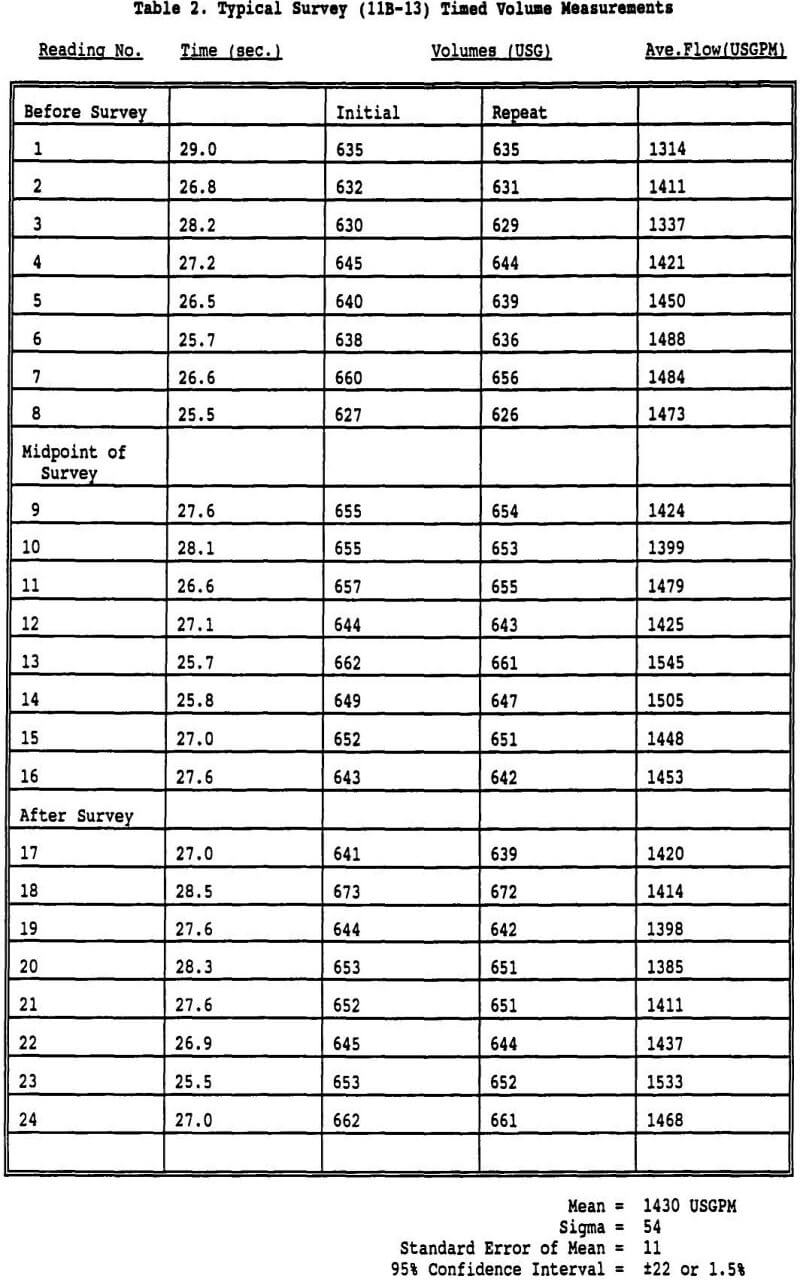

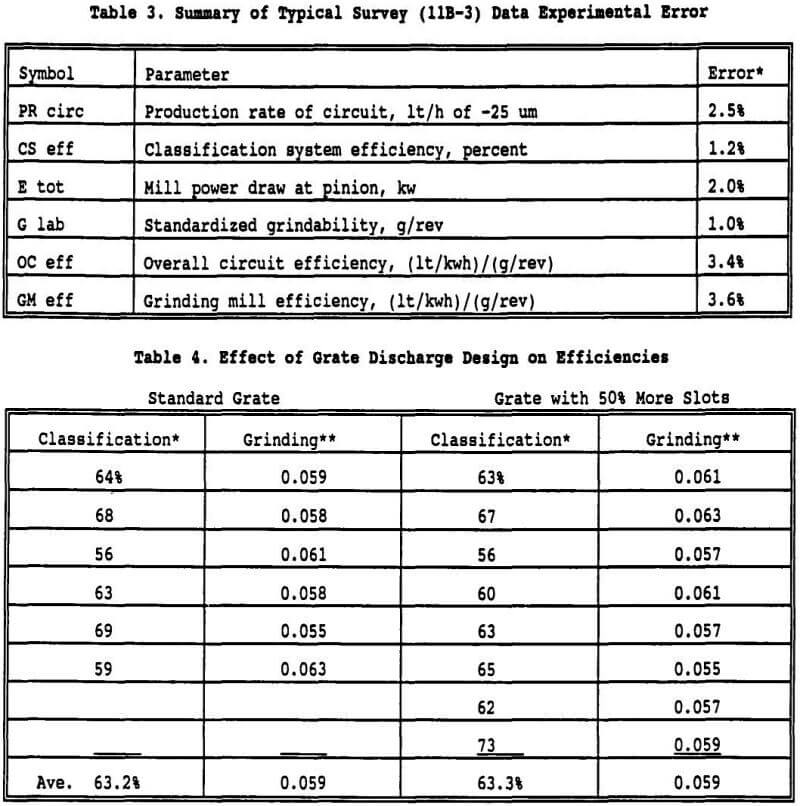

Functional performance analysis of ball milling has been described previously by Mclvor. “Coarse” versus “fine” or product particle cut-off size is first selected, usually equal to some benchmark passing size of the circuit product (e.g., 80%). The function of the grinding circuit is to generate new product size material (or “fines”) from “coarse” particles in the circuit feed as efficiently as possible. Because all breakage takes place inside the mill, it can be stated that the production rate of fines of the circuit (PR circ) is equal to the energy being (effectively) applied to the coarse particles (E effec) multiplied by the energy specific grinding rate of coarse particles in the mill (GR co). This process is represented by Equation 1.

PR circ = E effec x GR co………………………………………………….(1)

The effective energy, i.e., that portion being applied to the coarse particles, is the total rate that energy is consumed by the mill (E tot) multiplied by the fraction (or percent) of the mill inventory of coarse versus fine material. Since the mill coarse solids inventory quantifies the circuit’s ability to sort and present the desired (i.e., coarse) particles for breakage (McIvor, 1988b), it may also be termed the circuit classification system efficiency (CS eff).

