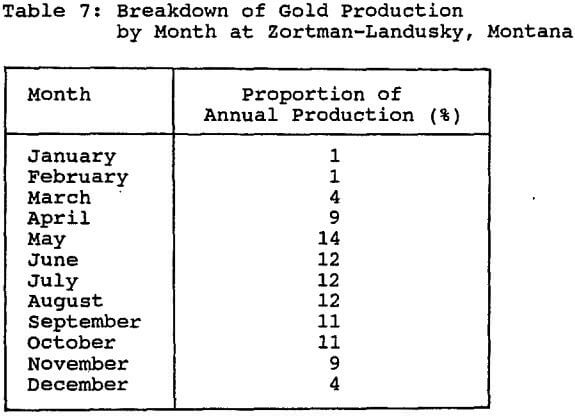

Table of Contents

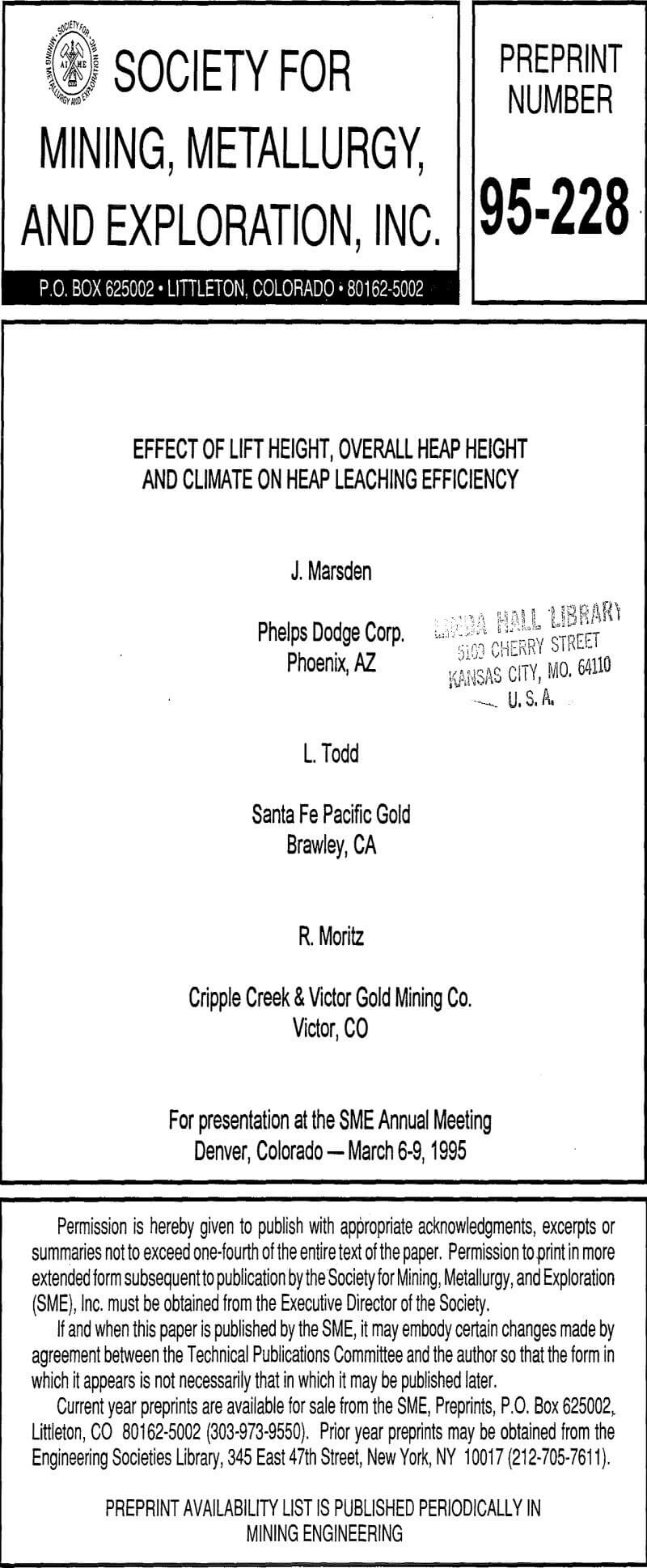

Individual Lift Height

The height of each lift, or bench, of ore placed on the leach pad determines the area of liner required for a given amount of ore before subsequent lifts are placed over the first lift. The higher the lift height, the less liner required (at least initially), the higher the solution grade, and the less area required for solution application to a given amount of ore. However, the higher the lift height, the greater the potential for solution channeling, fines migration and ore compaction to occur, and the greater the amount of ore that must be placed before leaching of a given area of heap can be started. Also, the use of higher lifts creates more side slope area as a percentage of total leach pad area. For example, one million tonnes (1.1 million short tons) of ore placed in a 6 m (20 ft) lift produces side slopes over 8 percent of the pad area compared with 22 percent when a 12 m (40 ft) lift is used. High lift heights also give less opportunity to respond to poor metallurgical performance. In practice, lift heights used typically vary between 3 and 15 m (10 and 50 ft). The lower lift heights, i.e. 3-4.5 m (10-15 ft), are generally required for high clay ores with high fines content which may require agglomeration, whereas higher lifts, i.e. 12-15 m (40-50 ft) are often used for low clay ores treated at run-of-mine size.

Solution Grade

The lift height also affects the grade of the run off solution: the higher the lift; the higher the solution grade for a given material. This is important in optimizing the design of gold recovery systems, i.e. carbon adsorption or Merrill-Crowe precipitation. Generally, the higher the solution grade, the more efficient (and lower cost) the recovery system. However, the higher the solution grade, the higher the gold-in-solution inventory in the heap which is exacerbated as the overall heap height increases. This factor is considered in a later section.

Reagents

For high cyanide or alkali consuming ores, there may be an economic incentive to use a low lift height to avoid excessive depletion of reagents and/or improve leaching efficiency. Overall heap height is generally a more important consideration for reagent consumption because any effects observed through a single lift are amplified when multiple lifts are used. This is considered in the following section.

