The Sylvinite ores mined in conventional mines contain Sylvite (20 to 30% K2O), Halite, sometimes Carnallite and 1 to 5% insol. Liberation, in some cases, is substantial at 1 cm (3/8 inch), and virtually complete in all cases at 14 mesh. The separation processes include dissolution of the Carnallite, and removal of the insols, followed by mechanical separation of Sylvite from the Halite.

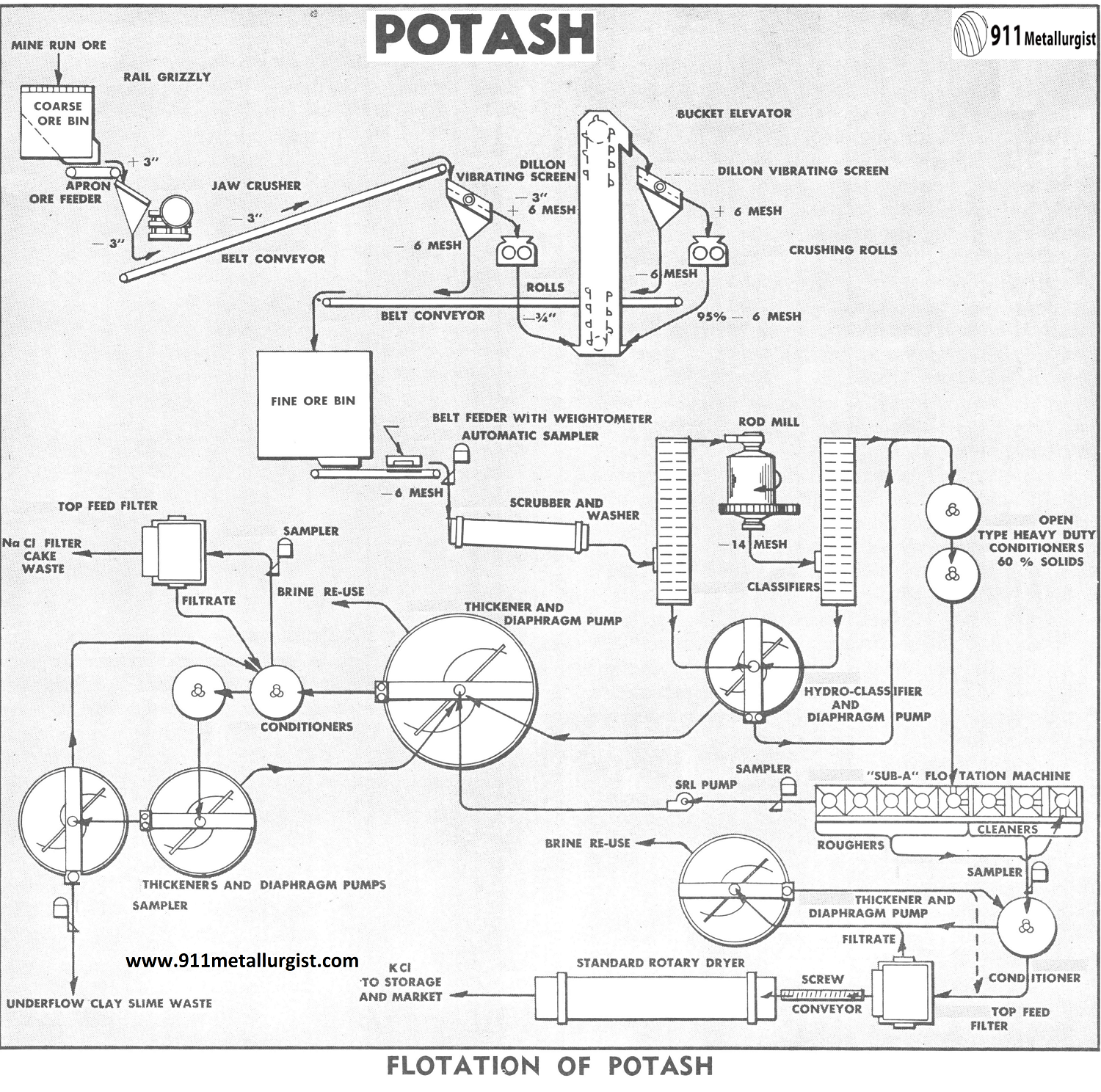

Generally the ore is processed through single or double roll crushers in the mine, and sometimes on surface, to reduce the largest lumps to the 15 to 25 cm range (5 to 10 inches) to minimize transportation problems in the mine and en route to the mill.

