An exploration process is normally consisted of four major phases: regional reconnaissance, detailed mapping, sparse drilling, and infill drilling. Regional reconnaissance focuses on promising areas for a given type of ore deposit by using geological, geochemical, and geophysical data. Once one or more areas are selected, a detailed mapping program will be enacted in order to delineate drilling targets. This may include smaller geochemical survey grids, trench sampling, structural mapping, and high-resolution geophysical mapping (e.g., IP and CSAMT). Sparse drilling (usually in a regular grid) will be first conducted within top-ranked targets from the detailed mapping. The goal is to detect unknown ore deposits and roughly delineate the spatial extent of mineralization. This phase is critical since it generates detailed information on geological control, ore types, and the spatial variability of ore elements. All these data will then be necessary inputs in feasibility studies to evaluate the economic viability of mine development. If the deposits are financially attractive, infill drilling programs will be developed to define minable (proven/probable) reserves for detailed mine plans.

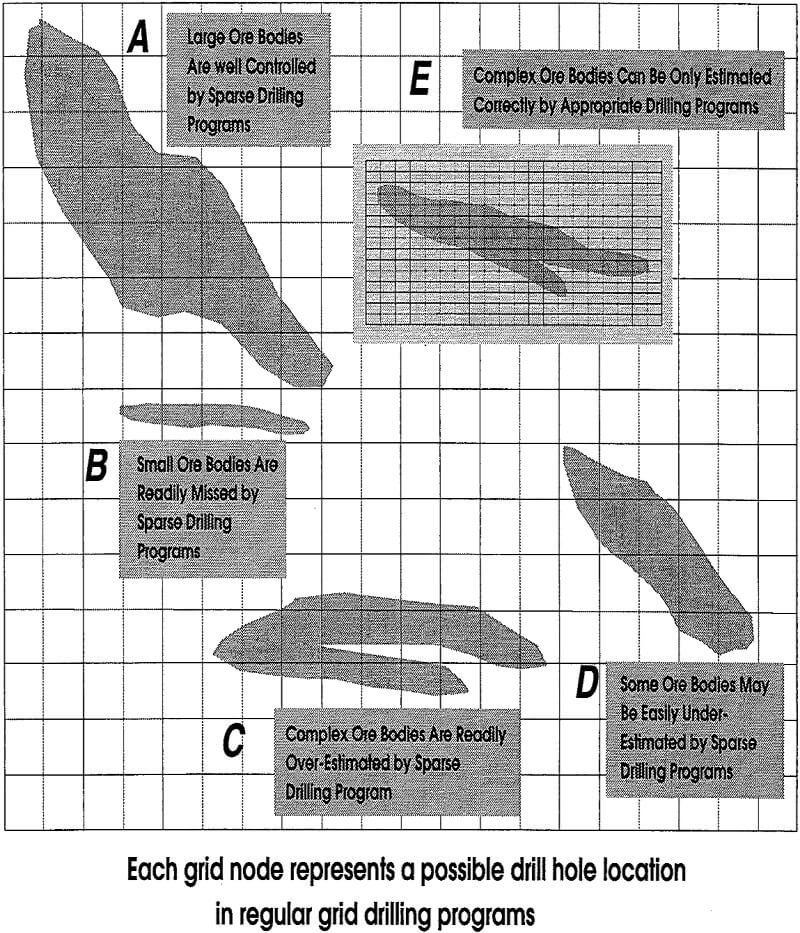

Exploration history shows that the high quality of infill drilling plays an important role in accurate reserve estimations and mine plans. A major purpose of infill drilling is to confirm the continuity of mineralization in a deposit and adequately delineates ore bodies particularly for small and narrow ore pods or veinlets. Since ore bodies are often distributed in preferential directions and locations, infill drill holes should be designed to take into account of the geological models derived from previous mapping and drilling.

A drilling pattern designed by geologists relies primarily upon geological controls. A mine engineer uses the concept of continuity to define minable reserves. Yet the concepts of continuity may differ between geologists and mine engineers. This difference may lead to different tonnage-grade relations and mine plans thereafter. Drill hole patterns determined by geologists enough for geological continuities may not be sufficient for determining ore continuities in reserve modeling and mine planning. Conversely, trends of mineralization identified by mining engineers can be lack of geological grounds.

