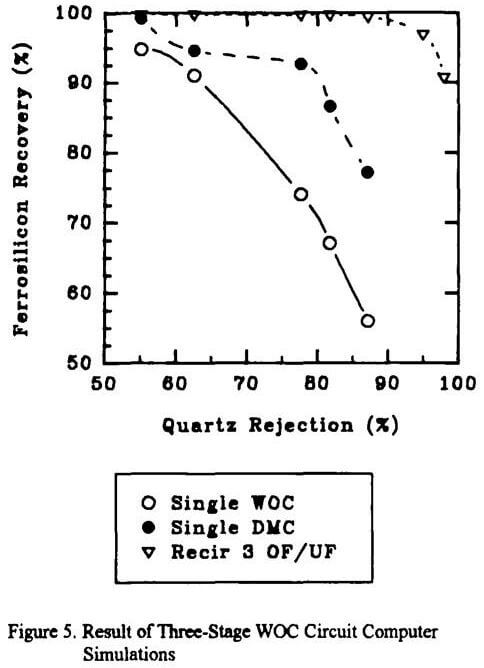

A hydrocyclone utilizes centrifugal and drag forces to separate materials based on differences in physical properties such as size, density, and shape. For a particle system that contains a mixture of two different-density materials, the separation between two components can be achieved by concentrating the mixture into dense and light fractions. In classifying hydrocyclone separations, density and size effects occur simultaneously, with the size effect dominating. Hence, the separation of the particles into light and heavy fractions are not possible. In order to increase the density effect, it is necessary to modify the geometry of the hydrocyclone. The modified hydrocyclone is termed a “water-only cyclone” (WOC), although other terms have been used such as autogenous cyclone, wide-angle cyclone, auto-medium cyclone, large cone-angle hydrocyclone, water cyclone, short-cone wet cyclone, and cyclone washer. The WOC has a wider cone angle and a longer vortex finder (Figure 1) compared to a conventional classifying cyclone. Cone angles up to 120° and more have been used for water-only cyclones compared to 10° to 20° for classifying hydrocyclones. By increasing the cone angle, the effect of particle density can be enhanced. The wide angle results in a build up of an autogenous bed of particles along the conical section of the hydrocyclone. This bed prevents particles from moving unimpeded, and “hindered- settling” conditions prevail [Wills, 1992].

Another important modification is the longer vortex finder of a WOC. Extending the vortex finder toward the underflow opening reduces the distance between the end of the vortex finder and the wall of the conical section of the cyclone. The relative shortness of this distance means that the vertical path traveled by particles in the upward central current of the cyclone is sufficiently reduced so that large low-density particles caught in the upward current will not reach their terminal settling velocity and settle out to the wall, but will be captured inside the vortex finder and discharged with the light low-density fraction [Miller et al., 1985]. The result of the wider cone angle and longer vortex finder is that the separation will occur primarily on the basis of differences in particle density as opposed to particle size.

Water-only cyclones have been used throughout the coal and mineral industries to concentrate a high-density fraction from lower-density particles. For example, water-only cyclones are effective in rejecting pyrite (5.0 g/cc) from coal (—1.4 g/cc) [Weyher and Lovell, 1969], recovering gold (19.3 g/cc) from placer material (-2.6 g/cc) [Walsh, 1985], and concentrating iron ore (-5.0 g/cc) from gangue (2.6 g/cc) [Visman, 1966]. In the latter two cases, the WOC was used as a preconcentration device to reduce the volume of solids that needs to be processed using a higher cost unit operation.

Because a WOC relies on the size/density differences of particles for separation, it can be applied to other systems such as those found in soil washing and metallurgical processing plants. Contaminated soil may contain heavy metals (e.g., lead) of a similar size as the soil matrix. The lead particles can be removed to produce a clean soil, while achieving significant volume reduction of the contaminated fraction.