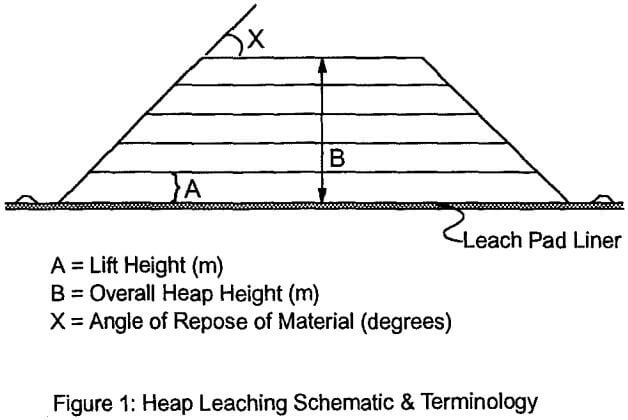

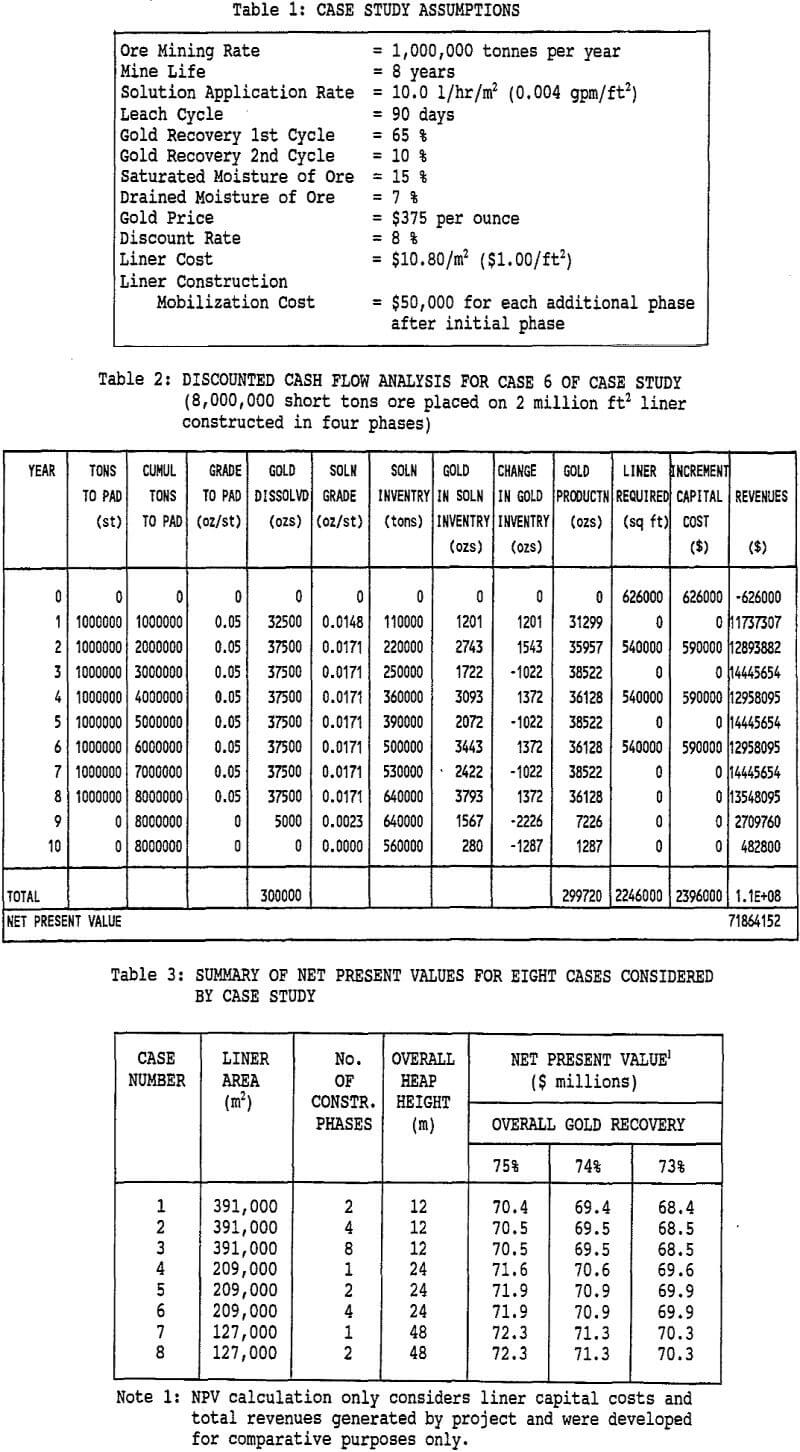

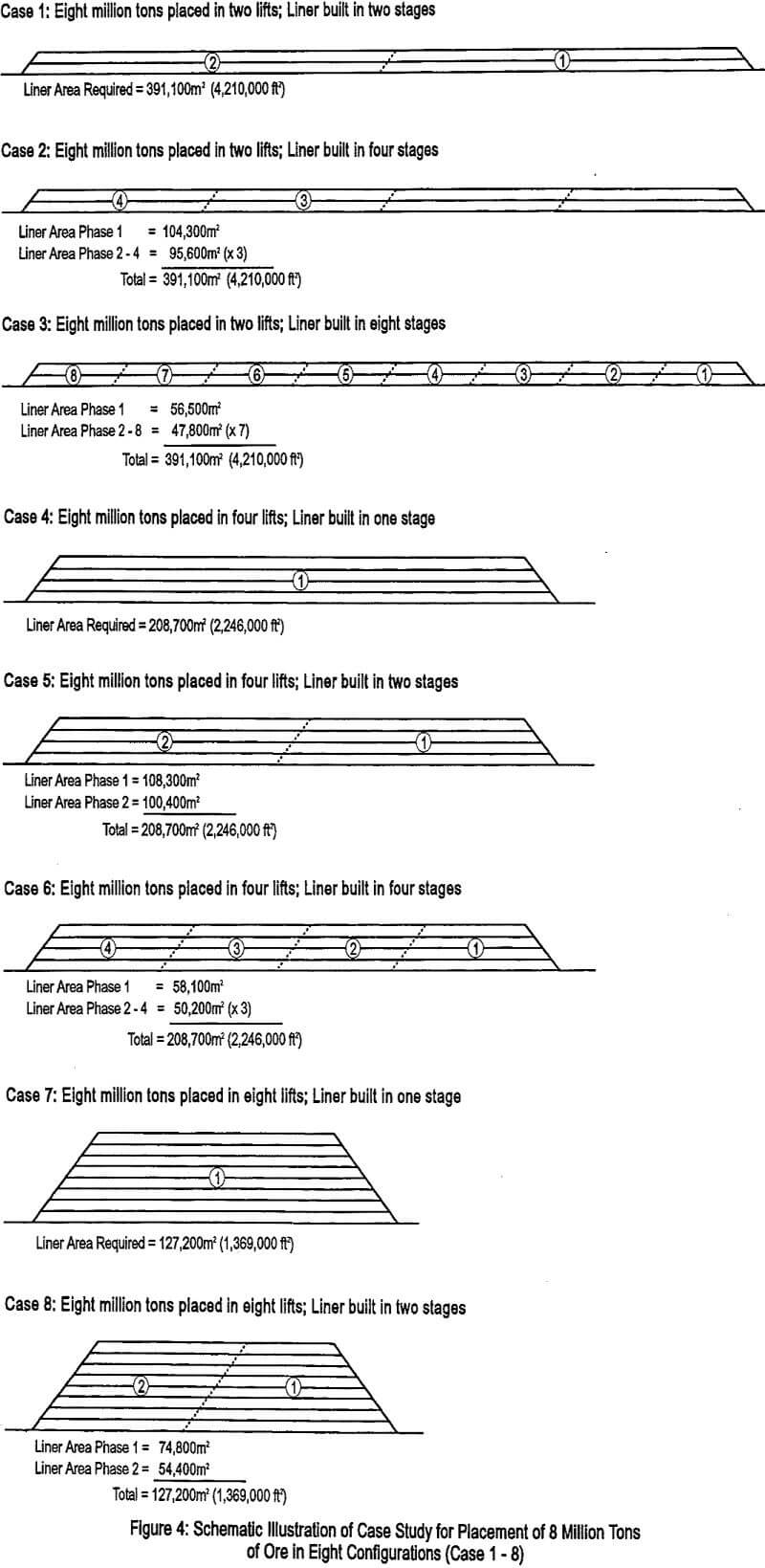

Overall Heap Height

The overall heap height determines the total amount of material that can be stored on a given area of liner, but also affects the time for solution breakthrough, the shape of the leaching curve (i.e. recovery rate), and the total amount of material that can be stored on a given area of leach pad. The higher the overall heap height, the lower the liner capital cost requirement. One million tonnes (1.1 million short tons) of ore placed in a single 6 m (20 ft) lift requires approximately 96,600 m² (1,040,000 ft²) of liner, assuming a heap ore density of 1,760 kg/m³ (110 lbs/ft³).

