Table of Contents

In January of 1964, the Board commenced a vigorous program using appropriated funds and funds donated by the coal industry to finance a research program devoted to seeking solutions to the mine drainage problem. A review of published literature on the treatment of mine drainage indicated that much work done up to that point in time concerned only the mechanism of mine drainage formation and theoretical chemistry.

Mine Drainage Abatement Program

The basic approach of the Department of Mines and Mineral Industries is to divide its abatement efforts into two logical parts:

- Reduction of volume or complete prevention of acid mine drainage.

- Treatment of acid mine drainage.

The treatment approach is being aimed at each of 2 different objectives; i.e. treatment solely for the return of a legally acceptable discharge to streams of the Commonwealth, or more refined treatment to prepare a satisfactory water for potable use. The work supported by the Department along both of these major lines has borne fruit and is considered to be most encouraging. Moreover, it will continue to lead to significant action programs on the part of State government and private industry.

AMD Processing for Potable Use

The Department of Mines and Mineral Industries as one of its steps in seeking to find solutions to the mine drainage problem has tackled the combined problem of mine drainage abatement and drinking water supply. Several projects supported by the Coal Research Board of the Department have been aimed at the regeneration of mine drainage for reuse. The various techniques which may be applied to mine drainage demineralization include: evaporative or distillation processes; freezing; membrane and ion exchange processes.

Work has been sponsored by the Coal Research Board of the Department on the ion exchange beneficiation of mine drainage. Results indicate that waters containing less than 2000 ppm of total dissolved solids can be treated economically by ion exchange processes. The Department is now building a 500,000 gallon per day mine drainage treatment facility utilizing an ion exchange system in western Pennsylvania in order to provide water for a domestic water system.

AMD Treatment by Multi-Stage Flash Evaporation

Evaporation is a drastic treatment for purifying water. The mechanism for separating contaminants from pure water is a phase change from liquid to vapor by application of heat; subsequent condensation of this vapor provides the product stream. A decision to treat a given water by evaporation sets the inherent level of capital and operating costs; they then vary hardly at all for different levels of impurity to be removed. Costs for all the processes previously described (chemical or membrane) vary in some significant proportion with impurity level, or concentration of undesirable ions in the water requiring treatment.

It has long been known that CaSO4 can occur in numerous solid forms: the dihydrate (gypsum), the hemi-hydrate (plaster of Paris) and the anhydrite are the most commonly known, and some of these occur in more than one distinct crystal structure. These different forms have different solubility limits with temperature in any given aqueous solution. The entire solubility diagram as it relates to acid mine drainage water has not been established, but empirical tests are available to establish the operating conditions under which any candidate water may be processed to induce the CaSO4 to Precipitate as non-adhesive fine particles which will not scale heat exchanger tubes. Controlling factors in achieving precipitation of undesirable ions without scaling are: adding seed crystals to the evaporator charge at startup, and limiting the maximum temperature to which the water is heated during processing.