Drilling plans have been designed in regular or lateral grids. This strategy has frequently resulted in inefficient drilling, that is, some areas are overly drilled while some other areas are under-drilled. Inefficient drilling may incur millions of dollars more costs than what mining companies should invest for the same or higher level of confidence. Unfortunately, the issue has not been loudly addressed by explotationists, although some quantitative design methods have been proposed. In addition, optimal sample spacing has been also examined, including drill hole spacing for open-pit reserve estimation, underground exploration, and blast-hole sampling.

At a quick glance, optimal infill drilling appears like academic overkill. A straightforward geological call, however, does not necessarily lead to

- minimal number of infill drill holes necessary for a given level of confidence.

- optimal spatial distribution of infill drill holes for revealing grade variabilities and ore geometries.

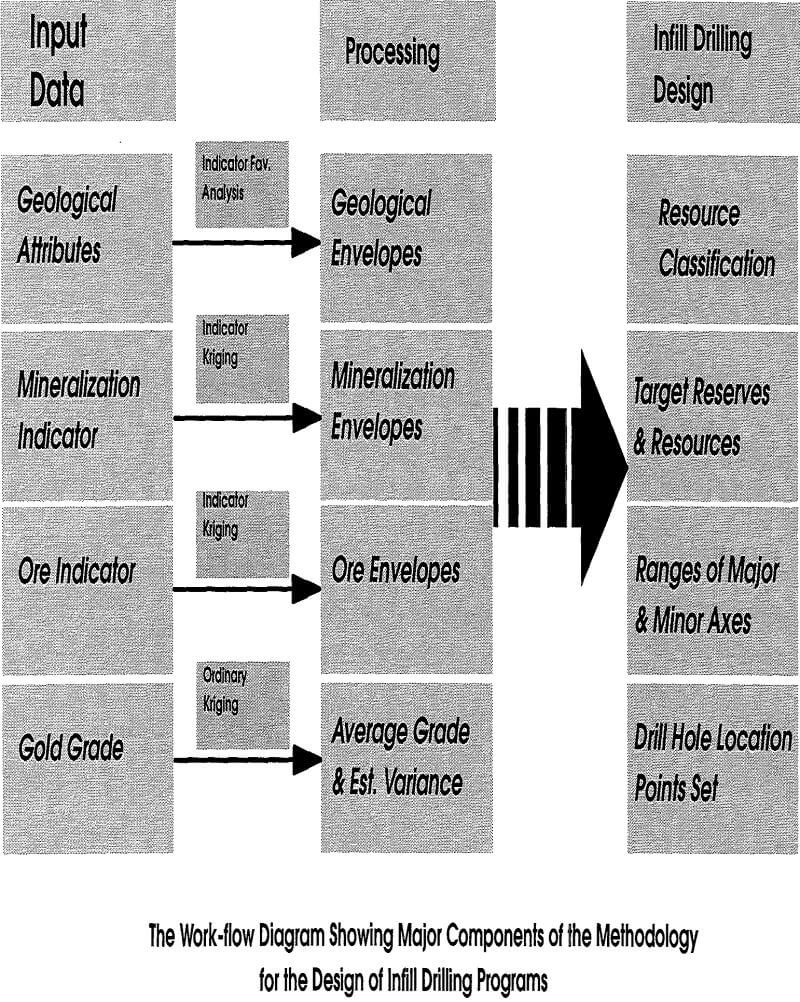

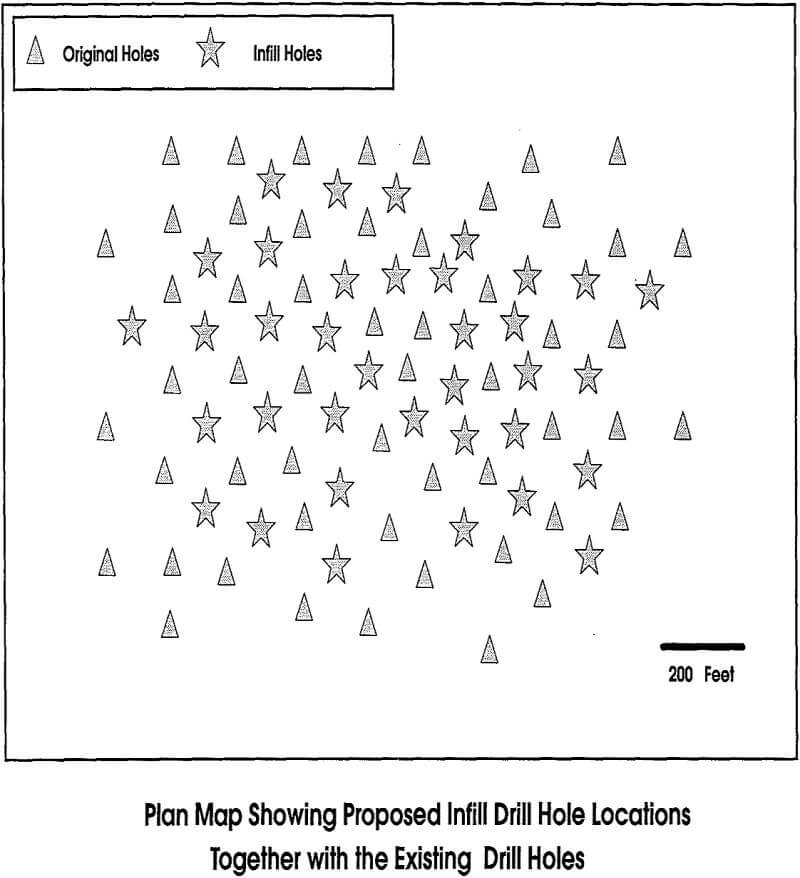

A geostatistical approach is proposed for quantitative design of infill drilling plans for a given set of known drill holes in a deposit. The major feature of the methodology is the use of all assay and geological data acquired from previous exploration efforts. The technique is developed on the basis of quantitative reserve/resource classifications. The geostatistical framework involves indicator kriging, ordinary kriging, as well as indicator favorability analysis. A case study is presented to demonstrate the implementation and usefulness of the method. The study shows that a substantial portion of the drill holes has been reduced from the traditional regular infill drilling plan.

Basic Concepts

Instead of rushing into the complexity of methodology, an introduction of some basic concepts related to continuity, favorability, and resource should serve as useful eye-openers. Classification of reserves/resources provides a ground on which local potentials are judged in light of infill drilling. Continuity is also critical, since most infill drilling programs attempt to confirm the spatial variability of ore grade. The use of favorability analysis is predicated upon the need for defining favorable geological environments of blocks as being permissible for additional drilling.

