Table of Contents

Any critical evaluation of the potential for contamination of groundwater by leachates from mining wastes must include consideration of the waste quantities and locations, the physical and chemical characteristics of the waste, and the waste disposal practices. The primary types of solid wastes generated by mining activities include overburden and waste rock from surface mining, waste rock from underground mining, bulk tailings from the milling of metal ores and non-metal minerals, and refuse from coal preparation-plant processes.

In the United States, more than 65 commodities, including coal, metal ores, and non-metal minerals, are presently mined.

In the remainder of this section, the amounts of wastes generated during the past 20 years are quantified on a regional and mineralogical that is, commodity) basis. Then, the character of these wastes is presented to describe the amounts of acid-forming or toxic-product-forming components they contain, finally, the waste disposal practices commonly employed in the mining industry are reviewed, with emphasis on the extent to which these practices favor or inhibit the formation of an acid or toxic leachate.

Quantities of Wastes Generated

Bases for Estimates

Waste-quantity estimates presented in this report were either taken directly from or estimated on the basis of data and information published in the Bureau of Mines Minerals Yearbooks and the Department of Energy/Energy Information Administration’s Energy Data Reports. These are the most comprehensive sources of mining-waste quantity data available and are based on data reported annually by the industry itself. Nearly all other reports of waste quantities found in the literature during this study are also based on these sources. Those reports which are not based on these sources generally reflect estimates for single years based on independent surveys.

Wastes from Mining Coal

In this report, waste-quantity data for coal are divided according to wastes associated with the production of bituminous coal and lignite and wastes associated with the production of anthracite.

A chapter dealing with coal, entitled “Coal-Bituminous and Lignite,” was first published in the Bureau of Mines Minerals Yearbook in 1965. However, this chapter also contains waste-quantity data for the years 1960-1964.

The Bureau of Mines continued to publish the coal-data chapter until 1976, when the responsibility for this task was transferred to the U.S. Department of Energy (DOE,. The appropriate DOE publication is entitled “Bituminous Coal and Lignite Production and Mine Operations” and is published annually. The most recently available data are for the year 1977. Therefore, at the time of writing of this report, data for the quantity of overburden produced by surface mining of coal was available for the years 1960-1977 inclusively as was data for the quantity of preparation-plant refuse produced. Data for the quantities of waste rock produced at underground coal mines are not available.

During recent years, bituminous coal and lignite have been mined in 26 states, the bulk of the production coming from six states east of the Mississippi (that is, Kentucky, West Virginia, Pennsylvania, Illinois, Ohio, and Virginia) and one state west of the Mississippi (that is, Wyoming).

As tables 3-1 and 3-2 indicate, the greatest quantities of overburden and coal preparation-plant refuse have generally also been produced in these same states. For example, during the period 1960-19, 53,566 million cubic yards of overburden were generated by surface mining for coal, and 5 percent of this in just nine states-Kentucky, Pennsylvania, Illinois, Indiana, Alabama, West Virginia, Virginia, Tennessee, and Missouri. Likewise, during the period 1966-1977, 1215 million short tons of preparation-plant refuse were produced, and 97 percent of this in just eight states-West Virginia, Pennsylvania, Illinois, Kentucky, Alabama, Virginia, Ohio, and Indiana.

The geographic locations of bituminous coal and lignite deposits on a more regional basis are illustrated in figures 3-1 and 3-2.

The quantities of overburden and coal preparation-plant refuse produced on a yearly basis during the period 1960-197 are given in tables 3-3 and 3-4. Table 3-3 reflect that the quantity of overburden produced has been rapidly increasing during recent years. This observation is consistent both with the fact that coal production has been increasing and with the trend for increasing production by surface mining methods, as shown in figure 3-3. Table 3-4 reflects that, although the percentage of raw coal being cleaned is decreasing, the quantity of preparation-plant refuse being produced is increasing, due both to increasing coal production and to the trend for an increasing percentage of refuse production per unit of raw coal cleaned. This latter trend has been attributed to the increasing use of underground mining methods and machinery which remove more roof material above the coal seam (with subsequent rejection of this material at the preparation plant) and to increasingly stringent air emissions regulations placed on coal-burning electrical power generation stations which, consequently, require cleaner coal.

