Concentrating Tables

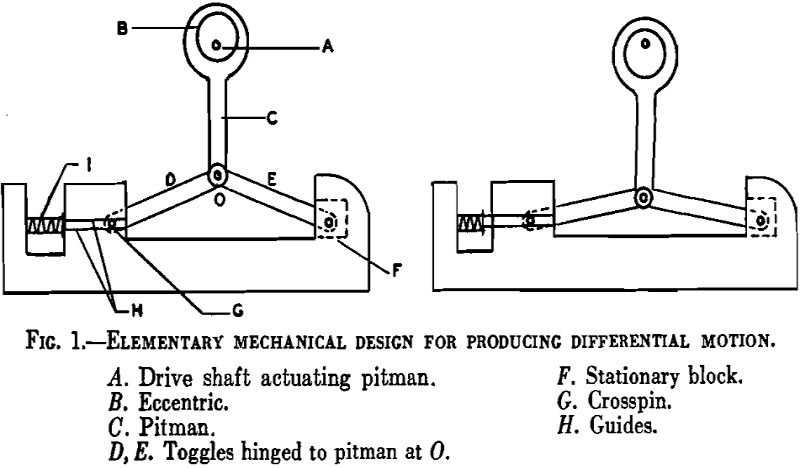

Wet-Process coal-washing tables as we know them today have been in use in this country for approximately 25 years. The literature records only a few table installations worthy of note prior to adoption of the present-day differential-motion table. According to Phillips, six Campbell bumping tables were being operated by the St. Bernard Coal Co., Earlington, […]

Alluvial Tin Mining

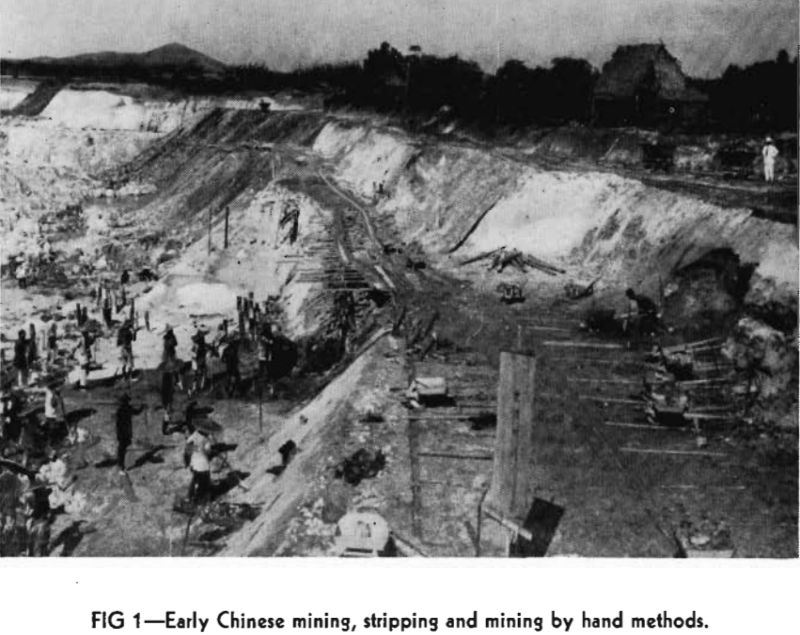

A relatively small area in Malaya, about 200 miles long by 40 miles wide, is the most important source of tin in the world. Some tin is recovered in other parts of the peninsula. Of the tin mined, 98 pct is recovered from alluvial deposits. From 1935 to 1941 the average annual world production of […]

How to Recover Flake Mica

A new method for concentrating the flake mica either from present washing plant tailings or from new feed has been developed. In this paper, flake mica refers to that which occurs in weathered granites, alaskites, pegmatites, and schists in a form too fine to be considered sheet mica. It ranges in size from 1 in. […]