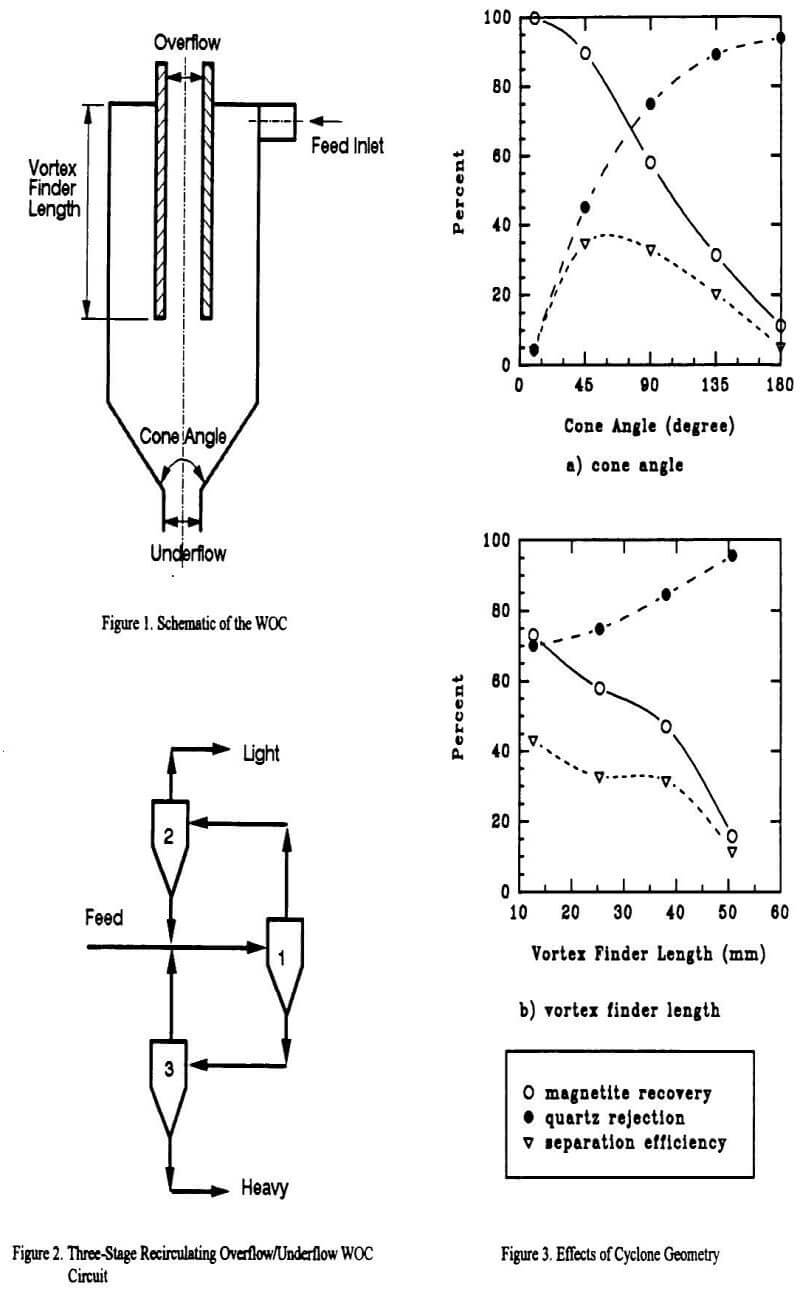

The primary objective of this study was to examine the effects of changes in hydrocyclone dimensions and operating conditions of a 25.4 mm diameter WOC when separating fine, liberated particles (-150 µm) as might be encountered in a soil washing application. A lower size of 25 µm was used. Tests were performed to study the effects of cone angle, vortex finder length, inlet diameter, solids concentration, particle size, and particle density on hydrocyclone performance.

