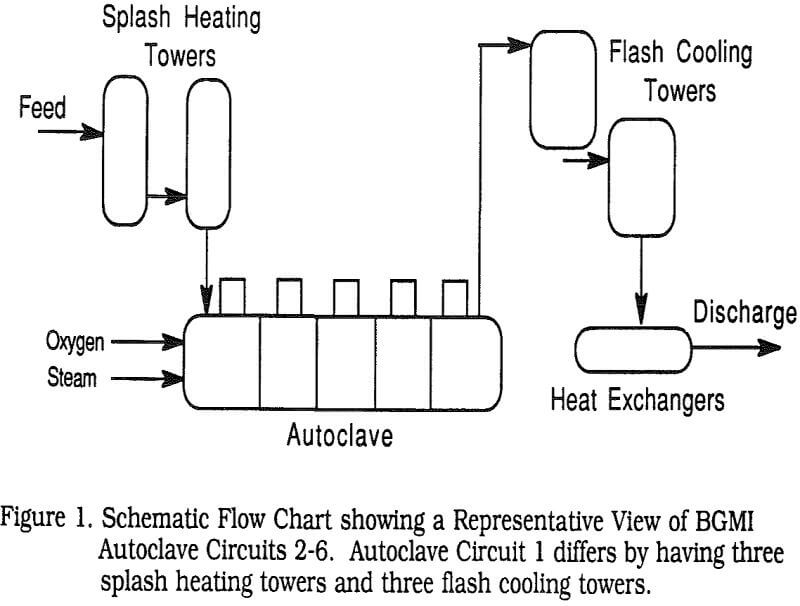

As shown in Figure 1, there are other accessory vessels (splash and flash towers) in the autoclave circuits, that are also brickwork lined. The linings used to date, other than small test sections, have all been acid-resistant fireclay bricks, bonded with alkali silicate mortar, PbO-based mortar, and/or vinyl ester mortar, but mainly alkali silicate mortar.

Several different zones exist within the autoclaves, including the vapor zone (above the liquid/slurry), the splash zone (interface between the vapor and liquid zones), which fluctuates up and down, and the liquid zone. In these different zones, the brickwork lining is exposed to continuous exposure and attack, and is progressively deteriorated. Although the conditions in the autoclaves and accessory vessels appear to be relatively mild, even high grade refractories like 90% and 99% alumina, have been observed to soften and fail within 6 months of vapor zone exposure.

The following different lining zones, in which most wear/deterioration occurs, have been identified:

- Vapor Zone

- Liquid Zone, under the Agitator

- Compartment Walls

- Anti-Swirl Sidewall Baffles

- Offtakes/Nozzles

- High Pressure Splash (heating) Dome

- High Pressure Flash (cooling) Dome

The refractories program has included:

- Monitoring of lining installation/repair and control of the installation conditions.

- Quality control of refractories including chemistry, physical properties, acid solubility, and non-destructive sonic testing.

- Inspection of used linings and analysis of deterioration.

- Exposure of samples of commercial and experimental bricks and mortars in test panels and vapor zone test cells.

Practical guidelines and specifications for increased lining life, are mentioned below:

- The ambient temperature for brickwork installation and repairs in the autoclave and towers, should be controlled in the range 70°F to 90°F.

- Mortar should be prepared using the optimum liquid addition and clean mixers and containers. Mortar contamination must be avoided. The mortar batch size should be adjusted according to the working time, to minimize the inclusion of dried or set chunks of mortar in the joints.

- Mortar joints should be less than 1/8″ thick.

- Wear of the brickwork under the agitators must be carefully monitored and properly maintained.

- Aggressive removal of gypsum buildup from the autoclave lining using a jack-hammer should be minimized or avoided.

- The spraying of cold water on the hot lining, to speed access to the autoclave for repair work should be avoided, because of the thermal shock damage that is caused.

- Brick products with high modulus of elasticity (> 6-7 x 10 6 psi) are susceptible to excessive cracking and catastrophic failure by spalling, and should not be used in applications where there are sudden/cyclic temperature and/or pressure changes.

- Quality control of the bricks is important for optimizing the lining life. Given the aggressive, dynamic conditions in the autoclave, and high pressure splash and flash towers, it is important that bricks with cracks or other internal defects, such as underfired, soft-centers, not be used, because they offer greater surface area for reaction, which can result in faster than normal wear, and possibly catastrophic failure. Non-destructive sonic testing is a quick and efficient way to monitor the brick quality.

- Larger brick shapes sometimes deteriorate faster than standard brick shapes, apparently because of differences in the firing efficiency during manufacture.