Table of Contents

The Bureau of Mines has investigated an electrolytic recycling process to recover lead from scrap batteries as part of the effort to improve secondary recovery of metals, minerals, and other values from waste products. This process eliminating sulfur dioxide (SO2) generation and minimizing particulate lead emissions, is an acceptable alternative to the pyrometallurgical processes currently used by the secondary lead industry. The lead recovered by electrolysis is free of antimony and suitable for producing maintenance-free batteries.

In previous bench-scale studies lead was recovered from grids and lugs by electrorefining and from battery sludge by leaching-electrowinning. The process, based on the bench-scale data, has been considered to have economic potential.

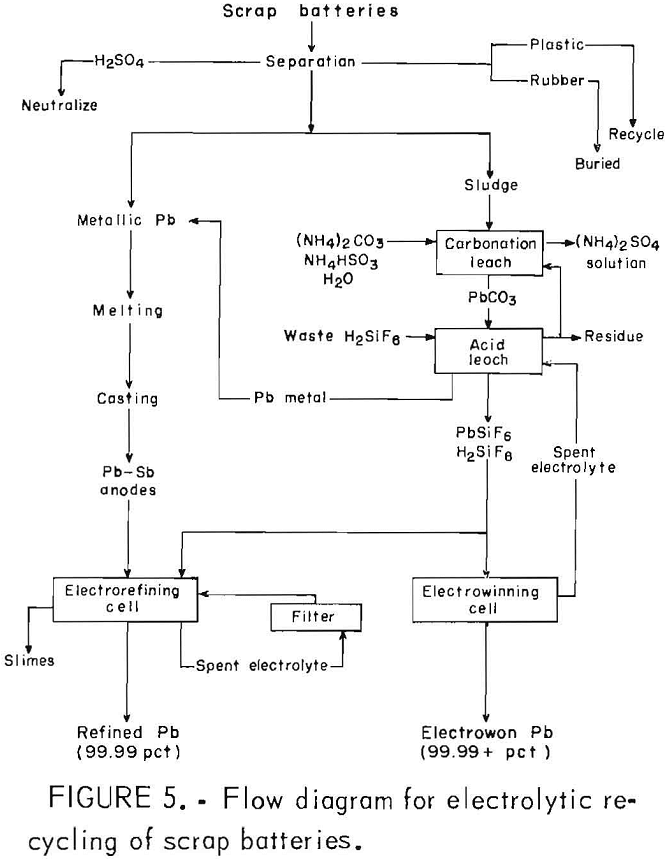

In commercial practice, scrap batteries are first drained, then crushed in a hammer mill and separated into four fractions: plastic, rubber, large pieces of metallic lead, and a fine sludge. Plastics are recycled, and rubber is buried. In this work the large metallic fraction of the crushed batteries is melted and cast as anodes for electrorefining in lead fluosilicate electrolyte. The sludge is leached with ammonium carbonate [(NH4)2CO3] and ammonium bisulfite (NH4HSO3) to convert the lead sulfate (PbSO4) and lead dioxide (PbO2) into lead carbonate (PbCO3), which is acid soluble. Leaching the carbonate sludge with fluosilicic acid or spent electrolyte produces an electrolyte from which lead is electrowon.

The objective of this investigation was to identify possible problems in the scale-up. Specific areas of concern were impurity buildup in the electrolyte, generation of wastes, lead levels in the workplace, and worker health hazards.

Acknowledgments

Thanks for furnishing materials used in this investigation are due to RSR Corp., Dallas TX; AGRICO, Donaldsonville, LA; Georgia-Pacific Co., Bellingham, WA; Peter Cooper Corp., Oak Creek, WI; and Eagle Picher Industries, Inc., Cincinnati, OH.

The helpful suggestions by Dr. R. C. Kerby, senior development metallurgist with Cominco, Ltd., Trail, British Columbia, Canada, and Dr. R. D. Prengaman, Vice President—R&D, with RSR Corp., Dallas, TX, are sincerely appreciated.

Materials Equipment and Procedures

Battery Scrap

All of the lead metal and battery sludge used in this investigation was obtained from a large domestic secondary smelter in three different lots. Lot 1 contained shredded battery grids, terminals, and plastic-rubber materials. Lot 2 contained mostly finer shredded battery grids, mixed with some sludge and plastic-rubber materials. The lead grid samples were cleaned and sorted to remove the nonmetallic waste and melted to pour into lead pigs for later use in making anodes for electrorefining. About 90 kg of lead-antimony metal was recovered from lot 1 and 180 kg from lot 2.

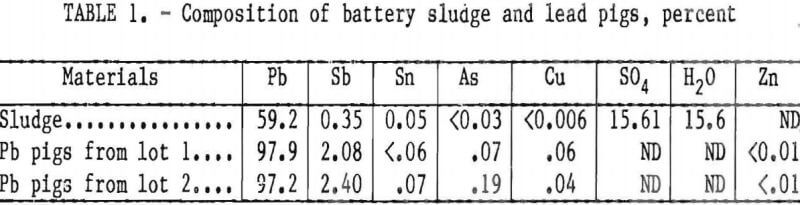

Lot 3, a sludge sample, weighed about 520 kg and contained 84.4 pct sludge powder and 15.6 pct H2O. Partial analyses of the battery sludge and lead pigs are given in table 1. The sludge contained mainly PbSO4, PbO2, and fine lead metal.

Electrodes

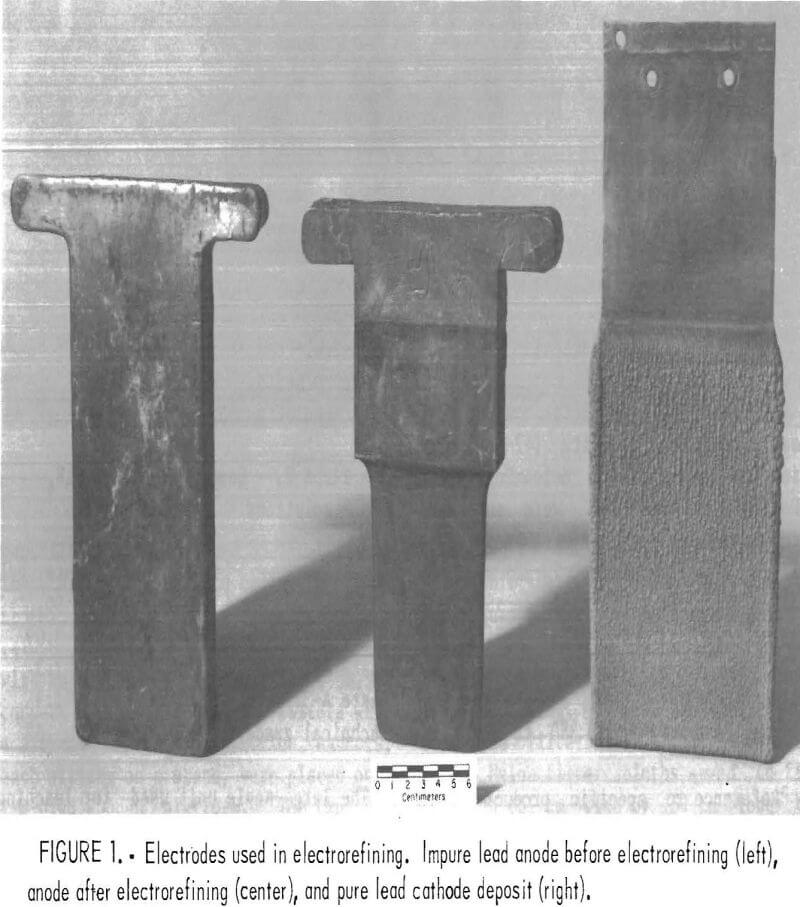

For electrorefining, impure anodes were prepared by melting the lead pigs at 425° to 450° C and pouring into a carbon or steel mold. A ZnCl2-NaCl flux was used as a cover on the molten bath to prevent oxidation and loss of antimony to the dross. Each anode weighed about 7 kg, was 2.3 cm thick by 10 cm wide by 24 cm high, and had a 2- by 18-cm integrally cast bus bar, making a T-shape (fig. 1).

