Table of Contents

A hydrometallurgical testing program to define the basic criteria, like recovery and sulfuric acid consumption, for a commercial heap leach system design, to process the oxide Copper (Chrysocola).

Leach parameters such as, amount of sulfuric acid in the cure solution, cure technique, particle size of the material, leach solution’s flowrate application, leach solution’s acid strength and height of the lifts, were evaluated using column leach tests results. 12″ inches column leach diameter were used to perform the tests and a 50% Andesite – 50% Granodiorite composite with 0.5 % soluble Copper grade as a sample.

Amount of sulfuric acid in the cure solution

Results from leach columns 2, 3, and 4 were used to evaluate three different amount of acid in the cure solution. Leach column 2 had 15 kg/ton, 3 had 10 kg/ton, and 20 kg/ton for leach column 4. The explanation of the cure technique used for these tests is describe down:

The necessary amount of sulfuric acid for cure was diluted in a volume of water which represents about 10% of ore weight contains in the leach column. The solution was apply to the material in a two days period and then allowed for a rest period of 15 days.

The results show that even the amount of sulfuric acid in the cure solution is changed, the total recovery will be the same in all cases, but the sulfuric acid consumption and time will be different for each case.

Leach column 2 reached the 80% recovery of soluble copper with 39.65 lbs/ton acid consumption in a 32 days period. Leach column 3 reached the 80% recovery with 36.52 lbs/ton acid consumption in a 36 days period. Leach column 4 reached the 80% recovery with 39.91 lbs/ton acid consumption in a 23 days period.

Particle Size

Results from leach columns 1, 2, and 9 were used to evaluate three different particle sizes. The maximum particle size in leach column 1 was ¾”, ½” in 9, and 3/8″ in leach column 2.

After 55 days of testing, leach column 1 reached a recovery of 68.8% of soluble copper, leach column 9 reached the 86.1%, and column 2 reached the 87.7% recovery of soluble copper.

In the same period the acid consumption in leach column 1 was 56.17 lbs/ton., 58.43 lbs/ton in leach column 9 and 52.48 lbs/ton in leach column 2.

To reach 80% recovery, the conditions for each column are: more than 55 days and more than 56.17 lbs/ton acid consumption for leach column 1, a period of 36 days and 45.39 lbs/ton acid consumption for leach column 9, and for leach column 2 a 32 days period and 39.66 lbs/ton acid consumption.

Flowrate

The purpose of leach columns 7, 8, and 9 was to evaluate the effect of flowrate, using their results, over the copper recovery, acid consumption and time.

Three different flowrates were testing (one for every column). Leach column 7 was irrigate with 0.003 lps/m², leach column 8 with 0.006 lps/m², and 0.004 lps/m² was used in leach column 9. The results show that does not matter what flowrate is used the total recovery will be the same for all cases, but the acid consumption and time will not be the same.

All three leach columns were operated for a 55 days period. Leach column 7 reached a recovery of 86.5% of soluble copper and had a value of 47.86 lbs/ton for acid consumption, the copper recovery for leach column 8 was 89% of soluble copper with 52.82 lbs/ton acid consumption, 86.1% copper recovery and 58.73 lbs/ton acid consumption were the results for leach column 9.

To reach 80% copper recovery leach column 7 needed 35 days and consumed 38.36 lbs/ton of acid, leach column 8 reached the 80% copper recovery in 28 days and consumed 36.23 lbs/ton of acid, 36 days and 45.39 lbs/ton acid consumption were the results to reach de 80% copper recovery in leach column 9.

Leach solution’s Acid Strength

Two leach solutions were prepared with different acid concentration to evaluate the effect over copper recovery, acid consumption and time. One of these solutions were apply to leach column 5 having 7.5 gpl acid strength, and the other one to leach column 6 having 10.0 gpl acid strength. Both solutions were apply at the same flowrate.

The copper recovery and time were the same in both cases. Leach column 5 reached the 88% recovery of soluble copper in a 55 days period, leach column 6 had the same results.