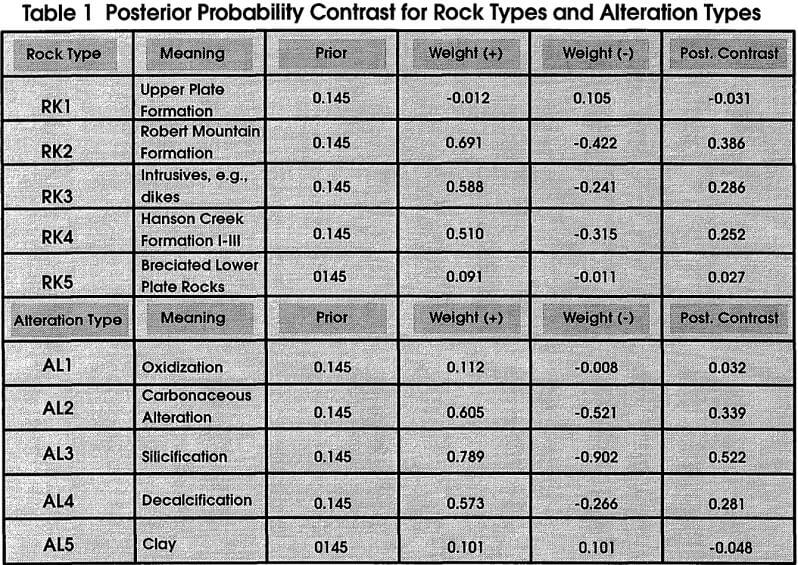

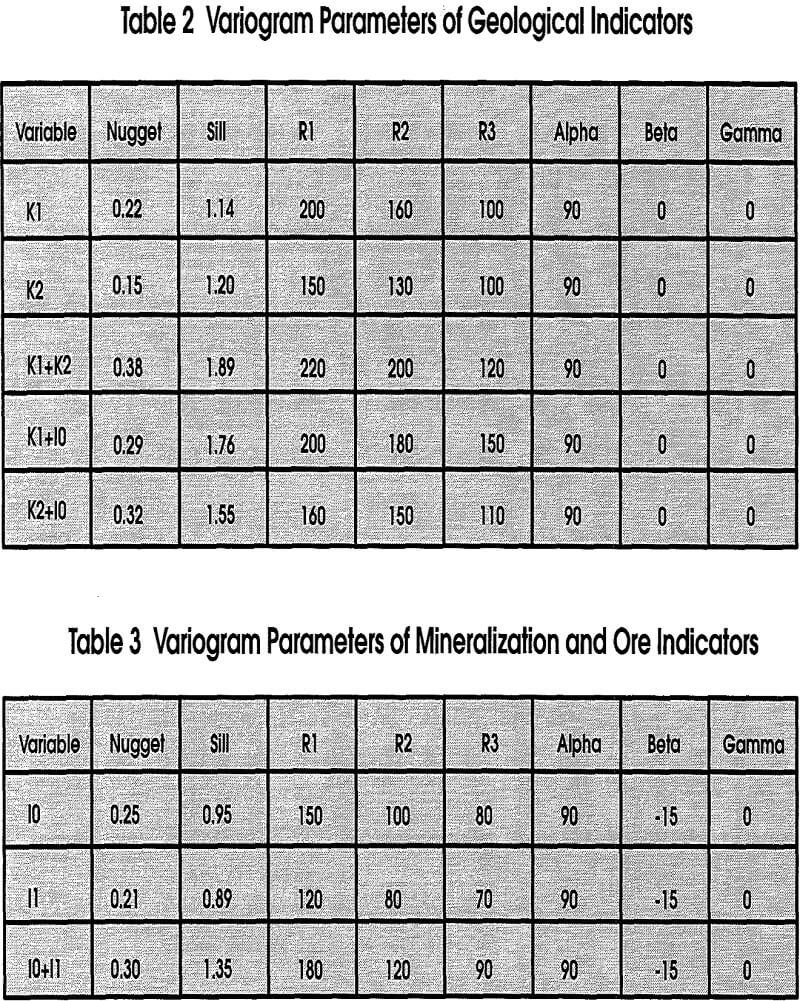

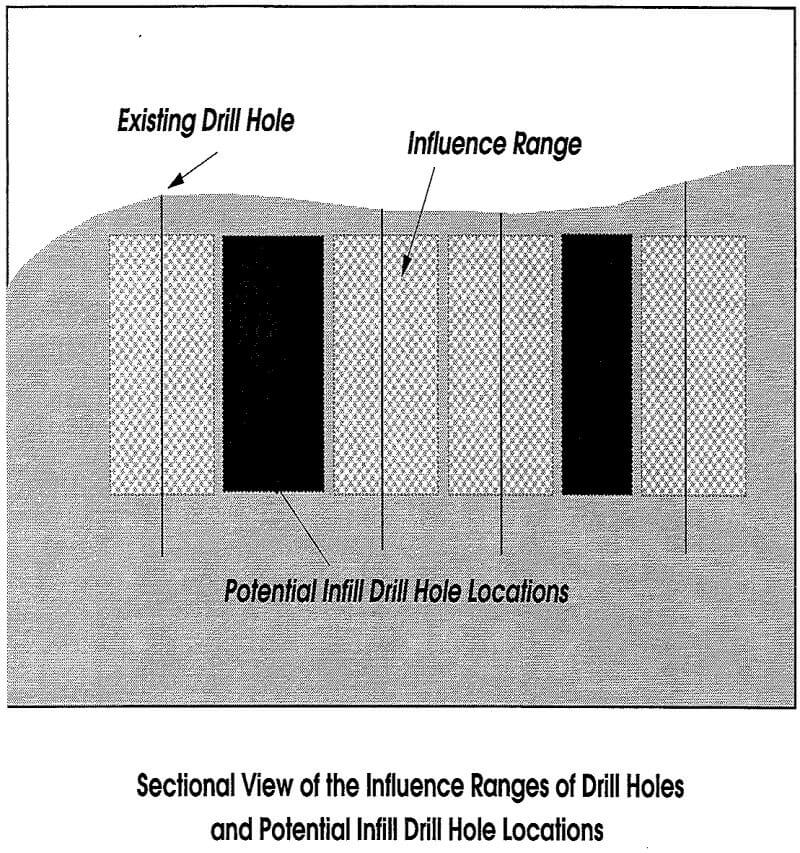

Continuity is an important concept in reserve calculations. Variogram modeling has been widely accepted as a means for quantifying spatial continuities of mineralization. Statistically, the continuity is understood as the extent of auto-correlations of mineralized grades in space. When a grade is correlated in a large spatial distance, it is said that the mineralization is highly continuous. The continuity is said low when the grade becomes uncorrelated at a short distance. Different spatial characteristics of ore bodies may require different drilling patterns (Figure 1).