Sand and Gravel Jig

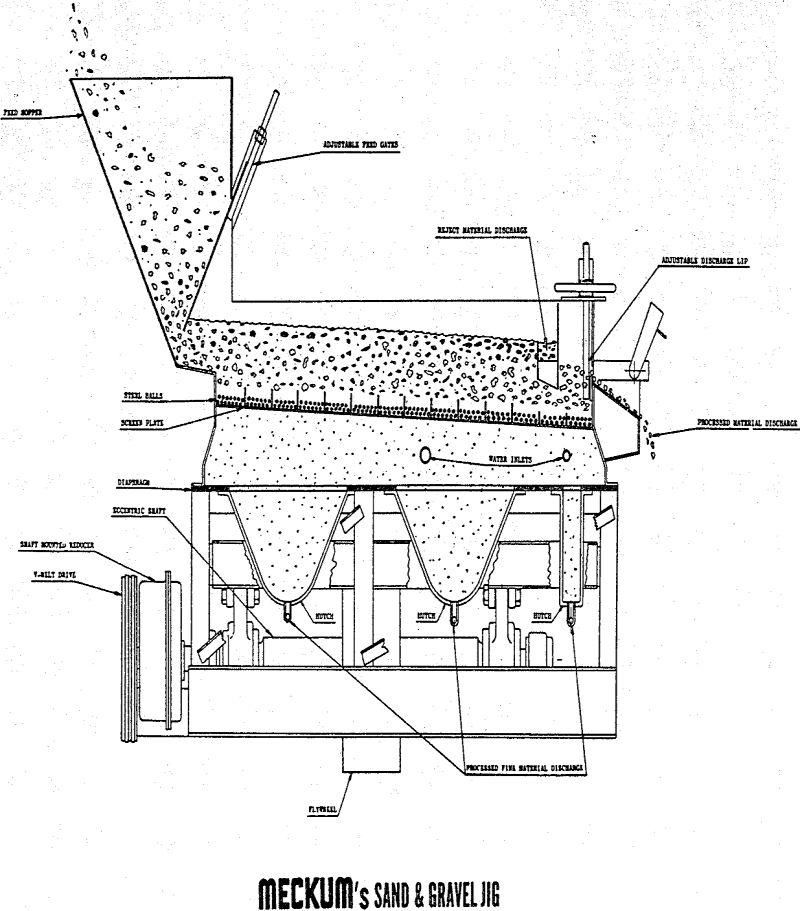

In general, the beneficiation of sand and gravel consists of the removal of certain low specific gravity deleterious particles from the sand and gravel. These particles are coal, lignite, ochre, chert, sandstone, wood, clay, shale, and chalk. These deleterious materials almost always have an apparent specific gravity which is less than 2.35 while good sand […]

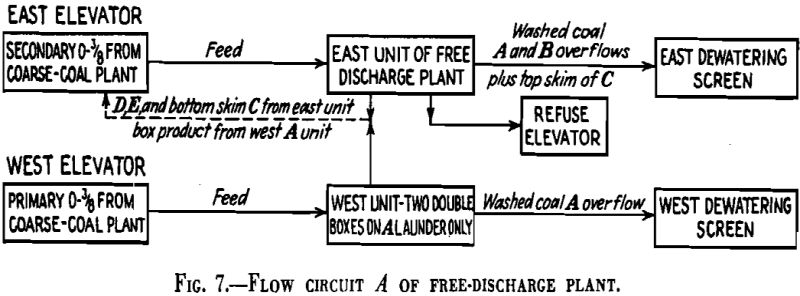

Launder Washers

Trough washers were among the earliest methods used for concentrating ores; they are referred to by Agricola about the middle of the sixteenth century as already being used while the hand-operated jigging sieve had only recently come into use. For cleaning coal the trough washer apparently was first used in France and Belgium about 1841. […]

