Silicosis, a debilitating and potentially deadly lung disease, develops through inhalation of excessive levels of respirable crystalline silica dust. In underground coal mines, continuous miner operators have historically been at a high risk of overexposure to silica, with over 25% of compliance dust samples exceeding the permissible exposure limit.

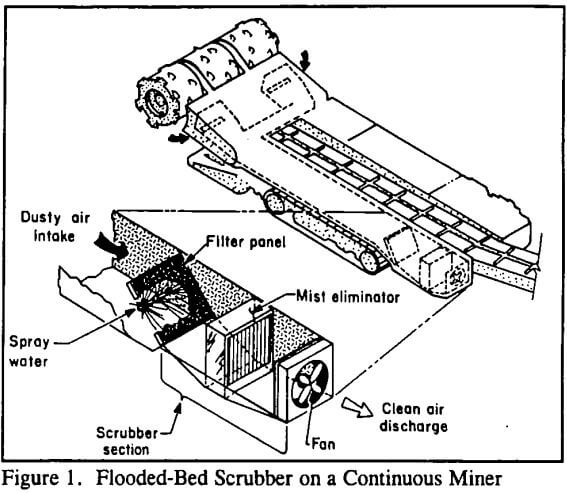

Flooded-bed scrubbers are fan-powered dust collectors utilized on continuous miners to capture dust-laden air from the cutting face, carry this air through ductwork on the miner, and pass the air through a filter panel that is wetted with water sprays, Figure 1. As dust particles impact and travel through the filter panel, they mix with water droplets and are removed from the airstream by a mist eliminator (Campbell, 1983). The cleaned air is discharged from the scrubber back into the mine environment. Flooded-bed scrubbers have been utilized on continuous miners for approximately 20 years and have been shown to be over 90% efficient in removing respirable coal and silica dust. However, the overall effectiveness of a flooded-bed scrubber is a function of the amount of ventilating air from the face that is drawn into the scrubber (capture efficiency) and the quantity of dust removed from the captured air (collection efficiency).

Over the last several years, two changes in the flooded-bed scrubber operation have occurred that have the potential to impact scrubber effectiveness: (1) the density of the filter media utilized in scrubber filter panels has been reduced by as much as 75%, and (2) the internal air velocity in scrubbers has increased by as much as 100%. These changes have occurred as mine operators expand efforts to reduce airborne dust levels generated by operations with high extraction rates and/or extended-cut mining. In these operations, higher quantities of air are often required to ventilate the face and the air capacity of the scrubber is often required to be equal to the face ventilation quantity. As a result, scrubbers capable of moving larger quantities of air have become more desirable. However, the physical size of scrubber fans and the space available on the

mining machines combine to limit the maximum quantity of air moved by an individual scrubber. An alternate means of increasing scrubber airflow is to reduce the internal resistance in the scrubber unit. Pressure drop across scrubber filters has been reduced by changing from a flat filter area to a pleated design and reducing the density of the filter media.

Stainless steel wire mesh was used as the filter media in the original scrubber filter panels and continues to be the most common media in use. Early filters panels contained 40-layers of stainless steel wire mesh secured in a flat filter panel (Campbell, 1979). Subsequent panels were developed that contained 30-, 20-, 15-, or 10-layers of stainless steel mesh held in a pleated filter. The pleated filter design increases the available filter area which allows the panel to operate for greater lengths of time before becoming overloaded. A filter panel containing an array of nylon bristle brushes (similar to bottle cleaning brushes) as the filter media is also being manufactured and utilized in the mining industry. The reduced density filters lower pressure drop and allow scrubber airflow to increase. However, the impact on dust collection efficiency was not documented.

A U.S. Bureau of Mines (USBM) evaluation of an original flooded-bed scrubber design found the scrubber to be over 90% efficient in reducing respirable dust (Divers, 1978). Laboratory testing to evaluate the silica collection efficiency of flooded-bed scrubbers was subsequently conducted in another USBM study (Colinet, 1990). These test results indicated that respirable silica collection efficiencies of over 90% could be obtained with the 40-layer stainless steel filter. A 30-layer stainless steel filter and a nonwoven synthetic fabric filter were also found to be over 90% efficient in removing respirable silica. However, further reductions in filter media density have occurred during the last several years and it is hypothesized that these reductions have had a negative impact on respirable dust collection efficiencies of flooded-bed scrubber filter panels. Higher quantities of silica would be contained in the scrubber discharge air, potentially exposing workers to higher concentrations of silica dust.