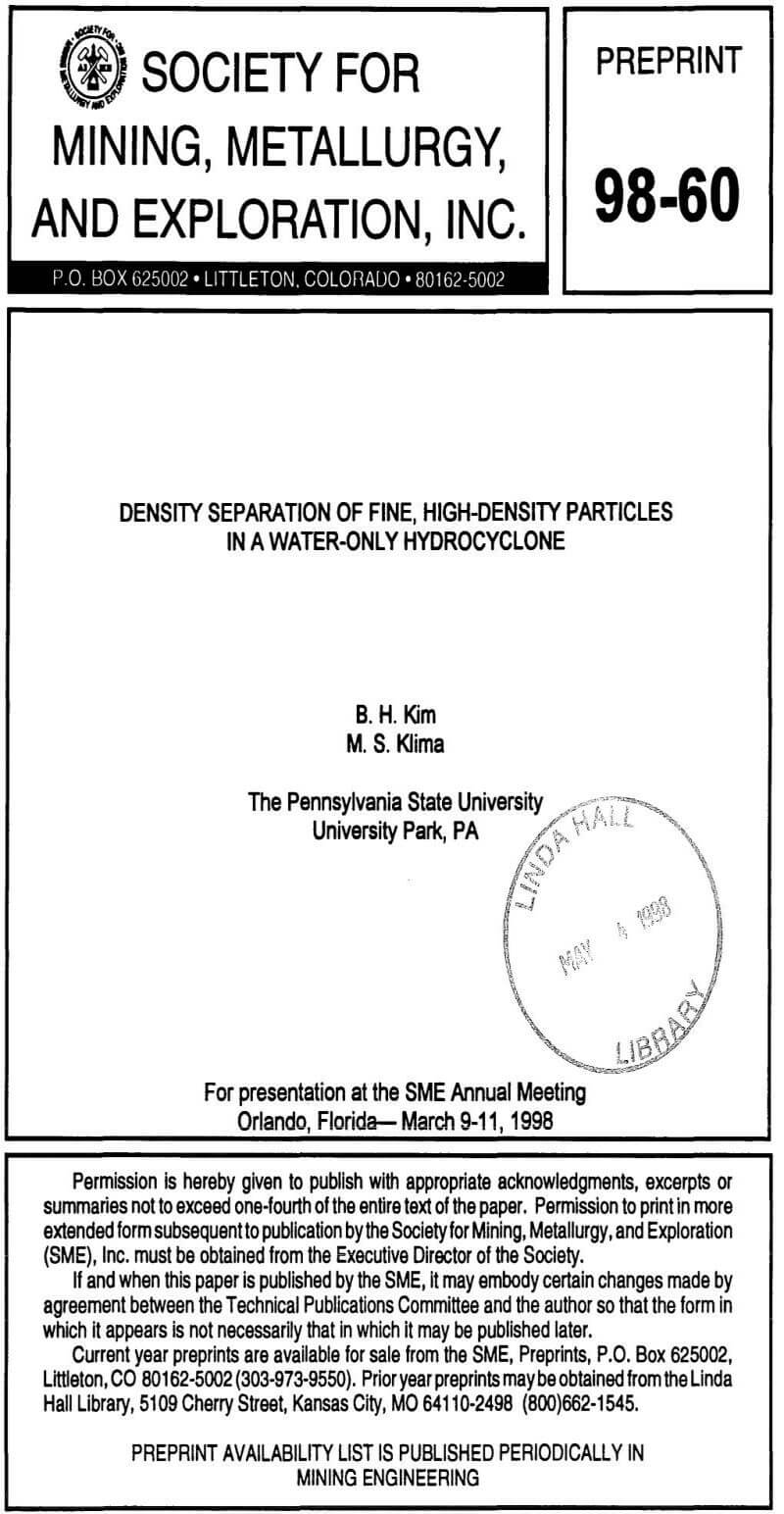

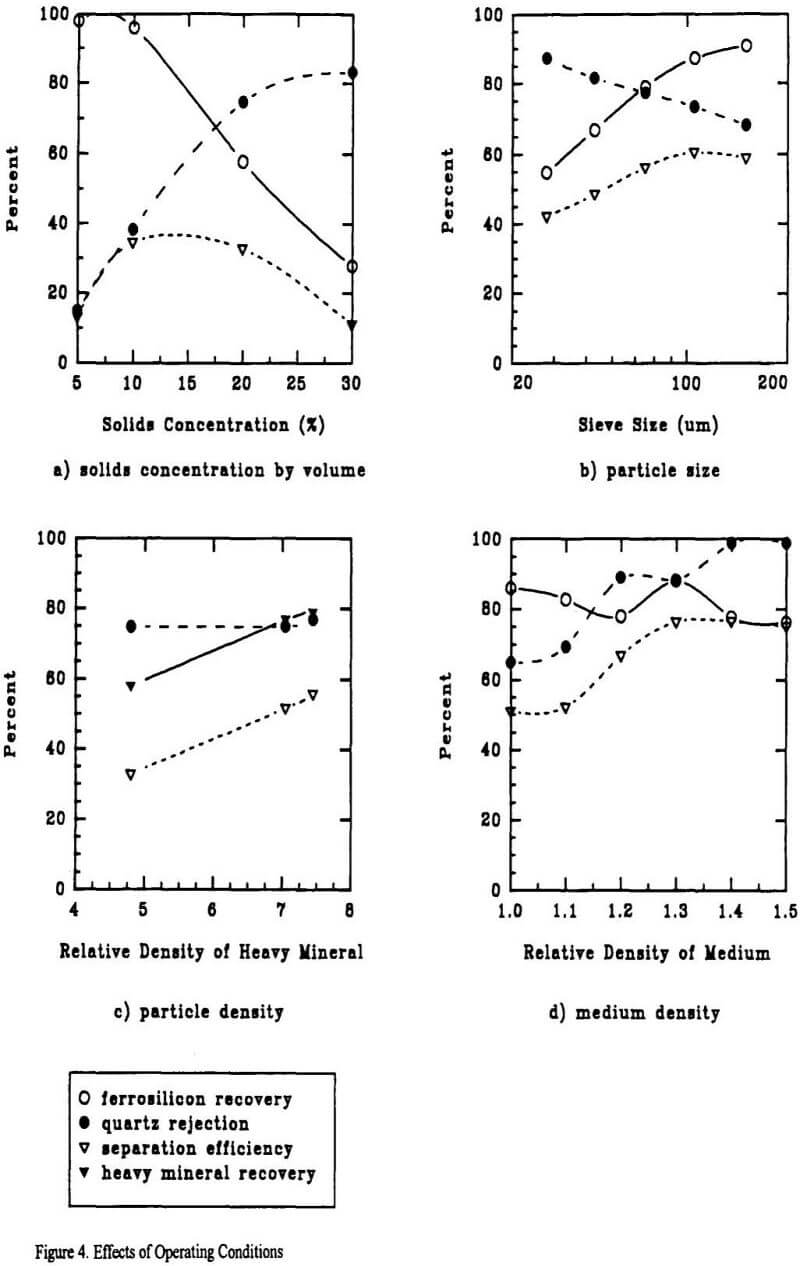

Separate tests were also carried out, in which ultra-fine magnetite was added to raise the medium density above that of water. Using the results from the experimental study, computer simulations of three-stage separations were performed to maximize both heavy mineral recovery and volume reduction.

The test variables included cone angle (90°), vortex finder length (25.4 mm), inlet diameter (5.0 mm), flow rate (8 L/min), solids concentration (20% by volume), particle size, and particle density. The values in parenthesis indicate the baseline condition. Replicate tests were performed over the course of the study as a check on the reproducibility of the results. The standard deviations were generally less than ±2 percent. The differences in the results above this level could be used as an indicator of a significant result.

decreased as the particle size increased. In general, the separation efficiency was higher for larger particles.