Table of Contents

It is a tradition in the brass industry that bismuth is an injurious element in brass, even more deleterious than antimony; but such a belief has lacked verification. The occasional presence of bismuth in commercial copper (although less frequent than was formerly supposed) led the author to investigate this tradition.

The following experiments were conducted in the same manner as those described in my paper on “ The Influence of Antimony on the Cold-Shortness of Brass,” to which the reader is referred for details. The purest copper was used, and after it had been melted the bismuth was introduced as an alloy of copper and bismuth. Zinc in the form of pure refined metal was next added, and the mixture was stirred and poured into an iron mould 5/8 by 2 3/8 by 24 inches. All rolling was performed cold. For reasons previously mentioned, a base alloy was used consisting of copper 60 per cent, and zinc 40 per cent.

Experiment No. 1

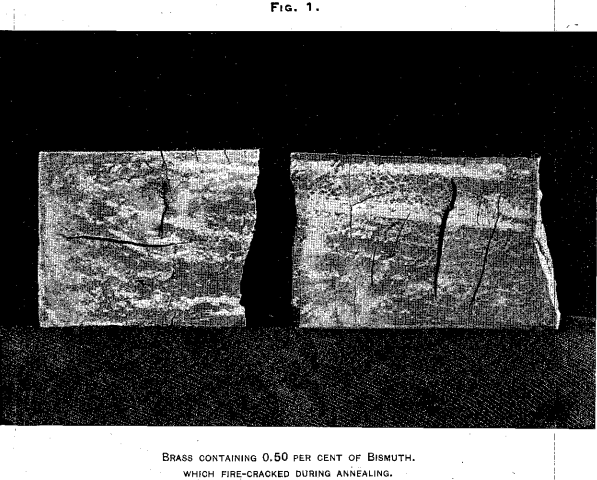

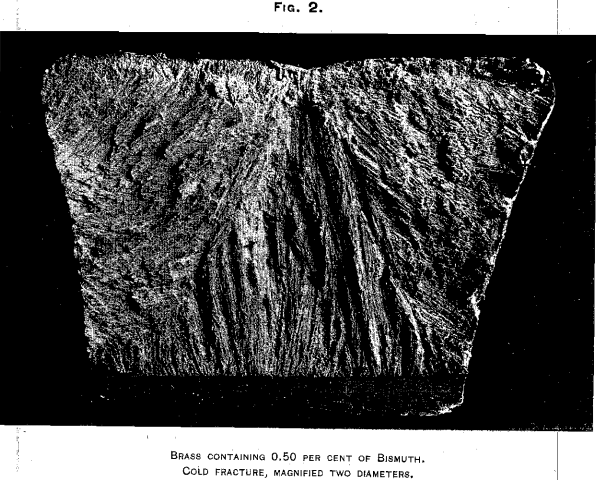

Copper, 59.50; zinc, 40; bismuth, 0.50 per cent. Melted 5.5 pounds of copper, added 0.5 pound of an alloy of copper 90 and bismuth 10 per cent., and then 4 pounds of zinc. Rolled from 0.595 to 0.472 inch, a reduction of 20 per cent. Cracked badly on one edge, but otherwise the surface appeared unchanged. Annealed, and the plate fire-cracked on both sides. While many of the cracks were merely superficial, others penetrated the metal so deeply that further rolling became impossible. The fire-cracked plate is reproduced in Fig. 1. While this alloy is cold-short, it is less so than the corresponding antimony alloy. The fracture is finely crystalline, as shown in Fig. 2.

Experiment No. 2

Copper, 59.69; zinc, 40.06; bismuth, 0.25 per cent. Melted 5 pounds 6 ounces of copper, added 3.75 ounces of an alloy of copper 90 and bismuth 10 per cent., and then 3.75 pounds of zinc. Rolled from 0.655 to 0.495 inch, a reduction of 24 per cent. Cracked slightly on the edges, and a few checks appeared on the surface. Annealed, and fire-cracks formed on both sides of the plate. These cracks were quite numerous, but did not penetrate the metal as deeply as those in Experiment No. 1. Rolled from 0.495 to 0.416 inch, a reduction of 15 per cent., and the fire-cracks became greatly enlarged; many others also appeared. The latter were apparently latent fire-cracks, as the plate did not show any additional cracks on the edges. Such latent fire-cracks were noticed in succeeding experiments, and are evidently due to the presence of bismuth, as the reduction in rolling was not sufficient to cause them. Rolled still further to 0.355 inch, a reduction of 29 per cent., and the plate cracked to pieces. The edge-cracks first formed did not increase in size perceptibly.