Therefore, since:

E effec = E tot x CS eff…………………………………………………………(2)

Then:

PR circ = E tot x CS eff x GR co……………………………………………..(3)

We can also multiply and divide the last term of the above equation by the grindability (G lab) of the coarse material as measured in a standard laboratory procedure and reported, for example, in grams per revolution.

PR circ = E tot x CS eff x GR co/G lab x G lab………………………………………….(4)

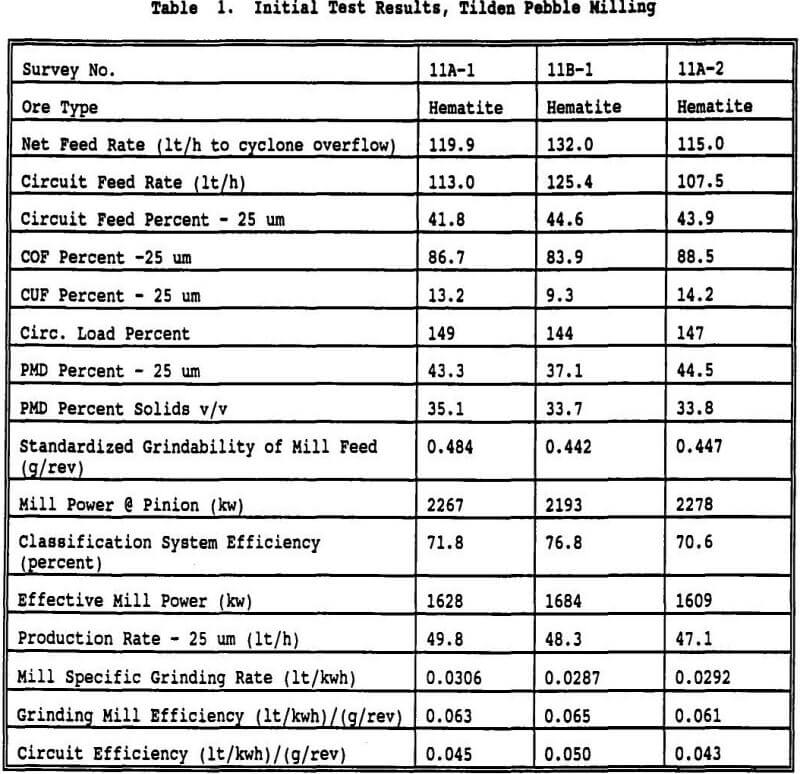

The reason for doing this is that the third term in the above equation now is the ratio of the grinding rates of the plant mill versus a standard laboratory mill on the same coarse material which, therefore, is also a measure of the relative efficiency of the two grinding environments. Since the laboratory equipment and procedure is standardized (i.e., constant) for all circuit surveys, this term represents the grinding efficiency of the environment of the plant mill (GM eff).

GR co/G lab = GM eff………………………………………………………………….(5)

Substituting yields the circuit functional performance equation, no. 6.