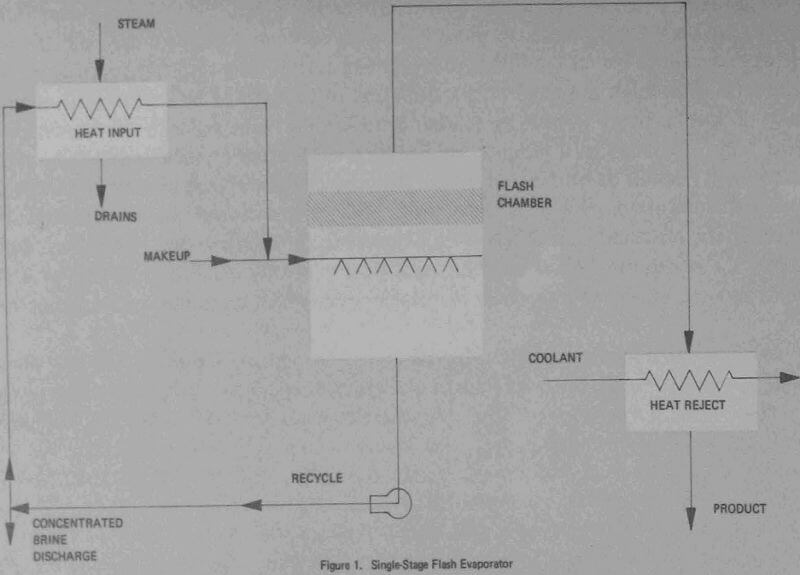

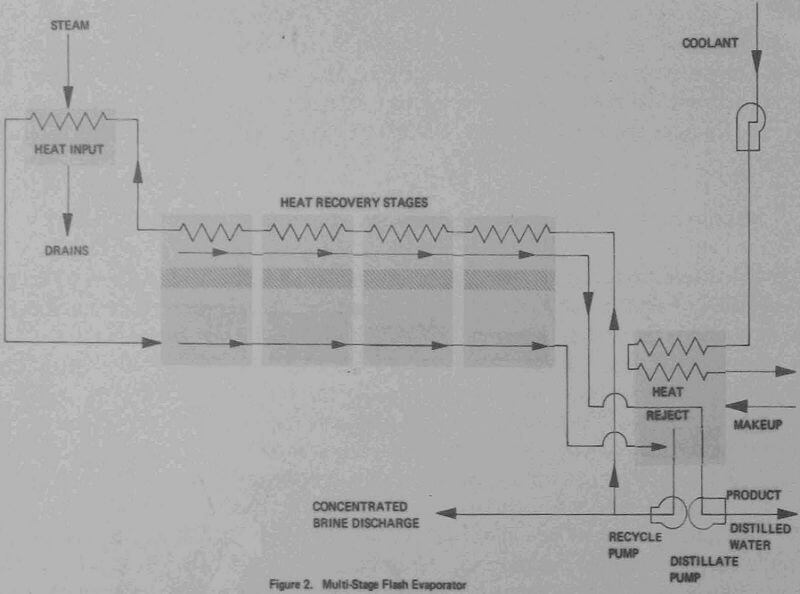

Essential features are: (1) heating water under pressure without boiling; (2) liberating vapor from the body of the heated liquid as it “flashes” when entering a chamber maintained at a pressure below saturation; and (3) recirculating the bulk of the unflashed liquid to act as a heat transport mechanism to pick up heat in the heat exchanger and liberate it in the flash chamber.

AMD Evaporator Demonstration Plant

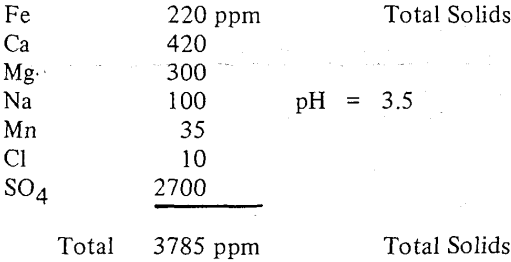

The Department of Mines and Mineral Industries of the Commonwealth of Pennsylvania has contracted with Westinghouse Electric Corporation to design, construct and initially operate a demonstration plant based on the recirculating multi-stage flash evaporator principle to process at least 5 million gallons per day of AMD water issuing from an outfall near Wilkes-Barre, Pennsylvania. Exact composition of the water to be processed varies with the seasons, but a typical analysis is as follows:

A decision to install the final crystallizer shown is still not made. With it, the plant produces an effluent of minimum volume which will set up hard upon being cooled to room temperature. Without it, the plant effluent will be of somewhat greater volume but will stay in fluid form indefinitely — even after cooling. Chemical analysis of several samples of the disposable “cake” made in the pilot plant crystallizer from AMD obtained at the Wilkes-Barre site showed them to be a mixture of the crystallized sulfates of iron, magnesium, calcium, and sodium, with some other salts present in trace amounts. Water of hydration bound in the crystals represented 36% of the weight of the “cake” samples.