The following test was made on a rod cut from an ingot which was cast at the same time as the plate. The results show that the cause of the cracks was not insufficient elongation.

Length, 12 inches; diameter, 0.270 inch; sectional area, 0.0572 square inch; breaking strain, 2560 pounds, or 44,700 pounds per square inch; elongation in 1 inch, 40 per cent.; in 6 inches, 27 per cent.; diameter of fracture, 0.205 inch; reduction of area, 42.3 per cent.

The cold-fracture of this alloy is finely crystalline, and the appearance so similar to that of the alloy containing 0.50 per cent, of bismuth that it is deemed unnecessary to show a reproduction.

Experiment No. 3

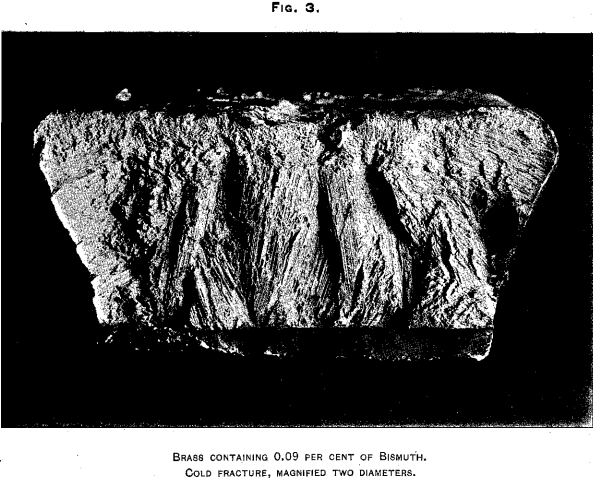

Copper, 60.01; zinc, 39.90; bismuth, 0.09 per cent. Melted 5 pounds of copper, added 1 1/3 ounces of an alloy of copper 90 and bismuth 10 per cent., and then 3 pounds and 6 ounces of zinc. Rolled from 0.660 to 0.485 inch, a reduction of 26 per cent. No cracks appeared during this reduction. Annealed, and the surface of the plate presented an unchanged appearance; no traces of fire-cracks were visible. Rolled to 0.420 inch, a reduction of 13 per cent., and an enormous number of fire-cracks appeared on both sides of the plate. No edge-cracks formed during this reduction. The cracks which were produced during the latter reduction were evidently of a latent nature, like those in Experiment No. 2. They penetrated the plate so deeply that further rolling was impossible. The cold-fracture of this alloy is finely crystalline, and is reproduced in Fig. 3.

Experiment No. 4

Copper, 59.95; zinc, 40; bismuth, 0.05 per cent. Melted 5.5 pounds of copper, added 0.5 pound of an alloy of copper 99 and bismuth 1 per cent., and then 4 pounds of zinc. Rolled from 0.594 to 0.420 inch, a reduction of 29 per cent. No cracks appeared. Annealed, and rolled to 0.319 inch, a reduction of 24 per cent. A few slight edge-cracks formed during this reduction, but otherwise the sheet remained unchanged. Annealed, and fire-cracks appeared on both sides of the sheet. Many of the cracks were so deep that the plate could not be rolled again. Rolled another portion from 0.420 to 0.371 inch, a reduction of 11 per cent., and then annealed. No fire-cracks could be seen. Rolled to 0.325 inch, a reduction of 12 per cent., and latent fire-cracks appeared in large numbers. The position of these cracks was different from those on the other plates; many were transverse, others diagonal, and others longitudinal. Rolled without annealing to 0.189 inch, a reduction of 41 per cent. No edge-cracks formed, and the fire-cracks seemed to have become obliterated, which gave the sheet the appearance of perfect homogeneity. Rolled the sheet still further to 0.058 inch, a total reduction of 84 per cent., and it cracked so badly on the edges that additional reduction was almost impossible.

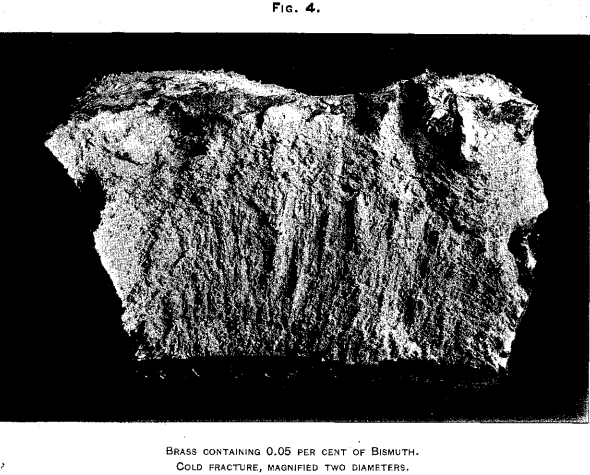

By an examination of the fracture of this alloy, shown in Fig. 4, one can readily see that crystallization has nearly disappeared.