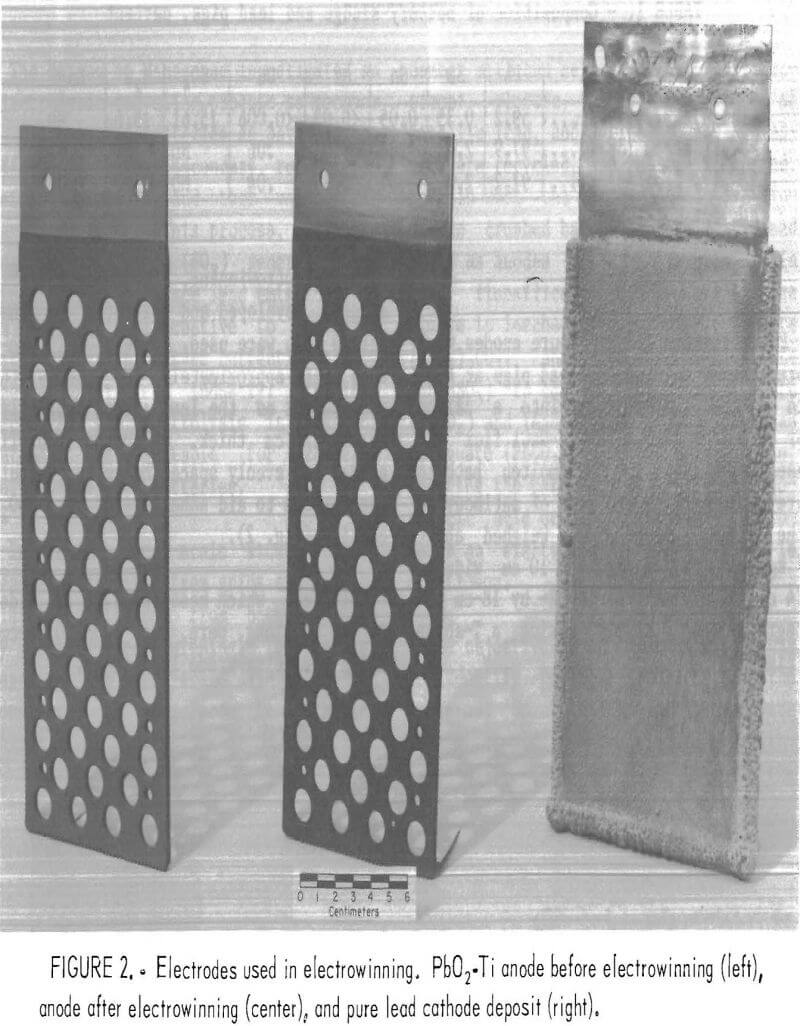

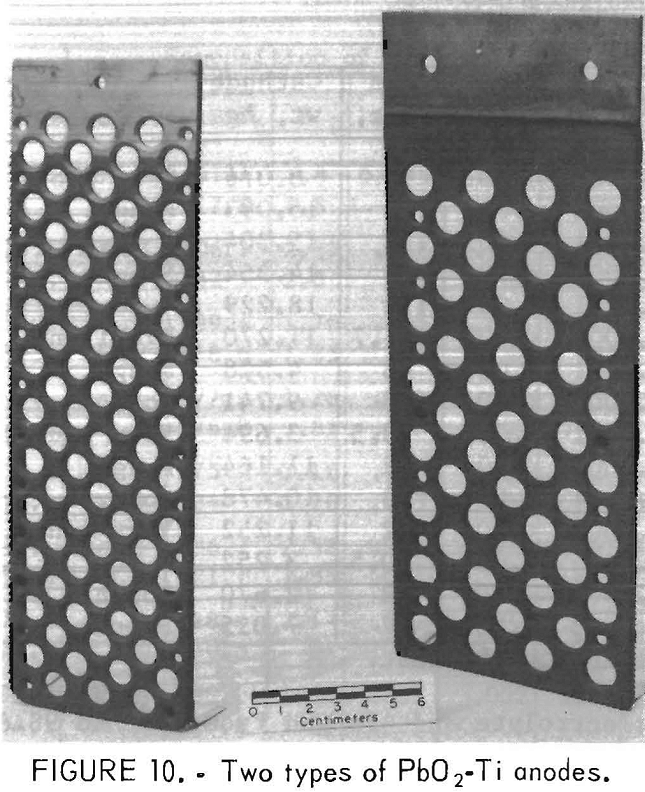

For electrowinning, insoluble PbO2-Ti anodes, developed and patented by the Bureau, were used. The PbO2-Ti anodes were approximately the same width and height as the lead anodes but only about ½ cm thick. Also the PbO2-Ti anodes had evenly spaced holes throughout the surface to aid adherence of the PbO2 coating (fig- 2).

Cathodes, which measured 12.5 cm wide by 28 cm long, were cut from 0.16-cm thick corroding-grade lead sheet.

Sludge Leaching Unit

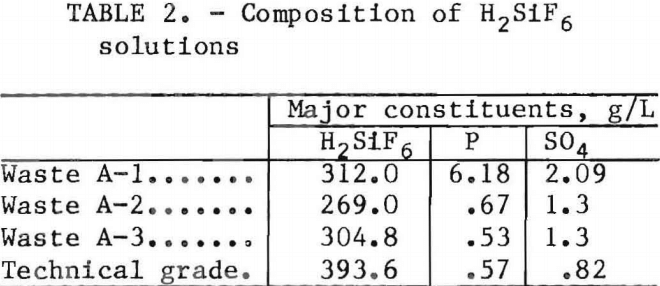

Ammonium carbonate, lead powder (200 mesh), ammonium bisulfite (47-pct solution by weight), and defoaming agent (Dow-Corning DB-110A) were purchased from commercial sources. A sample of filter aids (Diatomite, FW-20) was obtained from an industrial company. A large quantity of waste H2SiF6 was supplied by a fertilizer company in three batches (A-1, A-2, and A-3); batch volumes ranged from 380 to 570 L.

Technical-grade H2SiF6 was also purchased for some tests. Partial analyses of the H2SiF6 solutions are given in table 2.

