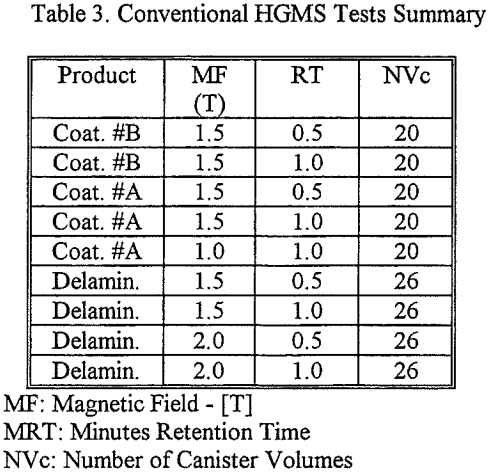

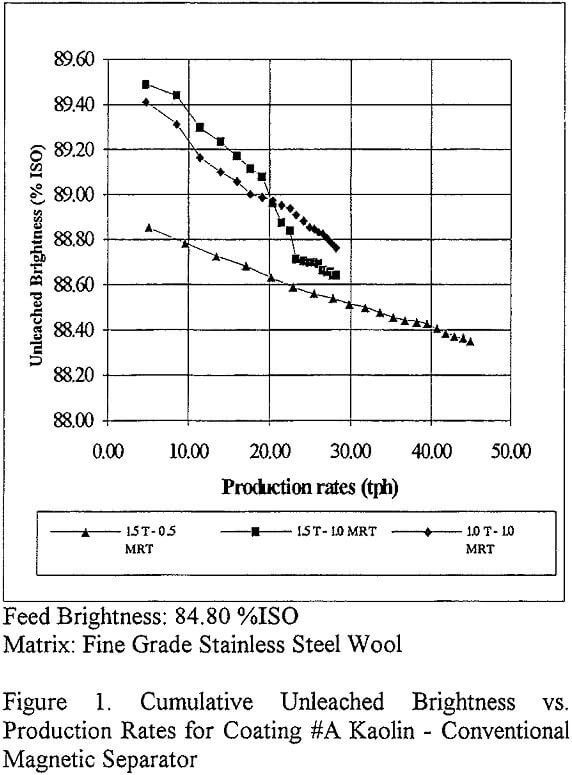

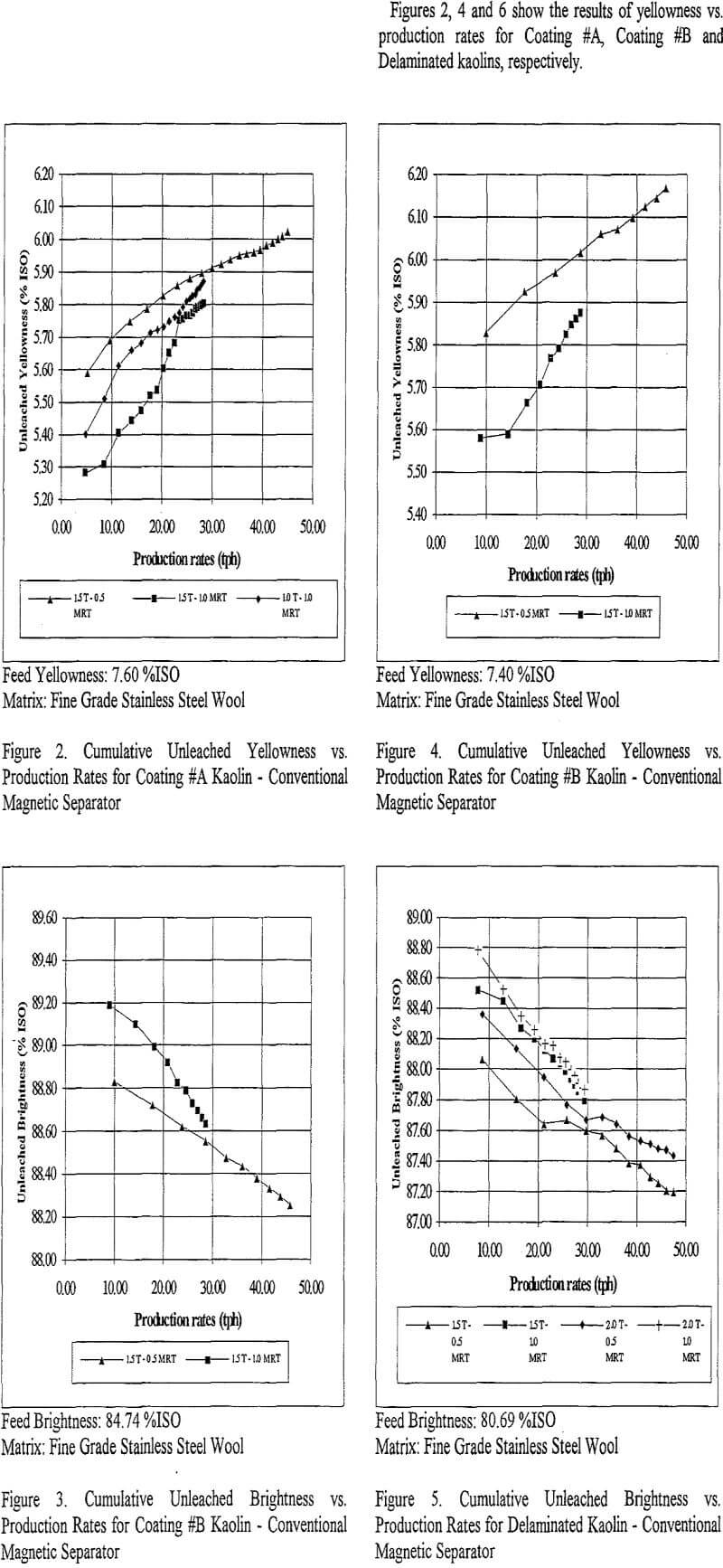

Conventional Magnetic Separator: An Eriez conventional high gradient magnetic separator (HGMS), model EL 20-4, with a 0.058 m canister diameter and a total volume of 1030 cm³ was used. The matrix was a fine grade stainless steel wool. The canister was packed to a 6 percent density with the matrix. The tests followed the recommended Eriez procedures.

Procedure:

Crude kaolin samples from Para Pigmentos S.A. (PPSA) were processed in Pilot Plant.

After degritting, the kaolin slurry was stored in a feed tank and sent to a centrifuge. The centrifuge cut was adjusted to produce Coating A (90 % below 2 µm) and Coating B (80 % below 2 µm). The coarse fractions obtained were mixed, delaminated and again classified in the centrifuge to generate a delaminated fine fraction (80 % below 2 µm).