Experiment No. 5

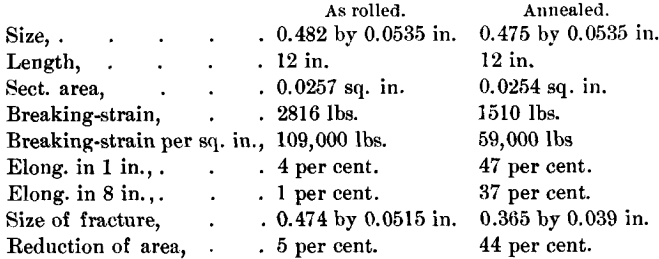

Copper, 59.98; zinc, 40; bismuth, 0.02 per cent. Melted 5 pounds and 12.75 ounces of copper, added 3.25 ounces of an alloy of copper 99 and bismuth 1 per cent., and then 4 pounds of zinc. Rolled from 0.590 to 0.504 inch, a reduction of 14 per cent. Did not crack on the edges. Annealed, and rolled to 0.384 inch, a reduction of 23 per cent. Neither edge-cracks nor latent fire-cracks appeared. Annealed, and rolled to 0.052 inch, a reduction of 86 per cent. At the thickness of 0.125 inch slight cracks began to appear on the edges, and at 0.052 the reduction had reached the maximum amount. No fire-cracks were detected during the rolling-process. This alloy seemed to roll nearly as well as brass free from bismuth; therefore, 0.02 per cent, of bismuth represents the dividing-line between satisfactory and unsatisfactory brass.

The following tests were made on sheet rolled from 0.384 to 0.053 inch, a reduction of 86 per cent.:

The fracture of this alloy shows no traces of crystallization, and compares favorably with that of brass free from bismuth or other injurious elements. The comparison of the results obtained by rolling this alloy, with those obtained on pure brass of the same composition, show that practically the same reductions can be given. The fracture is reproduced in Fig. 5.

Conclusions

While it has been known for some time that bismuth is an injurious impurity in brass, the author believes it has not been demonstrated before that this element is a cause of fire-cracks. The reason for this phenomenon is not well understood, but there is evidently a segregation of bismuth or an alloy of bismuth which is devoid of sufficient strength to stand the necessary strain.

The results obtained by Stead, in his researches on the microscopic examination of alloys, throw some light on the subject. By the examination of an alloy of copper 99 and bismuth 1 per cent., he found that a segregation takes place, and that if such an alloy is bent, fracture will take place along the lines of this segregation. It is reasonable to assume that the action of bismuth on brass is similar.

It must not be supposed that all fire-cracks in brass are due to bismuth. As a matter of fact, it is very doubtful whether this element is usually the cause of such trouble; in the majority of instances the amount of bismuth in copper is not large enough to interfere with its employment in the manufacture of brass.

The behavior of these alloys when forged hot is worthy of notice. The alloy containing 0.50 per cent, of bismuth could not be forged at any heat. The 0.25 per cent, alloy behaved in a similar manner. The alloy containing 0.09 per cent, of bismuth would forge to a thin edge, but if bent upon itself fractured at the bend. The 0.05 per cent, alloy likewise fractured at the bend. The 0.02 per cent, alloy would forge to a thin edge and bend over on itself, showing, but few cracks, but did not behave as well in this respect as brass containing no bismuth.

The results obtained in the preceding experiments are collated in the following summary :

- Bismuth renders brass cold-short, and is similar in this respect to antimony, although the effect is not as marked.

- Bismuth is a cause of fire-cracks in brass.

- High brass intended for cold-rolling should not contain over 0.01 per cent, of bismuth.

- Bismuth produces hot-shortness in brass.

- Bismuth is a cause of latent fire-cracks in brass.

In the use of the term latent in connection with fire-cracks it is the author’s belief that while annealing is the cause of their existence, they do not exist as cracks in the metal after annealing, but as lines of inferior cohesion in an apparently homogeneous mass; rolling, however, develops them, and to all appearances they then partake of every characteristic of true fire-cracks. It seems advisable, therefore, to apply such a distinguishing term, especially as latent fire-cracks are liable to be mistaken for rolling-cracks.