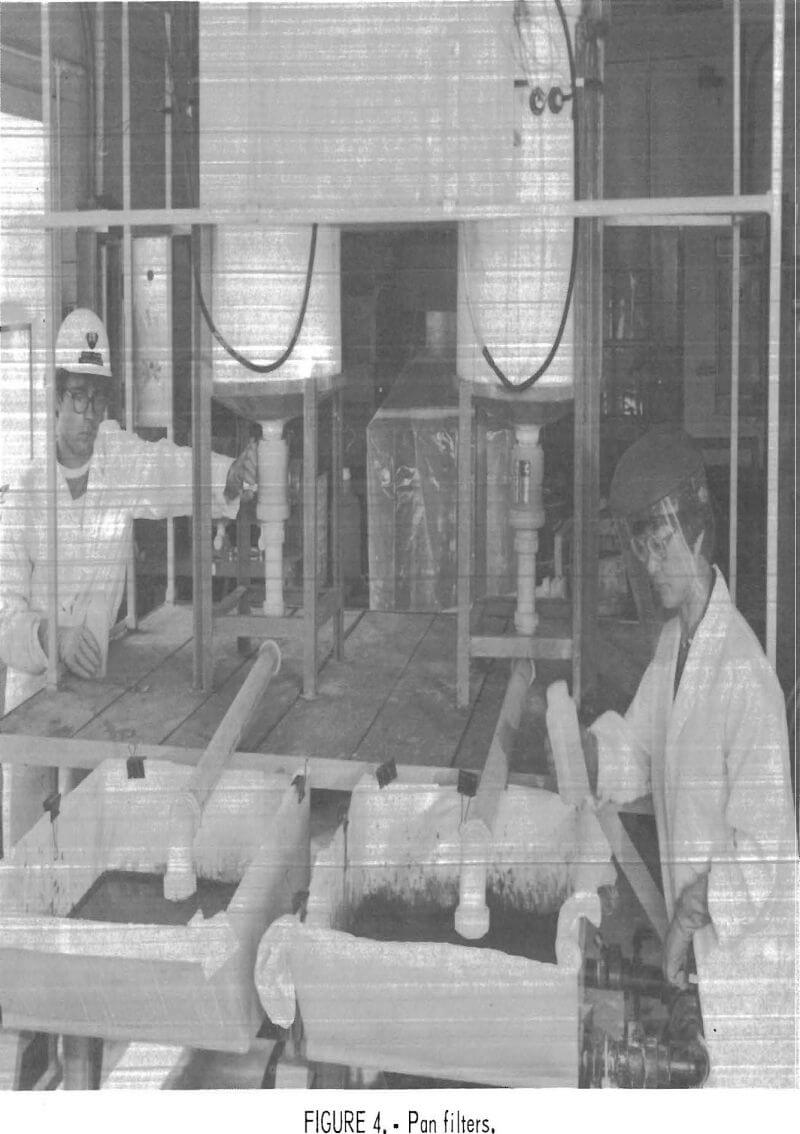

The large-scale unit used for leaching consisted of two 100-L cylindrical reactors (fig. 3), two polypropylene vacuum

pan filters (fig. 4), and a 160-L glass-lined steel tank used to collect the filtrate. The reactors were polypropylene reinforced with a fiberglass casing and with an opening at the conical bottom, to connect the reactors and pan filters with a 7.6-cm valve and pipe. The reactors, each sitting on a stand, were placed on a 1-m-high wooden platform. The two pan filters were arranged side by side next to the platform so that the discharge from the reactor could feed the pan filters by gravitation.

Both the steel tank and vacuum pump were installed under the platform and connected to the pan filters with polyvinyl chloride (PVC) pipes. Each reactor was equipped with a mechanical stirrer and a thermostatically controlled immersion heater (2-kW) in a -56-cm-long alumina casing. The steel tank, reactors, and filters were all acid resistant. Nylon filter cloths sewed to fit the pan (61 cm wide by 61 cm long by 20 cm deep) and filter papers (S&S No. 595) of size -1 m² were used to line the filter pans. A heavy-duty drum pump, also acid resistant, was employed to transfer liquid to the reactors.

Sludge Leaching

Sludge was leached in a two-step batch process, as outlined in figure 5. In a typical leach, in the first step, one reactor was filled with distilled water, 10 kg (NH4)2CO3 was added, the stirrer was turned on, and then 25 kg wet sludge, shredded to ½-in lumps, was added. Finally, 3.75 L NH4HSO3 solution and an additional 30 L H2O were added to increase the volume of the mixture to about 85 L to cover the Immersion heater to a safe level. The thermostatic controller was set at 55° C: and the mixture was allowed to digest for 1 h at temperature prior to filtering; 0.4 kg (0.5 pct of bulk) filter aids was added to the mixture and coated the filter paper with a thin layer, which ensured rapid filtering. The cake was thoroughly washed with distilled H2O to remove any (NH4)2SO4. The filtering process usually lasted about 1 h, including washing.

The filtrate, about 90 L in volume, containing (NH4)2SO4 and excess (NH4)2CO3, was recycled until the concentration of SO4- was too high to be effective.

The filter cake, containing mainly PbCO3, was divided into two equal parts, and each was placed in a reactor and blended with 10 L H2O to make a uniform slurry. The necessary amount of waste

H2SiF6 and/or spent electrolyte was added to each reactor to convert the PbCO3 into PbSiF6. Carbon dioxide foam formed immediately as the waste acid was added and was controlled by sprinkling 1 L defoaming agent into each reactor. The slurry was allowed to react with H2SiF6 at 45° C for 15 to 30 min before filtering. Again, 0.4 kg filter aids were used to coat the filter paper prior to filtering. The resulting leachates, normally containing 100 g/L lead as PbSiF6 and 90 g/L free H2SiF6, with minor amounts of P, Sb, As, Sn and Cu, were suitable for use as electrolyte for electrowinning.

The first 10 leaching experiments were made using lead powder (200 mesh) to reduce PbO2 during the second-stage acid leach. Later, it was found that NH4HSO3, when added to the first-stage carbonation leach, would successfully reduce PbO2. Because of this change in procedure, a series of bench-scale tests was made to optimize parameters.

Electrolyte

Electrolyte for electrorefining, in volumes of 25 L, was prepared initially from industrial-grade PbO (litharge) powder, technical-grade H2SiF6, and additives. Later, waste H2SiF6 and PbO were used for most of the electrorefining runs.

Animal glue and calcium lignin sulfonate were the additives used as leveling agents and grain refiners for both electrorefining and electrowinning experiments. Aloes extract (0.5 g/L) was also used in several experiments to compare its performance to that of glue. The starting electrolyte contained 50 to 70 g/L Pb, 90 to 110 g/L free H2SiF6, 4.0 g/L calcium lignin sulfonate, and 0.05 g/L glue.

Electrorefining in the 20-L cell was conducted prior to sludge leaching; thus the sludge leachate was not available for electrorefining.

Electrolytes for electrowinning were obtained from leaching sludge. Spent electrolyte, usually low in lead and high in H2SiF6, was recycled repeatedly. Phosphorus levels in the electrowinning electrolyte were maintained at 1 to 2 g/L using 85 pct H3PO4.

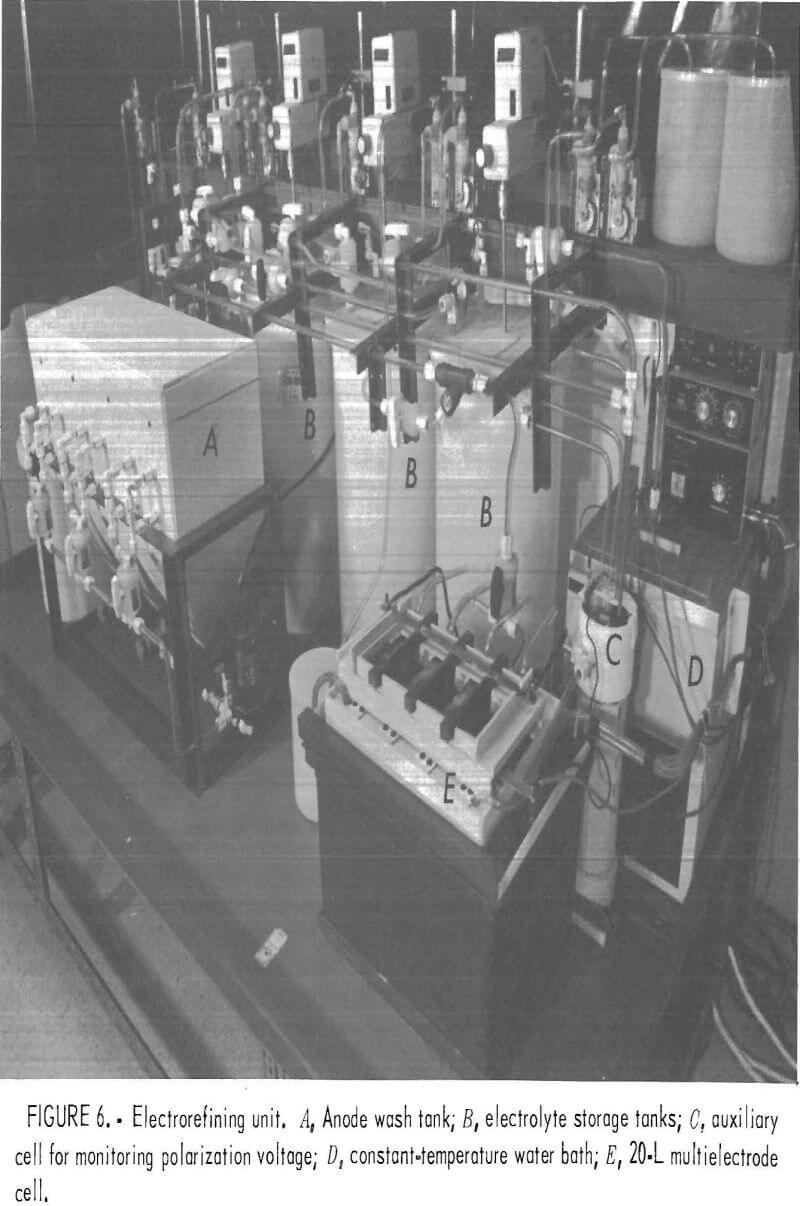

Electrorefining Unit

The unit used for electrorefining is shown in figure The molded polyethylene cell, 36 cm long by 25 cm wide by 25 cm deep, was used to electrorefine four 2.5-cm-thick impure anodes with three cathodes. The electrodes rested on two copper bus bars and were spaced with 3 cm between the surface of each anode and cathode. The cell was heated by a thermostatically controlled circulating water bath to maintain the electrolyte temperature between 30° and 40° C.

