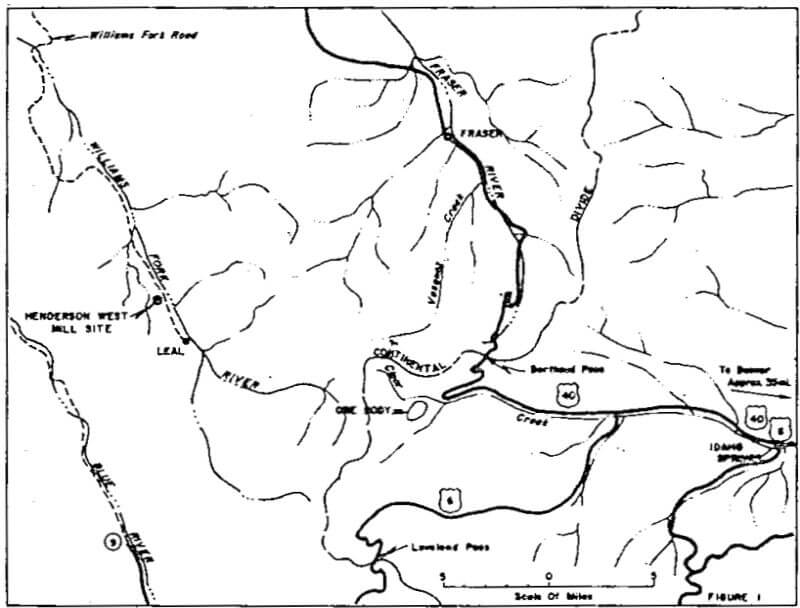

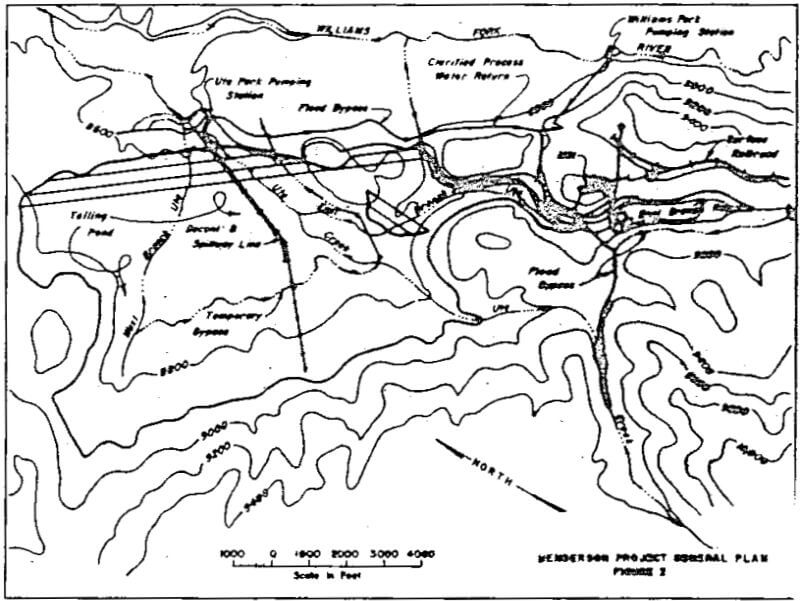

When the Henderson Project is completed in 1975, it will become one of the Free World’s largest primary molybdenum producers. The Henderson Mine will be located approximately 50 miles west of Denver, Colorado, on the eastern slope of the Continental Divide. Ore reserves are currently estimated to be 303,000,000 tons with a grade of 0.49% MoS2. The mill and tailing area will be located approximately 14.5 miles from the mine in the Williams Fork Valley, which is on the western slope of the Continental Divide. Ore haulage from the mine to the mill will be by ten miles of underground railroad and 4.5 miles of surface railroad. The concentrator has been designed to mill 30,000 tons per day and will yield approximately 50,000,000 pounds of contained molybdenum per year.

One of the first steps in the design of the Henderson Project was the search for a suitable tailing disposal area. Three hundred million tons of tailing will fill a rather large area. The first area considered was the west fork of Clear Creek in the immediate vicinity of the orebody. All facilities necessary for a tailing pond in this area were layed out and a cost estimate was made. However, after careful consideration, it was decided that a tailing pond in this area was impractical.

Therefore, it was decided to set up some ground rules for the selection of a tailing site and to investigate all likely sites in the vicinity. The most important of these ground rules were as follows:

- The tailing site should be located off any major stream so as to allow the economical design of a closed circuit mill water system.

- The tailing site should have favorable hydrology so that tributary drainage can be by-passed; thus eliminating spills from the tailing pond water pool to natural drainage.

- The tailing site should have a sufficient volume to contain the proven and probable ore reserves.

- The tailing site should be as close to the orebody as practical.

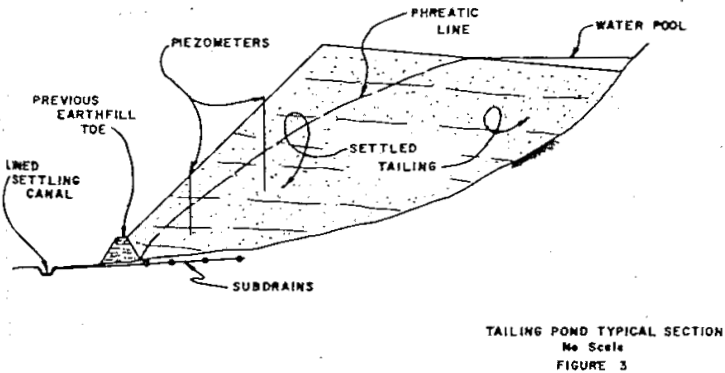

Underdrainage from the tailing pond subdrains is expected to contain dissolved minerals and other contaminates. Therefore, this water will be returned to the tailing pond. The surface water runoff from the tailing dam face and the controlled underdrainage will be intercepted by a large canal where solids will settle and may be periodically removed. The clarified water will flow through small ditches to a pumping station to be returned to the tailing pond. This pumping station will initially have two vertical turbine pumps to pump 2,000 gallons per minute with provisions for increasing the pumping capacity when or if required.