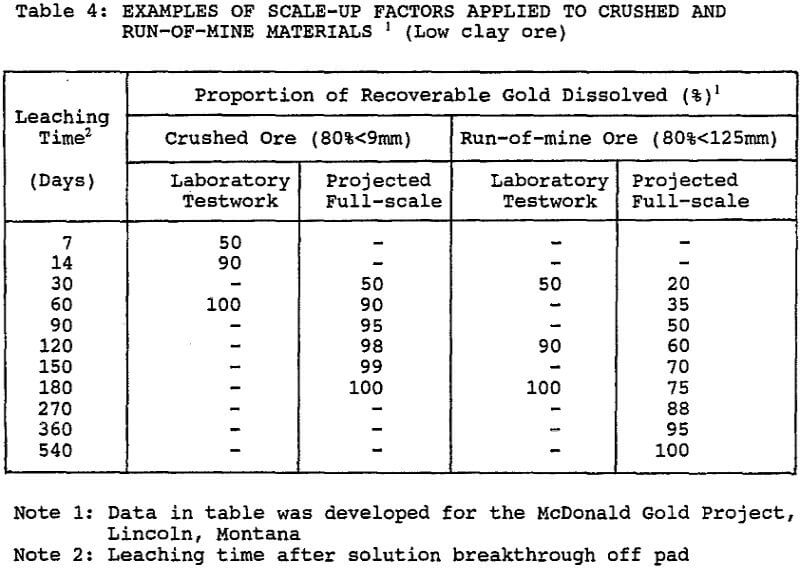

Solution Breakthrough – Multiple Lifts

The time for solution breakthrough from a single lift has been discussed. The time for solution breakthrough from subsequent additional lifts is approximately the number of lifts multiplied by the time for breakthrough for the first lift. However, several operators have noted that the increase in time for breakthrough with increasing heap height can be non-linear, as reported by Lofftus, et al (1990), and this is substantiated by the authors’ observations. The degree of non-linearity appears to depend on the type of material, the size and geometry of the pad (including the horizontal distance that the solution must travel under the heap before breakthrough can occur), and variations in other operating conditions.

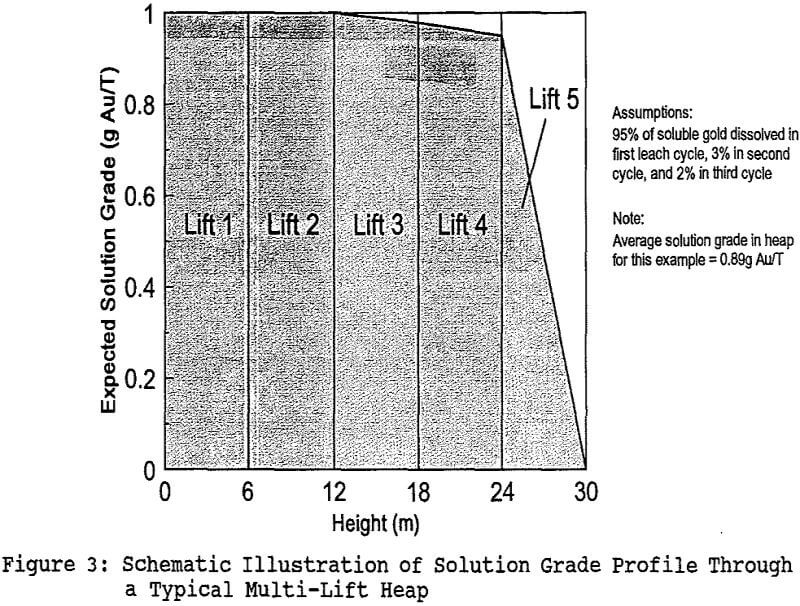

Gold-in-solution Inventory in Heap

The gold-in-solution inventory in the heap can be estimated as follows: The field moisture of the material should be known from column leaching tests and/or from empirical data obtained during leaching. The grade of solution at the bottom of each lift on the heap can be estimated using gold recovery data from leaching of the first lift placed on a heap. If it is assumed that the majority of the soluble gold is leached during the first leaching cycle, then the grade of solution at the bottom of the top lift of material is almost at the grade of the run off solution from the base of the heap.

Metallurgical Factors

An important factor to be considered is the increasing possibility for leaching “problems” to occur as the overall heap height increases, which can adversely affect metallurgical performance. These “problems”, which are usually difficult to quantify, include channeling of solution, creation of dead spots in the heap, potential for preg-robbing/borrowing, migration of fines, compaction and plugging of portions of the heap.

As overall heap height increases, several chemical factors become increasingly important. The first is the potential for a decline in free cyanide concentration, pH and, to a lesser extent, dissolved oxygen concentration. This potential is particularly evident for ores which contain unoxidized or partially oxidized sulfide minerals, or other cyanide, hydroxide or oxygen consumers. While significant cyanide depletion routinely occurs through many leach pads (e.g. from 0.20 g/l NaCN to 0.05 g/l), oxygen depletion is far less common and no oxygen depletion has been observed at either the Mesquite or Zortman-Landusky operations, both of which have deep heaps and minor quantities of sulfides in their ores.