A constant current of about 20 A kept, the current density at 170 to 180 A/m². The voltage varied from 0.3 to 1.0 V with

variations in electrolyte temperature and as the slime blanket increased in thickness.

Electrolyte was circulated between electrodes by adding it to a trough along one side of the cell and drawing it out from the bottom of the cell at the other side. Electrolyte flowed into the cell through the evenly cut notches made on the trough wall to ensure equal distribution in the cell.

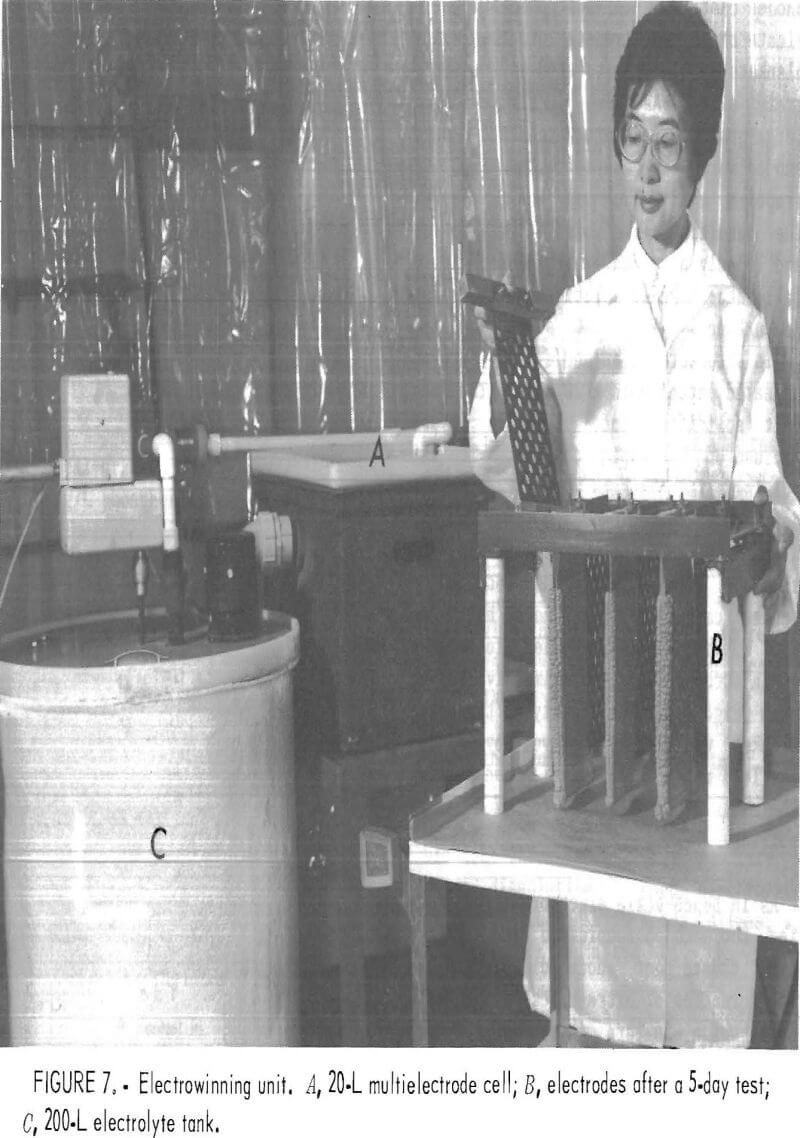

Electrowinning Unit

The electrowinning unit (fig. 7) consisted of a 20-L cell on a stand next to a 200-L cylindrical tank for storing electrolyte. The tank was equipped with a stirrer, an alumina-sheathed immersion

heater (2-kW), and an acid-resistant pump. During electrolysis, electrolyte was pumped continuously into the cell bottom through a 2.5-cm PVC pipe from the tank and was allowed to overflow back into the tank through a 5-cm-diam opening on the upper side of the cell. The cell held three cathodes and four PbO2-Ti anodes.

The parameters used for both electrorefining and electrowinning were similar to those used in the bench-scale studies.

The control system included a 40-V, 50- A dc power supply, a chart recorder, an ampere-hour meter, and a digital thermostatic controller for the immersion heater.