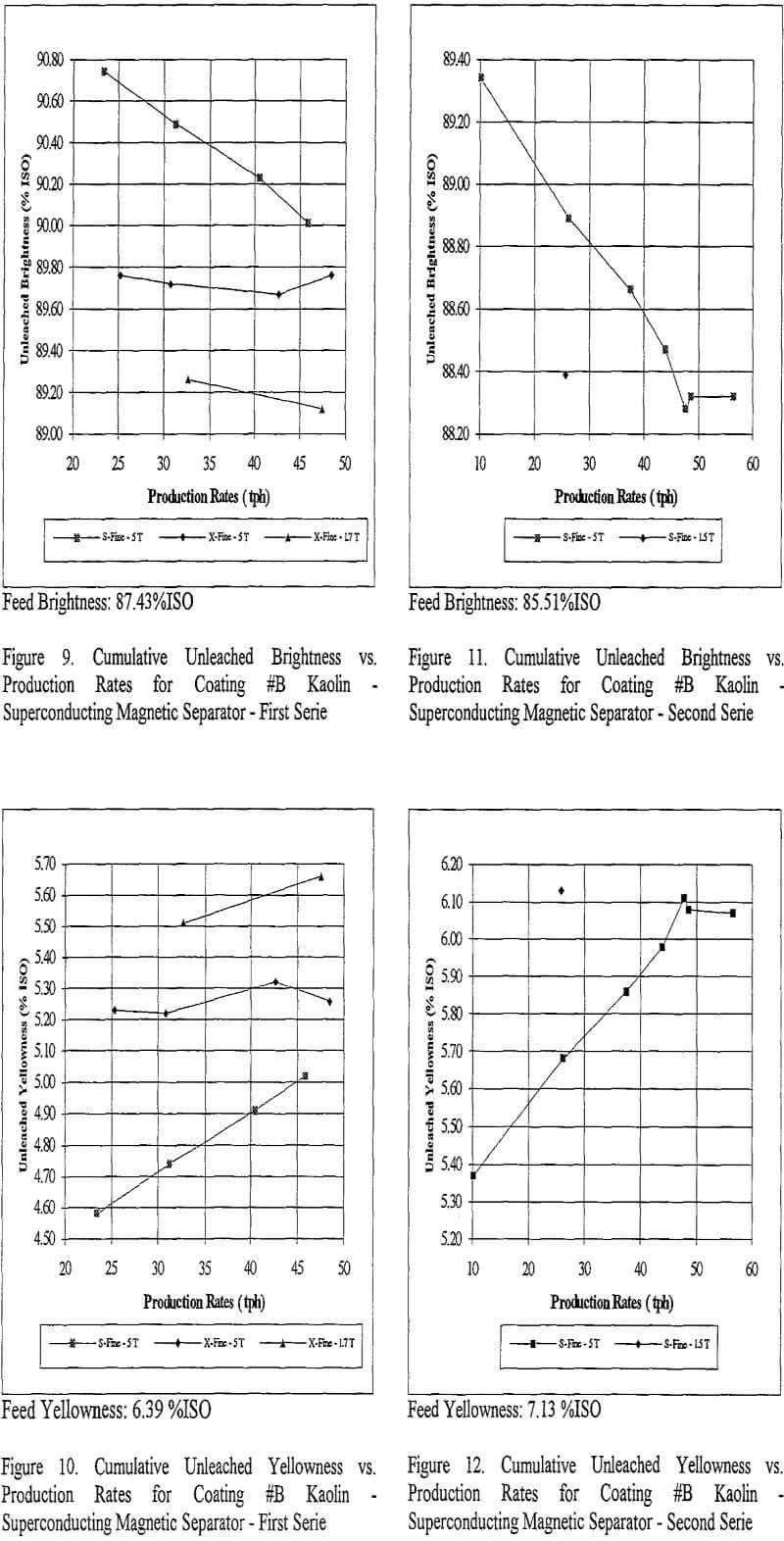

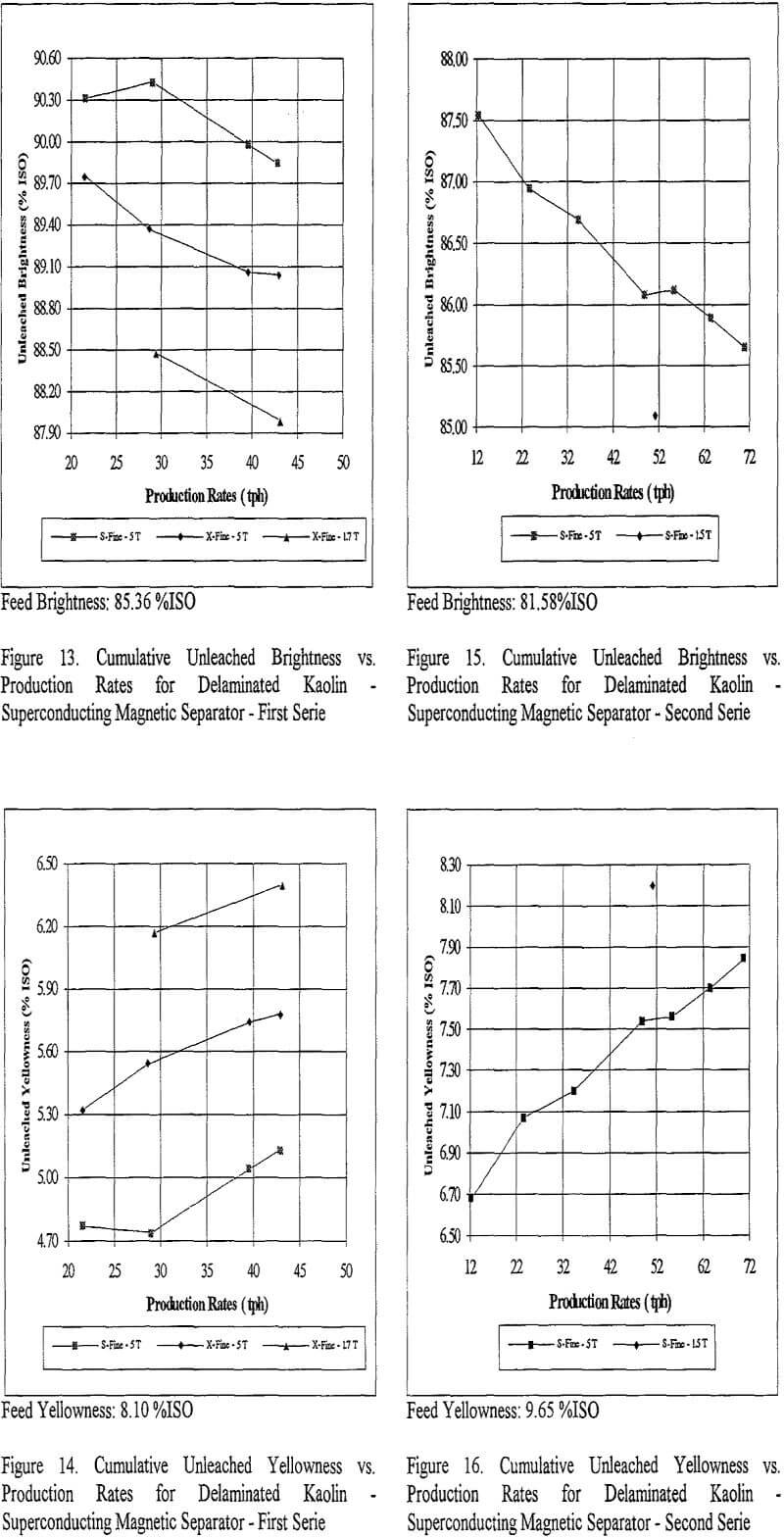

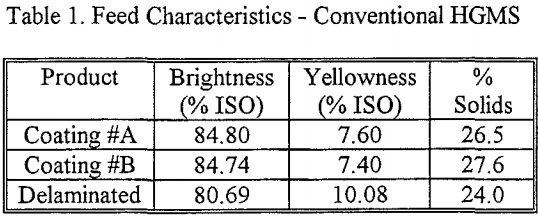

Table 1 shows the HGMS feed characteristics.

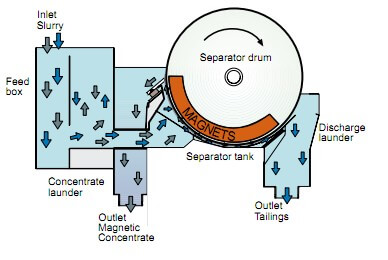

The magnetic separation tests started after adjustment of the magnetic field intensity. The kaolin slurry was fed to the HGMS by a constant flow pump.

Samples corresponding to each volume of canister processed were taken from the outlet line, until the desired number of canister volumes had been reached.

The non-magnetics builtup in the matrix were removed by stopping the feed pump and rinsing the canister with water, while the magnetics particles were backflushed with water, after turning off the power supply.

The brightness and yellowness of the non-magnetics fractions were measured as described in Tappi Standard T 525, OM-86.