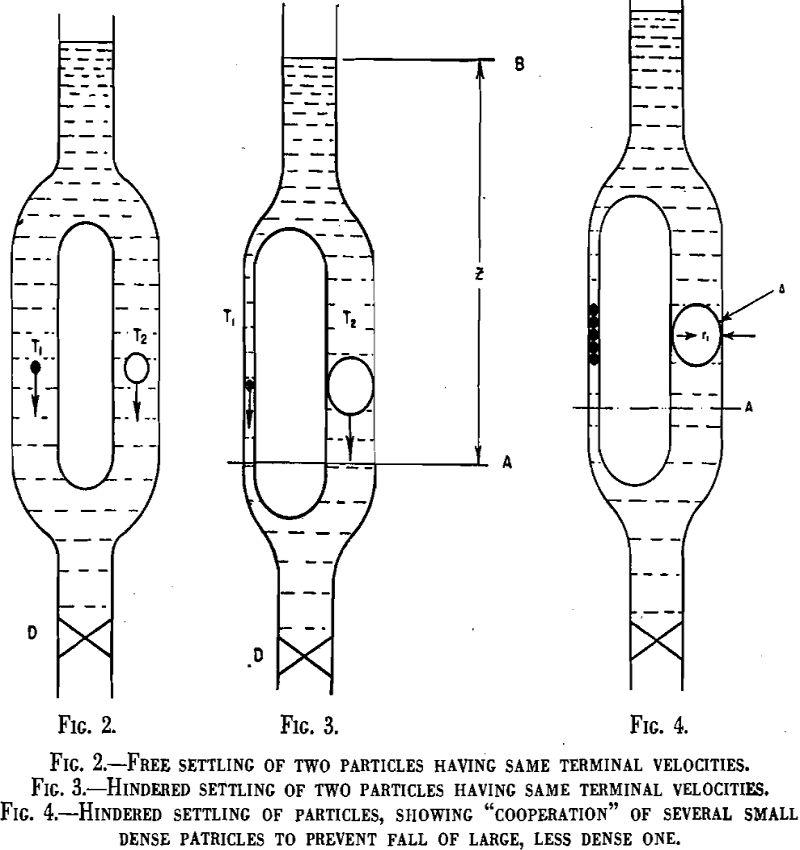

Principles of Gravity Concentration

Gravity concentration is a general term designating processes for separating and sorting granular material by means of forces that depend on the density, size and shape of the particles. When these forces are applied to the particles the latter are caused to move, those of a given density along one path and those of a […]