Results and Discussion

Metal Recovery

Anode and Slime Blanket

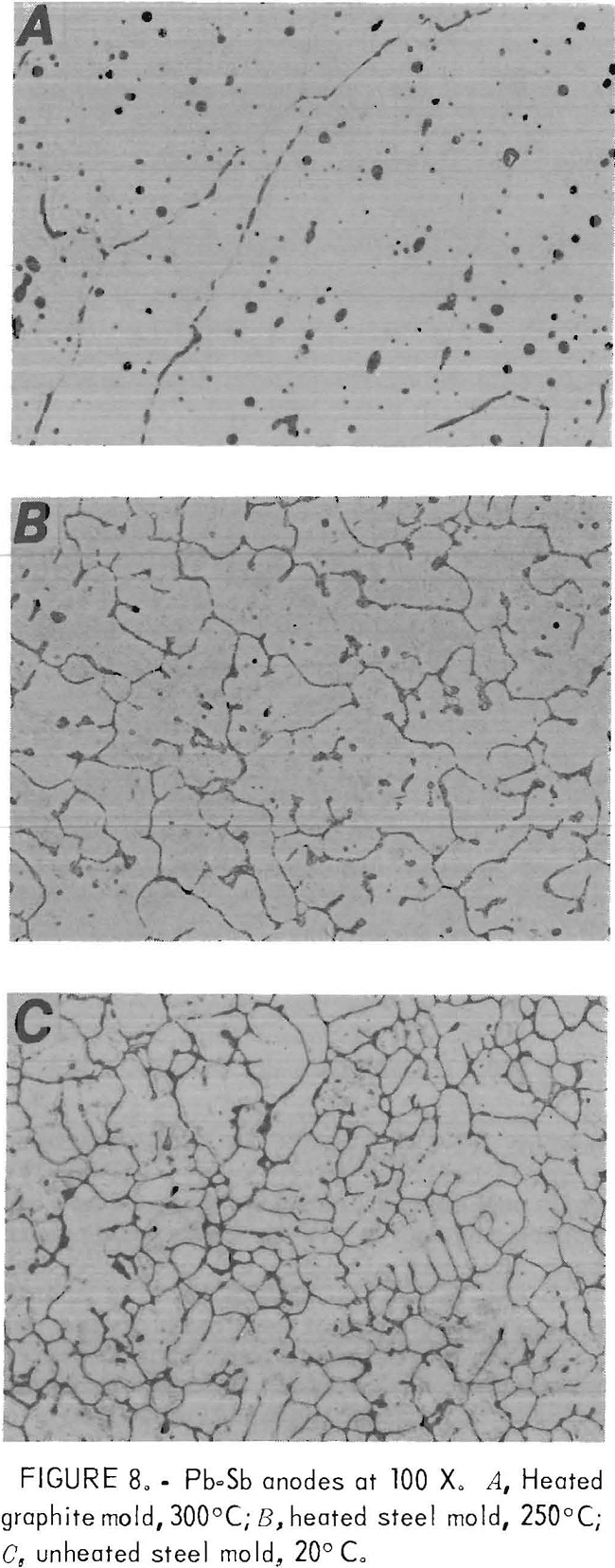

The lead metal obtained from scrap batteries contained 2 to 2.5 pct antimony. Anodes cast from this metal usually produced firm and adherent slime blankets. Electrorefining was an ideal method for eliminating Sb, As, Cu, and Sn from the lead. The results of electrorefining in the 20-L cell for 4 to 7 days using anodes cast under various conditions indicate that the firmness of the slime blankets was closely related to the anode grain size. As shown in figure 8A, a large-grain structure resulted when anodes were cast in a heated (300° C) graphite mold, which was cooled slowly. The resulting slime blanket was coarse and loosely attached, which caused it to fall into the cell solution at the least disturbance. Figure shows the fine-grain structure of an anode cast into an unheated steel mold (20° C). The lead melt solidified Into numerous layers because of the rapid cooling. The resulting slime blankets were very firm but detached from the anode as their thickness increased with time. A firm and adherent slime blanket was obtained on anodes cast into a steel mold heated to 250° C, which was air-cooled to give a grain structure of approximately 1.30-cm diam (fig. 8-B). The quality of the slime blanket was further improved by melting the lead metal at 480° C and holding the melt at temperature for 2 h before pouring.

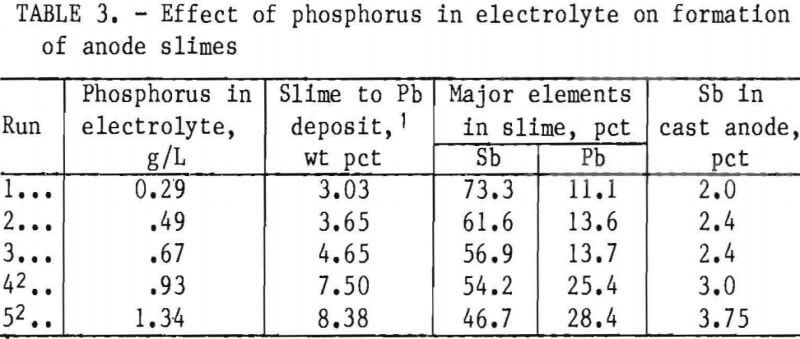

As in bench-scale electrorefining studies, too much phosphorus in the electrolyte caused poor anode dissolution and the formation of extra-thick slime blankets, which in turn increased the cell voltage and energy consumption. Figure 9 shows that the half-cell voltage increased from 0.36 to 0.59 V at a phosphorus content of 0.35 g/L, and from 0.34 to 1.4 V at a phosphorus content of 0.5 g/L at the end of 4.5 days of electrorefining in the 20-L cell.

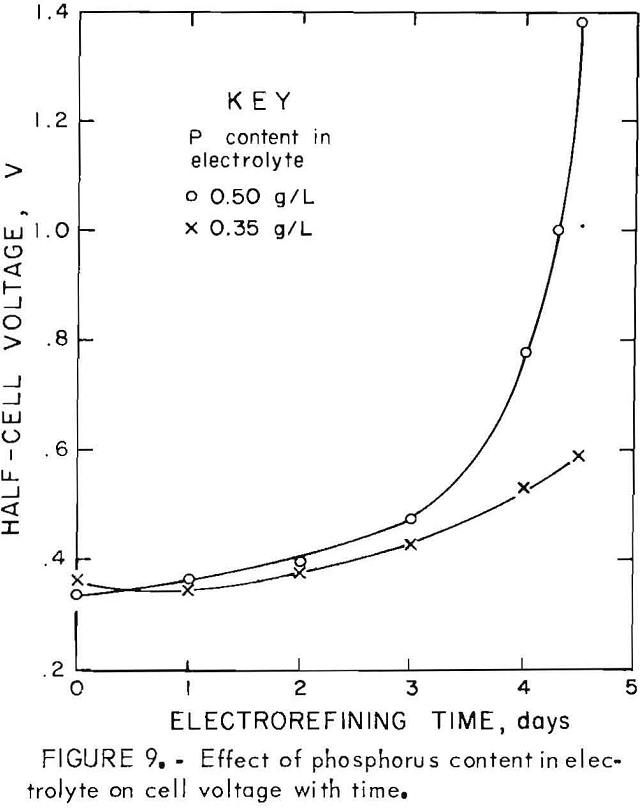

Table 3 shows that the amount of slimes generated doubled as the phosphorus content in the electrolyte increased from -0.5 to -1.0 g/L, the percentage of antimony in the slimes decreased, while lead content increased regardless of the percentage of antimony present in the anodes. Therefore, it was necessary to eliminate phosphorus as much as possible from the electrolyte before using it for lead electrorefining.

Electrolyte made from PbO and technical-grade H2SiF6 contained about 0.35 g/L phosphorus, which was suitable for electrorefining. When phosphorus-containing waste H2SiF6 (table 2) was used to dissolve PbO, it was critical to use the stoichiometric amount of acid, so that most of the phosphate compounds were eliminated as a precipitate in the less acidic solution. The PbSiF6 solution then obtained was rich in lead and low in H2SiF6 and was adjusted to the proper concentration of free acid by adding technical-grade H2SiF6.

The precipitate formed when PbO reacted with waste H2SiF6 contained mainly Pb5(Cl, F)(PO4)3 and PbSO4. The lead in the lead phosphate compound was recovered by leaching with concentrated H2SiF6, and the remaining PbSO4 was then mixed with the battery sludge to recover the lead by the carbonation leaching process.

At the end of each experiment, the electrolyte had less lead and more free H2SiF6 because the increase in slime blanket thickness reduced the rate of anode dissolution. Used electrolyte, even contaminated with anode slimes, was filtered and adjusted to the proper concentration of lead, free H2SiF6, and additives and was used successfully in subsequent electrorefining experiments.

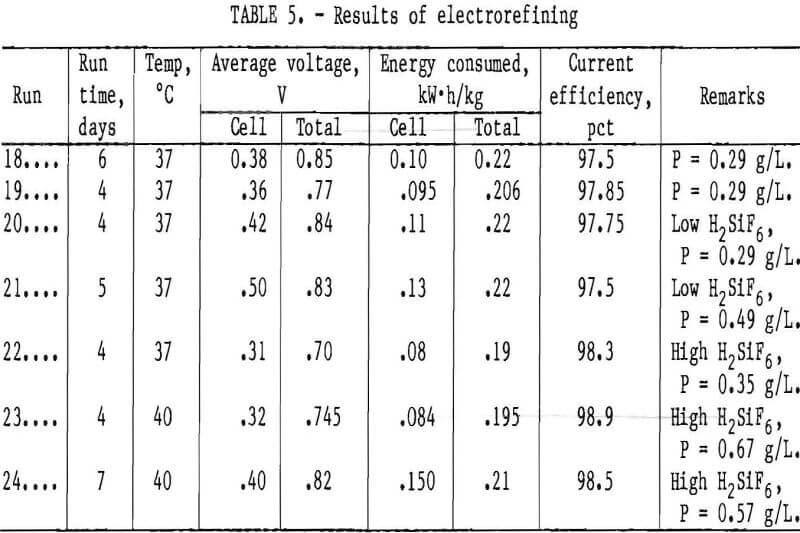

The lead concentration varying from 50 to 80 g/L had no significant effect on the process. As the free H2SiF6 level increased from 75 to 115 g/L, energy consumption decreased from 0.13 to 0.09 kW·h/kg of lead refined, while the current efficiency increased from 97.5 to 99.0 pct. Electrolyte containing high free H2SiF6 (-120 g/L) exhibited lower cell voltage, hence lower energy consumption, even when the phosphorus content was 0.6 g/L; however, the resulting cathode deposits, assaying 99.77 pct lead, were brittle and rough.

The antimony-rich slimes can be sold to smelters for producing Pb-Sb alloy in a blast furnace.