However acid strength in leach solution causes effect over the acid consumption. Leach column 5 consumed 41.44 lbs/ton acid in a 55 days period and leach column 6 consumed 57.68 lbs/ton in the same period.

Cure Technique

Three different cure techniques were evaluated to see their effect over copper recovery, acid consumption, and time. Static cure technique was one of the three and it is described in page 2 of this paper. Dynamic cure technique was another one and consist of mix the cure solution and the ore in a revolving drum before the ore is placed into the column. The other one was a No Cure technique and consist of start apply leach solution once the ore have been placed into the column.

The total copper recovery is almost the same in each test (86.3%, 84.3%, and 83.9%), however there is a difference in the time that every test takes to reach the same recovery value. Dynamic cure test reached the 80% copper recovery in 22 days, static cure test took 27 days (plus 15 days of cure) to reach the 80 %, and no cure test reached the 80% in 31 days.

Results showed a significant difference in acid consumption. The value for acid consumption in Dynamic cure test was 31.2 lbs/ton, 51.0 lbs/ton in No cure test and 45.4 lbs/ton in Static cure test.

Lift height

To evaluate the effect of lift height over the recovery, time, and acid consumption, two different lift height were tested, 3 and 6 meters. Leach column 9 was 3 meters height. To simulate 6 meters height two 3 meters leach columns were used, PLS from leach column 10 was used as leach solution for leach column 11.

The copper recovery in the 3 meters lift was 89% in a 45 days period, 6 meters lift reached the same recovery but in a 55 days period.

Acid consumption for 3 meters lift was 33 lbs/ton and 85 lbs/ton for the 6 meters lift. The big difference in the acid consumption is due to acid strength in the leach solution (15 gpl for 6 meters lift and 7.5 gpl for 3 meters lift).

Once all tests had been finished the next step was to choose those leach parameters in which the results were the best ones for the design.

Those parameters were:

- Particle size = 3/8″ nominal.

- Lift height = 3 meters.

- Amount of acid in cure solution = 30 lbs/ton.

- Cure technique = Dynamic cure.

- Leach cycle = 33 days.

- Flowrate = 0.006 lps/m² for the first 11 days and 0.003 lps/m² for the rest 22 days.

- Leach solution’s acid strength = 7.5 gpl acid.

Expectancy:

- 80% copper recovery of soluble copper.

- 37 lbs/ton sulfuric acid consumption.

Column Testing. The following procedure was adopted: the whole ore was blended and crushed to the desired particle size. The crushed material was washed with a Sweco screen to separate the fine material from the coarse. The screen opening was 65 Tyler mesh. The coarse ore was split, weighted, cured (when required), and loaded into the columns. The cured ore was allowed to rest for two days (unless otherwise stated) and the irrigation started at the application rate for study. The lixiviant and the pregnant leach solution (PLS) volume were measured every eight hours and the PLS pH was measured and recorded every two hours. The copper and acid concentration in the lixiviant were analyzed daily. When the leaching cycle was completed, the column was washed with water for three days and rinsed for two days. The column was then unloaded, the ore residue was weighted, and samples for chemical and screen analyses were taken.

Column Testing

A program of column tests was performed to define the leaching parameters for treatment of the washed coarse ore. The column sizes were 0.15 m diameter x 1 m high (small columns), 0.15 m diameter x 3 m high and 0.30 m diameter x 3 m high (medium columns), and 1 m diameter x 4 m high (large columns). Initial testing used the small columns to define basic leaching parameters. The medium column tests studied leaching conditions for the proposed lift height of three meters. The large columns were used to verify the conditions found in the medium columns testing. The large column experiments were coupled with a solvent extraction unit for Cu removal from solution and raffinate generation.

Small Column Testing. Small column (0.15 m diameter and 1 meter high) tests were performed to study the effect of the following parameters on copper dissolution and acid consumption: ore particle size, application rate, Iixiviant acid concentration, cure strength, weak acid leach, resting time, ore height, and ore grade.