Data to quantify the amount of waste rock produced from underground coal mines are not available. However, it is notable that the majority of coal mined underground in recent years is subsequently cleaned. (For example, during 1977, 62 percent of the coal mined underground was cleaned.) In such cases, most of the material mined underground is sent to the preparation plant with only large boulders, timbers, and pieces of machinery being removed by coarse screening first. In many instances, when waste rock is separated from run-of-mine coal within the mine, it is deposited in mine voids rather than being brought to the surface. Therefore, at most underground mines, very little waste rock requiring separate disposal results subsequent to the initial mine-development activities.

Anthracite occurs in Arkansas, Colorado, Pennsylvania, Utah, and Washington. Reported production of anthracite, however, is entirely from northeastern Pennsylvania. The Pennsylvania anthracite region is divided geographically into four zones: the Northern, Eastern Middle, Western Middle and Southern Zones.

Detailed statistics on the quantities of wastes produced by anthracite mining operations have not been maintained by any agency. However, it has been reported that, since 1941, refuse that has accumulated from anthracite mining and preparation operations has represented nearly 5 percent of the total solid mineral waste produced in the nation. Furthermore, it has been estimated that, as a result of anthracite mining in Pennsylvania since 1869, over one billion tons of refuse remain above ground.

A survey conducted by the U. S. Bureau of Mines during 1966 indicates that anthracite mining and preparation wastes are deposited among 800 banks occupying 12,000 acres of surface and containing a total of over 900 million cubic yards of material. An additional 63 banks were also located during this survey, but since each of these contained less than 10,000 cubic yards, their volume was not included in the tabulations. In addition, spoil banks that resulted from strip mining were not considered in the survey. A description of the volume of each type of waste in these refuse banks is given in table 3-5.

Based on industry opinions and assumptions relative to the amount of refuse in run-of-mine anthracite, the Bureau of Mines has estimated the quantities of preparation-plant (that is, breaker) refuse produced in the anthracite mining region since 1958. These estimates, presented in table 3-6, indicate that the accumulated volume of anthracite breaker refuse has actually been decreasing during recent years. The reasons for this trend, as illustrated in figure 3-4, are rapidly decreasing production of anthracite by strip mining and underground methods and an increasing percentage of the production resulting from the recovery of coal from existing refuse piles (that is, culm banks). The coal currently being recovered from culm banks was previously discarded as a result of inefficient preparation technology and due to the lack of a market for the fine sizes of anthracite. Improved preparation technology and a market in the metallurgical and electrical power generation industries now make recovery of this coal economical.

Wastes from Mining Metal Ores and Non-metal Minerals

Detailed waste-quantity data for the metal-ore and non-metal mineral mining industries were first published in the Bureau of Mines Minerals Yearbook in 1959 in a chapter entitled “Technologic Trends in the Mineral Industries.”

The title of this chapter was changed in 1973 to “Mining and Quarrying Trends in the Metal and Non-metal Industries.” The waste-quantity data and information reported in these chapters is the most comprehensive data available and are based on data reports submitted by the individual members of the industry itself. For this reason, the waste-quantity data presented in this report were either taken directly from or estimated on the basis of the data and information published in the Bureau of Mines Minerals Yearbooks. As with coal, however, the most recently available data are for the year 1977. Therefore, waste-quantity data for the metal-ore and non-metal mineral industries is presented for the period 1960-1977.

During the period 1960-1977, metal-ore mining was conducted in 28 states- 10 east of the Mississippi River, 17 west of the Mississippi River, and Alaska Non-metal mineral mining is ubiquitous, occurring in all 50 states. Table 3-7 presents a summary of the quantities of metal-ore and non-metal mineral mining wastes produced in each state during the period 1960-1977. The regional distribution of waste generation during the same period is illustrated in figures 3-5, 3-6, and 3-7.