Liberation of the minerals is attained by both dry and wet crushing methods, often combined with secondary wet grinding in rod mills. Various types of impact crushers are used, generally in closed circuit, to crush to 1 cm (3/8 inch) for processing, or secondary grinding or crushed to the final 8 to 10 mesh for flotation. In one case, autogenous mills were used to crush run of the mine ore to about 8 mesh for flotation.

Scrubbing is usually accomplished in a series of small highly agitated cells, designed to liberate the fine clay from the Potash mineral. During this stage, enough fresh water is added to the high Carnallite ores to dissolve the magnesium. The use of rod mills for grinding, also proves beneficial in liberating the clay. Two-stage scrubbing is common in the high insol areas.

The desliming stage is considered critical, as a virtually slime-free product is necessary to minimize reagent costs and to ensure good potash recovery.

Desliming is accomplished in two or three stages. The primary separation may be done with cyclones, syphon sizers or wet screens, while the secondary separation is usually accomplished with hydro separators, cyclones, rake classifiers or thickeners. Desliming has been accomplished with three stages of cycloning, but this method has not proven popular. Recently, one operator has converted to flotation to float the insol away from the ore. This method has the advantage of reduced capital expenditures for desliming equipment, but suffers the disadvantage of higher reagent costs.

Coarse material is conditioned separately, in rotary drum conditioners or vertical agitator tanks. Both coarse and fine material is conditioned with a depressant and a collector. An extender is added to the coarse conditioner. An alcohol is used to promote the froth. The fines are usually conditioned in vertical agitator tanks. Some conditioning is required for tailings scavenger circuits where large particles require optimum reagentizing, or flotation is preceded by secondary grinding to liberate the mids. The cleaning, recleaning and centrifuge scavenging circuits require no further reagentizing.

Cleaner and recleaner circuits utilize the same size cells as the rougher circuit, but in shorter banks. Generally, the flow from the roughers to the cleaner and recleaner cells, is by gravity to slave banks, but pumps are sometimes used to accommodate intervening process steps or to accommodate a smaller ratio of cleaner to rougher banks.

One company has developed and patented a heavy media separation using magnetite and cyclones. This company separates a very coarse tailing and product from the H.M. circuit. The mids are ground and subjected to conventional flotation along with the fines developed in the initial crushing stages. Reagent costs are lower than with conventional flotation, but maintenance costs are high because of the erosive properties of the magnetite. This process has proven successful on the, coarse grained ore.

Screen bowl centrifuges are usually used to debrine the flotation concentrate, but pusher centrifuges are used in a few cases.

Both rotary and fluid bed driers are common. In the case of rotary driers, most if not all, have been converted to direct firing. Knockers have been removed from most driers in a successful attempt to reduce noise levels. Driers are fired with natural gas, but a standby fuel (diesel) is also provided for interruptable service. Driers are co-flow. A recent innovation is the addition of an air-cooled product cooler. This is a rotary drum with a counter flow of air. The pre-heated air is used to fire the rotary drier, with a resultant saving in heat.

Drier exhaust gases are subjected to cyclonic dust recovery, usually followed by wet scrubbers. In one case, an electrostatic precipitator is used for final gas cleaning. Low pressure wet scrubbers are marginally successful in some cases, more successful in other cases, combined with tall stacks up to 300 ft. high. Mist elimination is a problem with wet scrubbers since the common mist eliminators salt-up in this service. A wet scrubber with a 20 cm (8″) w.g. pressure drop and a modest stack, has proven successful with a fluid bed drier, and a particular product, however, the effects of direct firing, on exhaust scrubbers, are unknown at this time.

Undersize from the screening process and drier cyclones is commonly subjected to crystallization. The crystallizer upgrades the product chemically, by leaching, to at least 60% K2O for blending with the red products, or 62.5% for soluble grade. When blending, it is desirable to produce a coarse crystal to increase the proportion of the premium coarse product. Soluble is a finer product permitting high capacity production from the crystallizers. Three producers market a chemical grade, 63.15% K2O, produced by double crystallization. There has been a slow trend to automatic analysis of crystallizer circuit brines using sodium iodide crystals to count the K40 emissions.

Air separation is generally restricted to cycloning and air separators for recovering fines or separating a coarser fraction from the fines.

Products are screened into -6 mesh, +14 mesh Granular; -8 mesh, +20 mesh Coarse; -14 mesh, +48 mesh Standard; or -35 mesh, +150 mesh Special Standard. The meshes overlap the products due to operating requirements and screening efficiency.

https://www.youtube.com/watch?v=vZ-ZddPSh9w

https://www.911metallurgist.com/blog/potash-flotation

https://www.911metallurgist.com/blog/potash-flotation