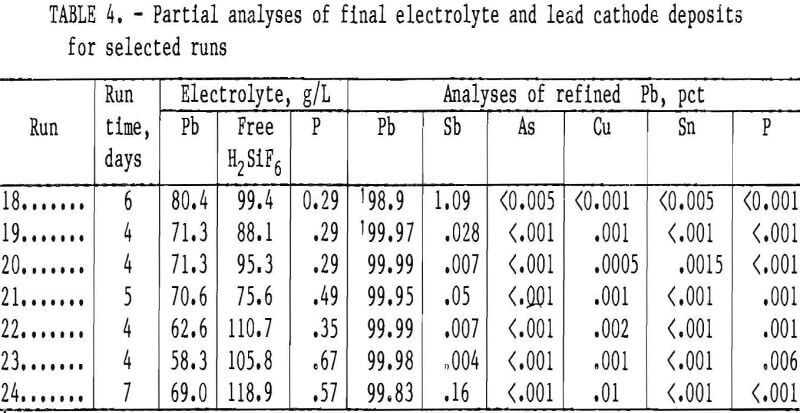

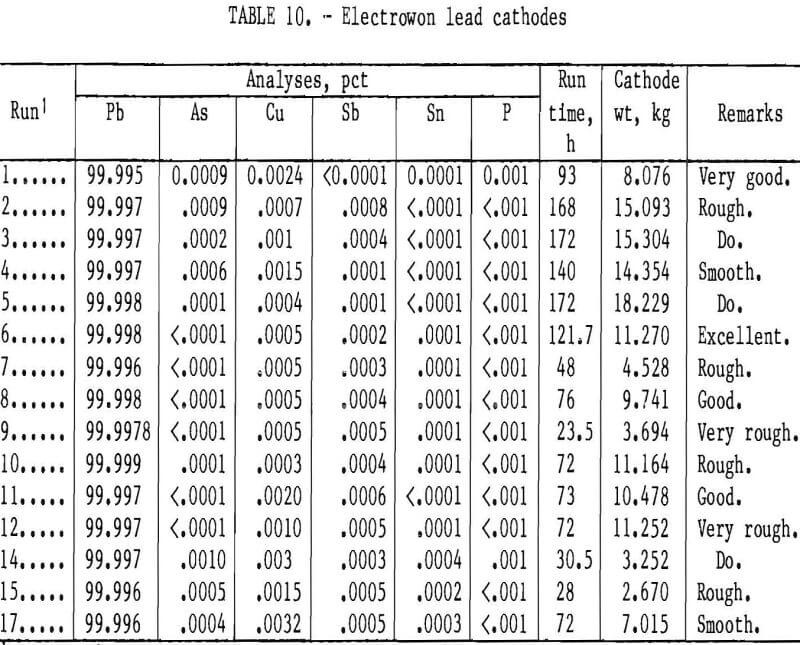

Cathodes

Electrorefined lead deposits assaying 99.99 pct Pb (table 4) were obtained in the 4-day runs, at a current density of 170 A/m², and a temperature of 35° to 40° C, using electrolyte containing 60 to 80 g/L Pb, 90 to -115 g/L free H2SiF6, and less than 0.35 g/L P, along with 4 g/L calcium lignin sulfonate, and 0.04 g/L glue as additives.

The purity of the lead deposits was reduced to less than 99.9 pct when the phosphorus content was greater than 0.5 g/L or in runs longer than 4 days, especially when the electrolyte was contaminated by antimony from the slimes. Then the lead deposits contained 0.03 to 1.1 pct Sb, depending on the degree of slime contamination. Longer electrorefining time also resulted in higher energy consumption and lower current efficiency (table 5).

Sludge Recovery

Leaching

Fourteen sludge leaching experiments were completed. Lead metal was recovered from the PbSiF6 solution by electrowinning. Each leaching operation produced about 200 L of leachate, containing sufficient amounts of lead and free H2SiF6 to support a 3- to 7-day continuous electrowinning test in the 20-L cell.

The wet sludge from scrap batteries consisted of 40 pct PbSO4 , 28 pct PbO2, 2 pct metallic Pb, and 15.6 pct H2O as received. Initially, sludge was leached with (NH4)2CO3 solution to convert PbSO4 into PbCO3, which is soluble in H2SiF6. After solid-liquid separation, the residue containing PbCO3 and the unreacted PbO2 was leached with H2SiF6 and lead powder (200 mesh). The lead powder was added to reduce the PbO2 to acid soluble PbO, as in reaction A.

PbO2 + Pb → 2PbO…………………………………………………………..(A)

Later the procedure was modified to use NH4HSO3 in place of the lead powder. The NH4HSO3 was added during the first leach along with the (NH4)2CO3, and the PbO2 was converted to PbSO4 and then to PbCO3. Additional (NH4)2CO3 was added to handle the PbSO4 from the PbO2 and NH4HSO3 reaction. The residue from the first leach now consisted mainly of PbCO3, which was solubilized by H2SiF6 in the second leach. The two-step leaching procedure can be described by the following reactions:

Step 1:

PbSO4 + (NH4)2CO3 → PbCO3↓ + (NH4)2SO4…………………………………………………..(B)

PbO2 + NH4HSO3 + (NH4)2CO3 → PbCO3↓ + (NH4)2SO4 + NH4OH…………………..(C)

Step 2:

PbCO3 + H2SiF6 → PbSiF6 + CO2………………………………………………………………….(D)

The cost of using NH4HSO3 for PbO2 reduction was approximately one-third that of using lead powder.

The best leaching parameters for maximum lead recovery from bench-scale tests were found to be (1) a mole ratio, in the sludge, of 1:2 Pb: (NH4)2CO3 and 1:1 PbO2:NH4HSO3, (2) a digestion temperature and time of 55° C for 60 min for carbonation and of 45° C for 30 min for the acid leach, and (3) 250 to 400 g sludge per liter of water.

The first large-scale acid leach was conducted with waste H2SiF6 (A-1) only. In subsequent leach tests, recycled spent electrolyte was used with the waste H2SiF6 as makeup. Waste A-2 was used for runs 2 through 12; A-3 was used beginning with run A-13. If required, phosphoric acid was added. In the beginning, because the spent electrolyte contained organic additives which formed very stable CO2 foam when used to acid leach PbCO3, it was necessary to add the waste H2SiF6 first to reduce the problem of foaming. Later, foaming was controlled by spraying with defoaming agent (DB- 110A, Dow-Corning).

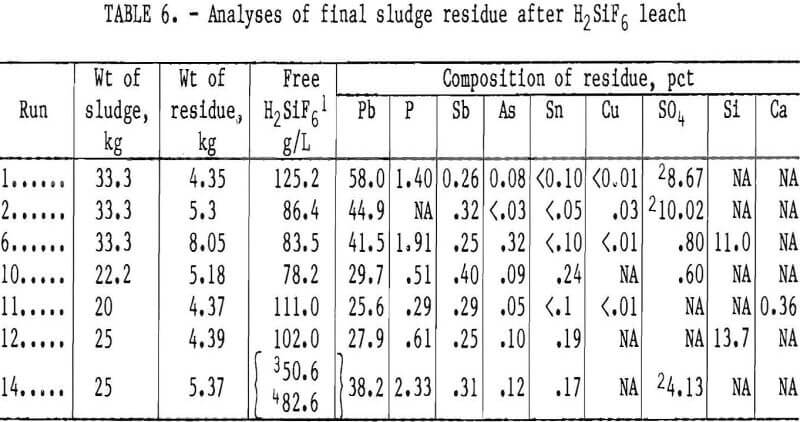

Both the waste H2SiF6 and the spent electrolyte contained some phosphate compounds. After the acid leach, the final sludge residue contained an insoluble lead phosphate compound Pb5(CI,F)(PO4)3 (pyromorphite) and PbSO4 , and was very difficult to filter. The residue also contained minor amounts of Sb, As, and Sn and comprised about 25 wt pct of the wet

sludge. (See table 6.) Adding 0.5 pct (bulk weight of the slurry) of filter aid to the slurry prior to filtering and coating the filter paper in the pan with a 0.3-cm-thick layer of filter aid decreased the filtering time from 6 h or more to about 1 h.