More than 62 different mineral commodities have been mined in the United States, including 21 metal ores and 41 non-metal minerals. The distribution of waste by commodity for the period 1960-1977 is shown in table 3-8 for the metal ores and in table 3-9 for the non-metal minerals. The quantities of metal-ore and non-metal mineral wastes produced on a yearly basis since 1960 are presented in tables 3-10 and 3-11, respectively.

Based on a review of the data presented in the foregoing tables and figures, some general observations can be made with respect to the types and quantities of mining wastes produced on regional and mineralogical bases. For example, tables 3-10 and 3-11 reflect that approximately 95 percent of all metal ores and non-metal minerals are mined by surface mining methods. This explains the fact that 67 percent of all the metal-ore and non-metal mineral mining wastes generated during the period 1960-1977 was overburden and waste rock from surface mining, while only 0.8 percent was waste rock from underground mining. The remaining 32.2 percent was tailings from ore processing operations.

Tables 3-10 and 3-11 also reveal that the number of metal-ore mines steadily declined until 1974, while the number of non-metal mineral mines has been increasing steadily since 1960. Furthermore, although non-metal mineral mines far outnumber metal-ore mines (by a factor of 22.3:1), more than 71 percent of the waste is produced by the metal-ore mines. This disparity is largely accounted for by the fact that approximately 60 percent of the non-metal mineral mines are sand, gravel and stone operations, which market nearly all of the material which they mine and handle. Conversely, in the metal-ore mining industry, it is necessary to move great quantities of overburden and waste rock to obtain ore which contains only 15 percent to less than 1 percent of the metal or metal mineral desired. Therefore, subsequent processing of this ore to upgrade and concentrate the desired metal mineral also produces a great quantity of waste. This is especially true of the copper, iron, and uranium industries.

A total of 31,191 million tons of overburden, waste rock, and tailings was generated by the metal-ore and non-metal mineral mining industries during the period 1960-1977. Of this total, approximately 40 percent was generated by the copper mining industry alone. Approximately 81 percent was generated by the copper, iron, uranium, and phosphate industries combined, including 84 percent of the overburden and waste rock from surface mining, 42 percent of the waste rock from underground mining, and 76 percent of the tailings.

The copper, iron, uranium, and phosphate industries not only account for the bulk of the metal and non-metal mineral wastes generated, they are also highly regionalized industries. For example, during the period 1960-1977, approximately 96 percent of all copper ore production was centered in just five states, four of which are located in the southwest-Arizona (54 percent), Utah (19 percent), Montana (10 percent), New Mexico (7 percent), and Nevada (6 percent). During the same period, approximately 82 percent of all iron ore was produced in just two states-Minnesota (69 percent) and Michigan (13 percent) Uranium production, like copper, has also been centered predominantly in the Southwest-New Mexico (47 percent), Wyoming (24 percent), Colorado (15 percent), and Utah (8 percent). Finally phosphate production has been centered primarily in Florida (73 percent) during this period, with three other states contributing-Idaho (11 percent), Tennessee (10 percent), and Montana (6 percent).

On the basis of the preceding discussion, it is apparent that the mining and ore processing activities in the cupper, iron, uranium, and phosphate mining industries dominate the regional and mineralogical distribution of wastes produced in the broader metal-ore and non-metal mineral mining industry. As described above, copper and uranium mining, iron mining, and phosphate mining occur predominantly in the Southwest, Minnesota, and Florida, respectively. Therefore, it is not surprising that approximately 75 percent of all mining wastes generated in the metal-ore and non-metal mineral mining industries is generated in these same locations, as evidenced in figures 3-5, 3-6 and 3-7.

Character of Mine Tailings Wastes

Purpose and Scope of Discussion

The chemical characteristics of the various types of mining wastes (that is, the levels of potentially toxic trace elements and acid-producing minerals they contain) determine their maximum potential for contamination of ground water. During this study, 32 samples of coal mining wastes, including overburden, waste rock, and preparation-plant refuse, were collected. In some instances, samples of stockpiled coal were also obtained. The results of analysis of these samples are presented here to provide a basis for evaluation of their relative environmental hazard. Data available from the literature to describe mining waste characteristics are also summarized. In this regard, it is notable that few previous studies have been conducted to characterize mining wastes, and chemical data on them are, therefore, extremely limited.