Of course, the continuity may vary with directions, meaning that the variability is anisotropic. For infill drilling, our interest in the continuity is the ranges of influence within which a drill hole may impact on resource definition. Because of the complexity of grade distribution, the ranges of drill-hole influence determined by variograms represent only statistical averages. The range along the major mineralization trend is critical, since infill drilling is usually designed along this direction through either sectional or plan maps.

Another important factor that affects infill drilling plans is geological environments, which provide a precursor for the decision of exploration. Relevant geological attributes serve as clear-cut evidence for the existence of mineralization. The absence of favorable geological environments would surely preclude the occurrence of mineralization. Consequently, modeling geological environments establishes rules for the decision as to where should or should not be considered in infill drilling. Based on previous drilling and geological interpretation, geological environments can be classified as favorable or unfavorable to the occurrence of mineralization. Of course, unfavorable areas will be excluded from the plan of infill drilling. When an area is localized in a favorable geological environment, the decision as to whether it should be drilled out depends upon other parameters described in a later section.

Classification of reserves or resources has been a difficult and controversial issue. Different definitions have been motivated for different interests. For example, the definitions by governmental agencies serve for resource management and regulation. A common feature of most modern reserve classifications is the use of geostatistical concepts.

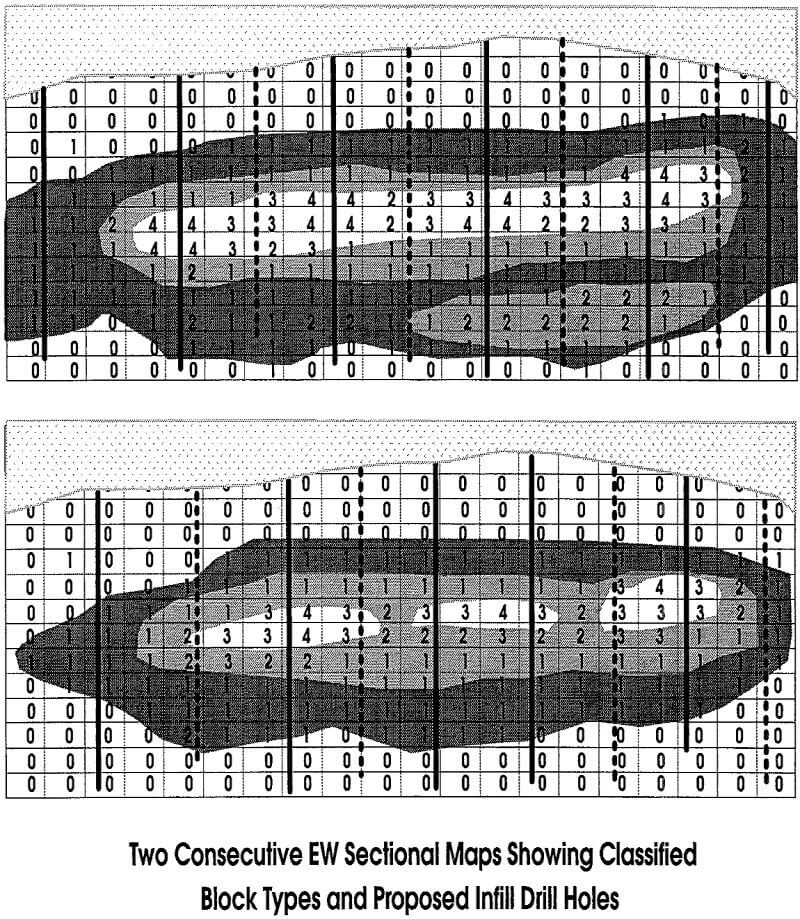

The definitions of reserves/resources described below are by no means to establish standards for mine development and resource management. Instead, they are introduced merely for convenience in the design of infill drilling programs. The following terms are used in this framework: probable reserves, indicated reserves, indicated resources, possible resources, and barren.