Another change in scrubber operation that has occurred since the scrubber was originally designed is the velocity of the airstream at the filter panel. In the original flooded-bed scrubber, the air velocity at the panel was approximately 11.18 m/s (2200 fpm). Today, air velocities of 17.78 m/s (3500 fpm) are common at the filter and some scrubber units are operating with velocities greater than 20.32 m/s (4,000 fpm) at the filter. The impact of these increased velocities on dust collection characteristics of filter panels had not been defined.

Information obtained from equipment manufacturers, industry, and MSHA indicated that the density of the filter media being used in filter panels for flooded-bed scrubbers has been reduced over the last several years by as much as 75%, when compared to original filter panels. Also, scrubbers are being operated at air velocities that are as much as two times greater than that found in the original scrubber design. No documentation was available to identify the impact on respirable silica dust collection and overall performance of flooded-bed scrubbers.

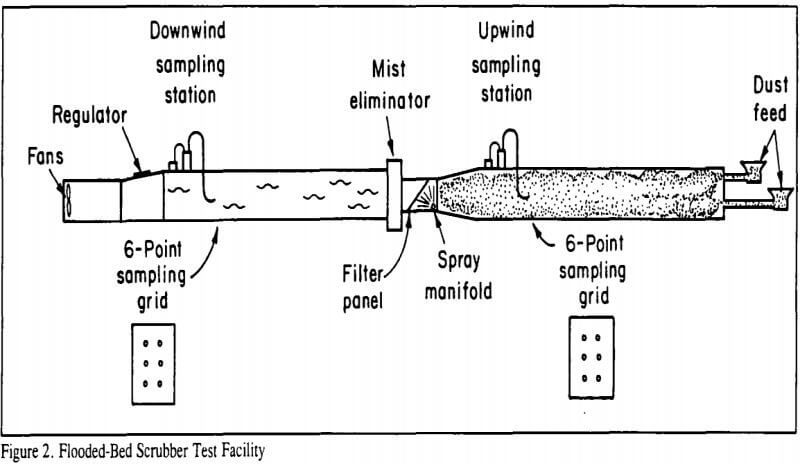

A series of full-scale tests were conducted at the Pittsburgh Research Laboratory to evaluate the silica collection efficiency of six different scrubber filter panels. The panels included: 30-, 20-, and 10-layer stainless steel panels from Manufacturer A, 15-layer stainless steel and synthetic fabric panel from Manufacturer B, and a nylon brush filter panel from Manufacturer C. Each filter panel was evaluated at scrubber air velocities of 11.18 and 17.78 m/s (2200 and 3500 fpm). Results of respirable dust sampling and subsequent silica analysis indicate that collection efficiency improved for all filters panels at the higher scrubber air velocity. The 30-layer and synthetic panels were the most efficient and removed between 91-95% of the respirable silica dust drawn into the scrubber. The 10-layer panel was the least efficient and only removed 58% of the silica at low scrubber airflow and 77% at high airflow. Utilization of the 10-layer panel will allow approximately 25-40% of the silica drawn into the scrubber to be discharged back into the ventilating air, and as such, reduces the scrubber unit to more of an air mover rather than an efficient dust collector.

The use of filter panels with greater density was shown to improve dust collection efficiency but also was found to reduce scrubber airflow capacity. Overall scrubber performance is determined by the dust collection efficiency of the filter panels and the quantity of face ventilating air that is drawn into the scrubber (capture efficiency). Optimum performance occurs when 100% of the ventilating air is drawn into the scrubber and over 90% of the respirable dust is removed by the scrubber.

Relative performance of the scrubber with each filter panel was calculated for both low and high airflow conditions. When assuming a 100% capture efficiency for each filter, the silica levels calculated for the scrubber discharge indicated that the lowest dust levels were obtained with the 30-layer stainless steel filter and the synthetic filter panels. The 10-layer panel was once again the poorest performing filter of those evaluated. When utilization of filters panels with greater density reduces the air moving capacity of the scrubber and a 100% capture efficiency is not obtained, the 30-layer and synthetic panel again provide the lowest silica levels at the low scrubber airflow test condition. At the high scrubber airflow, the brush filter resulted in the lowest silica levels and the differences in silica collection for the remaining panels were minimal.

In general, the 30-layer and synthetic filters were the most consistent performing filters regardless of test conditions and are recommended for those operations experiencing difficulty in controlling silica dust levels. The 10-layer panel typically allowed the highest quantities of silica to be discharged from the scrubber and is not recommended for use where respirable dust collection is an important goal.