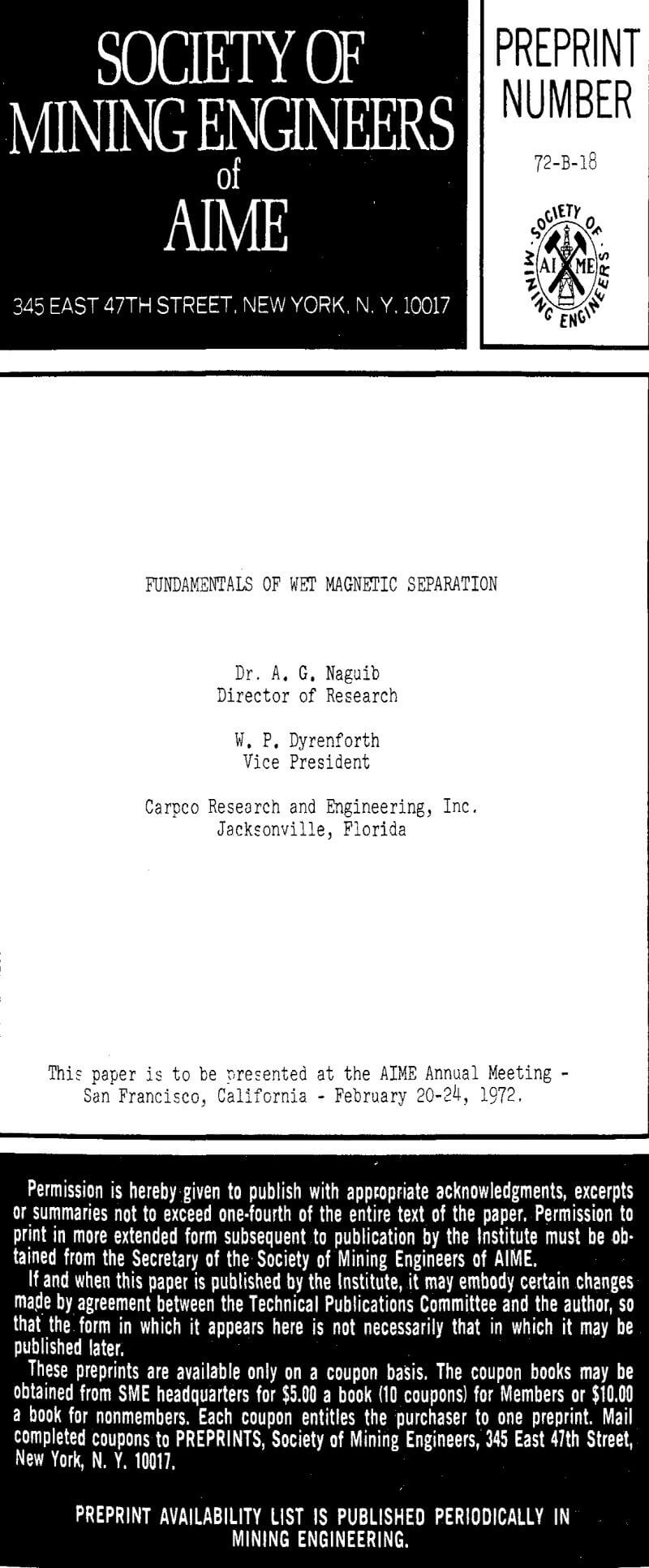

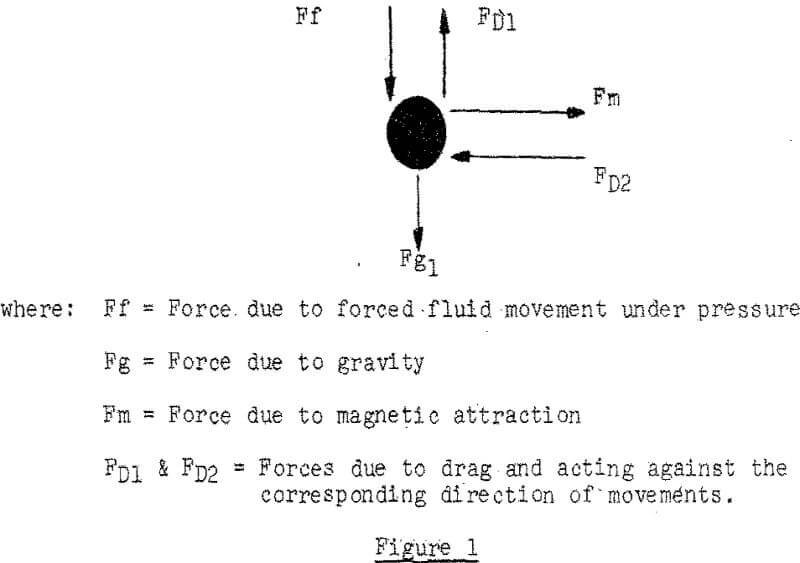

In essence, any magnetic separator operates on the basis of imparting a preferential magnetic force on particles of higher magnetic susceptibility which are to be separated from particles of lower magnetic susceptibility. A certain amount of directional deviation to the particles takes place thus allowing for collecting each category of particles separately.

Under fixed feeding conditions of same particulate feed, all above forces are fixed except for Fm which is to be discussed separately as follows:

Assuming a single spherical particle of a demagnetizing factor = 1/3:

Fm = r³ U – 1/U – 2 H dH/dx

where: Fm = Magnetic force in Dynes

r = Particle radius in centimeters

U = Permeability of particle

H = Field intensity in gauss (assuming permeability of both free space and fluid to be = 1)

Highly ferromagnetic minerals will result in the term U – 1/U + 2 = 0.5 approximately, while in case of feebly ferromagnetic or paramagnetic particles the term U – 1/U + 2 approaches zero.

From the above, it can be seen that:

- The magnetic characteristics of the particle affect the force applied on it by a factor ranging from zero to approximately 0.5.

- The magnetic force applied on a particle is a direct function of the cube of its radius. Hence, the great importance of the size of particles In wet magnetic separation.

- The force is a direct function of both H and dH/dx.

These principles lend themselves to a variety of designs of wet magnetic separators that can be broadly categorized as follows:

- Low Intensity magnetic separators. These are the simplest in design and application. They develop an intensity in the separating zone of about 1000-2000 gauss and could be built as drums, log washers, quadrupoles, or separating belts. They are mainly used to separate ferromagnetic materials such as magnetite artificial magnetite, titaniferous magnetite, or grinding iron. They are widely used and established in the iron ore industry and the separating characteristics are simple applications of the principles discussed.

- High intensity wet magnetic separators. Developing 7000 – 20 ,000 gauss. The need for a wet magnetic separator capable of economically separating the less magnetic minerals such as hematites and ilmenites can be seen from the volume of production of such minerals.

In a separator operating on the principle of a vertically fed gap, those particles that pass through the central plane, or for that matter, the central zone, of the gap are subjected to zero or effectively near zero force of attraction all along their downward vertical path. Whereas, in case of a spheroidal medium, such zones, though of course do exist, are by no means continuous along the whole passage of the particle. They exist between each cluster of neighboring spheroids only.