Wastes from Mining Coal

Data to characterize the chemical components of coal mining wastes are presented in tables 3-12, 3-13, and 3-14. Characteristics of stockpiled coal collected during this study are presented in table 3-15. Upon review of these data, it is evident that coal and coal mining wastes contain high levels of a number of trace elements which have been cited to be of primary environmental concern(11-12).

An important trend which is also evident is the generally higher content of pyritic sulfur in coal preparation-plant refuse than in coal mining overburdens and waste rock. As discussed later in this report (refer to Section 4, MODE OF FORMATION AND TRANSPORT OF ACID OR TOXIC LEACHATE), the oxidation of pyrite or similar minerals is the primary mechanism which leads to formation of an acid or toxic leachate. Therefore, the presence of pyritic material in a waste becomes a very important waste characteristic.

Although very little information exists describing the trace-element composition of coal mining wastes, a great number of studies have been conducted to investigate the presence of these elements in coal. It has been concluded that the trace elements found in coal probably were derived from the original coal-forming plant material, and three main stages of the enrichment of these elements in coal have been suggested: (1) concentration during the life of the plants; (2) concentration during the decay of the plants; and (3) concentration during the mineralization of the coal. Since coal preparation-plant refuse contains coal in the form of coaly shale, bony (that is, coal bound in a rock matrix), and fine coal, this waste might be expected to contain higher levels of trace elements than overburdens. Surprisingly, however, tables 3-12 and 3-13 reflect that the trace-element compositions of refuse and overburdens are very similar.

The coal refuse data presented in tables 3-13 and 3-14 are given for fresh coarse or fine refuse and aged or weathered refuse. Inspection of these data shows a general trend of trace-element depletion in the aged refuse, especially for cobalt, copper, iron, and nickel. A trend is not apparent, however, for the relative trace-element compositions of coarse and fine fresh refuse. In some instances, the coarse refuse contained higher elemental levels in others, the fine refuse contained the highest levels; while in still others, there was no distinguishable difference in the relative trace-element composition. The relative distribution of trace elements among clean coal and the various size fractions of refuse is thought to be a function of the mineralogical association of the trace elements and the type of coal cleaning process employed. Some evidence exists to indicate that the trace-element concentration in the fine refuse (that is, slurry-sized refuse is greatest when a flotation process is used to clean the fine-sized coal. Therefore, the variability observed between the relative composition of coarse and fine refuse is probably explained, in part, by the differences in coal cleaning processes employed.

To further evaluate the trace-element composition of coal mining wastes, a comparison has been made between the elemental levels contained in the waste material and the average elemental abundance of some sedimentary rocks. Most notably, these comparisons, presented in tables 3-16 and 3-17, reflect that some of the mining wastes were enriched by a factor of 10 or more in the following elements: arsenic, cadmium, cobalt, mercury, selenium, and thallium. In addition, all of the wastes were found to be impoverished by a factor of 10 or more in chromium. In most instances, however, the waste compositions were very similar to the average crustal-elemental abundance in sedimentary rocks.

A notable geographic difference that is apparent from tables 3-16 and 3-17 is the generally lower levels of trace elements in Western region coal mining wastes than in wastes from the Appalachian and Eastern Interior regions. This is especially true for aluminum and iron.

The chemical character of mining waste is important, since it determines to a great extent the presence or absence and magnitude of a potentially toxic component in leachate which emanates from these wastes. Of equal importance, however, are the physical properties of the wastes, since these properties also greatly influence the quantity and quality of leachate.

