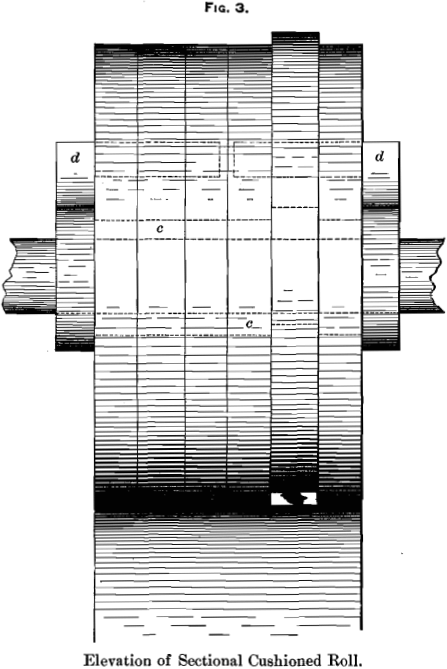

Every millman engaged in the operations incident to the handling of crushing-rolls knows that in ordinary practice, when fine product is desired, the ore-materials delivered to the machine, divided into four sizes, may be estimated, approximately, as follows :

This estimate refers more particularly to the requirements of medium-sized rolls and fine crushing.

But, depending largely on the character of work to be performed, the coarser material is often larger and of a greater percentage, while the bulk is always more or less fine.

As the common Cornish or other crushing-rolls are now operated in ordinary plants, it is almost impossible, economically, to regulate the first operation of preparing the ores for the rolls so that any approach to a uniform size may be obtained. Owing to this unevenness in size it is always necessary to pass and repass the same material several times through the machine in order to make a successful operation.

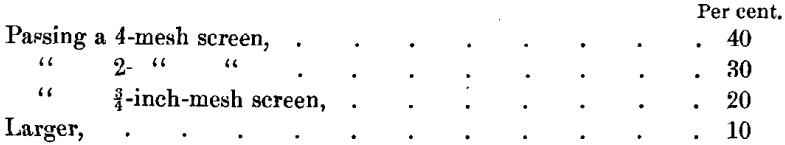

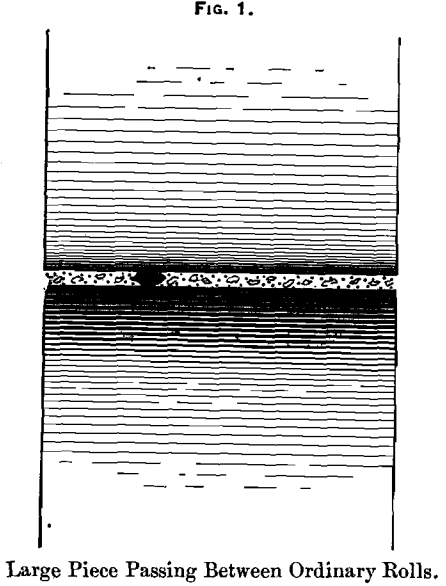

As the ore is fed into the rolls, when the larger pieces are clutched, and the pressure begins to bear upon them, the first strain on the springs tends to separate the rolls (Fig. 1 and

Fig. 2, a) until the crushing-point, or point of greatest resistance, is reached (Fig. 2, b) before the pieces are actually crushed. In this way, especially in crushing hard ores, the rolls are forced apart as much as 60 to 80 per cent, of the time. This parting is not infrequently as much as half an inch and more.

By far the greater part of the material being, as I have said, fine when it reaches the machine, has a tendency to pass through the rolls when thus opened by the larger pieces, and so to escape the desired grinding (Fig. 1). The same may be said of coarser work, the relative proportion of sizes being the same.

In order to correct this defect as much as may be, and increase the efficiency in crushing the finer material that would otherwise pass the rolls, as I have shown, I have devised and practically tested a sectional cushioned system of rolls, applicable as well to all mills using rolls or rollers as a means of crushing and grinding ores of all kinds.

The system, as applied to the Cornish, or ordinary rolls of

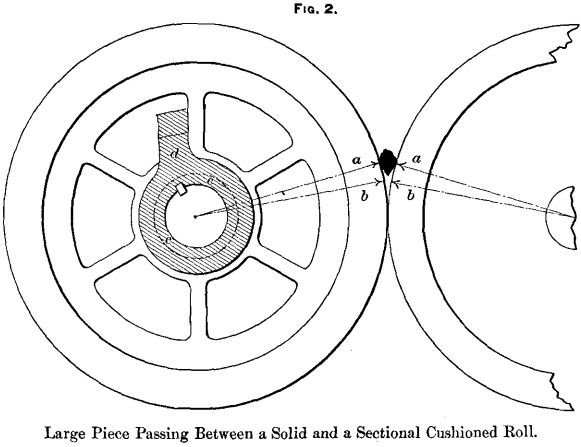

that class, consists in the division of one of the two rolls into several sections (four, six or eight), and the introduction of a stiff rubber cushion for each section, fitting snugly into the bore of the hub, and closely around the shaft which passes through it. This cushion is made of the stiffest car-spring rubber, from ¾ inch to 1 inch thick, according to the size of the machine (Figs. 2 and 3, c).

This sectional roll receives impulse from two steel arms, one on each side, keyed to the shaft, each arm passing through and pressing against the spokes of one-half of the sections (Figs. 2 and 3, d).

In every other respect the machine remains the same as usual, except that the main springs should be stiffer.

In the operation of this system it will be clear enough that when the larger and harder pieces of ore fall into the rolls, and the strain on the springs in the act of crushing causes the rolls to part, only that section in contact with such a piece will be parted until the necessary crushing-pressure is reached, after which it will spring back into place, while all the other sections will continue to crush such finer material as may fall in contact with each, which might otherwise pass between solid rolls without crushing.

Experiment has already proved more than 30 per cent, increased results.

When larger rolls are used, and coarser product is desired, the cushioned rolls, of course, may be set to crush to any size. With broader face to the rolls, and an even, well-distributed feed, the increase in capacity is very great.

The application of the sectional cushioned system to such pulverizing-mills as the Huntington, the Bryan, and others, gives great increase in output.