PR circ = E tot x CS eff x GM eff x G lab…………………………………………….(6)

This simple equation elegantly demonstrates that circuit production rate of fines is directly related to two inputs, energy and material grindability, and two distinct operational efficiencies, one due to the classification system and the other due to the mill grinding environment.

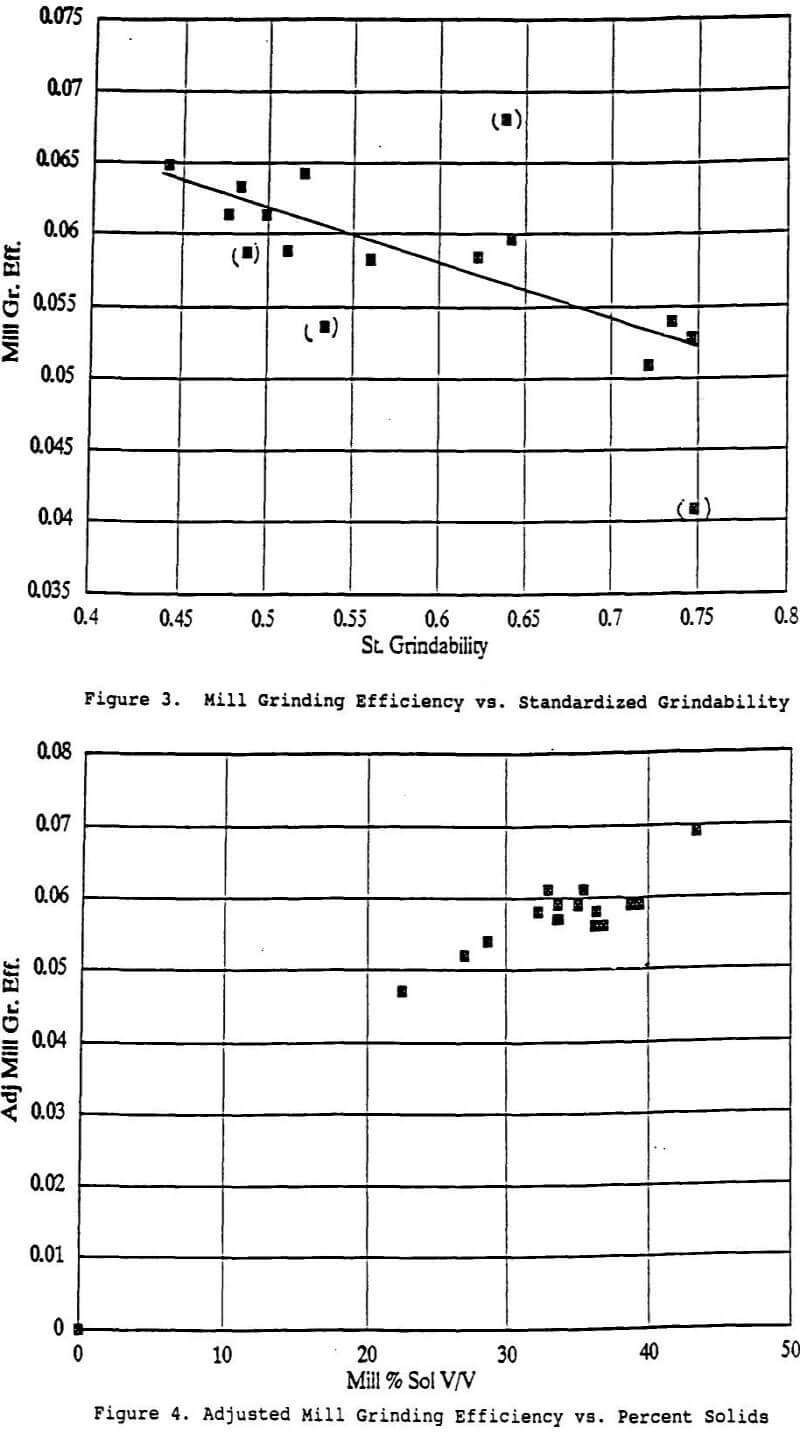

It also presents an excellent means of strategizing circuit improvements to increase production rate, for example, by increasing energy input (the mill power draw); by adjusting the classification system performance through pump and cyclone modifications; or, by improving the efficiency of the grinding mill environment through the media sizing, percent solids, liner design, etc.

Finally, by isolating the two efficiency terms, we arrive at a very rational term for overall circuit efficiency (OC eff).

OC eff = CS eff x GM eff = PR circ/E tot x G lab……………………………………………(7)

The overall circuit efficiency is the production rate of fines of the circuit per unit of energy consumed factored by the grindability of the material being ground.

The utility of functional performance analysis thus lies in its ability to relate circuit design and operating variables to classification, size reduction, and overall grinding circuit efficiencies using data readily obtained from plant experiments (McIvor, 1988a).