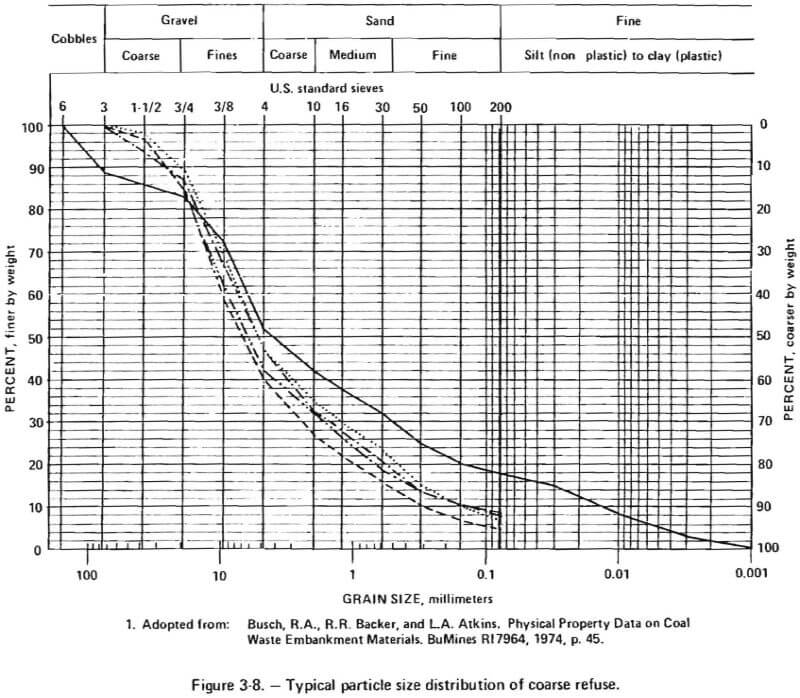

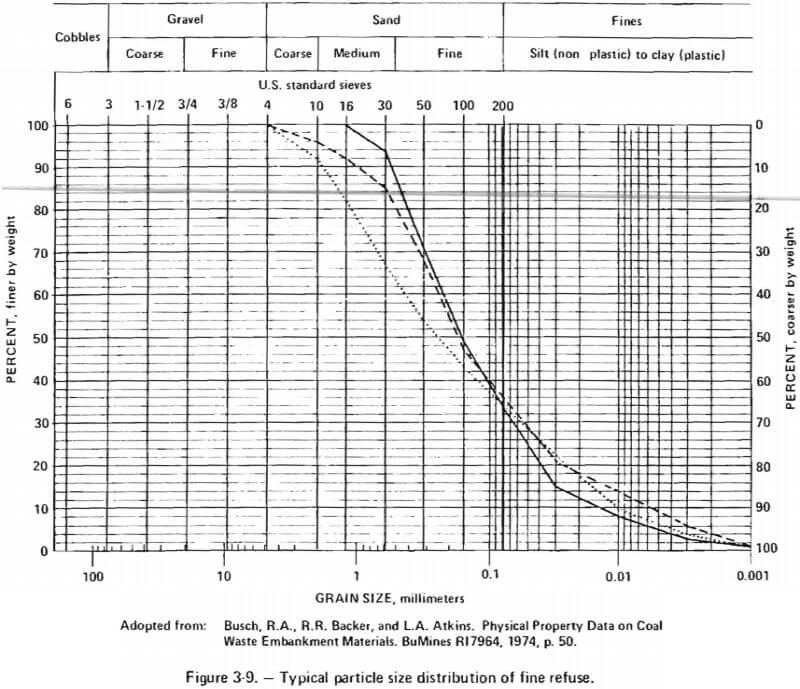

One of the most notable physical properties of mining waste is particle-size distribution. During the mining and processing of coal, mined material is inadvertently broken or deliberately crushed. Subsequently, upon disposal of the waste, this results in a condition more favorable to weathering (that is, leaching) of the waste due to the greater surface-area-to-volume ratio of the smaller particles. Coal refuse has generally been found to be well graded, although particle sizes vary over a broad range. For illustrative purposes, the particle-size distributions of “typical” coarse and fine coal refuse are presented in figures 3-8 and 3-9, respectively.