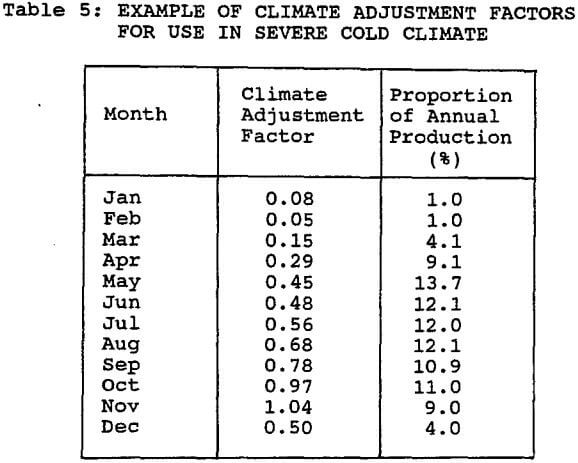

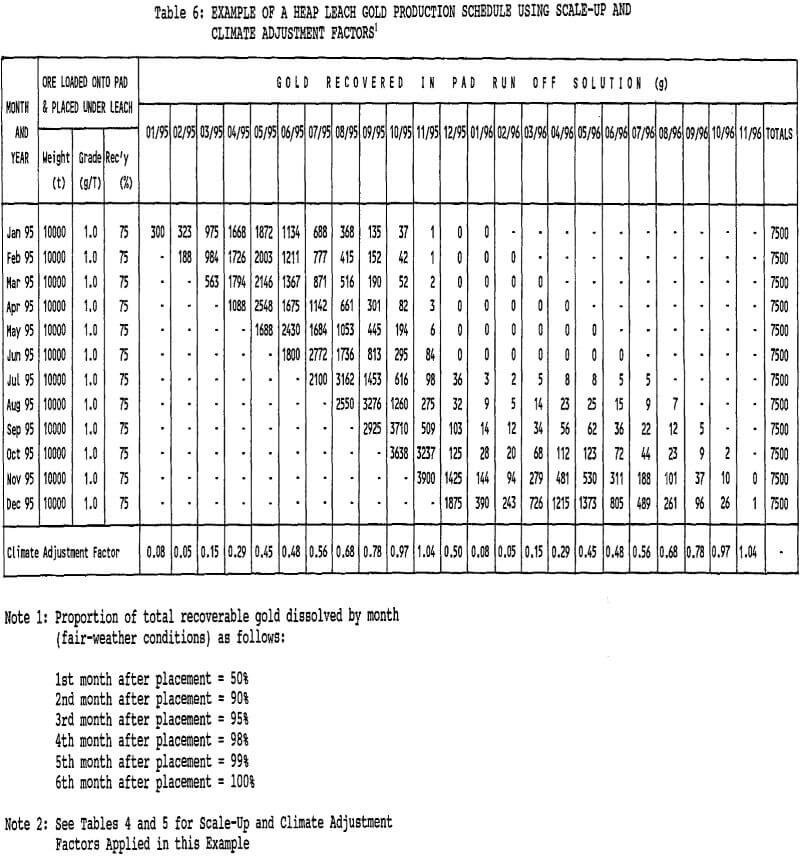

Climatological Effects

The effect of climatological variations on heap leaching is well known and has been investigated and reported by several other workers, including Lofftus et al (1990), Wilder & Dixon (1988) and Johnson (1988). Similarly, the ability to operate heap leach operations in a wide variety of climates has been demonstrated by the extensive application of the technology around the world. Heap leaching has been applied in temperatures ranging from -50°F in North Western Territories (Canada) and the north western USA in winter to +120°F in south western USA in summer.

