Initial ore grade control was based on blast hole samples collected in two stages by an “automatic” sample collection device (sometimes called a rocket sampler). A sample was collected for the top 3 m (10 ft) in a holes and then the bag was changed so that a sample was collected for the lower 3 m (10 ft). Each of these samples was prepared and assayed by fire assay to determine the grade. Large discrepancies were sometimes noted in the assays of top and bottom samples. The samples were averaged together and a plot was made showing the blasthole locations and their associated grades.

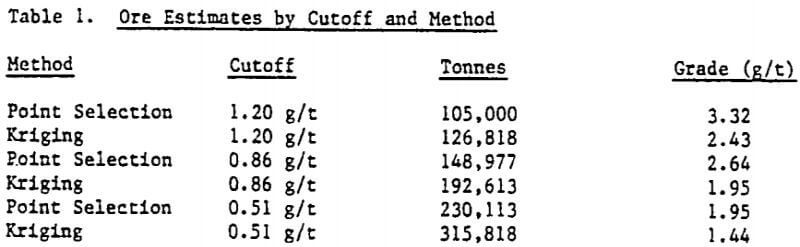

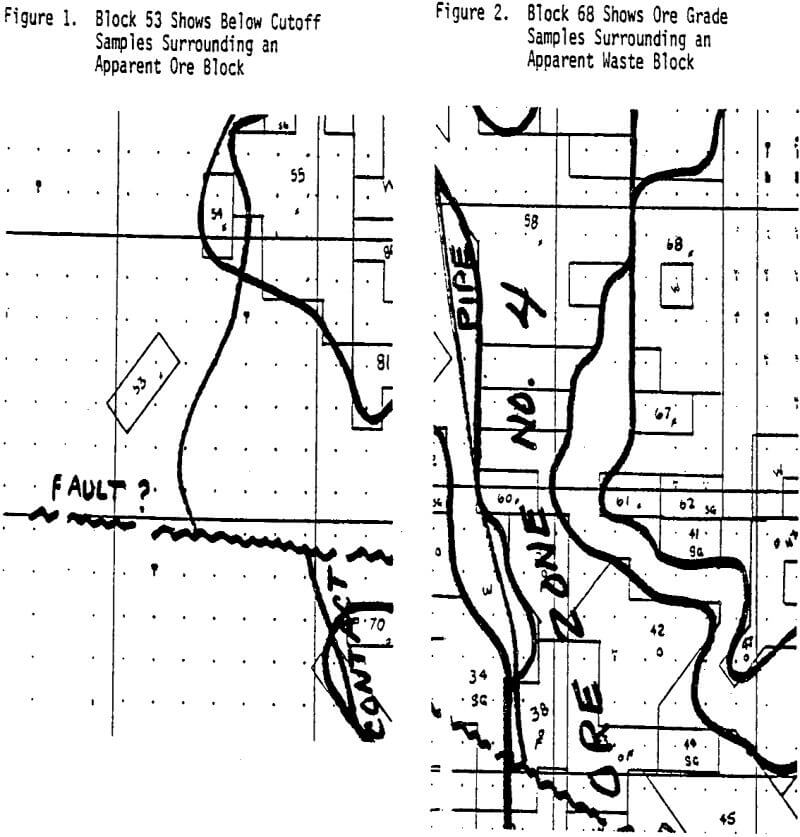

Discrimination between ore and waste was based on assigning the grade of the blasthole to the 4.6 m x 4.6m x 6.0 m (15 ft x 15 ft x 20 ft) volume surrounding the hole. (This process will be referred to as the “point selection” method.) The average grade of the selected ore was estimated by averaging the blasthole grades of the selected material. It should be noted that assignment to the ore or waste category was not solely a function of blasthole grade. Isolated blocks of above cutoff material as shown in Figure 1 were not included as ore. Conversely, below cutoff material surrounded by above cutoff holes (see Figure 2) was selected as ore.

Discrepancies between the average blasthole grades and mill head grades were quite large. In December, 1987 mill head grades averaged 39% lower than corresponding estimates from the blast holes. The correlation between average blasthole grade and mill head grade had an r-value of 0.015. The magnitude of the discrepancy and the lack of correspondence between estimated and actual grades lead to a series of investigations.

The blasthole assays from one of the first benches mined were analyzed to look for clues as to how to reduce the discrepancy. One thing that was noticed about the data was the high coefficient of variation (standard deviation divided by the mean) of 2.5. A coefficient of variation of this magnitude is not uncommon in gold deposits but given experience with exploration samples it seemed large.

Variograms were calculated in four horizontal directions on the bench. These variograms are shown in Figure 3. For the given bench there appeared to be no anisotropy, but the nugget effect represented slightly more than forty percent of the total variation.

Given these observations on the spatial variability of the assays, several further investigations were undertaken. These studies involved looking for the source of the short range spatial discontinutiy. To this end the particle size distribution of the gold was determined and the sampling and sample preparation methods were examined.

The lack of correlation between the estimated and mill head grades was accentuated when the cutoff grade was increased in mid December, 1987 with no corresponding increase in the mill head grades. The correlation remained at near zero. These events suggested that some sort of randomization process was influencing ore selection. While this was suspected to be a function of sampling and sample preparation, because of the continuity structure seen in the variograms, additional contributing factors were sought. Blast movement was also investigated as a contributor to randomization.

As subsequent benches were mined the practice of taking two samples from the blasthole was studied. For 2125 blastholes on one bench, the standard deviation of the samples from the bottom of the hole was 25% greater than the standard deviation of the samples from the upper part of the holes. The correlation coefficient between top and bottom samples was 0.41. When only those holes where the average of the two samples exceeded 0.86 g/t (0.025 oz/st) were considered the correlation coefficient dropped to 0.36. While this evidence could not establish the cause of the lack of a strong relationship between top and bottom samples or why the bottom samples were more variable, it was speculated that the second sample collection process was the cause. It was suspected that the collection process was generating random errors which were manifest in the lack of correlation and increased variation. Collecting two samples from the blasthole was eventually abandoned in favor of single sample collected from the cuttings. Because this change occurred simultaneously with other changes described below, the effect of this change is unknown.