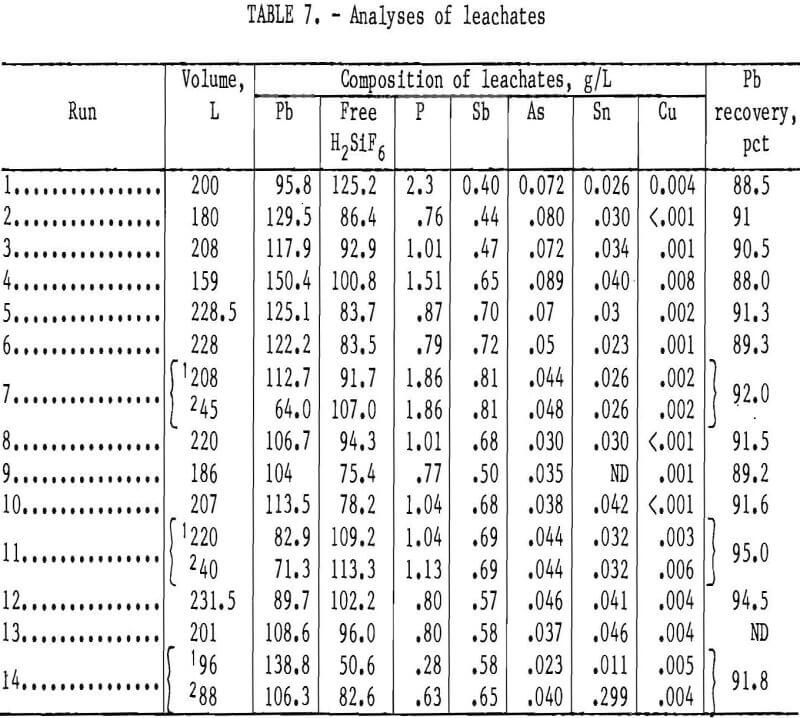

The percentage of the lead recovered was determined from the amount of lead in the PbSiF6 leachate and in the final sludge residue. Similar to the results of bench-scale leaching, the lead recovery from large-scale leaching ranged from 88 to 95 pct.

The analyses of the final leachates are shown in table 7. Since PbSiF6 is very soluble in H2SiF6, the concentration of lead ranged from 80 to 140 g/L and the free H2SiF6 ranged from 50 to 125 g/L in the sludge leachates; all ranges were proportional to the amount of the input. The concentration of phosphorus depended not only on the amount of input but more so on the concentration of free acid in the leachates. The amount of phosphorus recovered from the waste acid and spent electrolyte after sludge leaching decreased from -90 to 40 pct as the concentration of the free H2SiF6 decreased from over 100 to 70 g/L. To obtain PbSiF6 electrolyte with high lead and low free H2SiF6 concentration and also to recover phosphorus efficiently, a two-stage acid leach procedure was employed for leaching runs 7, 11, and 14. As the reaction of the first acid leach was completed, the agitation was stopped, allowing the sludge residue to settle for about 30 min. Then the PbSiF6 solution was siphoned out for filtering. More spent electrolyte, which was high in free H2SiF6, was added to dissolve additional amounts of lead phosphate compounds from the residue. As indicated in table 7, the second batch of leachates contained higher concentrations of phosphorus and free H2SiF6 than the first batches.

Lead sulfate was found in the residue when (1) fresh waste H2SiF6 containing H2SO4 was used to acid-leach the PbCO3 sludge, (2) the conversion of PbSO4 to PbCO3 was not complete, or (3) the PbCO3 sludge filter cake was not thoroughly washed to remove all of the (NH4)2SO4 residue.

Lead phosphate compound was formed and remained in the sludge residue when using recycled spent electrolyte containing to acid-leach the PbCO3 sludge at levels. Lead and phosphorus in the sludge residues can be recovered by releaching with (NH4)2CO3 and then with more concentrated H2SiF6.

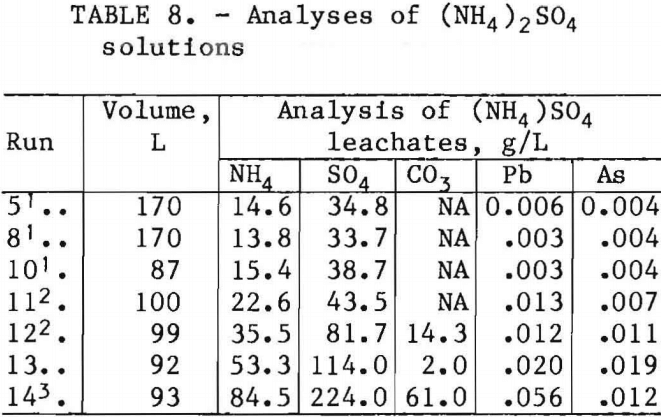

Ammonium sulfate solution is the by-product of the first step leach. The dilute (NH4)2SO4 solution from run 11 was recycled to leach the next batch of battery sludge with additional (NH4)2CO3. The recycling of (NH4)2SO4 solution continued until run 14, as listed in

table 8. The (NH4)2SO4 solutions increased in concentration from 43.5 g/L SO4²- for the first leach to 224 g/L SO4²- for the third. The lead and arsenic content in the solutions also increased from 3 to 56 ppm and 4 to 19 ppm, respectively.

Electrowinning

Seventeen electrowinning experiments were performed in the 20-L cell, the operating data are given in table 9.

The lead metal deposits recovered from all the sludge leachates were assayed and found to contain 99.995 to 99.999 pet Pb with trace amounts of Sb, As, Cu, Sn, and P (table 10). Among the impurities, copper was the only element in the electrolyte that codeposited with lead on the cathodes, as indicated by the <0.001 g/L Cu in all depleted electrolytes.

The cathode deposits, during electrowinning tests, usually were smooth for the first 3 days, then became rough or granular as the electrolyte decreased in lead content below 25 g/L and increased in free H2SiF6 content above -125 g/L. The current density was 170 A/m², and the electrolyte temperature was 30° C. The morphology of the lead cathode deposits was also adversely affected by increasing the current density to 300 A/m².

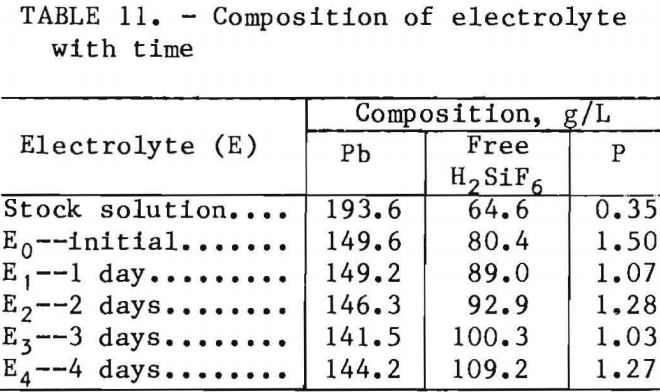

A 4-day bench-scale test was made to see if it would be possible to maintain a fairly constant lead concentration in the electrolyte with time. The test was conducted in a 1-L cell at room temperature (20° to 25° C) and 200 A/m² current density. The lead concentration in the electrolyte was maintained at 140 to 150 g/L during the 4-day run by periodically adding a very concentrated stock solution. The composition of the stock solution and the cell electrolyte during the run are given in table 11.

The starting electrolyte contained 3 g/L calcium lignin sulfonate and 0.05 g/L glue. Small amounts of glue and H3PO4 were added daily. The resulting cathode deposit was excellent in appearance. The current efficiency was 98.5 pct, and the total energy consumption was 0.735 kW’h/ kg of electrowon Pb, which was very reasonable for this low cell temperature (20° to 25° C).

In another 20-L test, the use of 0.5 g/L aloes in place of 0.05 g/L glue as additive improved the morphology of the deposits but also increased the cell voltage and energy consumption.

The cathode current efficiencies in creased slightly with increasing current density and flow rate of the electrolyte and ranged from 95 to 98.6 pct, similar to the results of bench-scale tests.