Santa Fe Pacific Gold – Mescruite Mine

At the Mesquite mine, located near Brawley in southern California, both crushed and run-of-mine ores are treated by heap leaching. The mine started leaching operations in 1986. Five leach pads are used to accommodate crushed ore with a total area of 1,580,000 m² (17.0 million ft²) containing 52 million tonnes (57 million short tons), giving an average specific loading of 32 t/m² (3.3 st/ft²). The average heap height is 27 m (90 ft), with a maximum heap height of 34 m (110 ft) on “completed” heaps. The most recently developed leach pads are permitted to heights of 49 m (160 ft), reflecting a trend to use higher heap heights. The ability to permit leach pads to greater heights is related to the design of the leach pad liner system, geotechnical considerations, and the comfort level of the appropriate regulatory agency with the proposed pad design.

One pad is used for run-of-mine ore with an area of 325,000 m² (3.5 million ft²) containing 7.3 million tonnes (8.0 million short tons), for a specific loading of 23 t/m² (2.3 st/ft²). The average heap height is about 26 m (85 ft), with a maximum height of 49 m (160 ft). This heap is permitted up to 61 m (200 ft).

Pikes Peak Mining Company – Cripple Creek and Victor

The Pikes Peak Mining Company has been operating the Victor mine in the Cripple Creek district in Colorado since 1991. The operations are located at an altitude of 3,000 m (10,000 ft) in the Rocky Mountains west of Colorado Springs. The mine operates two irregularly-shaped leach pads with liner areas of approximately 93,000 and 80,000 m² (1.0 and 0.86 million ft²) each. Ore is crushed to 80 percent minus 38 mm (1.5 ins) and placed on the leach pads in 6 m (20 ft) high lifts to a maximum permitted height of 30 m (100 ft) . The ore contains between 5 and 10 percent minus 75 micron material. A total of 4.4 million tonnes (4.8 million tons) of ore have been placed on the two leach pads and both pads have been filled to the 30 m (100 ft) pad height. Average specific loading on the pads is 25 t/m² (2.6 st/ft²).

Solution is applied by drip emitters to the top of the heap. Each twenty foot lift of ore requires approximately 24 hours to achieve solution breakthrough (5 lifts = 5 days for breakthrough). The fast breakthrough relative to the Mesquite operation is likely due to the clean nature of the ore (low percentage of fines) and the presence of coarser material, up to 75 mm (3 ins) diameter, which appears to enhance pad permeability. The small size of the pads, requiring little horizontal movement of solution, also contributes to this. During winter, drip emitter lines which run above ground are insulated with closed-cell pipe insulation to prevent freezing. In areas where no new ore is being placed, drip emitters are buried to a depth of 0.3-0.6 m (1-2 ft) to prevent freezing. Pikes Peak have observed a considerable benefit to gold recovery by heating the process solutions. Gold recovery is increased by approximately 2.5 percent for every 1°F increase in temperature when the temperature is below about 40-45°F. Consequently, barren solution is heated using electric heaters to aid gold recovery and help prevent solutions from freezing.

Peqasus – Zortman-Landusky

The Zortman-Landusky operation, near Malta in northern Montana, was started up in 1979. At Zortman there are seven leach pads with a total area of 470,000 m² (5.1 million ft²) containing a total of 18.1 million tonnes (19.9 million short tons) of ore. Specific loading is 38 t/m² (3.9 st/ft²). Overall heap heights range from 15 m (50 ft) for the first pad constructed to 61 m (200 ft) for the most recent. The average heap height is just under 43 m (140 ft), with a maximum heap height of 61 m (200 ft). At Landusky, there are seven leach pads with a total area of 1,030,000 m2 (11.1 million ft²) and containing 82.5 million tonnes (90.8 million short tons) of ore, giving a specific loading of 80 t/m² (8.2 st/ft²). Overall heap heights vary from 15 m (50 ft) for the first pad to 122 m (400 ft) for the most recent two pads. The average heap height is almost 90 m (300 ft), with a maximum heap height of 122 m (400 ft). At both Zortman and Landusky ore is placed on the pad at run-of-mine size; approximately 70 percent minus 90 mm (3.5 ins), 50 percent minus 18 mm (0.75 ins) and less than one percent minus 75 microns. Material is placed in 7-9 m (25-30 ft) lifts, although 12 m (40 ft) lifts have been used with no apparent detrimental effect. The time for solution breakthrough through the first lift is 3-4 days.