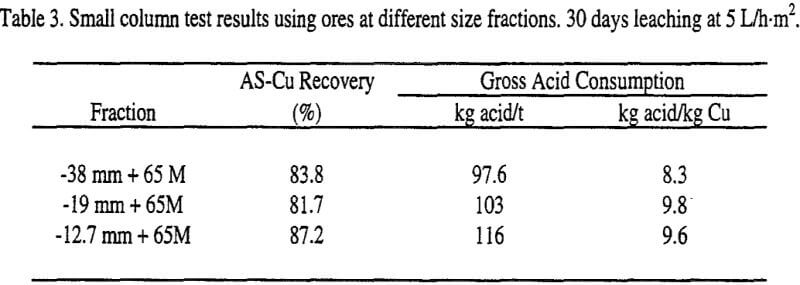

The initial column tests were performed to determine the appropriate particle size for heap leaching. The sizes chosen were -38 mm + 65 mesh, -19 mm + 65 mesh, and – 12.7 mm + 65 mesh. Each size fraction tests was duplicated. The average results for 30 days of leaching are presented in Table 3. The lowest acid consumption was obtained with the coarsest sample. It was concluded that this ore fraction had acceptable copper recovery with

lower acid consumption when compared to the other size fractions. This ore size is attractive because it can be achieved with only two crushing stages. It was determined that all future column tests would be conducted using this ore size.

The small column testing was extended to evaluate the other leaching parameters and concluded that leaching of the coarse ore would be a very challenging task. The high amount of carbonate ore present as gangue consumed most of the acid if a small acid amount was supplied. When sufficient acid was applied, for both the carbonates and copper minerals, the rate of copper dissolution is enhanced at the expense of increased acid consumption. To minimize the acid consumption, the amount of acid added is very important. It was noted that high curing strengths (15 to 30 kg/t) and high initial acid concentrations (100 – 150 g/L acid) in the lixiviant for two or three days were necessary to obtain good copper recoveries at reasonable acid consumptions. The optimum solution application rates were found to be 10 and 15 L/h-m² with two days of resting. Higher application rates increased the acid consumption without recovering more copper. Acid additions greater than 90 kg/t also did not enhance copper recovery.

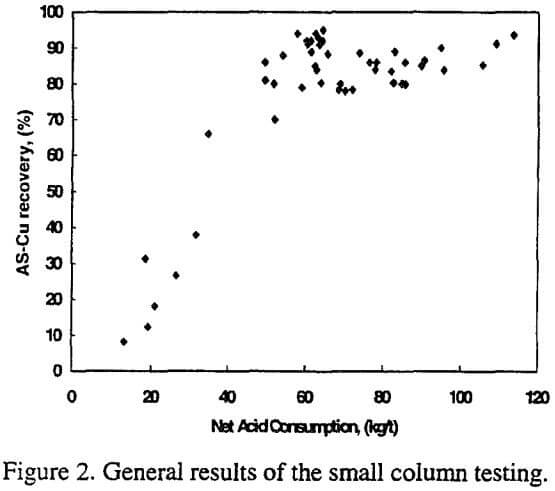

Figure 2 summarizes the test results of the small column testing. It can be noted that in order to obtain about 90% AS-Cu recovery, the net acid consumption will be about 60 kg/t.

Very high acid consumption resulted when the irrigation rates were higher than 15 L/h-m². Very low copper recoveries were achieved with very low acid cure and low acid concentration in the lixiviant.

Medium Column Testing. After defining the leaching parameters for one meter high ore, leaching tests in three meter lifts using the medium columns were performed. The experiment was expected to generate a reduction in acid consumption without affecting copper dissolution. The tests were designed to study the effects of several variables on Cu recovery, acid consumption, PLS pH, and iron dissolution. The variables studied were: application rate, surfactant, acid addition scheme, column height, acid cure at 15 and 50 kg/t, and ore moisture. The variables were further analyzed by conducting an experimental design to determine the optimal conditions.

Acid Addition Scheme. Preliminary 3 meter column tests indicated that acid additions higher than 50 kg/t were needed to achieve high copper recoveries. Using the Leach software developed by R. Roman (1974), the acid addition scheme for the irrigation was simulated. For an acid cure of 15 kg/t, acid concentrations of 225, 100, 65 and 12 g/L during irrigation were tested. After about 30 days of leaching the AS-Cu recovery reached 90% with a gross acid consumption of 75 kg/t and 6.8 kg acid/kg Cu. The obtained PLS pH ranged from 0.5 to 1.8.