Energy consumption in the 20-L cell using 4.5-cm electrode spacing was 0.7 to 0.8 kW·h/kg of electrowon lead, slightly higher than the 0.66 to 0.7 kW·h/kg for the bench-scale tests using a 3.5-cm spacing.

In an attempt to decrease energy consumption, several electrowinning tests were conducted with the electrode spacing reduced from 4.5 to 3 cm. The reduced spacing resulted in uneven lead deposits on the three cathodes and increased the risk of shorting; the effect on energy consumption was insignificant.

As shown in figure 10, two types of PbO2-Ti anodes were used in the electrowinning tests. The anodes with the smaller holes (0,9 cm in diam) spaced 1 cm apart were very stable and still in perfect condition after repeated use in eight consecutive tests. The anodes with the larger holes (1.3 cm in diam) spaced 1.3 cm apart tended to develop cracks in the PbO2 coating after repeated use.

A thin layer of PbO2 was formed on the anodes during each run. The newly formed

Pb0O layer was firmly attached to the anodes, did not pollute the cell solution, and was easy to clean after each test. The amount of PbO2 formed was limited to less than 1 pct of the total weight of the cathode deposits, as long as the phosphorus level in the electrolyte was maintained at greater than 1.2 g/L (table 10). The PbO2 collected from the anodes was leached with the battery sludge to recover lead as PbSiF6 in the leachates.

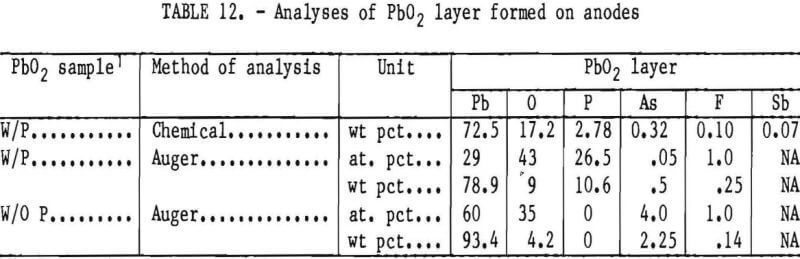

The chemical analysis of the PbO2 layer (bulk) and the Auger electron spectroscopy analysis of the surface of the PbO2 formed on the anodes during electrowinning are given in table 12.

The bulk PbO2 layer contained 2.78 pct P, compared with 10.6 pct P on the PbO2 surface. The mechanism by which phosphorus inhibits excessive PbO2 formation during lead electrowinning has not been determined.

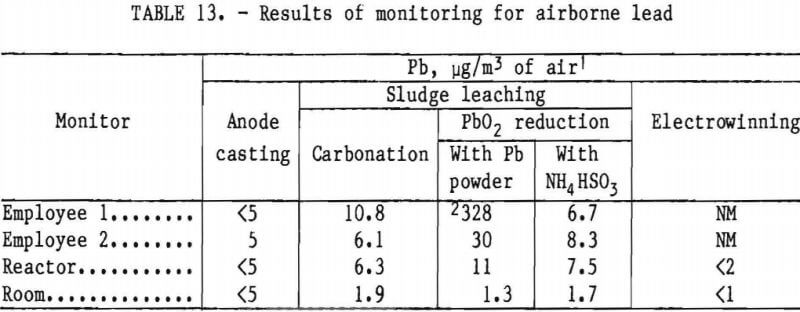

Lead Monitoring

The results of lead monitoring during anode casting, sludge leaching (with and without Pb powder), and electrowinning are listed in table 13.

Filters from the personal monitors were pinned to the lapels of the employees, as close to their breathing zones as possible. The reactor monitors were suspended 1 m above and directly over the melting pot, leaching tank, and electrolysis cell. For lead melting, the lead fume was drawn to a baghouse by a cone-shaped duct placed 2/3 m above the pot. The room monitors were approximately 5 to 7 m from the work area. Airborne lead was considerably less when NH4HSO3 was used to reduce PbO2 instead of minus 200- mesh lead powder.

Following 10 sludge leaching operations, the blood lead tests of employees 1 and 2 were normal at 17 and 15 µg/100 mL, respectively.

Economic Evaluation

Based on the data from bench-scale tests, a preliminary economic evaluation of the process was performed by the Process Evaluation Staff of the Bureau of Mines.

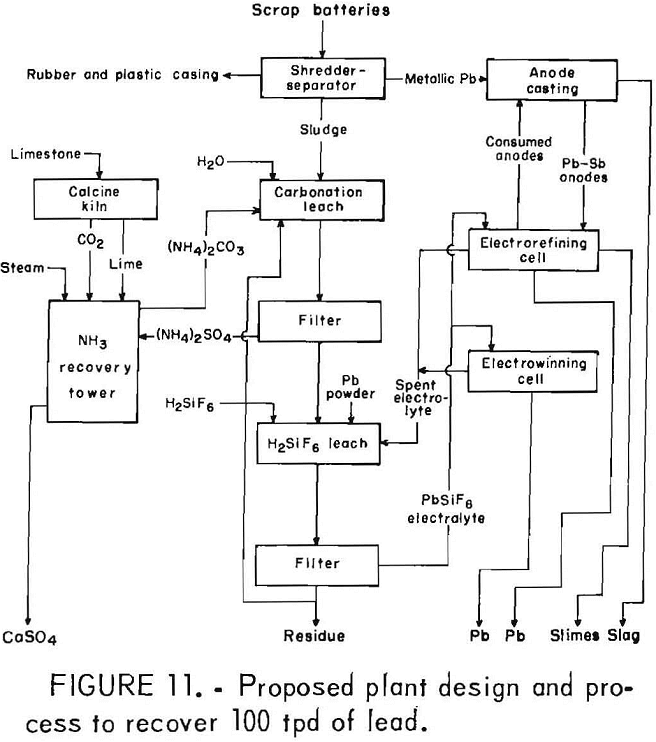

The evaluation was based on a plant designed to process 10,000 batteries per day and recover about 100 tpd of lead. This scale is equivalent to the capacity of a large secondary smelter. The plant is divided into five sections as shown by the flowsheet in figure 11: feed preparation, anode casting, leaching, electrolysis, and ammonia recovery. The evaluation was based on the flowsheet, except that lead powder was used In sludge leaching to reduce PbO2 during the acid leach, which was more costly than using NH4HSO3.

The capital cost was a “study estimate” used by Weaver and Bauman. Since the treatment of slag and anode slimes was not complete, the accuracy of the cost estimate may not be within the assumed ±30 pct. Capital cost was $21 million, and the operating cost per kilogram of lead recovered was 35.2 cents (16.0 cents per lb), excluding the cost of scrap batteries.

Conclusions

High-purity lead was recovered from scrap batteries by electrorefining lead metal and by leaching-electrowinning lead from sludge.

This recycling process minimizes environmental and health impacts, as shown by the results of lead-in-air and lead- in-blood monitoring. The working environment may be further improved when the leaching process is automated and operated in a closed system to avoid the escape of NH3 gas and recover CO2 for recycling as (NH4)2CO3.

In the leaching process, using NH4HSO3 to reduce PbO2 in place of the 200-mesh lead powder was more cost effective and resulted in lower emissions.

Similar to the bench-scale results, the current efficiencies were 97 to 99 pet for both electrorefining and electrowinning under a wide range of parameters. The total lead recovery for this process was approximately 92 pct.

Maximum energy consumption, based on the cell voltage, was 90 and 800 kW·h per metric ton of lead electrorefined and electrowon, respectively. Care must be taken to reduce the electrical trans¬mission loss from the power supply to the cell, which could be as high as 110 kW-h per metric ton of lead deposit in this electrolysis system.

The byproduct of the sludge leaching is ammonium sulfate solution, which can be used as fertilizer or recycled to recover NH4OH.

The spent electrolyte was repeatedly recycled to leach more sludge without any impurity buildup.

Because of the discovery that small amounts of phosphorus in the electrolyte will prevent PbO2 formation at anodes, lead electrowinning could become a viable commercial process.