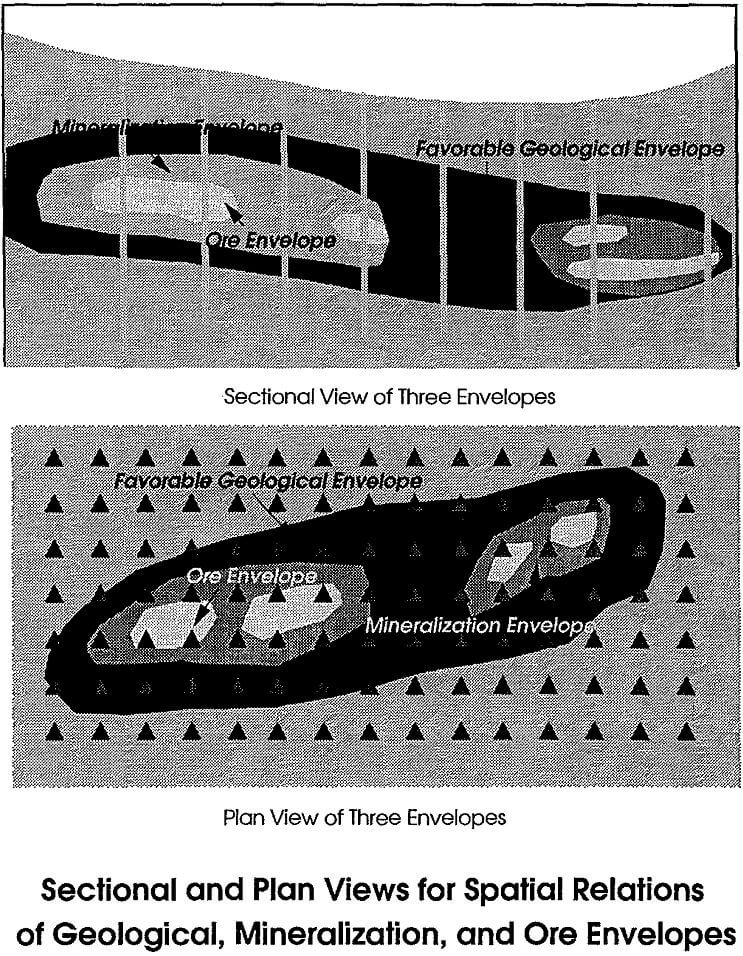

Probable Reserves. This category of reserves refers to those whose presence has been confirmed directly by previous drilling. The average grades are not less than the cutoff determined by economic and engineering parameters. The spatial extent are confined within the ranges of spatial influence. All blocks of this type must locate inside favorable geological environments.

Indicated Reserves. This category refers to those blocks which contain resources with grades potentially exceeding an economic cutoff. The grade values, however, are less certain for a required level of confidence. These blocks must be localized in favorable geological environments. The blocks should be outside the influence of existing drill holes.

Indicated Resources. This class includes those blocks whose grades would be below an economic cutoff but greater than or equal to a mineralization threshold, meaning that they are localized in the mineralization envelopes but outside the ore zones. These blocks must be localized in favorable geological zones.

Possible Resources. This includes those blocks outside mineralization envelopes but inside favorable geological zones. The grades of these blocks may exceed the mineralization threshold, but are uncertain.

Barren. This is self evident. It includes all blocks outside favorable geological envelopes.

Clearly, the blocks containing probable reserves should be excluded from the consideration of further verification, unless they are being developed into minable reserves for detailed mine designs. New drill holes should not be placed in blocks which contain only possible resources or barren. Infill drill holes should be designated to the blocks where the potentials of indicated reserves or resources are greatest. Consequently, the key to the optimal design is the development of a methodology to accurately classify the status of re¬source potentials for each block within the deposit.

Although geological environments are key for defining potential and non-potential blocks, separation between probable reserves and indicated reserves requires the information on the uncertainties of grade within mineralization envelopes. The blocks close to known drill holes should be more statistically certain than those that are far away from the holes. Quantifying uncertainty, in fact, is another key to the optimal design of infill drilling plans.