Wastes from Mining Metal Ores and Non-metal Minerals

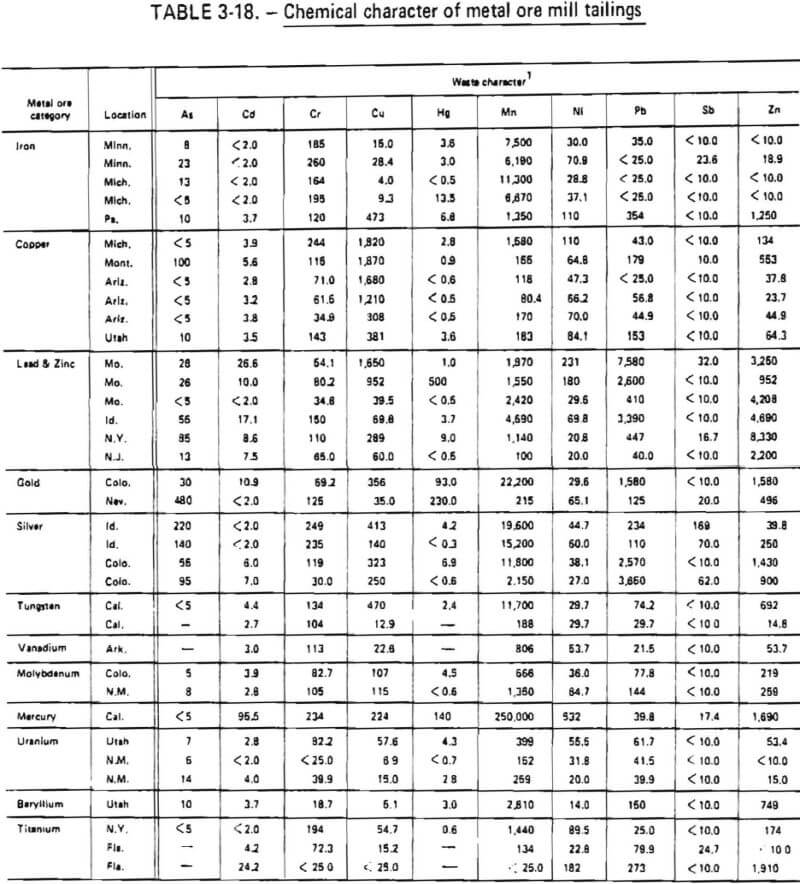

Data available from the literature describing the chemical character of metal-ore mill tailings are presented in table 3-18. It becomes clear upon review of these data that metal-ore tailings are highly enriched in their metal content. Therefore, these wastes potentially represent a very significant source of ground water contamination.

Although detailed data describing the pyritic mineral content of metal-ore tailings are not available from the open literature, it has been reported that, in the Province of Ontario, Canada, tailings that are well known as acid producers have iron sulfide contents ranging from 2.5 percent to 72 percent.

An additional feature of metal-ore tailings which greatly enhances their potential for leaching is their small particle size. At present in the United States, base-metal, precious metal, and ferro-alloy mining operations which employ the flotation process grind ore to approximately 75 percent minus 100 mesh, on an average. It is evident, therefore, that metal-ore tailings have a very high surface-area-to-volume ratio.

Detailed data describing the chemical composition of overburden and waste rock from metal-ore and non-metal mineral mining are not available from the open literature. Non-metal mineral tailings have, likewise, not been described, with the exception of phosphate slimes.

Nearly one-half of all the non-metal mineral mining wastes generated during the period 1960-1977 resulted from phosphate mining in two mining districts in North and Central Florida. Because of both the quantity of these wastes and concern for the environmental hazards presented by their radiological content, they have been extensively studied.

Phosphate is mined in Florida by surface methods, which requires the removal of a large quantity of overburden. Beneficiation of the matrix (that is, phosphate-containing material) results in two additional solid waste products: sands and a non-recoverable fine (-0.1 mm) material referred to as “clays.” The radium contents of the overburden and processing wastes are given in table 3-19. Other known constituents of phosphate wastes include aluminum, iron, manganese, chromium, vanadium, barium and fluorine.

Although quantitative data are not available describing the chemical character of other non-metal mineral wastes, it is possible to qualitatively describe waste components potentially present on the basis of known mineralogical associations. This information is presented in table 3-20.