The Paques technology for the biological treatment of sulfate and metal containing waste waters or process waters, marketed under the name THIOPAQ, consists of different biological processes complemented with liquid/solid and gas separation steps. The produced hydrogen sulfide can be used in various metallurgical processes.

The most important biological reaction is the reduction of sulfuric acid to produce hydrogen sulfide. In order to make the reduction possible, another compound has to be oxidized by the bacteria. For large scale applications, e.g. more than 2 tons of hydrogen sulfide produced per day, hydrogen gas is used as reductant. Hydrogen gas can be produced on-site (if not already available on-site) by cracking methanol or by steam reforming natural gas or LPG. For small scale applications, ethanol or an organic waste stream can be used as electron donor. If ethanol is used, the chemical costs are somewhat higher than in the case of hydrogen gas but the investment is lower since no reformer is needed. The main reaction that occurs in the anaerobic sulfate reducing reactor is:

H2SO4 + 4H2 → H2S + 4 H2O………………………………………….(1)

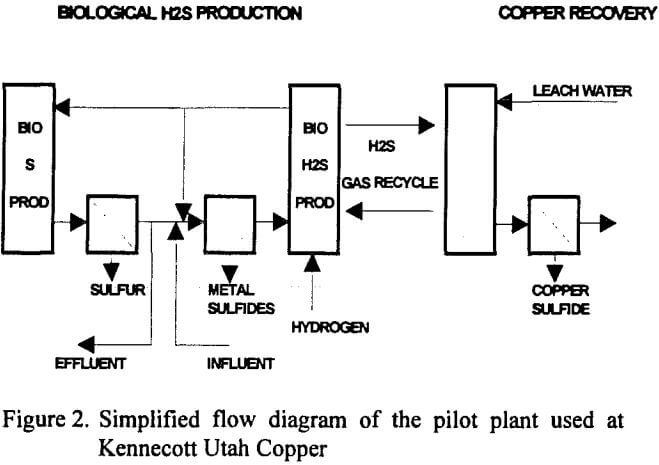

A CIRCOX type gaslift loop reactor is used to ensure optimal mixing and mass transfer of hydrogen from the gas to the liquid. In addition to the hydrogen feed, gas recycled from the top of the reactor is injected at the bottom of the reactor to ensure a high efficiency of the hydrogen transfer. A specially designed gas/liquid/solid separator at the top of the reactor ensures optimal gas/liquid separation and biomass retention.

The hydrogen sulfide present in the recycle gas (3-15 %) can be used for precipitation of metals by contacting the recycle gas with the process stream to be treated. Compared to the addition of a chemically produced sodium sulfide solution (NaSH) the advantage is that in the biological system no sodium is introduced to the process stream. For some applications the biologically produced hydrogen sulfide has to be more concentrated before is it can be used. This can be accomplished by membrane separation or by using (selective) absorption and stripping techniques.

Controlling the pH and oxidation/reduction potential (O.R.P.) of the process liquid contacted with the hydrogen sulfide results in selective recovery of the metals. Multiple contacting stages at different pH’s can used if more than one metal has to be selectively recovered. For example copper already precipitates as copper sulfide at pH below 2 where as zinc starts precipitating at pH 3 at atmospheric pressure and 1 to 5 % hydrogen sulfide.

If only part of the biologically produced hydrogen sulfide is used in the production process, the remaining part of the hydrogen sulfide can be biologically converted into elemental sulfur:

H2S + ½O2 → S°↓ + H2O……………………………………………………..(2)

The overall equation for the conversion of sulfuric acid to elemental sulfur is:

H2SO4 + 4H2 + ½O2 → S°↓ + 5H2O…………………………………………..(3)

Equations 1 and 3 show that acid is neutralized without adding large amounts of alkaline chemicals as is the case in lime treatment. Using the sulfate from waste acid bleeds for production of hydrogen sulfide will lower the operational costs of the existing neutralization system significantly. Less chemicals have to be added and less sludge has to be disposed off. Excess hydrogen sulfide is converted to elemental sulfur and can be used in a sulfuric acid plant for sulfuric acid production.

Metals present in the waste acid bleed used as a source for hydrogen sulfide production will precipitate as metal sulfides according to:

Metal + sulfide → metal-sulfide↓……………………………………………..(4)

The metals can be precipitated before entering the anaerobic reactor by recycling part of the hydrogen sulfide to the untreated water. Selective recovery of the metals (in multiple stages) is possible. As the solubility of metal sulfides is lower than the solubility of the respective metal hydroxides (Peters and Ku, 1985) much lower discharge standards can be met compared to lime treatment. In addition the metal sulfide sludge is less voluminous resulting in lower disposal costs.

Biological production of hydrogen sulfide from bleed streams for use in nickel, zinc and copper mining and metallurgical processes has significant economical and environmental benefits compared to use of chemically produced hydrogen sulfide. Sulfates in solution from metal roasters and refineries are generally precipitated as produced. Up to now, there has been no economic option for removing sulfates other than precipitation with lime to produce some form of calcium sulfate that has to be disposed off. The Paques technology of converting sulfates to hydrogen sulfide and/or elemental sulfur offers a new degree of metallurgical freedom.