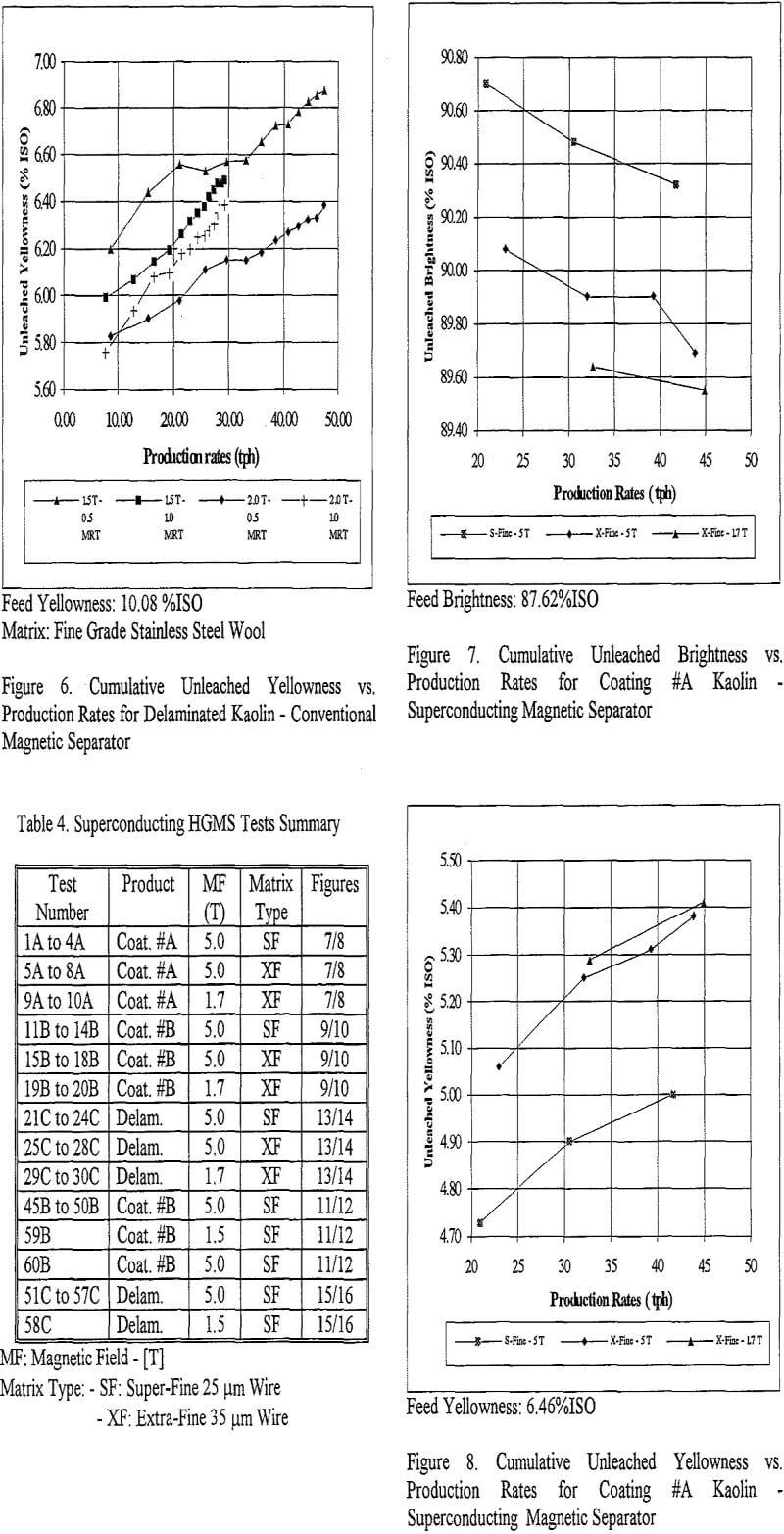

Superconducting Magnetic Separator

The tests were performed in a Carpco superconducting HGMS, model 6T/75.

Canisters of 0.069 m diameter by 0.10 m length and 0.054 m diameter by 0.08 m length were used.

Two different stainless steel matrix types were tested, super-fine (25 µm wire) and extra-fine (35 µm wire). The canister was packed to a 6.5 percent density with the matrix.

Procedure:

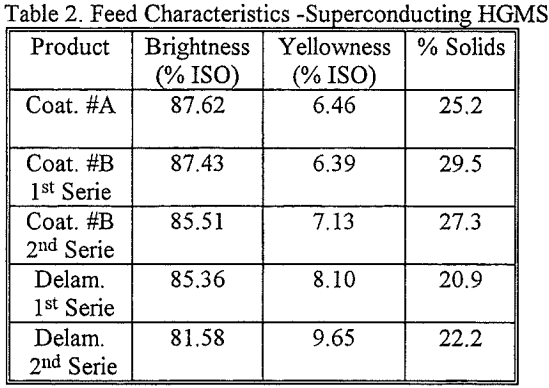

The feed characteristics of the samples tested are shown in Table 2.

The period of time for each test was calculated as a function of the feed flow rate, in order to assure the same duty factor for all the tests. The duty factor is defined as the ratio between time processing clay in one cycle and total time of one cycle. Three non-magnetics samples were collected in aproximately equal intervals of time.

The non-magnetics builtup in the matrix were removed by stopping the feed pump and rinsing the canister with water. The power supply was turned off and finally the magnetics were backflushed with entrained air rinse water.

Equal volumes of the three non-magnetic samples were mixed, generating a composite sample. The brightness and yellowness were measured as described in Tappi Standard T 525, OM-86.