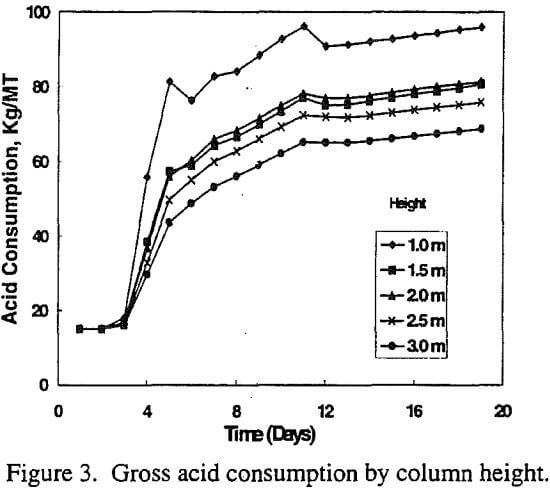

Effect Of Column Height. In order to determine the effect of ore height using the above acid addition scheme, five column tests were conducted with 1.0, 1.5, 2.0, 2.5, and 3.0 m ore height. The same acid addition scheme was applied to each column so that the PLS analysis of the shorter columns would indicate variations in solution chemistry. Figure 3 shows the gross acid consumption by ore height.

Figure 3 demonstrates that acid consumption increased as the column height decreases. Therefore, the lowest acid consumption was achieved in the 3 meter high column. About 95% AS-Cu recovery was obtained in the first meter column. The recoveries for the 1.5, 2.0 and 2.5 meters tall columns were similar to each other. For the 3 meter column, the AS-Cu recovery was about 90% with an acid consumption of about 75 kg acid/t.

Acid Cure With 50 kg Acid/t. Further testing was performed curing the ore with 50 kg acid/t to supply most of the acid to the ore before irrigation. The copper recoveries and the acid consumption were similar to the lower acid cure and the PLS pH was more uniform and averaged about 2. It was concluded that the high acid cure produced a PLS solution which was more compatible with SX.

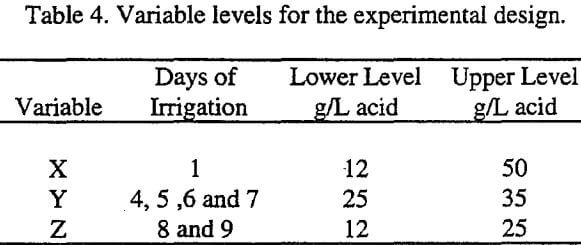

Experiments with different acid concentrations were carried out to determine an adequate acid scheme during irrigation with the goal of obtaining a PLS pH of 1.8 – 2.0. A 23 Yates experimental design was chosen to study the acid levels during irrigation. For the second and third day of irrigation, the acid concentration was 50 g/L for all tests. The experimental levels of the variables are summarized in Table 4.

The averages of the Cu recoveries for the experimental tests are 71.8 and 87.8% for T-Cu and AS-Cu, respectively. The variable X or the concentration of acid in the first day of irrigation had a positive and largest effect on copper recovery. It was also concluded that better copper recoveries were achieved when the leaching was performed at 25 g acid/L for days 8th and 9th. An average gross acid consumption of 81.6 kg/t was reported in the experimental design. This response was affected by variables Y and X which generated higher acid consumptions. The interactions between variables X and Z gave a negative effect (less acid consumption) probably due to the fact that the ore reached its acid requirement when both variables were at their higher levels.

An average PLS pH of 2.46 was obtained for the experimental testing. The pH ranged from 2.32 to 2.64. The lowest pH values were obtained when the variable Z was tested at its higher level. The interactions of variables XZ and YZ also gave lower pHs when tested at their higher level. The average copper grade in the PLS was 7.68 g/L. Higher copper grades were obtained when the variables X and Z were tested at their higher level.