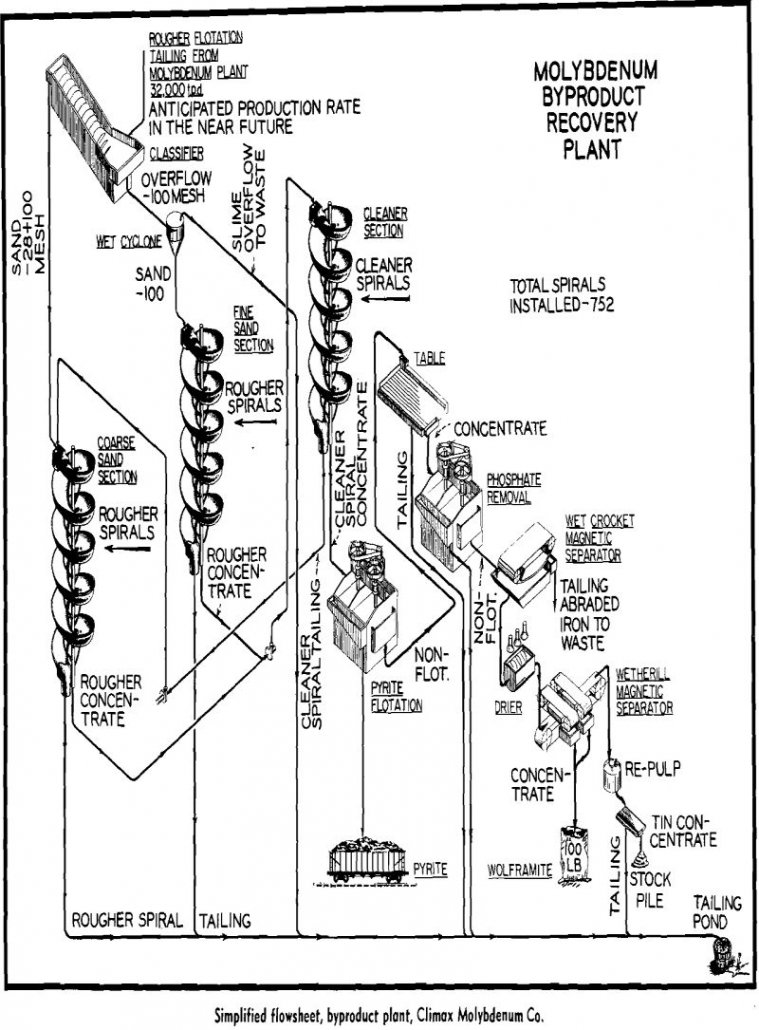

Humphreys Spiral Concentrator

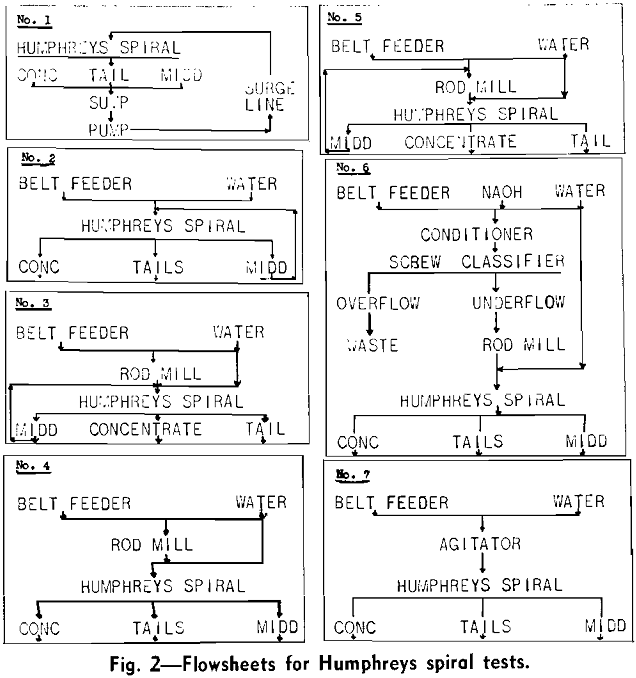

Since it was introduced in 1943 to recover chromite from Oregon beach sands, the Humphreys spiral concentrator has proved successful in several fields of wet mineral beneficiation. By the end of 1957, 9390 Humphreys spirals had been manufactured. Most of these are still in service. Requirements for Spiral Concentration: Valuable heavy minerals to be recovered […]

Dyna Whirlpool Process

The success of Heavy Media Separation, the static sink-float process, is evidenced by the operation of an estimated 300 installations treating many millions of tons per year of a wide variety of mineral products ranging in value from gravel to diamonds. The static heavy media process is usually limited to the treatment of plus ¼ inch […]

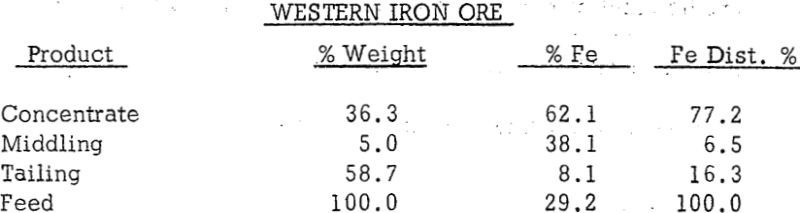

Separation Efficiency

The technical excellence of separation achieved in a mineral concentration process, or any other process where two constituents of any kind are physically separated from each other, is expressed uniquely and quantitatively by the Separation Efficiency: Es = (R – Rg) where R is the percentage of the valuable constituent and Rg the percentage of […]

Batac Jig for Cleaning Fine and Coarse Coal Sizes

The cleaning of coal by the use of jigs is one of the oldest methods of separating coal from its impurities. Although in many situations jigs have been replaced by other methods, by far the largest percentage of coal today is still being cleaned by some form of jigs. Description of the Batac Jig In […]